Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Lower package thermal resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

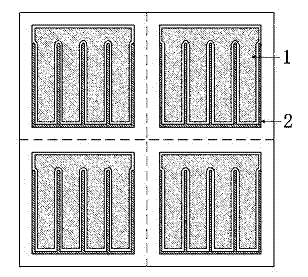

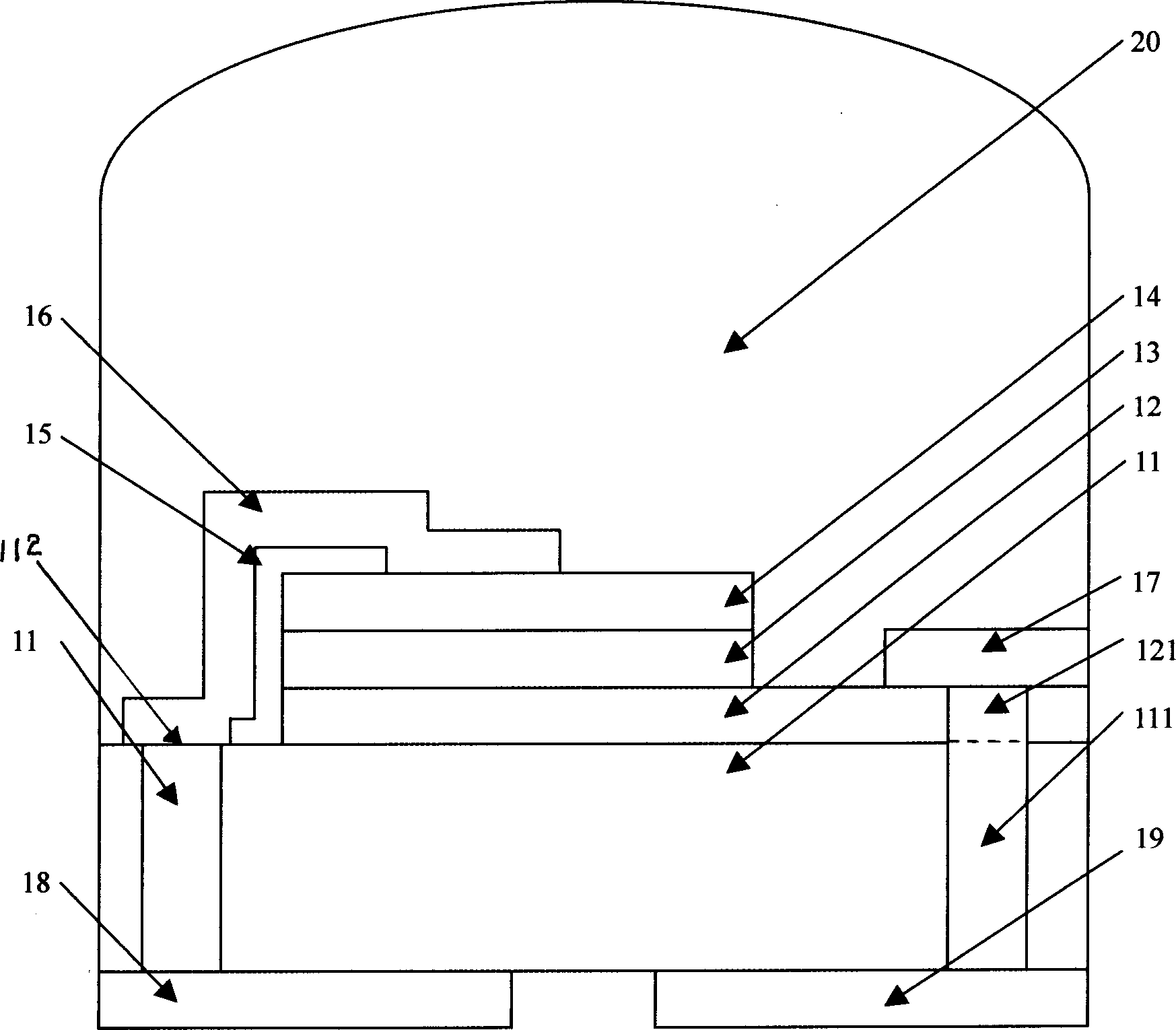

High-power COB-packaged LED structure and wafer-level manufacturing process thereof

InactiveCN102931322AReduce in quantityLower lumen costSolid-state devicesSemiconductor devicesOn boardEngineering

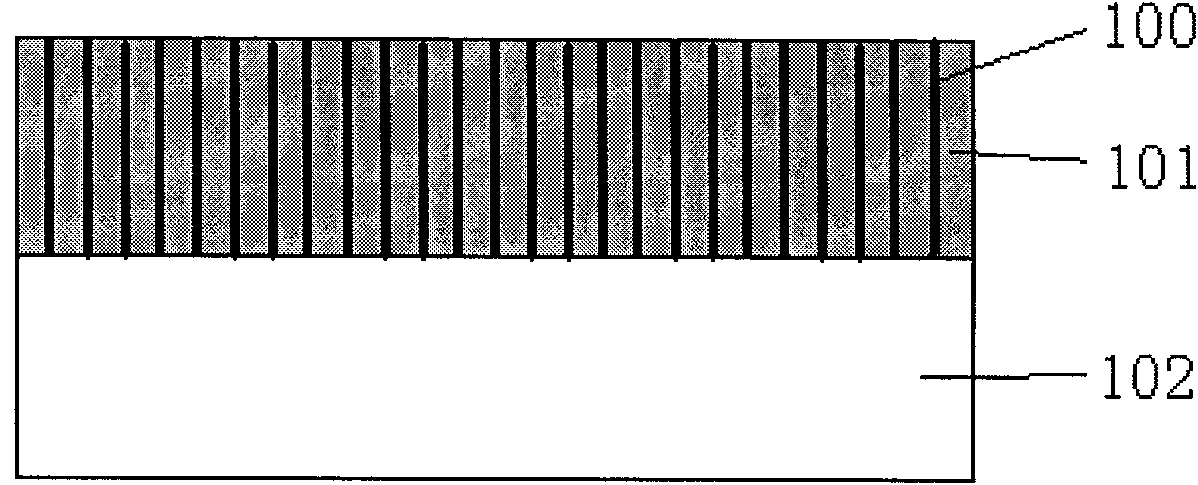

The invention discloses a high-power COB (Chip on Board)-packaged LED (Light Emitting Diode) structure. The high-power COB-packaged LED structure comprises a sub-mount, a wiring electrode, an interconnection circuit, a chip electrode, a p-type GaN layer, an active region, an n-type GaN layer and a fluorescent powder layer, wherein the sub-mount is positioned on a bottom layer; the wiring electrode and the interconnection circuit are formed on the sub-mount; the chip electrode corresponds to the wiring electrode; the p-type GaN layer, the active region and the n-type GaN layer are positioned above the chip electrode; the fluorescent powder layer is coated above the n-type GaN layer; and the wiring electrode and the chip electrode are bonded together. The manufacturing process is based on a chip flip technology and comprises the following steps: on the wafer level, bonding a p-type electrode and an n-type electrode of a high-power chip with corresponding p-type electrode and n-type electrode on the sub-mount; connecting integrated chips in series or in parallel by electrode arrangement of the sub-mount; stripping an original sapphire substrate; transferring the chips to the sub-mount; carrying out spin coating on a photosensitive fluorescent powder solvent on the sub-mount wafer and photoetching to form a shape-reserving fluorescent powder coating. The wafer-level COB-packaged LED structure is higher in production efficiency and quality; and the invention provides a realization method for further reducing the lumen cost of a CO package unit.

Owner:FOCUS LIGHTINGS SCI & TECH

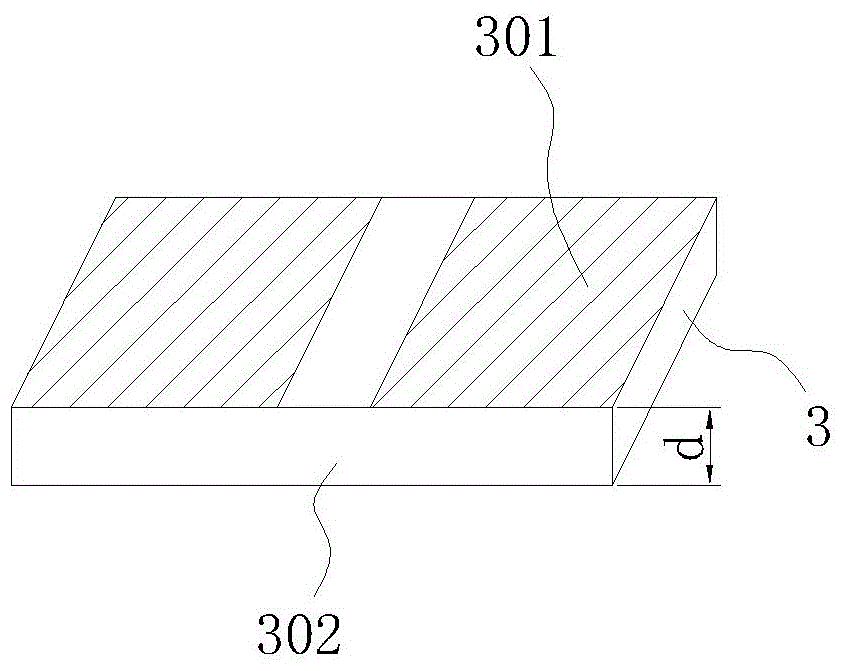

Thermal interface material for packaging and radiating chip and preparation method thereof

InactiveCN101864280AImprove cooling effectImprove stabilitySemiconductor/solid-state device detailsSolid-state devicesCarbon nanotubeLiquid metal

The invention discloses a thermal interface material for packaging and radiating a chip and a preparation method thereof. The thermal interface material comprises a carbon nano tube array on a substrate, and is characterized in that the thermal interface material contains liquid metal which is freely diffused and uniformly distributed in gaps of the carbon nano tube array. The invention uses the carbon nano tube having a high coefficient of heat conductivity to ensure that the thermal interface has a higher heat conductive property, uses the liquid alloy to promote the contact capability between the carbon nano tube and the heat sink and between the carbon nano tube and the chip so as to decrease the thermal resistance of the thermal interface and meet the radiating demand of high-performance chip. The preparation method thereof comprises the steps of: providing a carbon nano tube array vertically formed on the substrate, depositing a metal layer which is easily dissolved in liquid metal on the carbon nano tube, boosting to fully soak the carbon nano tube when the liquid metal is contacted with the carbon nano tube and filling the gaps of the carbon nano tube array.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

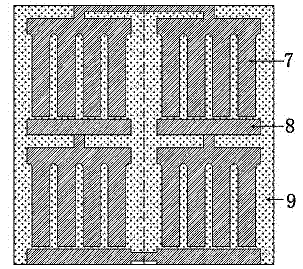

Light-emitting diode package structure manufacturing method

ActiveCN102231421AThe process path is simpleReduce package sizeSemiconductor devicesActive layerLight-emitting diode

The invention discloses a light-emitting diode package structure manufacturing method, which comprises the following steps of: sequentially growing an n-type layer, an active layer and a p-type layer on an insulating substrate by utilizing a metal organic vapor phase epitaxial method; downwards photoetching one side of the upper surface of the p-type layer with the photoetching depth of reaching the surface of the n-type layer to form a first tabletop, downwards etching the other side with the etching depth of reaching the surface of the insulating substrate to form a second tabletop; manufacturing conductive through holes on the first and second tabletops, and filling conductive metals; manufacturing an insulating layer partially covering the upper surface of the p-type layer on the sideclose to the second tabletop; manufacturing a p electrode covering the insulating layer on the insulating layer; manufacturing an n electrode on the conductive through hole on the first tabletop; thinning the insulating substrate; manufacturing a first back electrode and a second back electrode on the two sides of the back of the insulating substrate to form a substrate of a device; packaging an optical element on the substrate of the device to finish manufacturing the device on the substrate; and cutting the device on the substrate into independent devices in a mechanical way.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

