Low-order coal dry distillation device

A technology of low-rank coal and dry distillation, which is applied in special forms of dry distillation, direct heating dry distillation, petroleum industry, etc., can solve heat transfer and other problems, achieve the effect of increasing heat exchange area, eliminating heat transfer, and enhancing heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

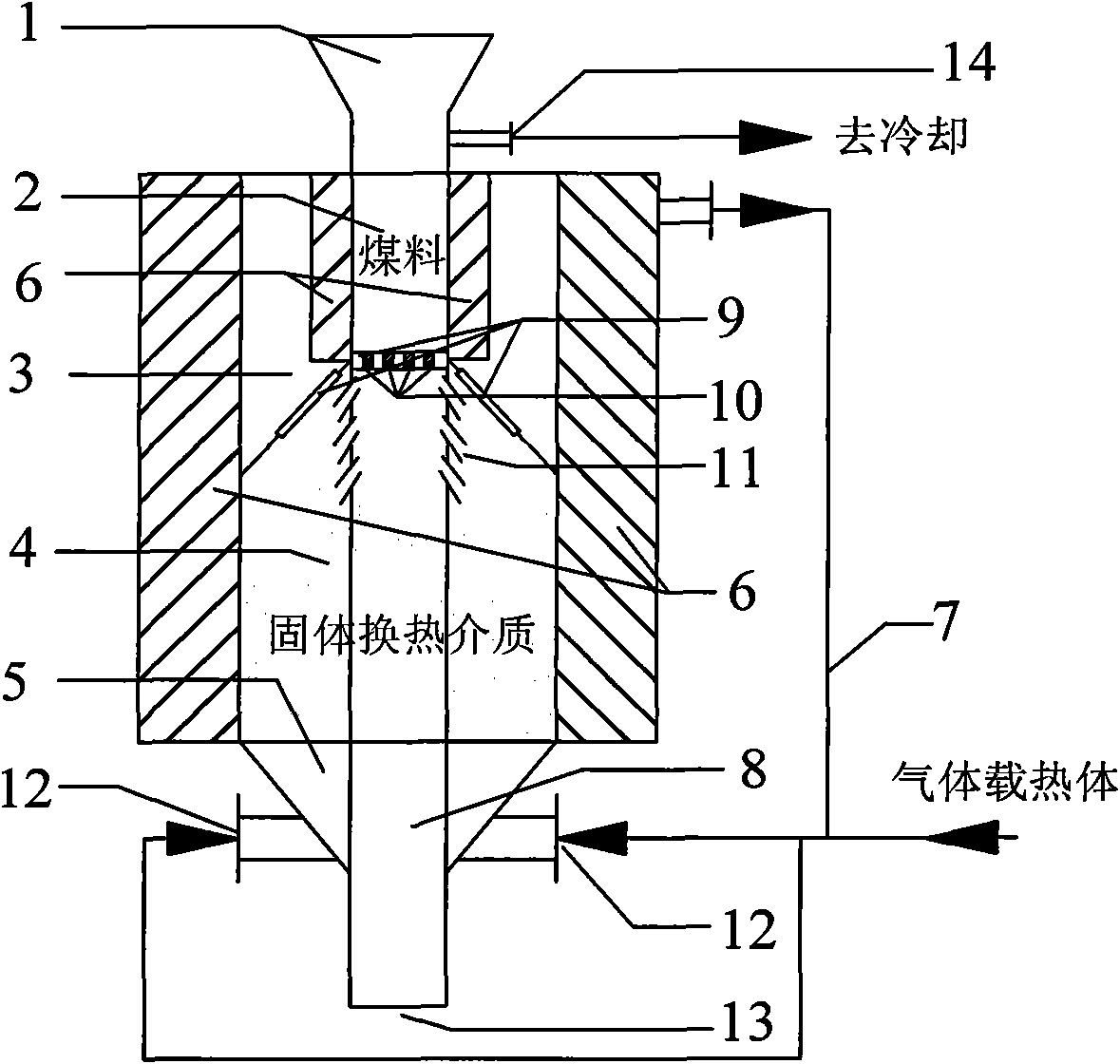

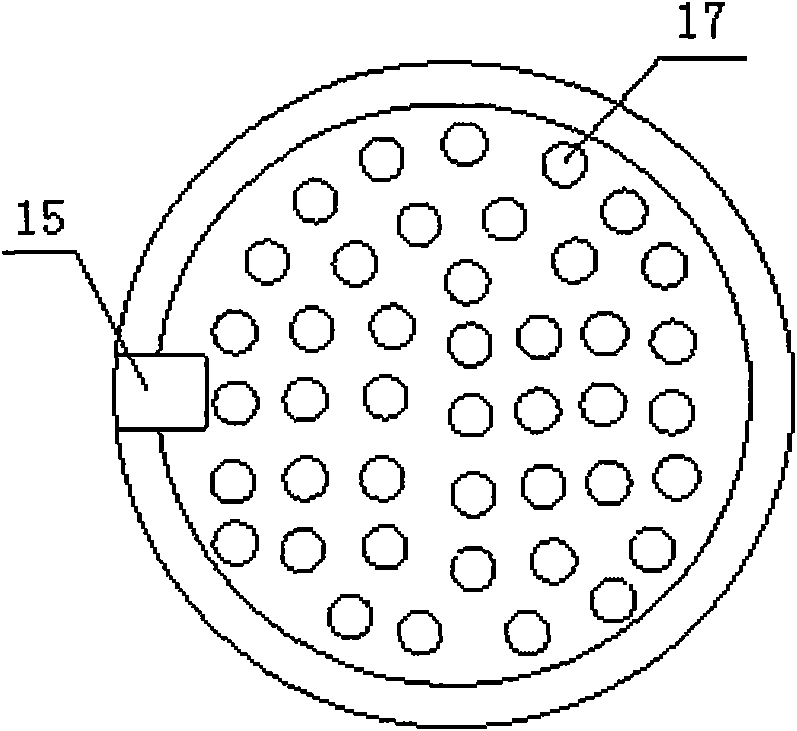

[0019] A low-rank coal carbonization device claimed by the present invention includes a hopper 1, a carbonization chamber 2, a heat preservation chamber 3, a heating chamber 4, a gas distributor 5, a heat preservation structure 6, a hot gas circulation pipeline 7 and a discharge channel 8,

[0020] Among them, the carbonization chamber 2 is placed in a heated gas environment for gas heating; the heat preservation chamber 3 is used to isolate the heat transfer between the carbonization chamber and the outside world; the heating chamber 4 is used to heat the gas heat carrier; the hot gas circulation pipeline and The discharge channel for outputting the semi-coke is used to input the gas heat carrier in the heating chamber into the heating chamber.

[0021] A low-rank coal carbonization device according to the present invention includes a hopper, a carbonization chamber, a heat preservation chamber, a heating chamber, a gas distributor, a heat preservation structure, a hot gas cir...

specific Embodiment approach 2

[0022] Embodiment 2 of the present invention is implemented on the basis of a low-rank coal carbonization device in Embodiment 1. Those skilled in the art can realize the idea of the present invention according to the following specific embodiments.

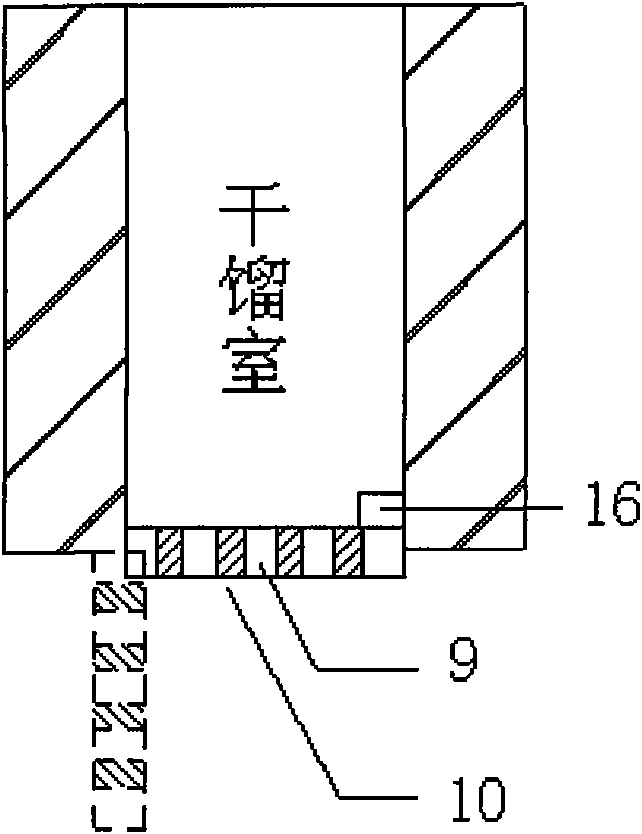