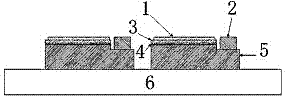

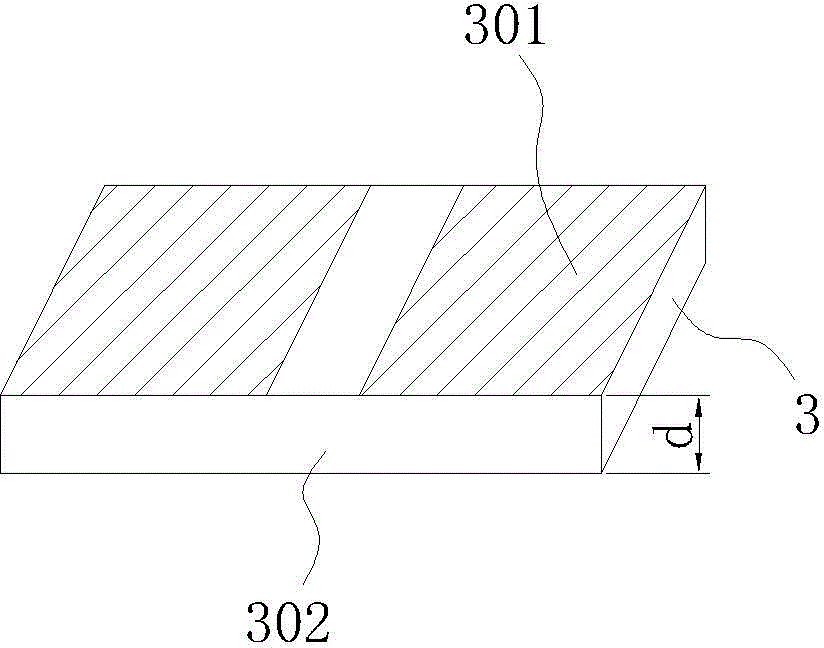

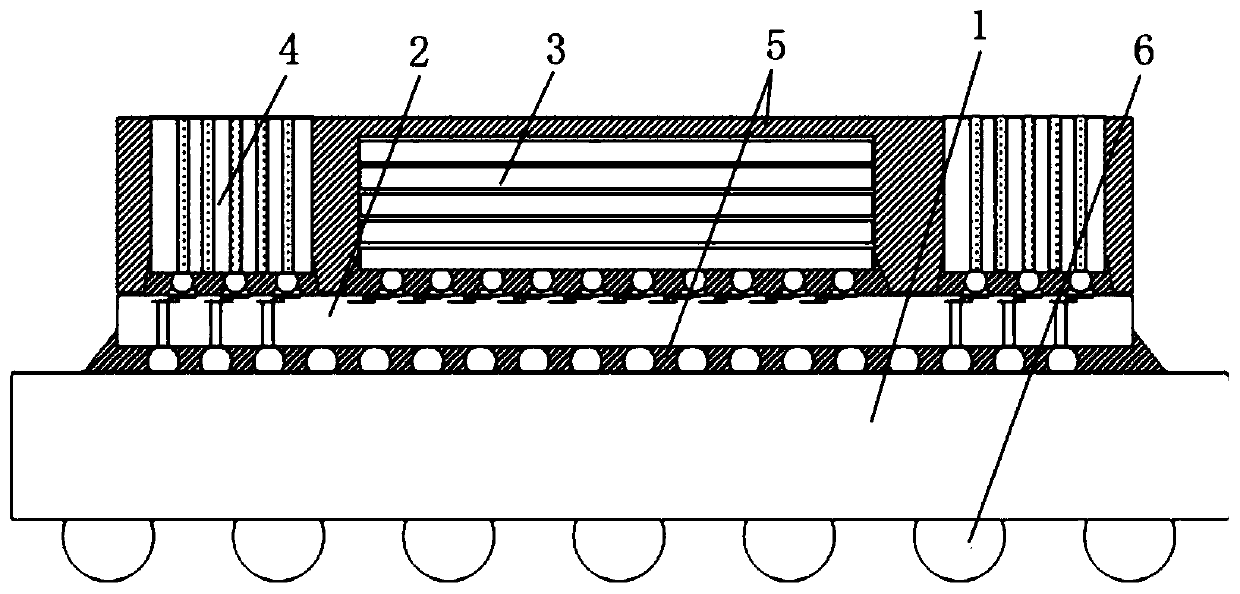

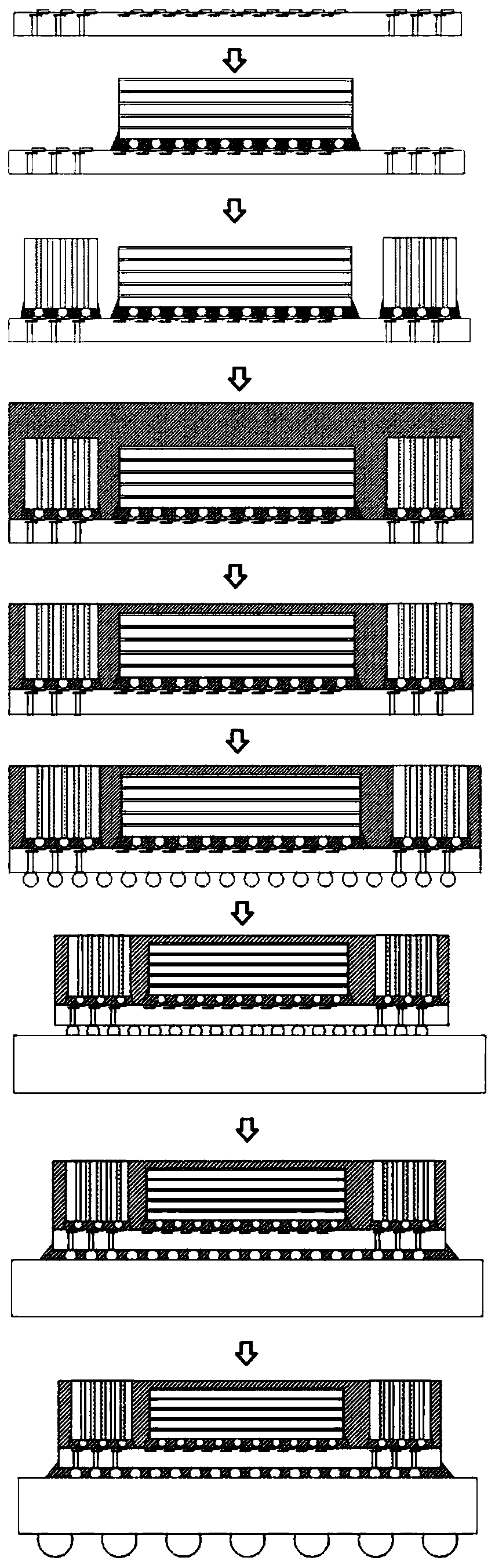

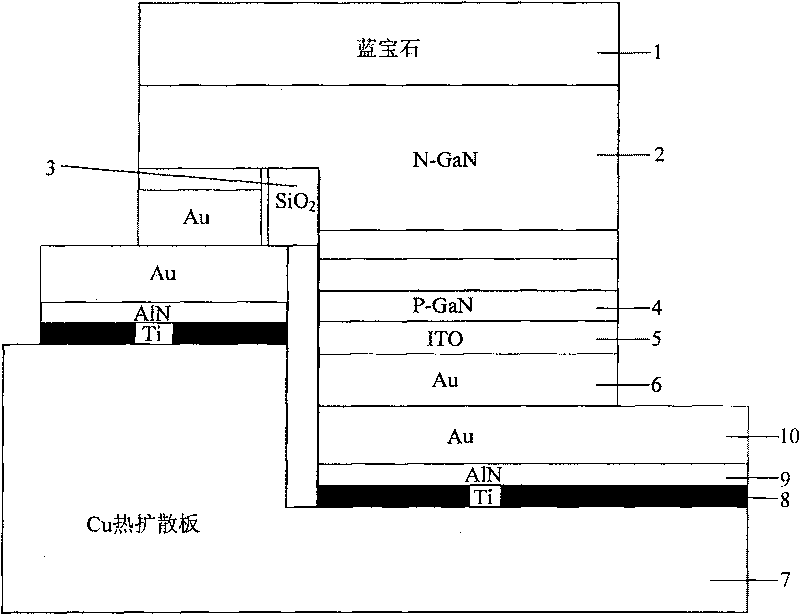

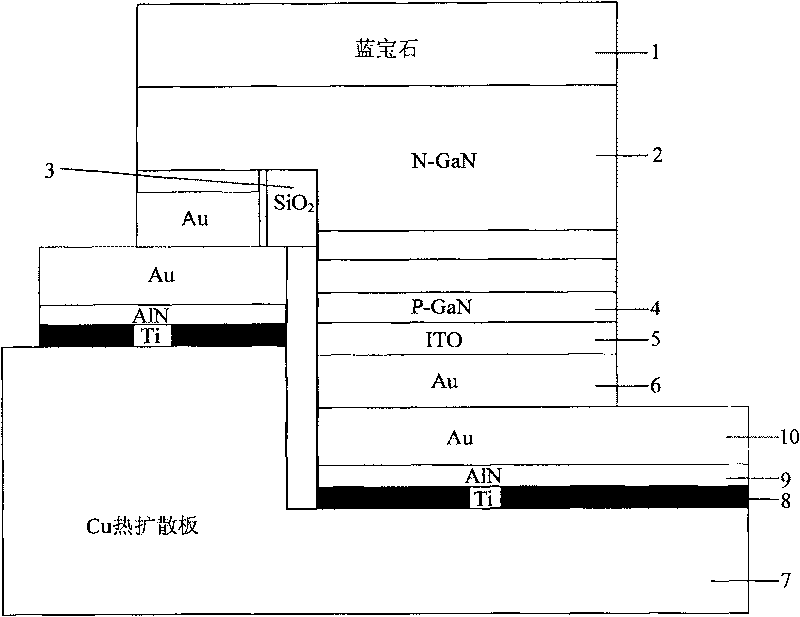

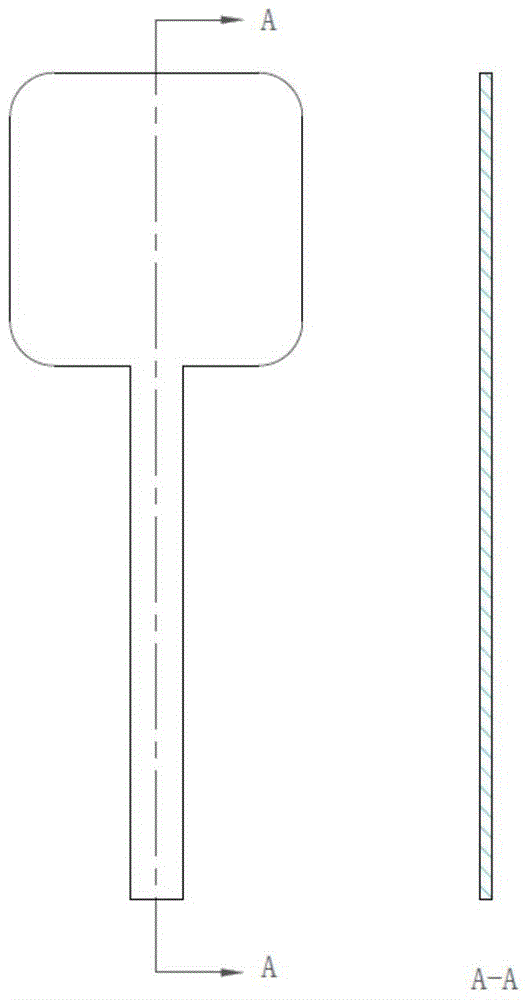

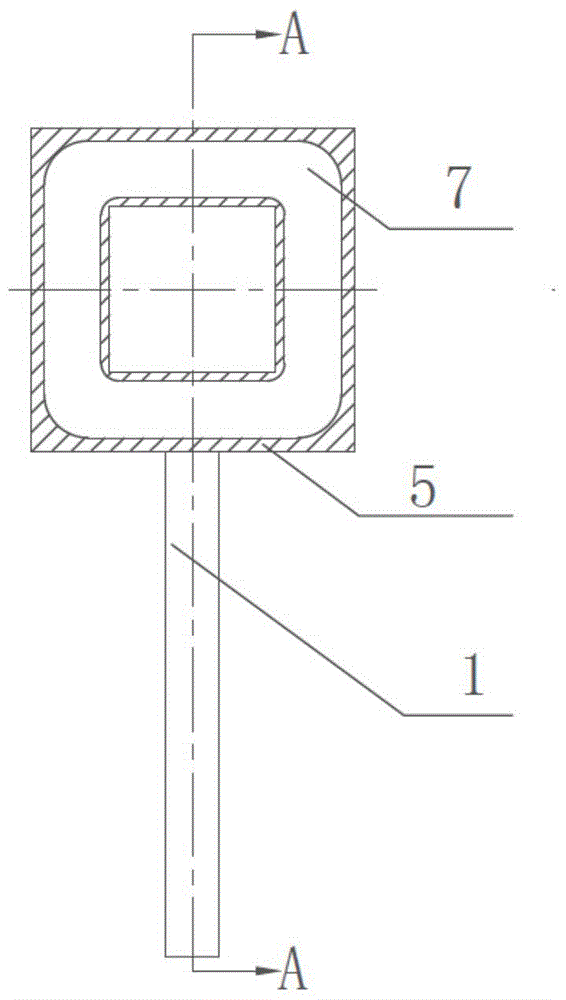

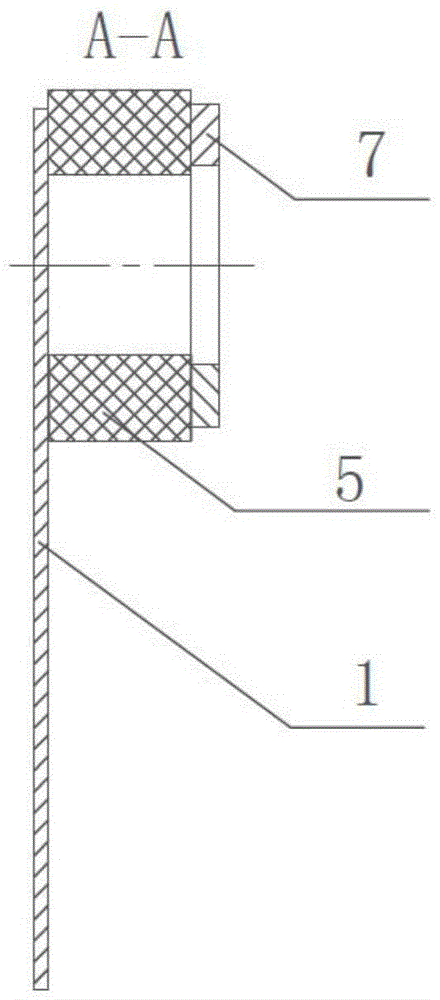

Method for construction of high power LED multilayer gradient material cooling channel

InactiveCN101281944AImprove cooling effectImprove stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesGradient materialThermal coefficient

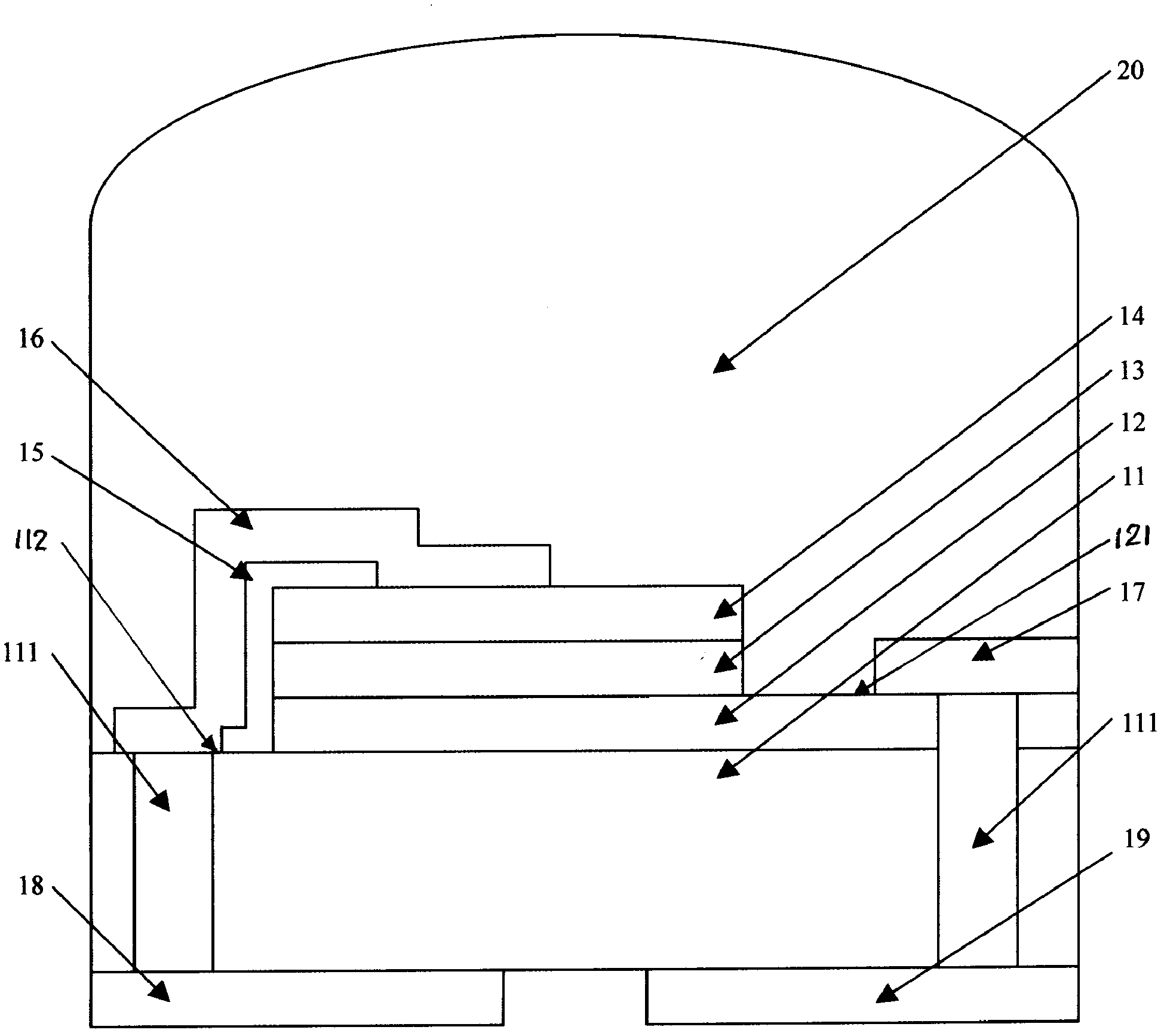

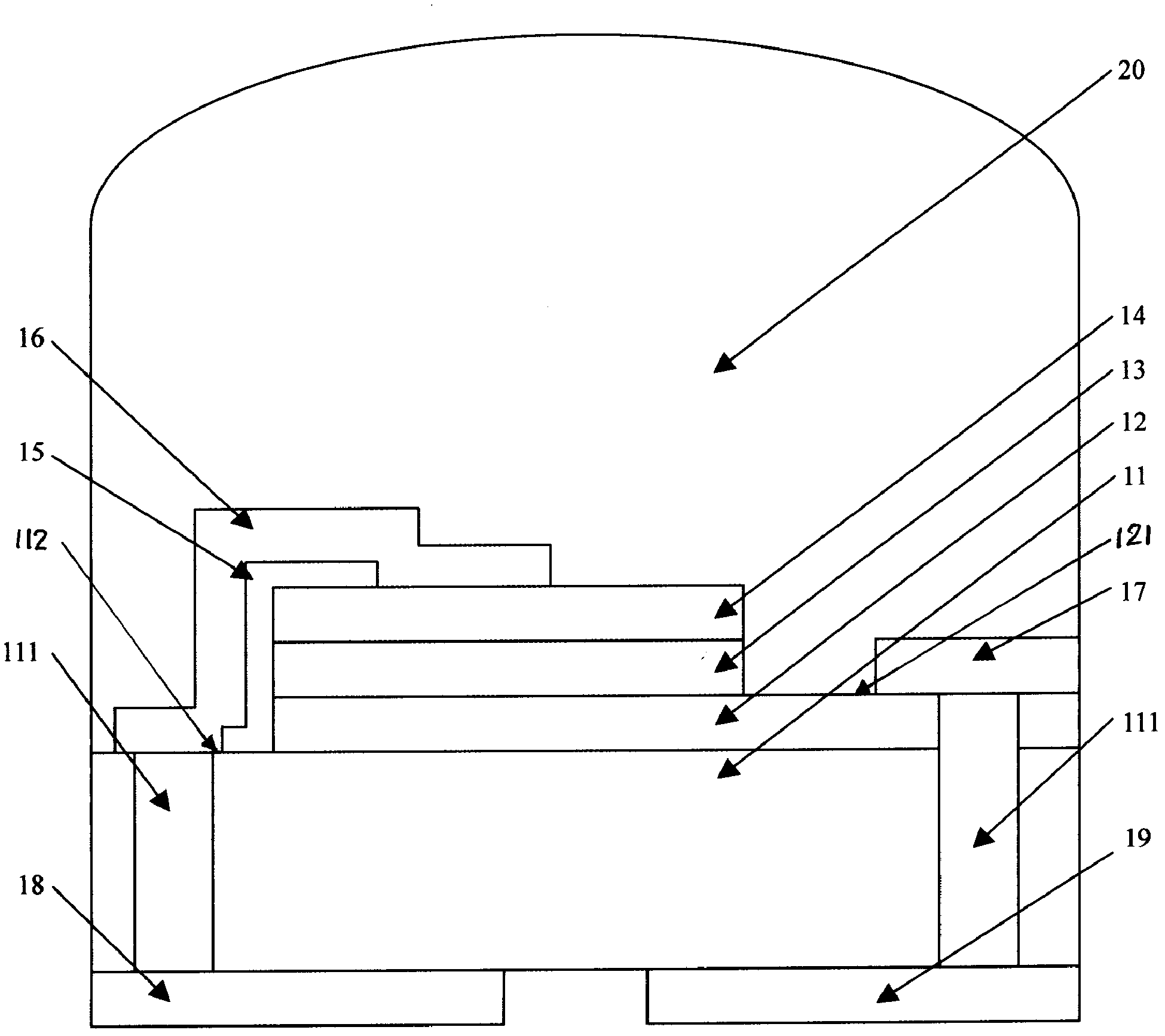

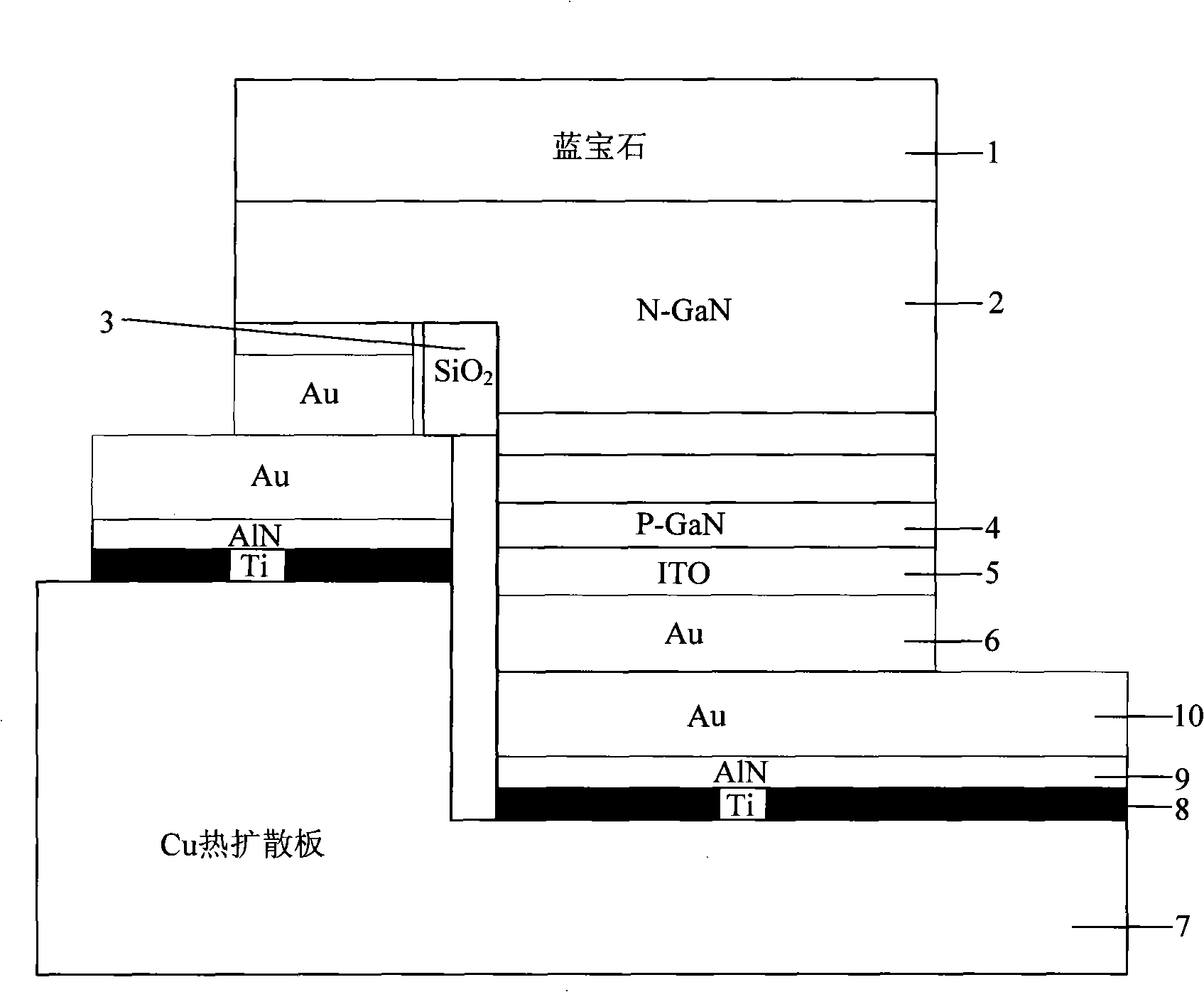

The invention provides a construction method for a high power LED multilayer gradient material heat dispersion channel, which includes steps: 1) GaN-base LED chip preparation: etching a GaN-base LED epitaxial wafer by dry process to form a L shape and expose N-GaN layer surface; vaporizing a indium tin oxide current expansion layer on surface of the P-GaN, vaporizing P, N electrodes and plating pure gold on the P, N electrode; 2) Cu fast heat diffusion board preparation: preparing a L-shaped Cu board, sputtering a layer of Ti or Cr by magnetic control to be used as a adhesive layer; sputtering a layer of AlN on the Ti layer by magnetic control to be used as a insulated layer; vaporizing a layer of thin gold and plating a layer of thick pure gold; 3) pure gold bonding by thermocompression bonding: upside-down mounting the LED chip on the Cu fast heat diffusion board. By employing Au-Au-AlN-Ti multilayer material with high thermal conductance and gradient changed thermal coefficient of expansion to construct the heat dispersion channel between the LED and the Cu fast heat diffusion board, heat diffusion problem of high power LED is resolved, heat diffusion capability and stability of device is increased.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

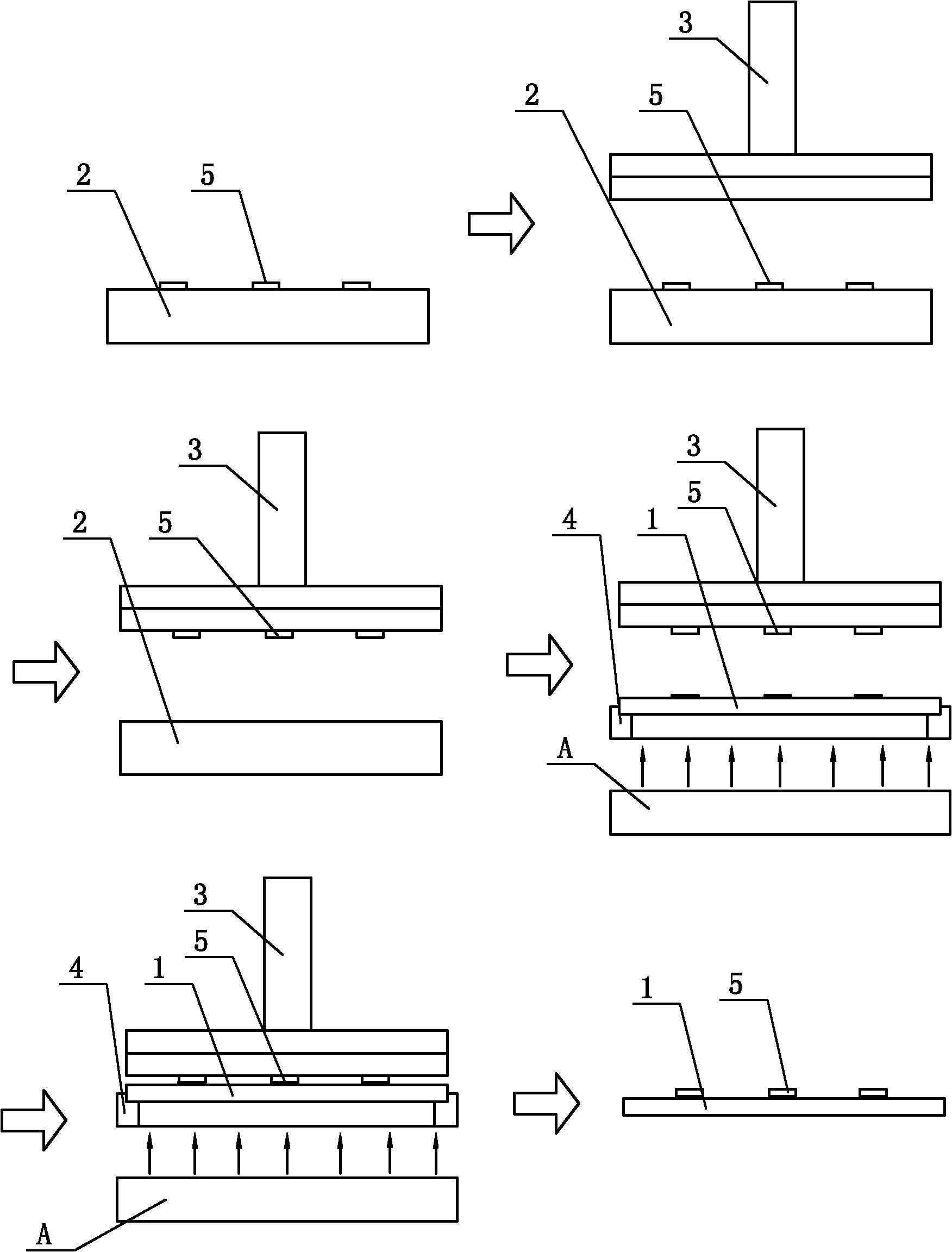

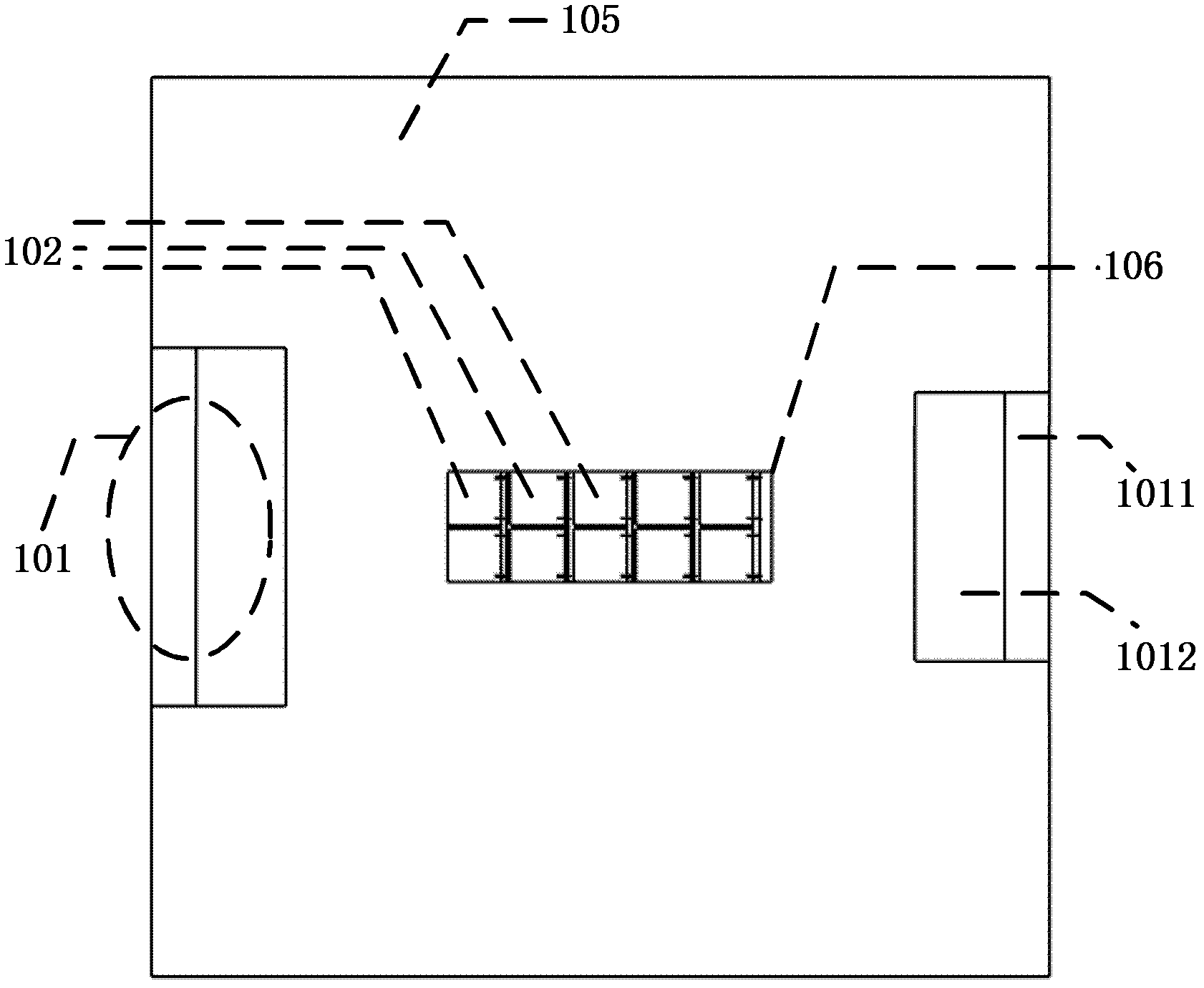

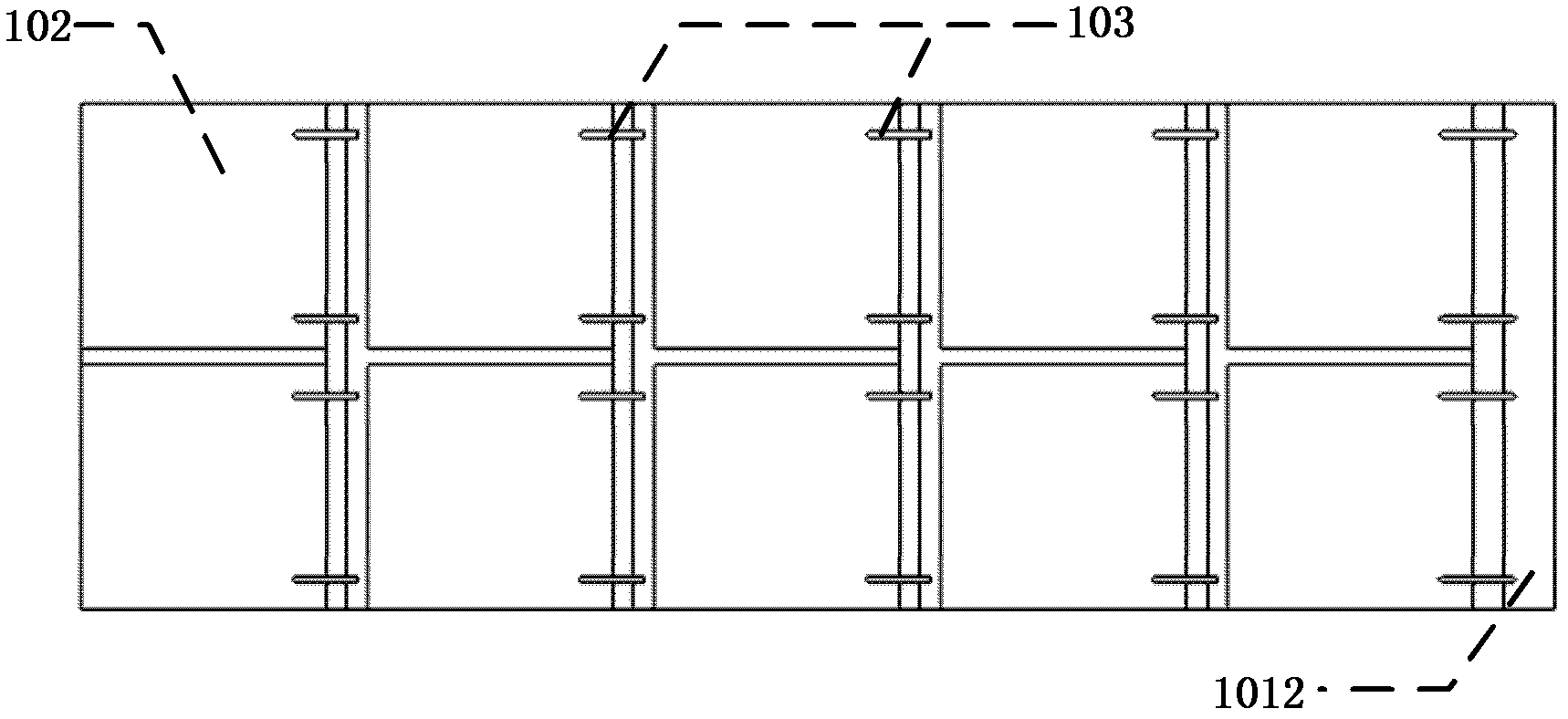

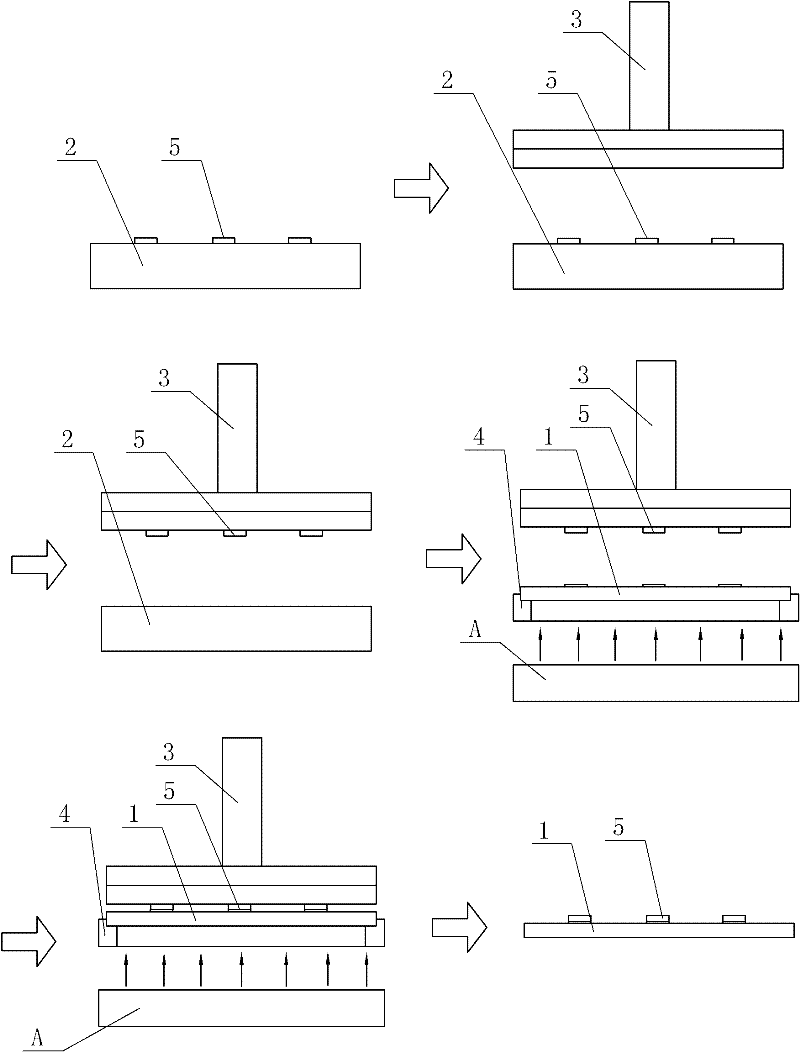

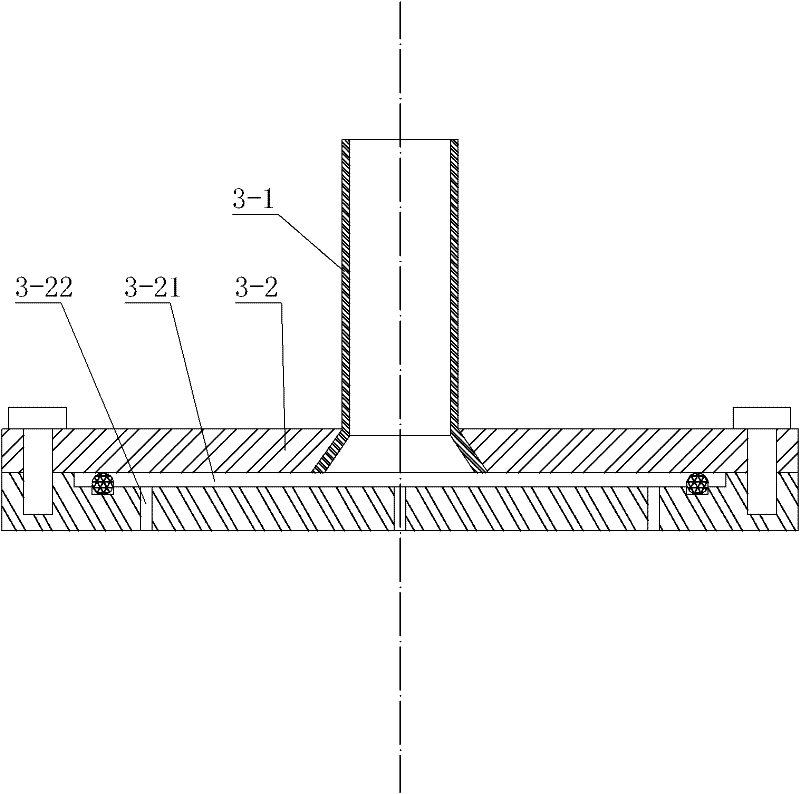

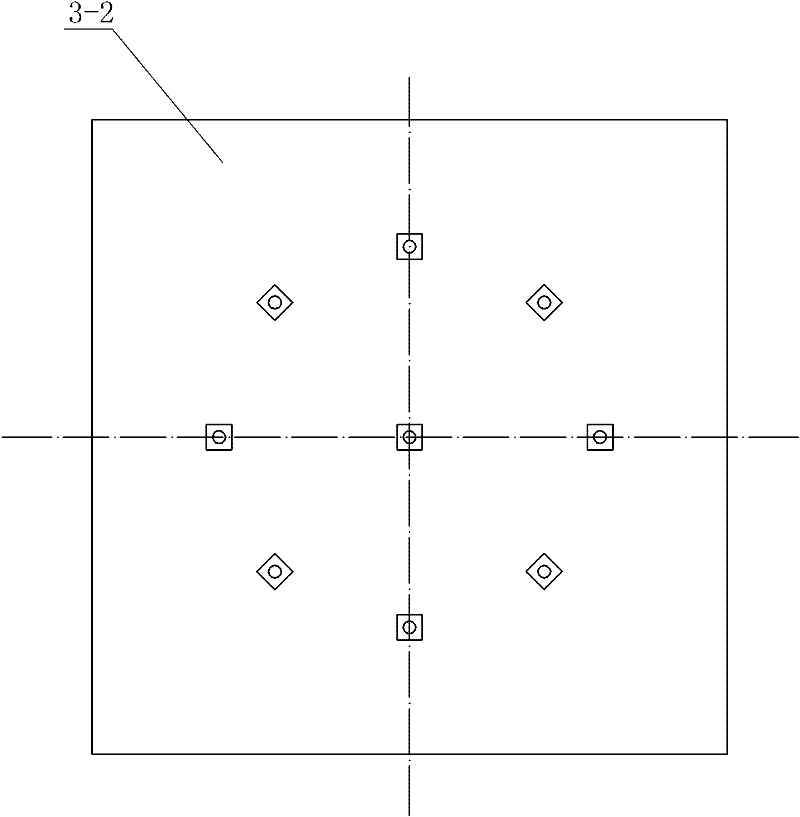

Single-substrate multi-chipset high-power LED (Light-Emitting Diode) encapsulation one-step bonding method

InactiveCN102157630ASolve driftReduce failure rateSolid-state devicesSemiconductor devicesScreen printingFree cooling

The invention relates to a single-substrate multi-chipset high-power LED (Light-Emitting Diode) encapsulation one-step bonding method, belonging to the technical field of multi-chipset high-power LED encapsulation. The invention solves the problem that the whole bonding time is too long as multiple chipsets are sequentially spliced in the traditional multi-chipset high-power LED encapsulation technology. The method comprises the following steps of: cleaning a substrate, a chip carrying platform, a multi-chip suction nozzle and a supporting platform; placing the substrate on the supporting platform; determining positions of chips to be bonded on the front of the substrate, and placing multiple chips to be bonded on the chip carrying platform corresponding to the positions of the chips to be bonded; uniformly coating soldering paste on the positions of the chips to be bonded by adopting screen printing, and then simultaneously picking up multiple chips to be bonded with the multi-chip suction nozzle; heating the back of the substrate, enabling multiple chips to align with the positions to be bonded and then attached to the soldering paste, continuously heating for 5-10s, naturally cooling to room temperature, and removing the multi-chip suction nozzle, thus the bonding process is completed. The invention provides an encapsulation bonding method.