[0023] First, 83.26 grams of Fugu long-flame coal with a particle size of 10-15 mm was added to the carbonization chamber 2, and 3.0 kg of metallurgical coke was installed in the heating chamber 4 as a heat exchange medium. The gas heat carrier at 24°C and the circulating hot gas at 522°C enter the heating chamber 4 through the gas heat carrier inlet 12, and exchange heat with the 800°C metallurgical coke in the heating chamber 4, and the gas heat carrier is heated to 647°C. At this time, the 45° control flap 18 between the heating chamber and the heat preservation chamber is in a closed state, and the gas heat carrier at 647°C all enters the retort chamber 2 through the screen hole 10 at the bottom of the retort chamber 2, and ...

specific Embodiment approach 3

[0024] 96.30 grams of Fugu long-flame coal with a particle size of 10-15 mm was added to the carbonization chamber 2, and 3.0 kg of metallurgical coke was installed in the heating chamber 4 as a heat exchange medium. The gas heat carrier at 24°C and the circulating hot gas at 561°C enter the heating chamber 4 through the gas heat carrier inlet 12, and exchange heat with the metallurgical coke at 800°C in the heating chamber 4, and the gas heat carrier is heated to 684°C. At this time, the 45° umbrella-shaped control flap 18 between the heating chamber and the heat preservation chamber is in a closed state, and the gas heat carrier at 684°C all enters the retort chamber 2 through the sieve hole 10 at the bottom of the retort chamber 2, and exchanges heat with the coal. , After a period of time, the temperature of the coal material rose to 684°C. At this time, the 45° control flap 18 between the heating chamber 4 and the heat preservation chamber 3 is opened, and a part of the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com