Owner:HARBIN INST OF TECH

Light emitting diode (LED) packaging structure

ActiveCN102255034AThe process path is simpleReduce package sizeSemiconductor devicesIsolation layerActive layer

The invention relates to a light emitting diode (LED) packaging structure. The LED packaging structure comprises an insulating substrate, an n-shaped layer, an active layer, a p-shaped layer; an isolating layer, a p electrode, an n electrode, a first back electrode and a second back electrode, wherein through holes are formed on both sides of the insulating substrate and are filled with conductive metal; the n-shaped layer is arranged on the insulating substrate, and a hole is formed in the n-shaped layer and is filled with conductive metal; the active layer is arranged on the n-shaped layer;the p-shaped layer is arranged on the active layer; the isolating layer is positioned on one side of the n-shaped layer, the active layer and the p-shaped layer and is used for covering a part of upper surface of the p-shaped layer; the p electrode is used for covering the isolating layer and covering a part of upper surface of the p-shaped layer; the n electrode is arranged on one side of the upper side of the n-shaped layer and is connected with the conductive metal in the through holes in the insulating substrate; the first back electrode is arranged on one side of the rear side of the insulating substrate and is connected with the p electrode through the conductive metal in the through holes in the insulating substrate; and the second back electrode is arranged on the other side of the rear side of the insulating substrate and is connected with the n electrode through the conductive metal in the through holes in the insulating substrate. A substrate of a device is formed by all the parts, and an optical element is packaged on the substrate to complete the production of the device.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

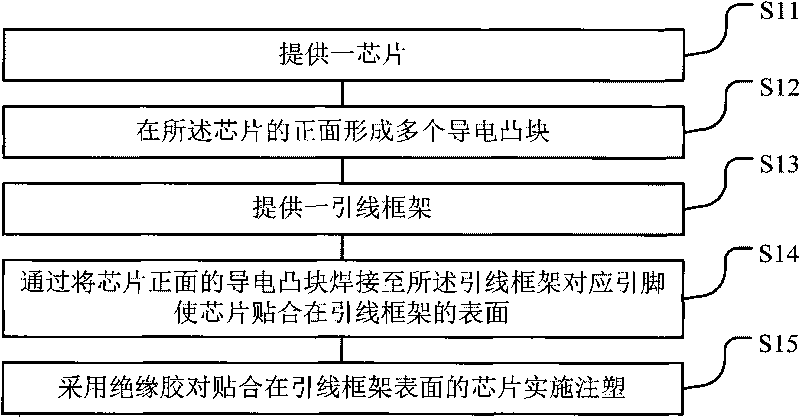

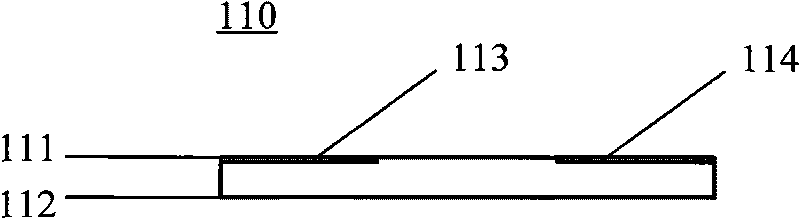

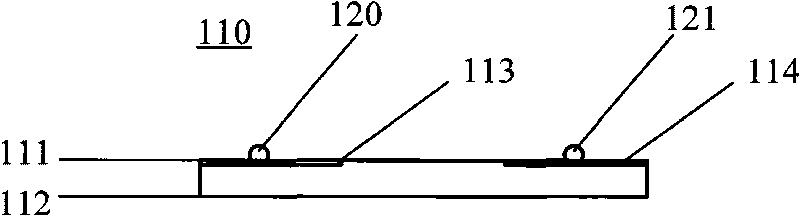

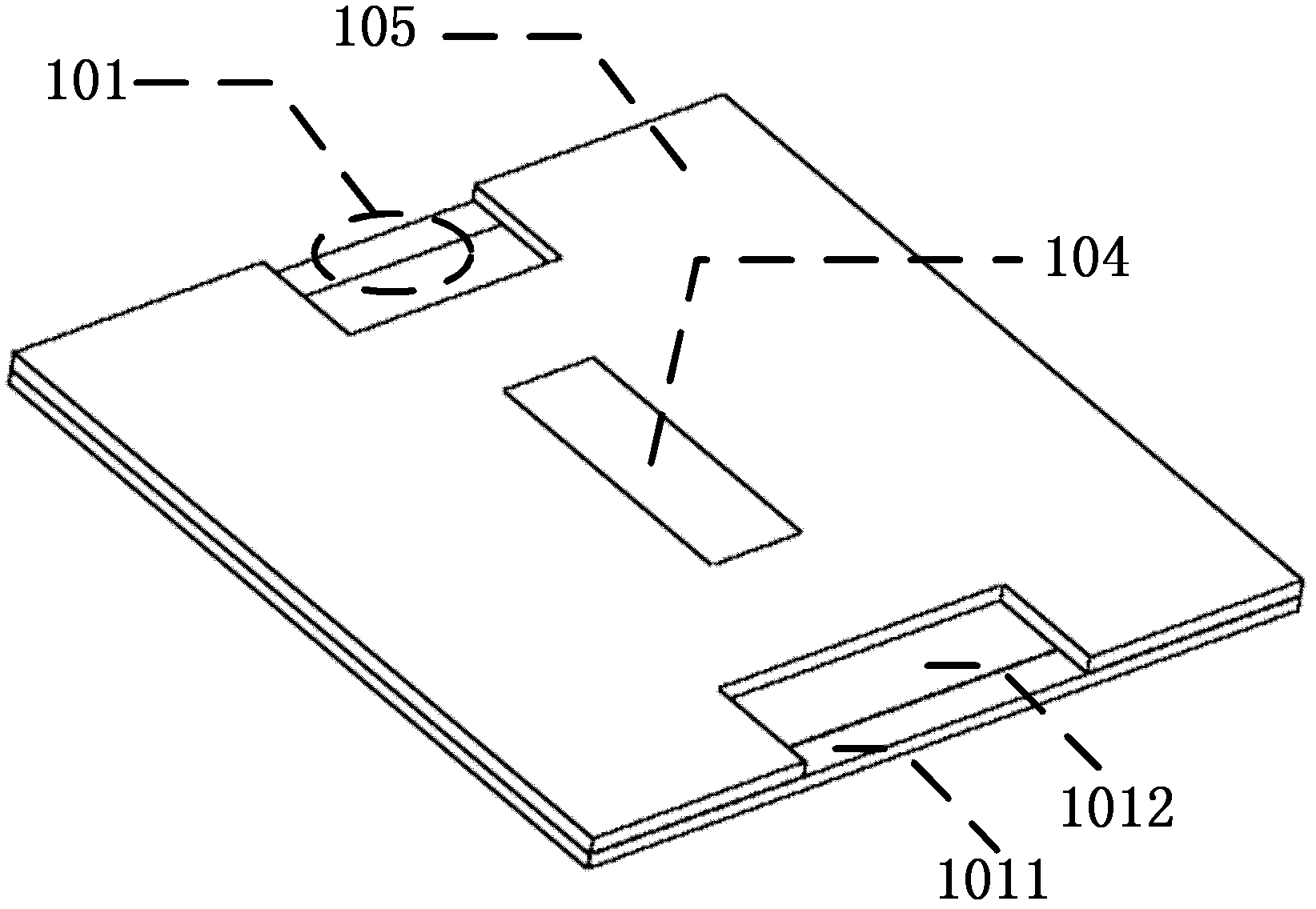

Inversion type encapsulation structure and manufacturing method thereof

InactiveCN101764114AImprove distributionShort processing cycleSemiconductor/solid-state device detailsSolid-state devicesHeat resistanceEngineering

The invention relates to an inversion type encapsulation structure, comprising a lead wire frame which is provided with a plurality of lead feet; a chip which is arranged on the lead wire frame and is provided with a front surface and a back surface, and the front surface is provided with a plurality of bonding pads which are electrically connected to the lead feed corresponding to the lead wire frame; a plurality of conductive lugs which are arranged between the chip and the lead wire frame and are electrically connected with the bonding pads of the chip and the lead feet of the lead wire frame; and a plastic body which is arranged on the surface of the lead wire frame, wherein the chip is arranged; the inversion type encapsulation structure has the advantages that: by adopting the method that the conductive lugs are directly bonded the lead wire frame, the process period is shortened, the encapsulation resistance between the lead wire frame and the chip can be reduced; metal lines are replaced by the lugs, creepage and crosstalk among the lead wires and the effect of external electromagnetic radiation on the working of the chip are avoided; in the preferential technical proposal, the back surface of the chip is exposed to outside of the plastic body, the encapsulation heat resistance is reduced.

Owner:SHANGHAI KAIHONG ELECTRONICS CO LTD

High-power LED chip making method

InactiveCN103715329ALower package thermal resistanceLow costSemiconductor devicesEngineeringMicroscopy

A high-power LED chip making method is provided in order to solve the problems of high packaging thermal resistance, low light extraction efficiency and high cost in the prior art. The method comprises the following steps: step 1, LED chip inspection microscopy: whether the material surface has mechanical damage, pocks or pockmarks, whether the chip size and the electrode size meet the process requirement and whether the electrode pattern is complete are detected; step 2, a film for bonding chips is expanded with the use of a film expanding machine to enable the spacing of the LED chips to be stretched to 0.6mm; step 3, LED dispensing: silver glue or insulating glue is dispensed in corresponding position points of an LED bracket; and step 4: LED back-gluing: silver glue is pasted on a back electrode of an LED by using a back gluing machine and then the LED with silver glue on the back is installed on the LED bracket, wherein the efficiency of back gluing is far higher than that of dispensing. By the adoption of the high-power LED chip making method of the invention, the effects of packaging thermal resistance decreasing, light extraction efficiency improving and cost reducing are achieved.

Owner:深圳市三创客科技有限公司

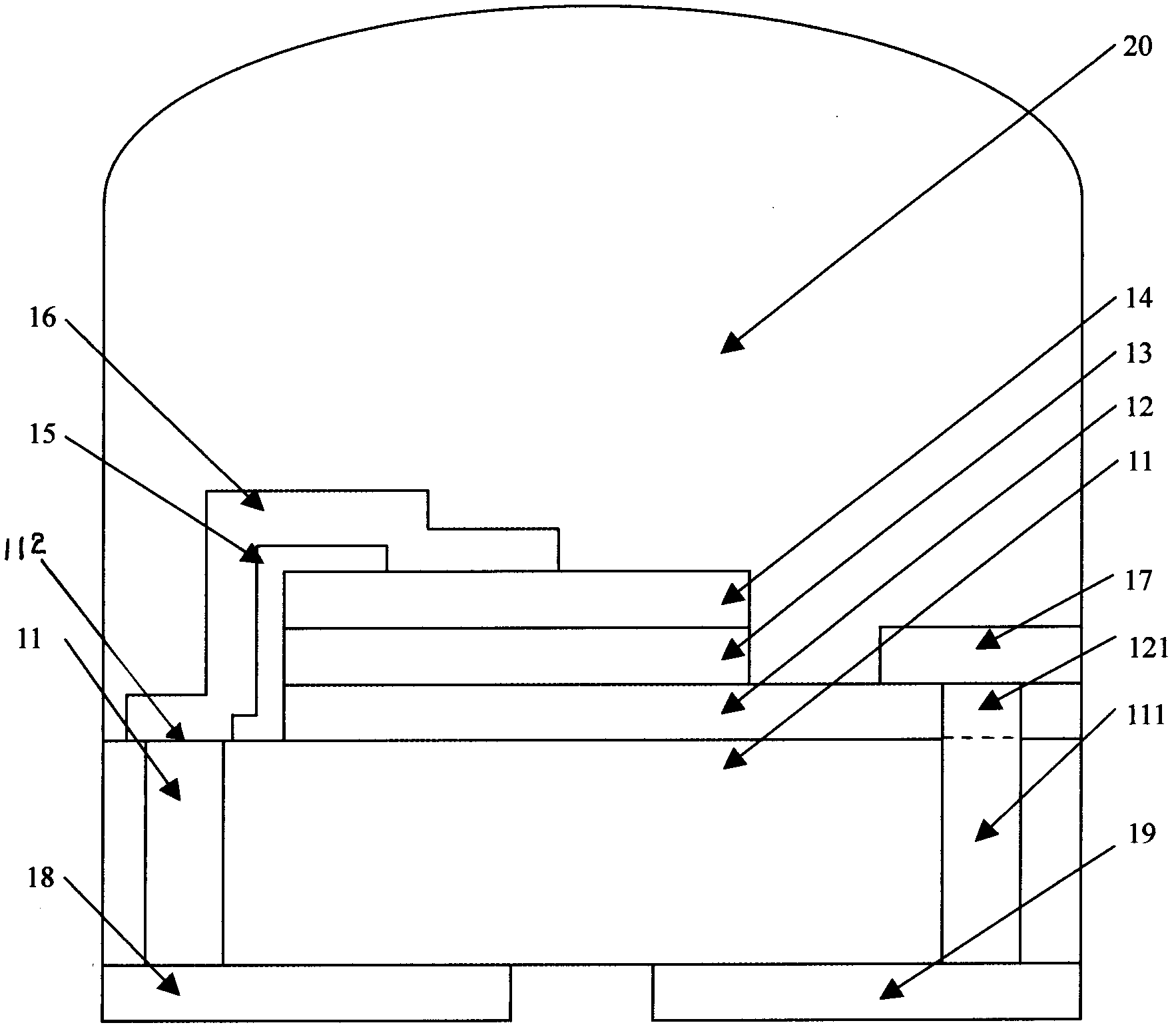

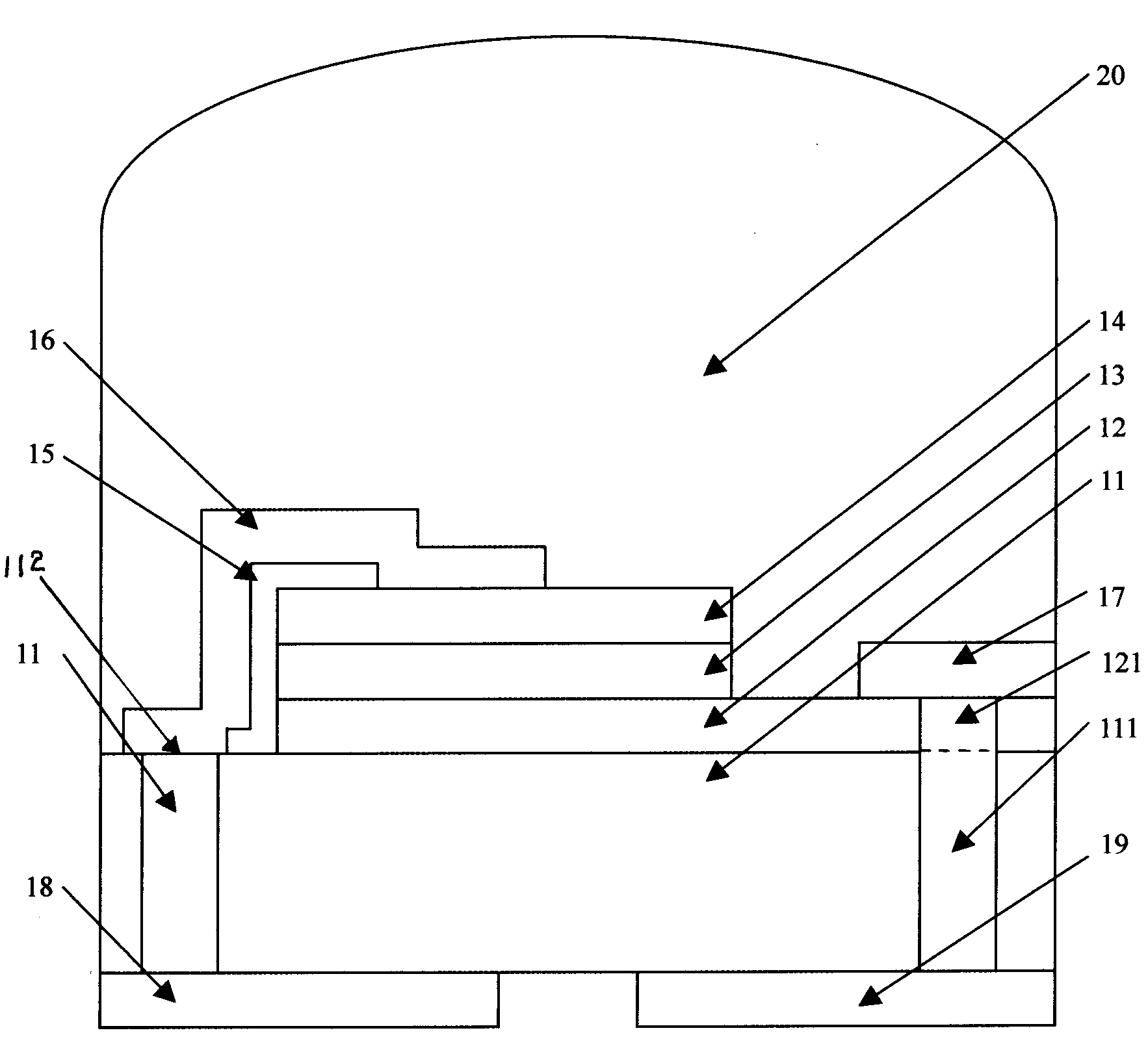

Light-emitting diode (LED) light source encapsulating structure special for automobile headlamp

InactiveCN102856310AClear Brightness CutoffLower package thermal resistancePoint-like light sourceSolid-state devicesFluorescenceHeadlamp

The invention discloses a light-emitting diode (LED) light source encapsulating structure special for an automobile headlamp. The structure comprises an encapsulating substrate, an LED chip, a fluorescent powder layer and an encapsulating cover sheet. The structure is characterized in that the LED chip is installed on the encapsulating substrate, the encapsulating cover sheet is posted on the encapsulating substrate, a rectangular hole is arranged on the encapsulating cover sheet, the LED chip is completely located in the rectangular hole, and the fluorescent powder layer is restricted in the rectangular hole which is located above the LED chip. The structure has the advantages that functions of work temperature detection, high temperature resistance and static electricity breakdown prevention are achieved, the structure is suitable for dipped headlights, headlights on full beam and fog lights, the luminance is high, the luminance cut-off line is clear, the encapsulating thermal resistance is low, and the structure can meet usage requirements of the automobile headlamp for the light source.

Owner:刘胜

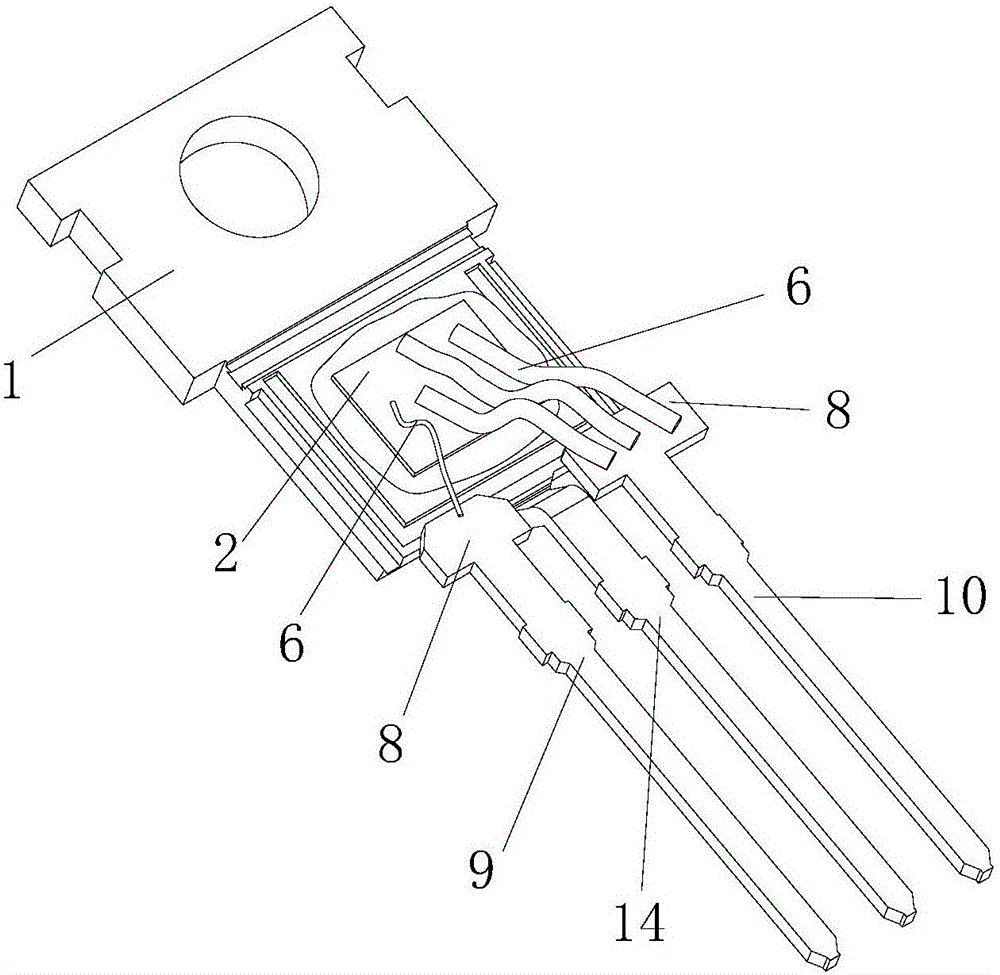

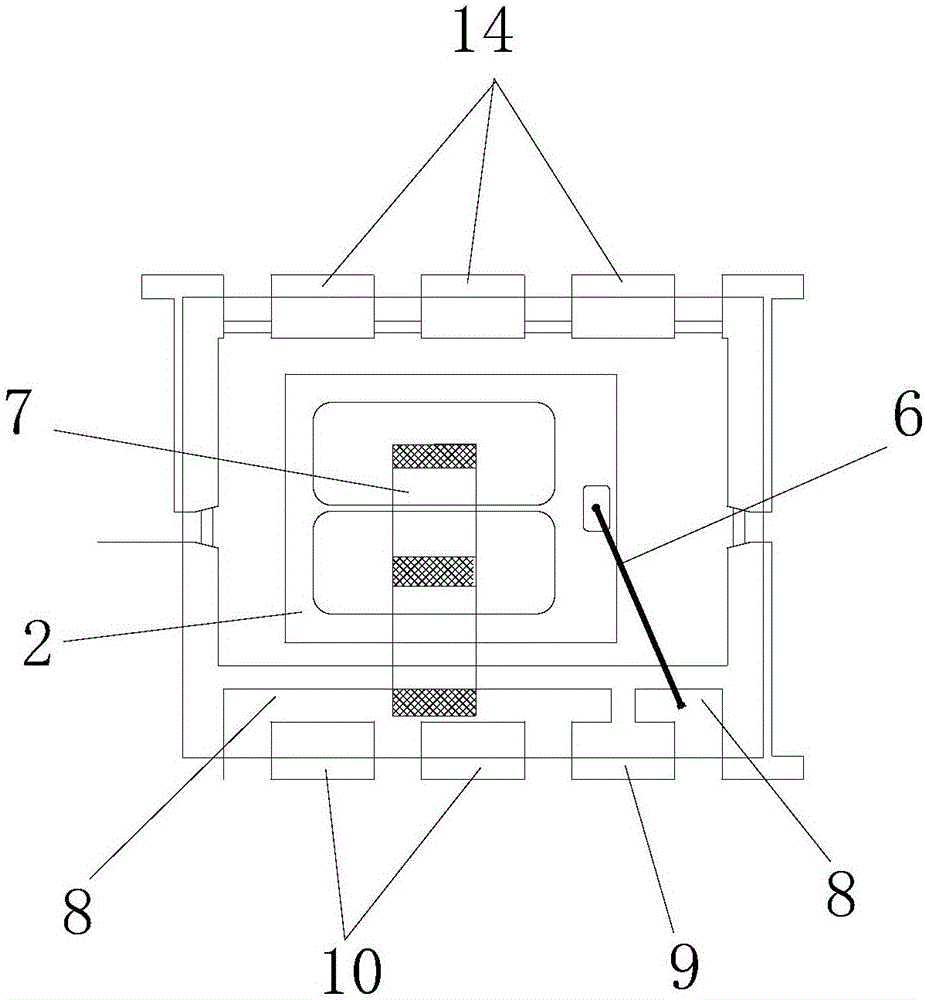

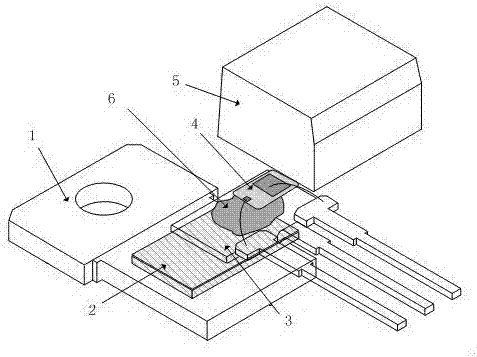

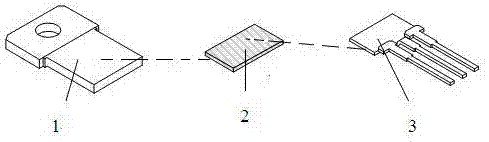

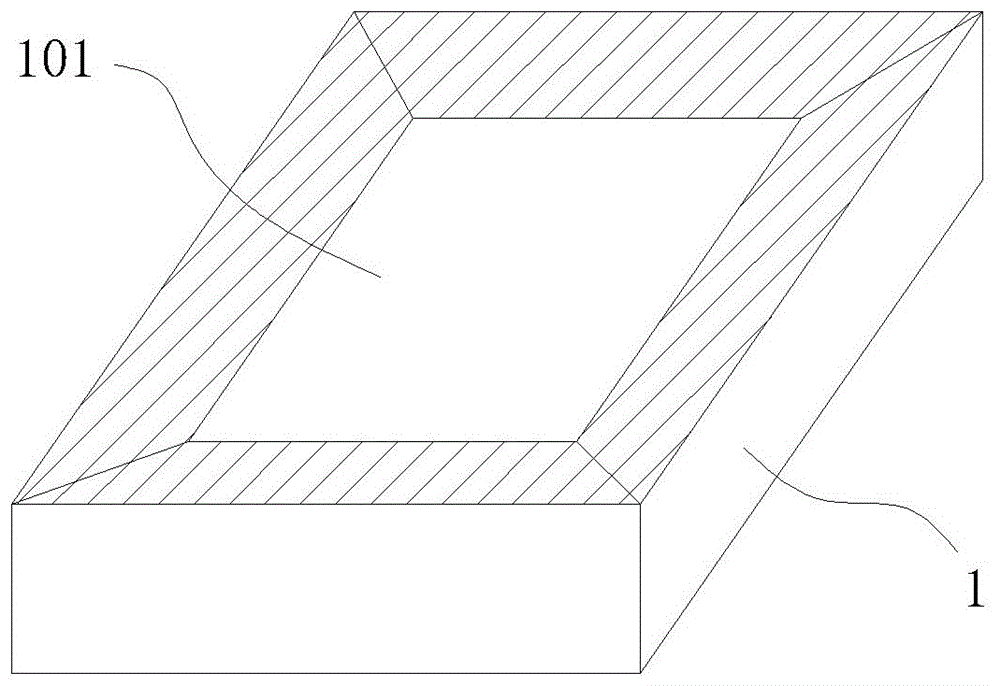

Packaging structure of high-current-power semiconductor device and manufacturing method

ActiveCN106298722AReduce package resistanceLower package thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesHeat sinkPower semiconductor device

The invention relates to a packaging structure of a high-current-power semiconductor device and a manufacturing method. The packaging structure comprises a cooling fin, a semiconductor chip, a plastic package body and a chip-holding island, wherein the chip-holding island is connected with the cooling fin; and a third electrode on a back side of the semiconductor chip is welded on a first surface of the chip-holding island. The packaging structure is characterized in that a first electrode on a front side of the semiconductor chip is welded with one end of a first current-conducting metal sheet; a second electrode is welded with one end of a second current-conducting metal sheet; the first surface of the chip-holding island, the semiconductor chip, a welding end of the first current-conducting metal sheet and a welding end of the second current-conducting metal sheet are packaged in the plastic package body; and the cooling fin, a second surface of the chip-holding island, the other end of the first current-conducting metal sheet and the other end of the second current-conducting metal sheet are exposed outside the plastic package body. The current-conducting metal sheets are directly welded with the electrodes of the semiconductor chip as pins, so that the package resistance of the device is lowered; the overcurrent capability of the device is enhanced; the cooling capability of the device is enhanced; the package thermal resistance is lowered; and the package reliability of the device is enhanced.

Owner:WUXI NCE POWER

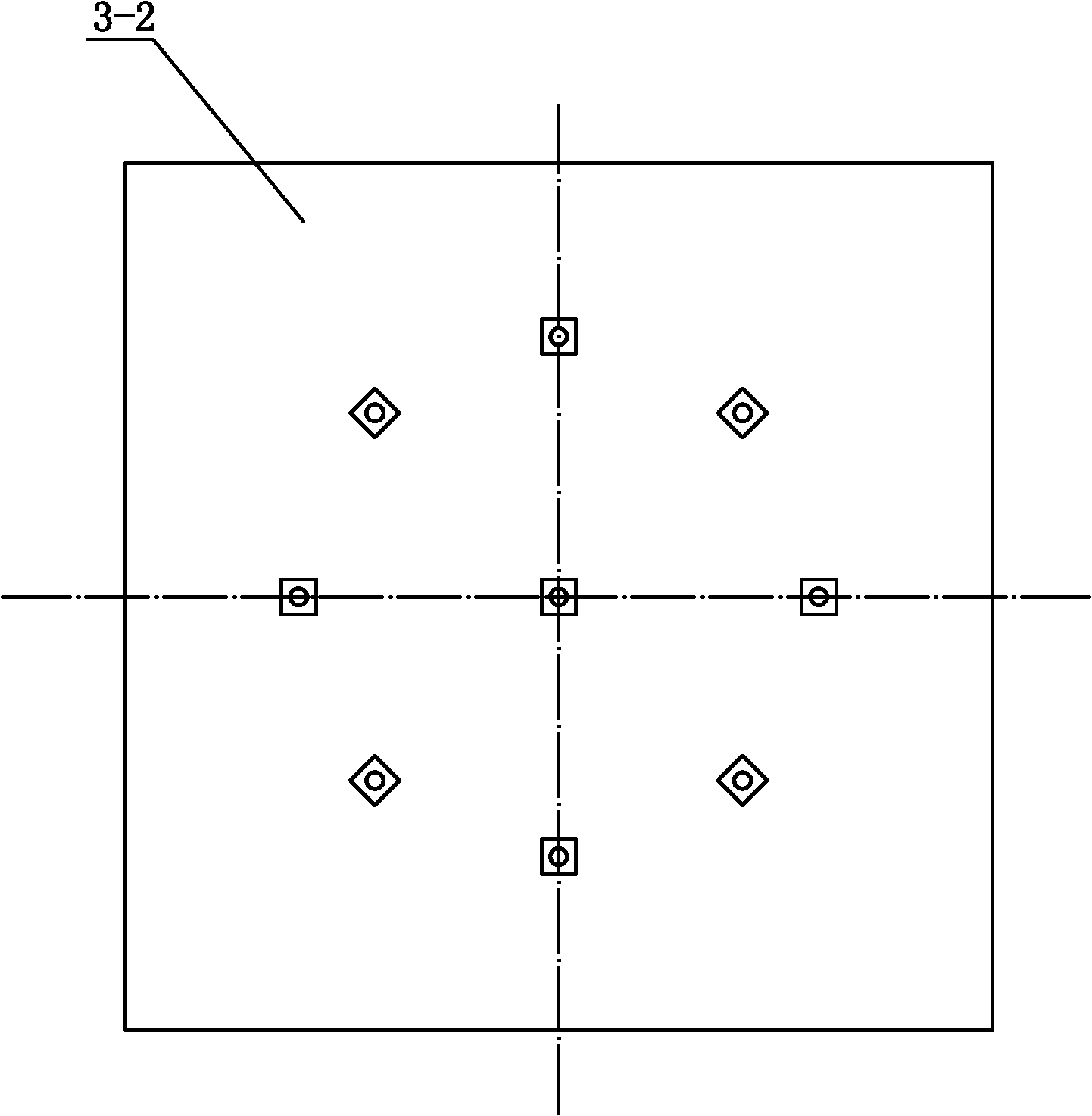

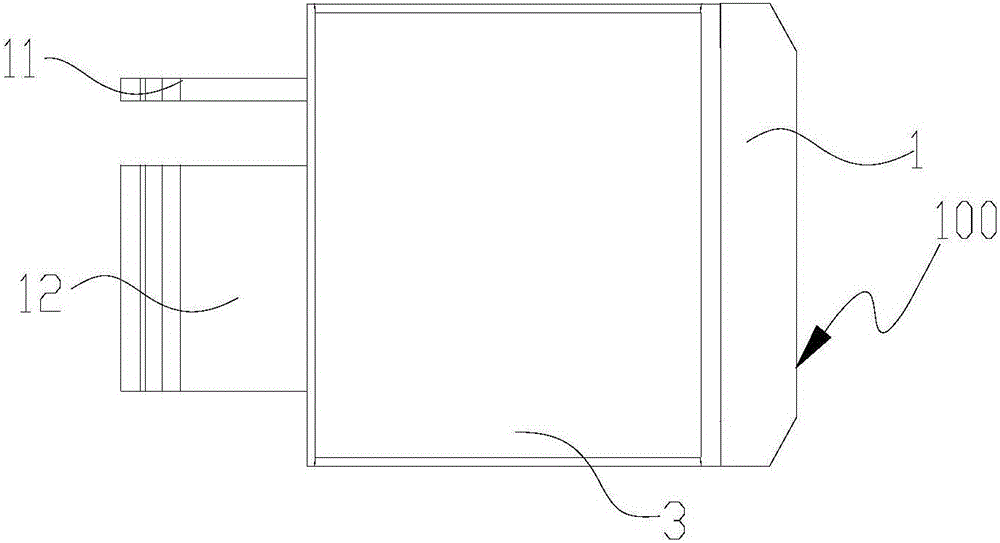

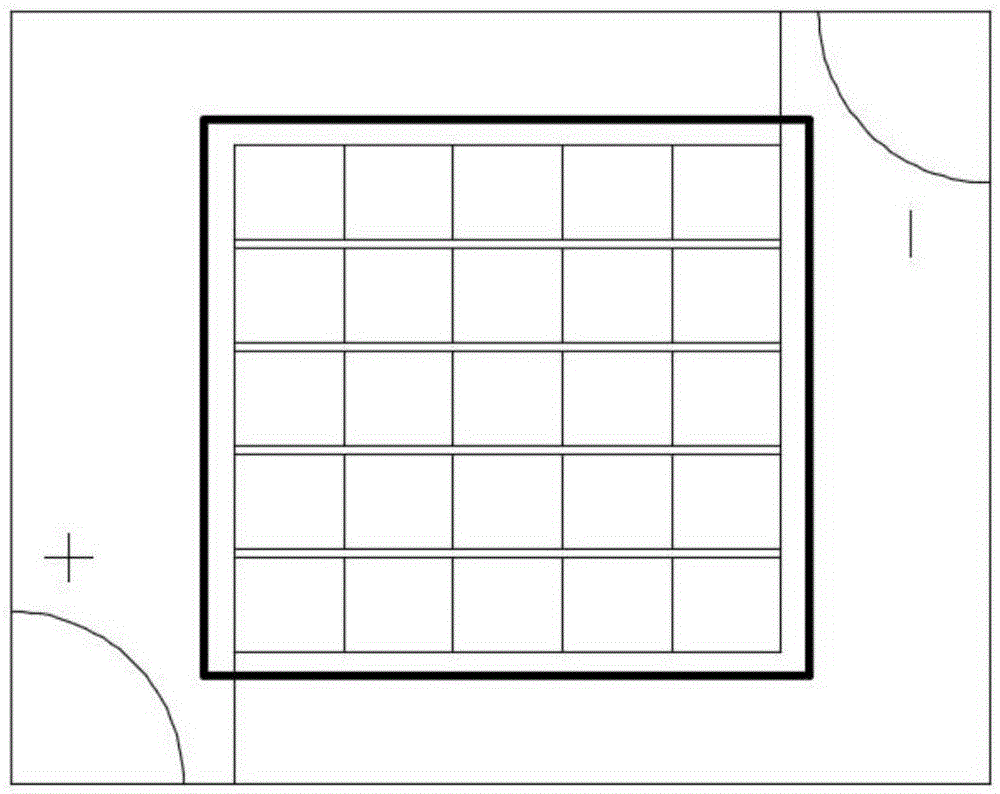

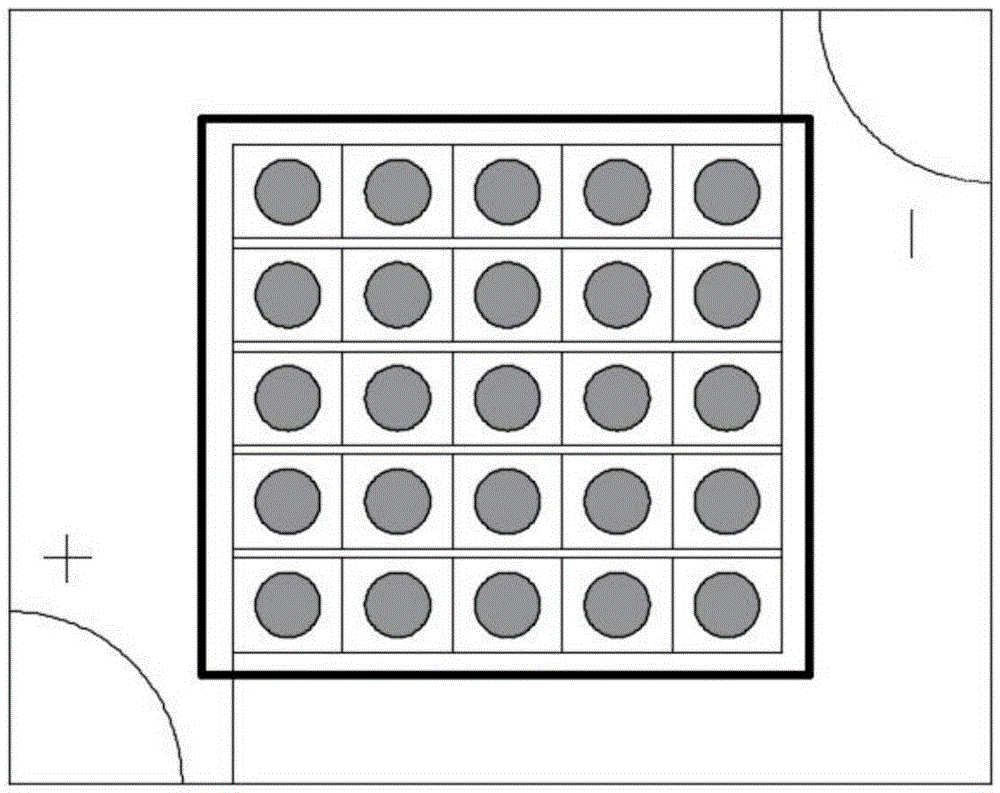

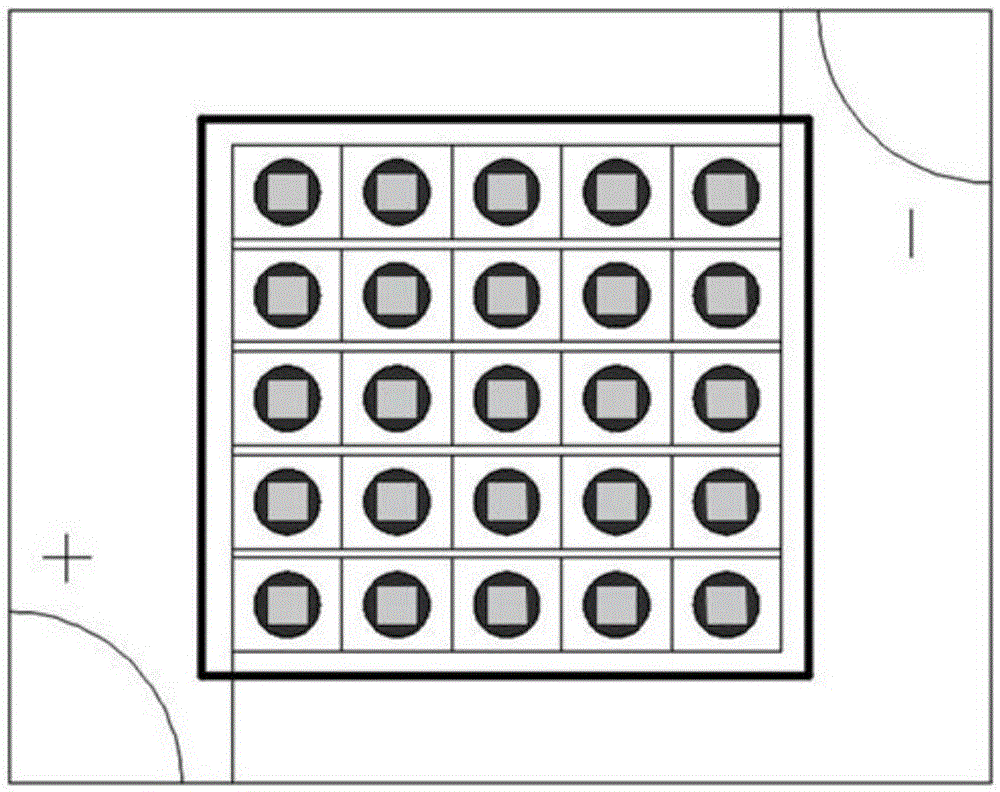

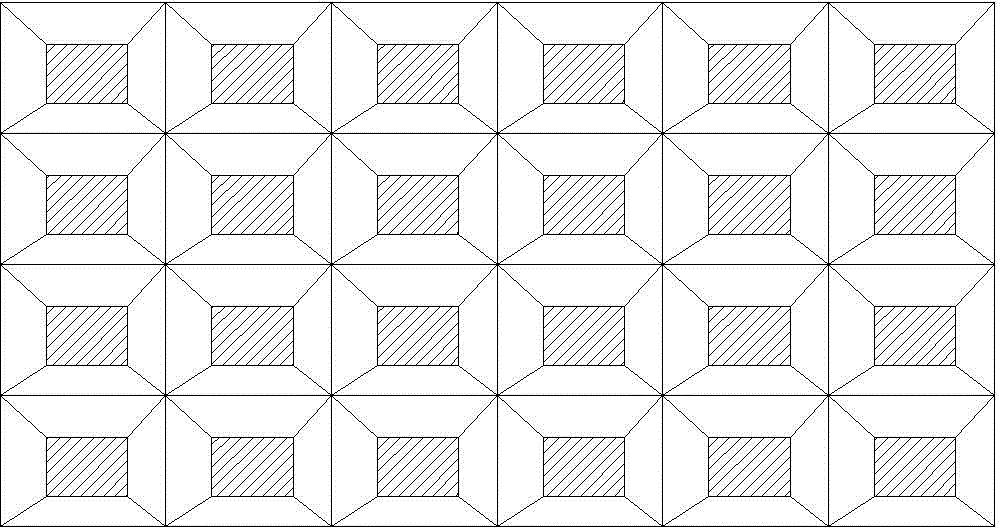

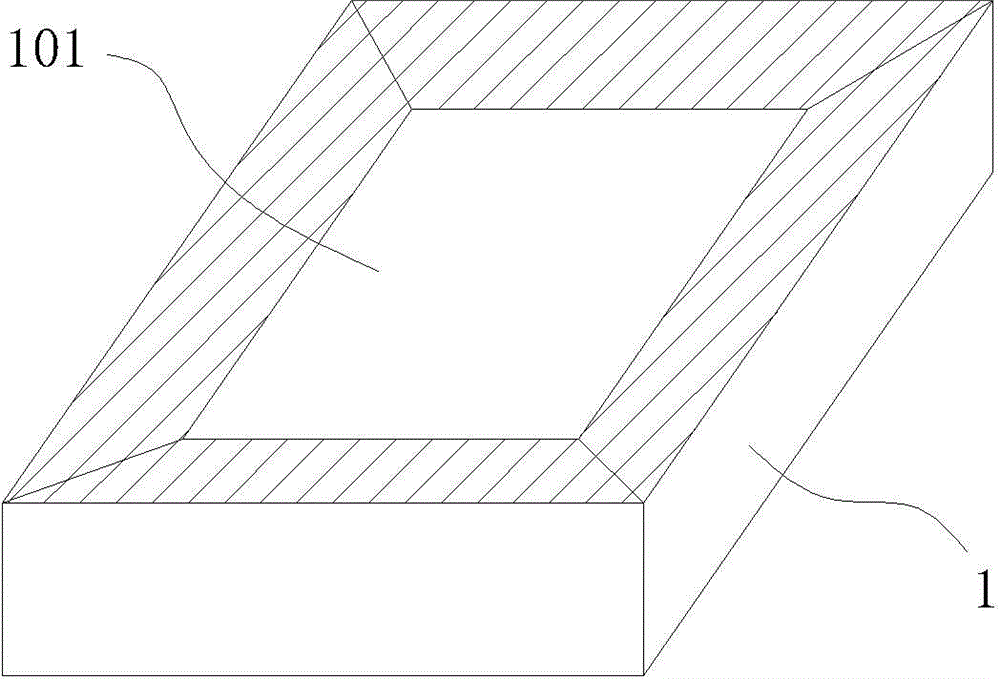

High power density COB (Chip On Board) packaged white LED (Light Emitting Diode) module and packaging method thereof

InactiveCN105609496AIncrease light outputReduce volumeSolid-state devicesSemiconductor devicesHigh power densityLed packaging

The invention relates to a high power density COB (Chip On Board) packaged white LED (Light Emitting Diode) module and a packaging method thereof. A ceramic substrate is provided with a circuit layer and a box dam which is used for fixing packaging glue onto the substrate, and a packaging unit matrix for packaging LED chips is arranged on the circuit layer; the LED chips are arranged on the matrix; the LED chips are stuck to the substrate via nano-silver paste; and gold threads bonded to the chips are connected with an input electrode and an output electrode of a power supply. By adopting the single high power density LED chip and multi-chip integrated LED packaging method, the white LED module is high in light output, small in size and good in heat dissipation; and the high power COB module is used with accessories such as a shell, a base, a precision machining radiator, a high-grade reflector, a heat conducting plate, a support and the like to provide a 25W high power COB light source with high photoelectric conversion rate, long service life, energy conservation and environment friendliness.

Owner:TIANJIN UNIV

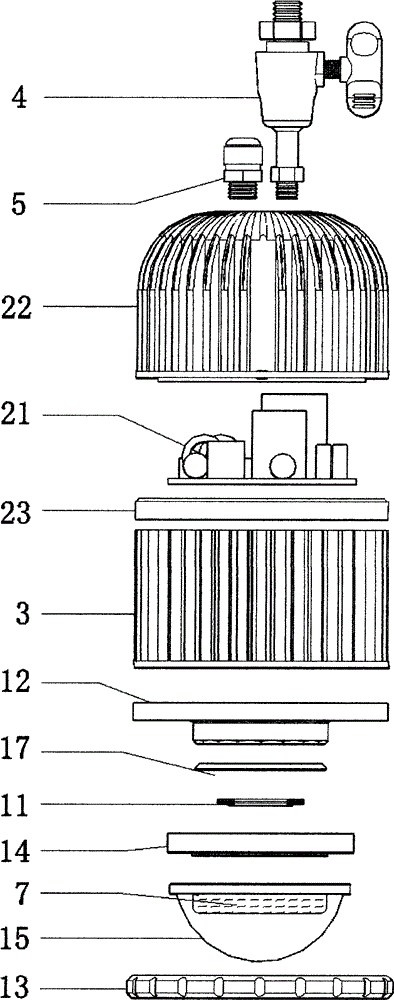

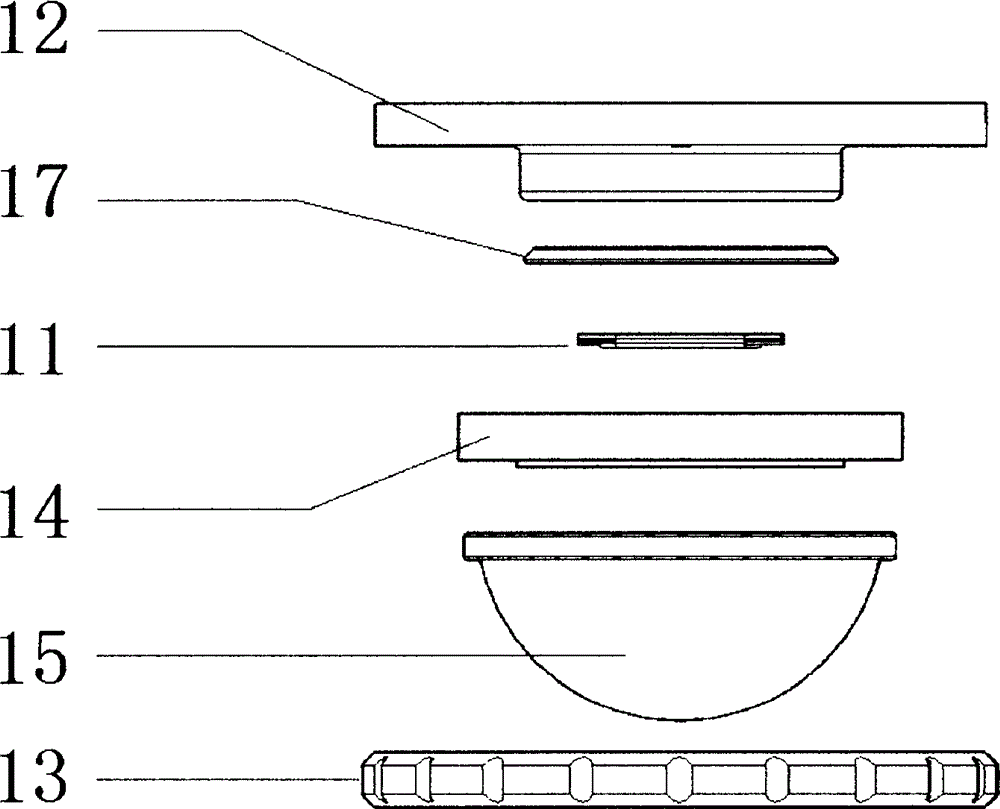

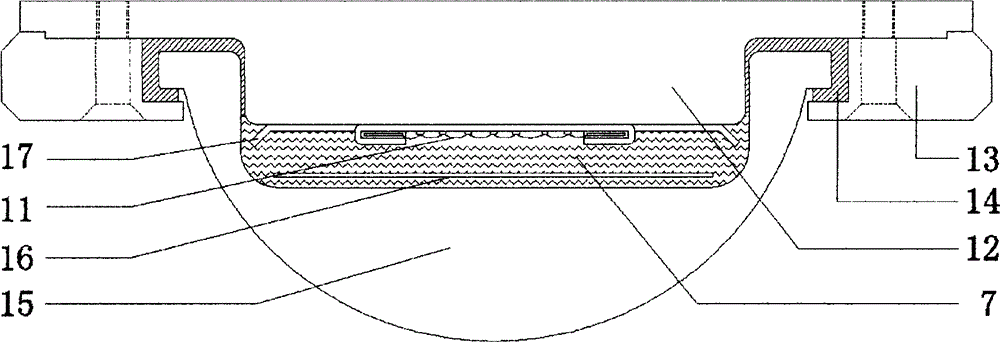

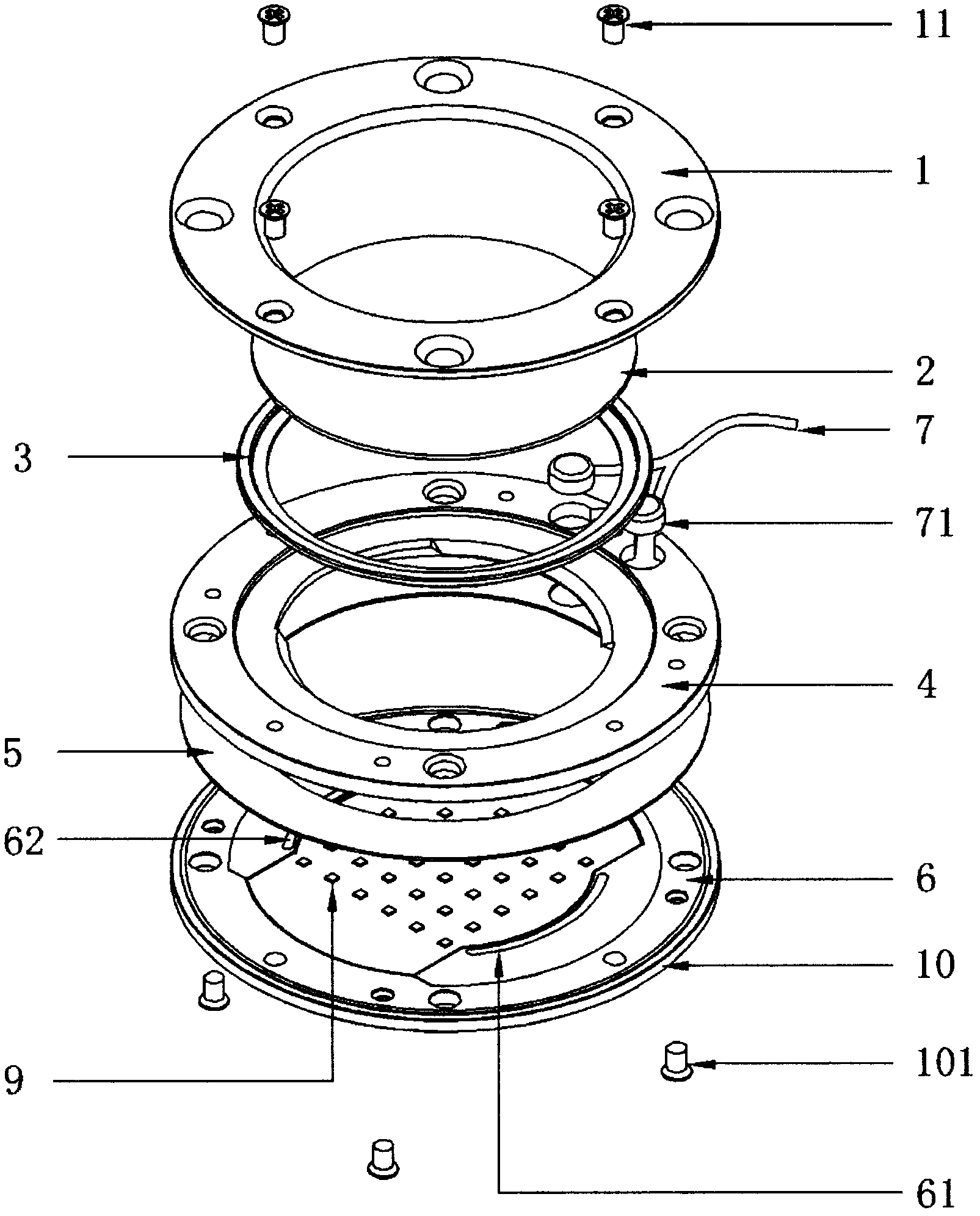

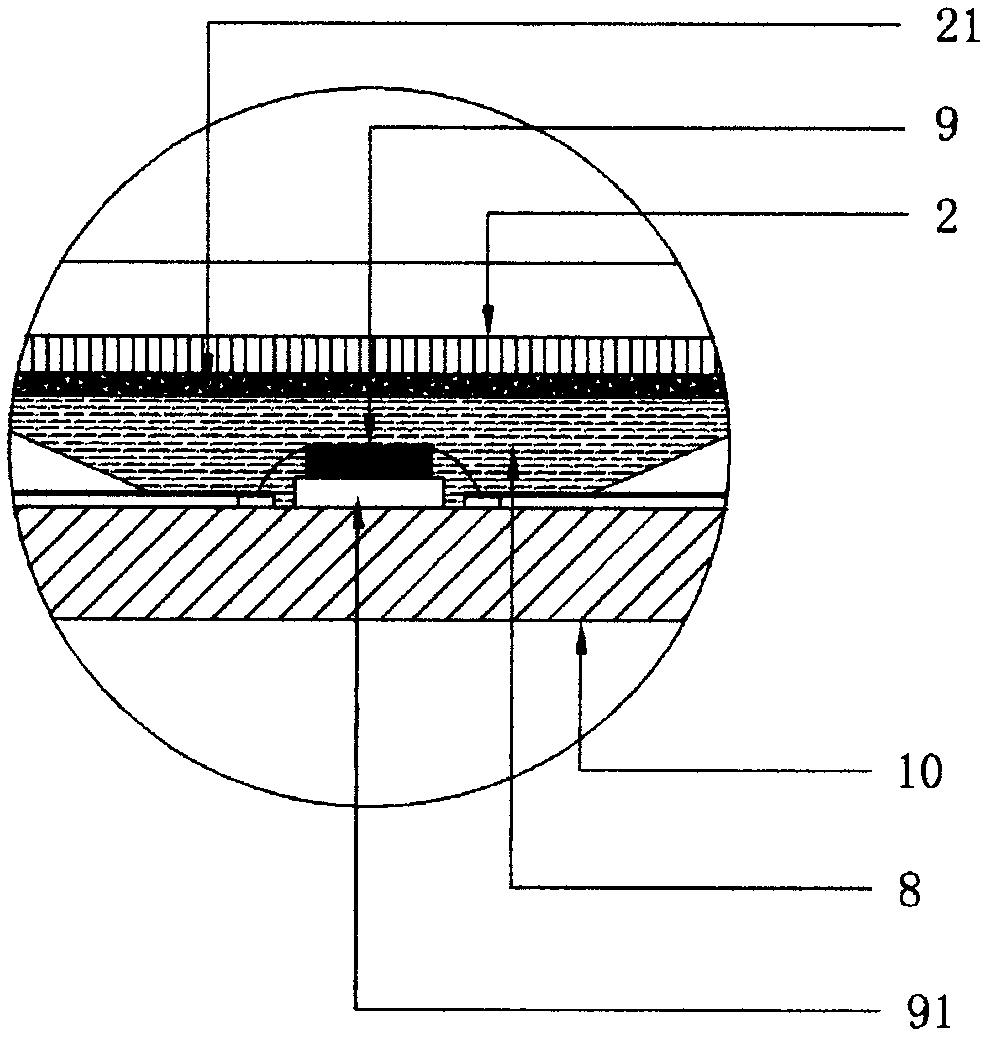

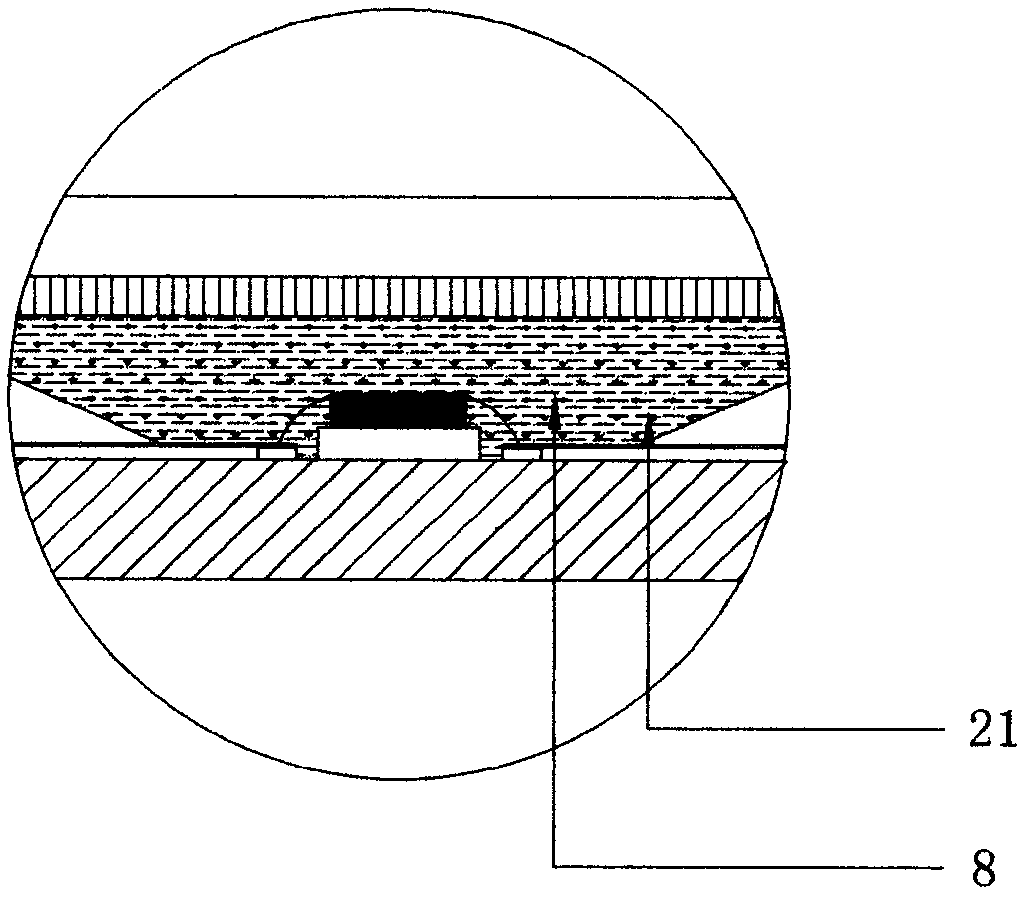

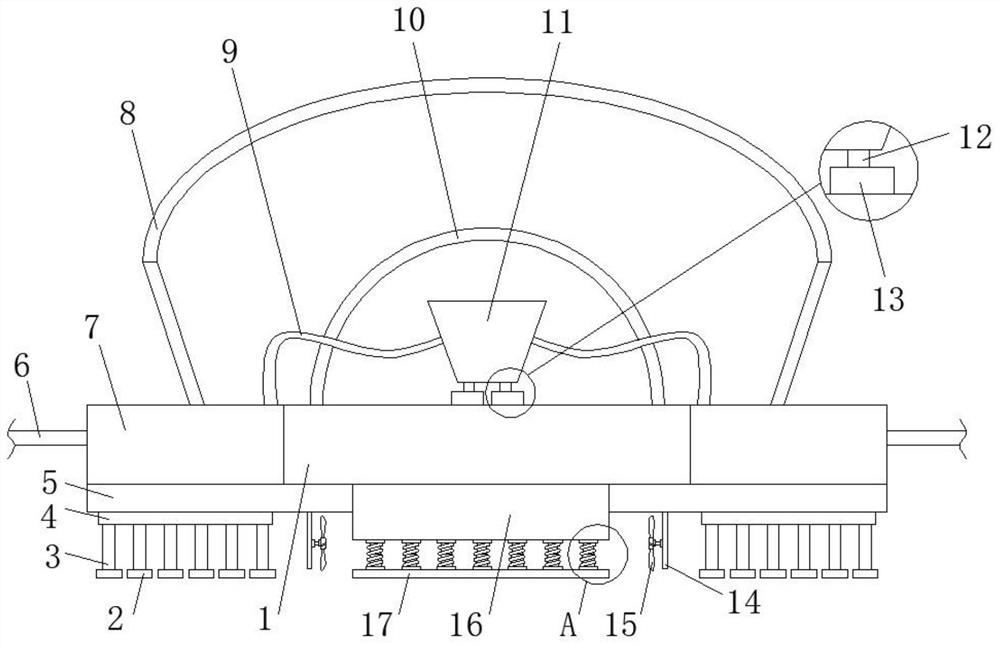

High-power LED liquid cooled module lamp

InactiveCN105588020ALower package thermal resistanceExtended service lifePoint-like light sourceLighting heating/cooling arrangementsEffect lightEngineering

The invention discloses a high-power LED liquid cooled module lamp which is characterized in that: 1. an LED light source, a drive power supply, heat dissipation, light distribution, and protection are integrated together to achieve a five-in-one LED module lamp; 2. the LED light source, the drive power supply are soaked in a cooling liquid to achieve the long service life of the LED light source and the drive power supply; and 3. a WFCOB light source is designed to achieve low thermal resistance, high lighting effect, high temperature resistance, and long service life.

Owner:汪绍芬

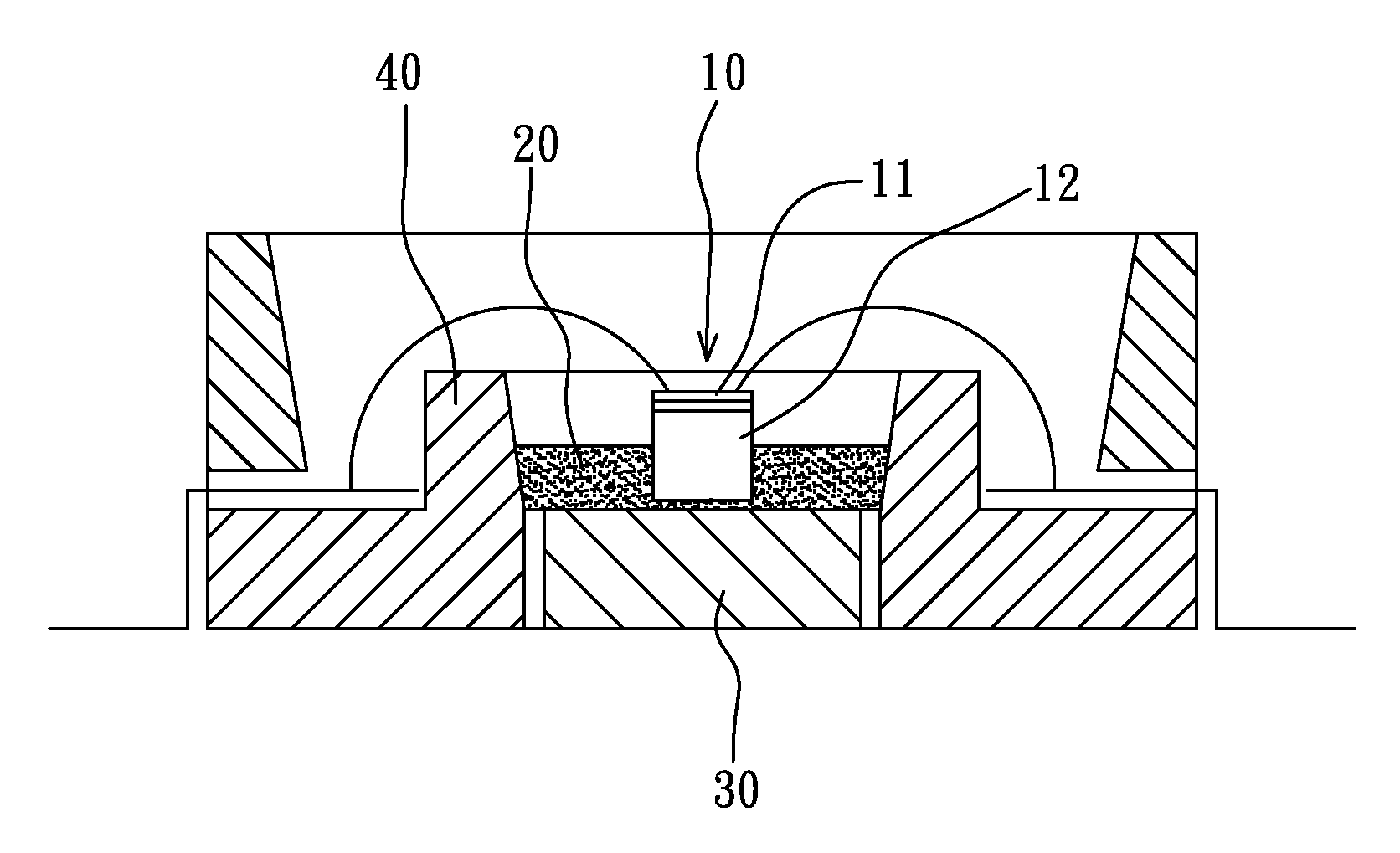

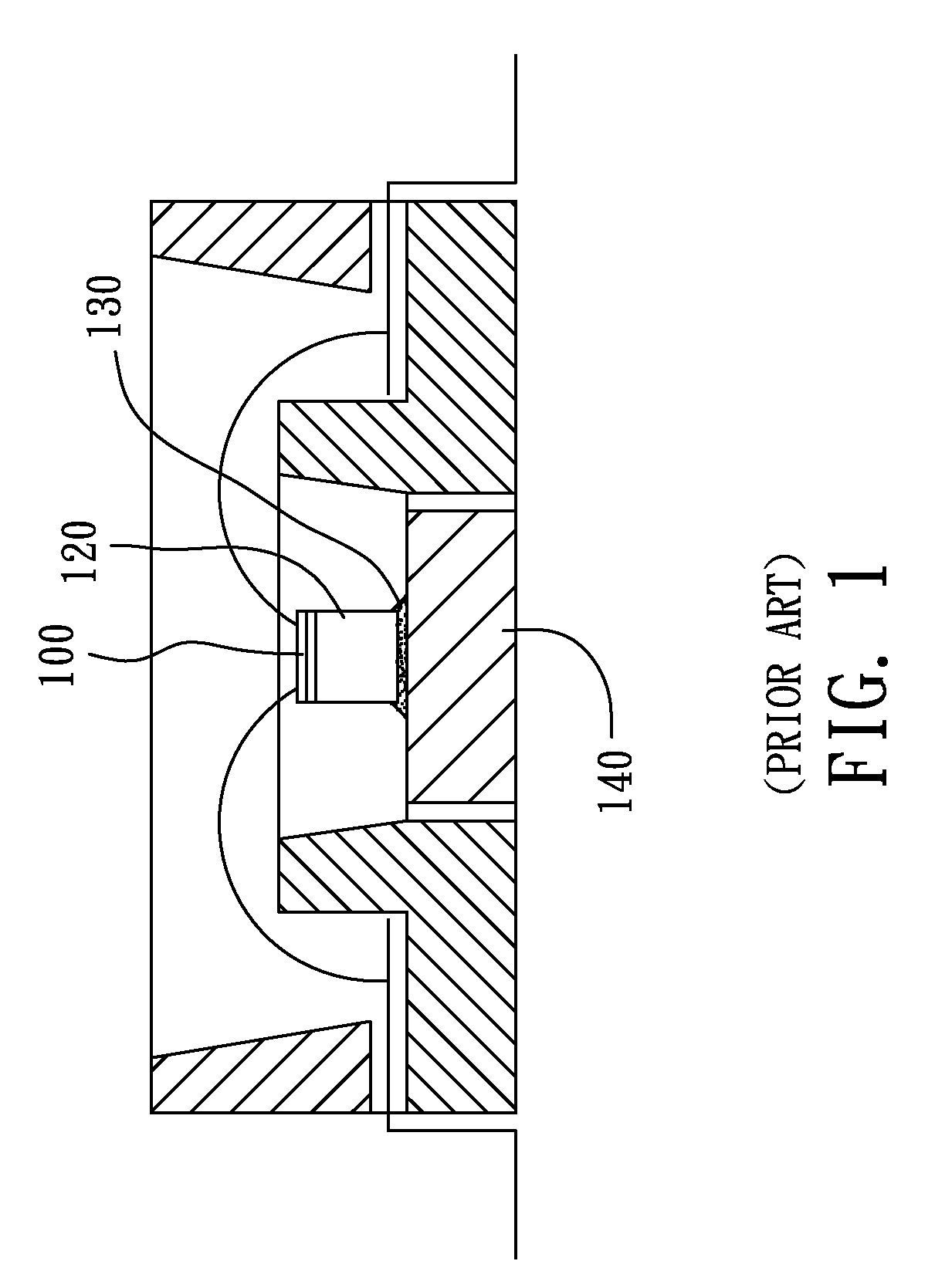

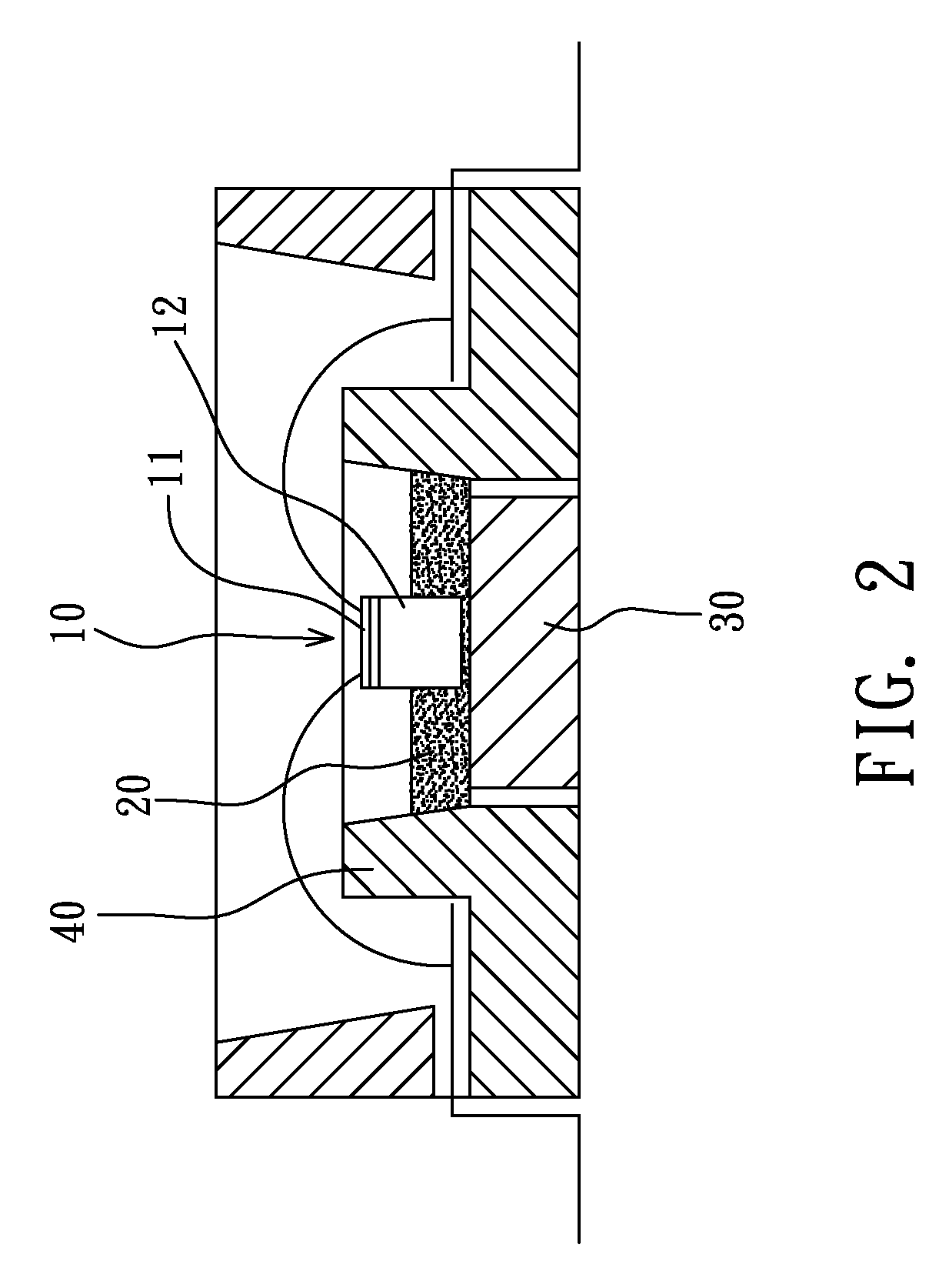

Packaging structure and method for light-emitting diode

InactiveUS20100025720A1Lower package thermal resistanceReduce heatSolid-state devicesSemiconductor devicesHeat conductingSolder paste

The present invention discloses a packaging structure for light-emitting diode, which comprises a grain to provide electroluminescence; a solder paste layer disposed on the bottom and perimeter of the grain to connect the grain with at least one support; and a heat-conducting layer disposed at the bottom of the grain to work as a heat-dissipating path for the grain, so that the aforementioned structure may significantly reduce the packaging thermal resistance of light-emitting diode. Further, the present invention also discloses a packaging method for light-emitting diode, which is capable of greatly reducing the packaging thermal resistance of light-emitting diode.

Owner:LO WEI HUNG

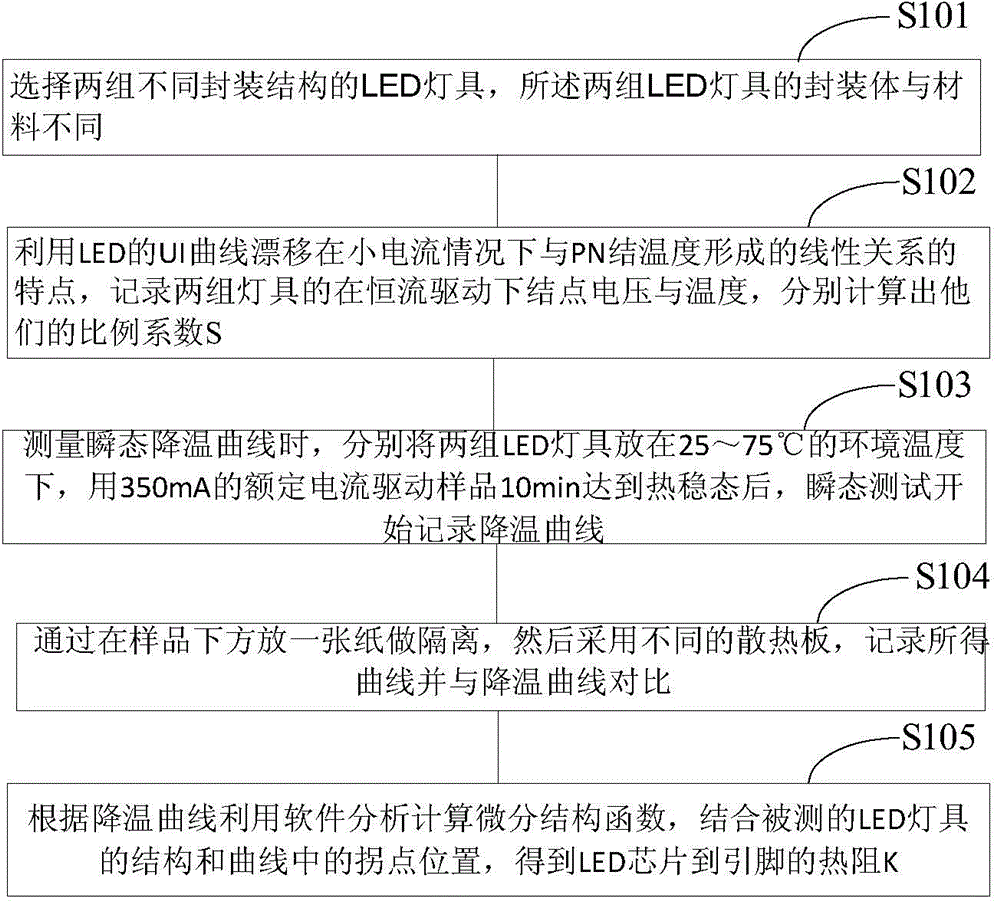

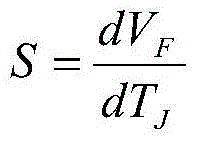

LED thermal characteristic test method based on structure function

InactiveCN103605085ALower package thermal resistanceImprove packaging qualityLamps testingStructure functionLED lamp

The invention relates to a LED light source construction body and discloses a LED thermal characteristic test method based on a structure function. The method comprises the following steps that two groups of LED lamps with different packaging structures are selected, wherein packaging bodies and materials of the two groups of LED lamps are different; through using a characteristic of a linear relation which is formed by a LED U-I curve drifting under a small current situation and a PN joint temperature, a node voltage VF and a temperature TJ of the lamps driven by a constant current are recorded and a proportion coefficient S is calculated; when a transient cooling curve is measured, the two groups of LED lamps are placed at a 25-27 DEG C ambient temperature, a 350mA rated current is used to drive a sample for 10mins so that a heat stable state is reached, and then it begins to record a cooling curve during a transient test; a piece of paper is placed below the sample so that isolation performance is achieved, then different heat dissipation plates are used to record an obtained curve; according to the cooling curve, software is used to analyze and calculate a differential structure function Rth, and the structure of the tested LED lamps and an inflection point position in the curve are combined so that a thermal resistance K from a LED chip to a pin is obtained.

Owner:桂林机床电器有限公司

Low-heat-resistance and high-light-efficiency light-emitting diode (LED) integrated light source

InactiveCN103208576AFast deliveryLower package thermal resistancePoint-like light sourceLighting heating/cooling arrangementsHeat resistanceColloid

The invention discloses a low-heat-resistance and high-light-efficiency LED integrated light source. The integrated light source comprises a sealed casing and is characterized in that a sealed cavity is arranged in the middle of the casing, a mixed liquid of fluorescent powder and silicone oil is filled in the cavity, and an LED chip is immersed in the mixed liquid. Accordingly, the problem of the light source color temperature degradation failure due to the over-high temperature caused by direct contact of the fluorescent powder with the chip is solved, and blocking of heat dissipation of the chip covered by a colloid is removed, and the packaging heat resistance is reduced effectively; and the transient light efficiency of the light source reaches 1201m / w, and the ratio of the transient light efficiency to the stable light source exceeds 95%, the water-proof grade can reach IP68, protection design of lamps is simplified, the light source application range is enlarged, and the system cost is reduced substantially.

Owner:汪绍芬

LED (Light Emitting Diode) down lamp

InactiveCN103016966AImprove cooling effectReduce packaging costsPoint-like light sourceLighting heating/cooling arrangementsEngineeringGlass sheet

The invention provides an LED (Light Emitting Diode) down lamp, which comprises a lamp cover, a glass plate, a reflecting cover, a radiator, a driver and an LED light emitting unit, wherein the LED light emitting unit is fixedly arranged in the radiator; the reflecting cover covers the LED light emitting unit; the glass plate is clamped above the reflecting cover; the lamp cover covers the glass plate; the driver is fixedly connected with the radiator; and the driver is electrically connected with the LED light emitting unit. According to the LED down lamp, the radiator and the LED light source are combined together, so that the radiating effect is improved.

Owner:熊志

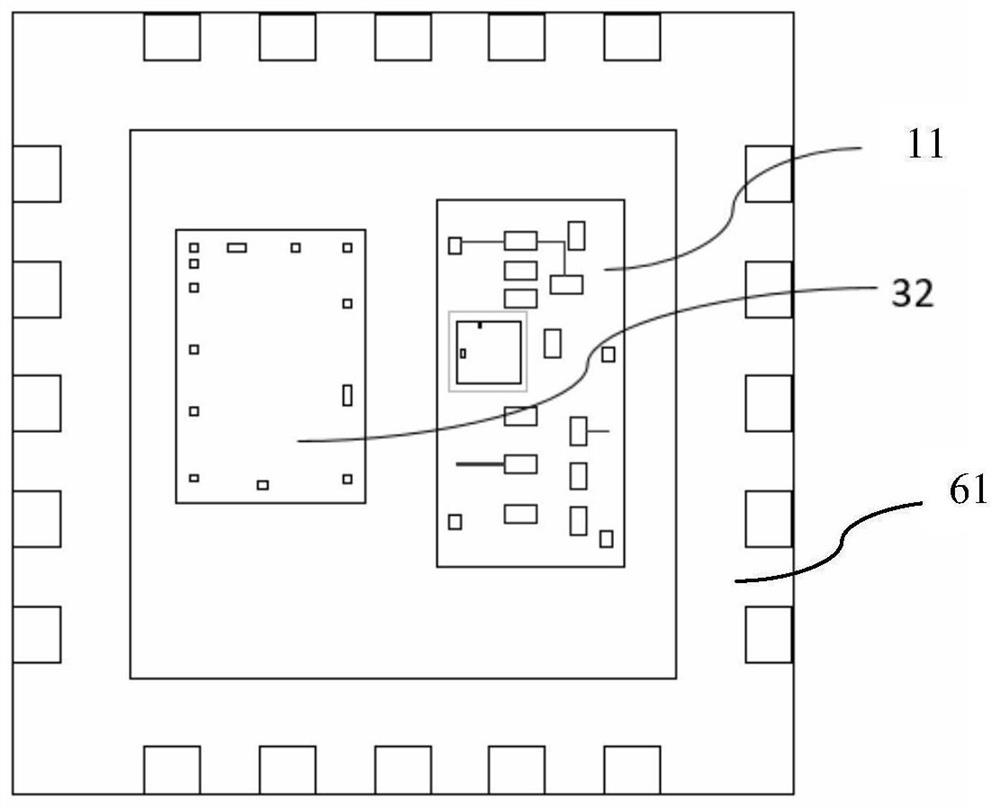

Hybrid packaging method and hybrid packaging structure applied to electronic device

PendingCN112599425AImprove performanceReduced appearance volumeSemiconductor/solid-state device detailsSolid-state devicesHemt circuitsEngineering

The invention discloses a hybrid packaging method and a hybrid packaging structure applied to an electronic device. The hybrid packaging method applied to the electronic device comprises the followingsteps: combining at least one substrate or at least one substrate with at least one first chip and a lead frame; and carrying out wire bonding processing on the lead frame combined with the substrateor the first chip and the substrate, and then performing packaging processing. The hybrid packaging method applied to the electronic device provided by the embodiment of the invention can be matchedwith a circuit to realize chip integration, high-requirement chip heat dissipation capability, reduction of packaging thermal resistance, stable chip performance, reduction of cost, reduction of the appearance volume of electronic equipment, improvement of the unit area use efficiency of a PCB and the like.

Owner:KUNSHAN HUATAI ELECTRONICS TECH CO LTD

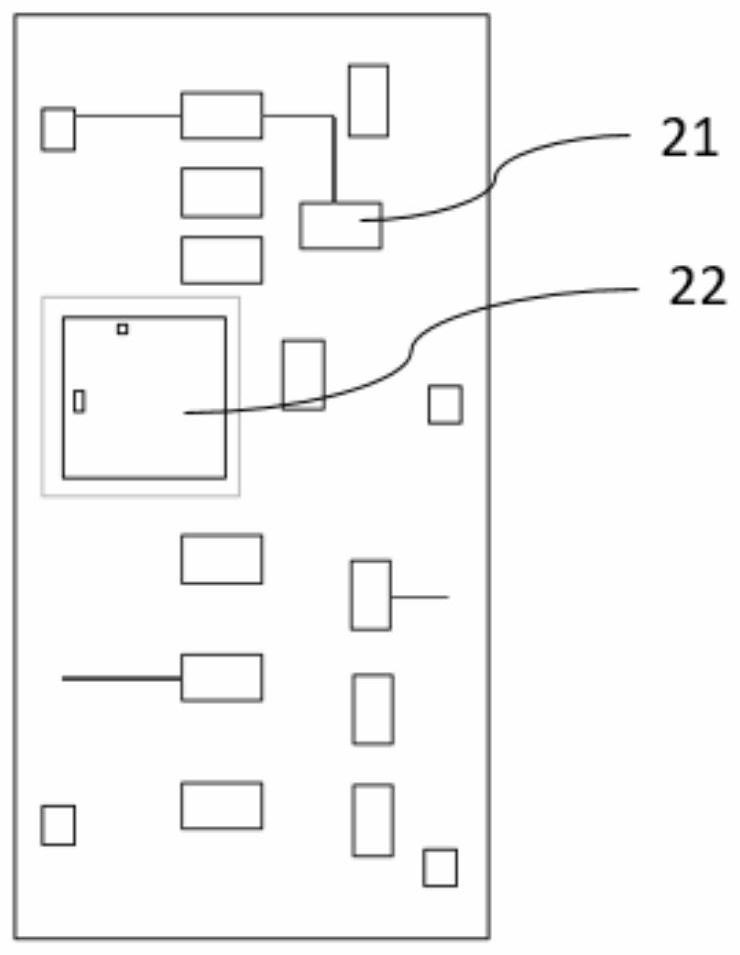

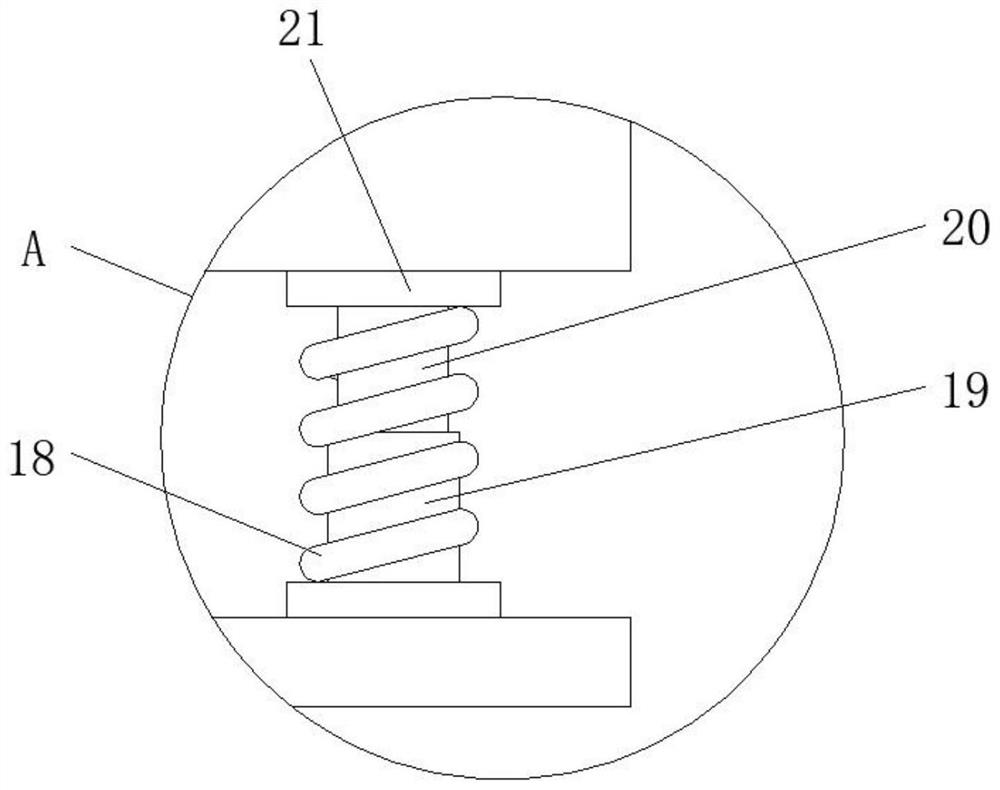

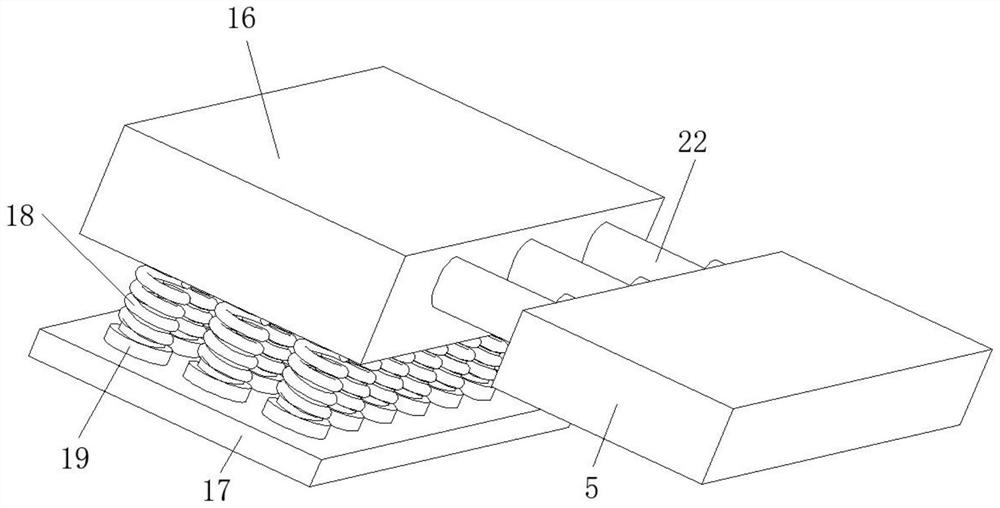

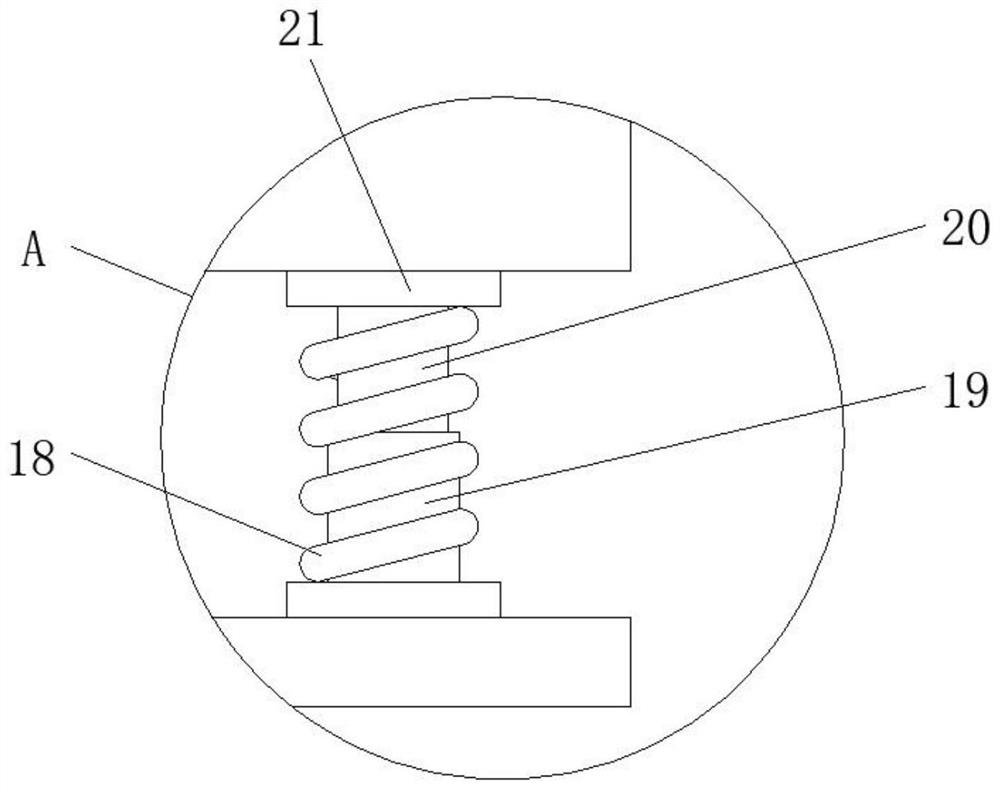

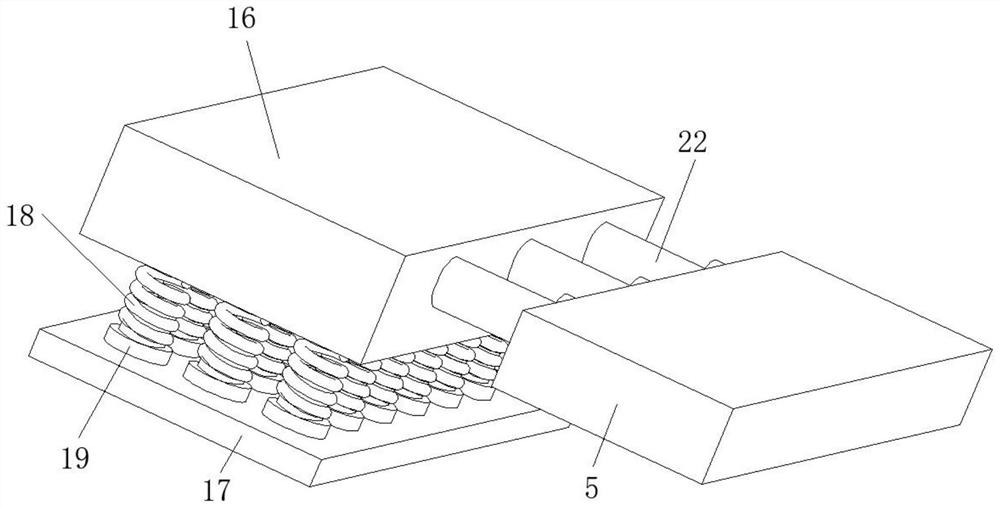

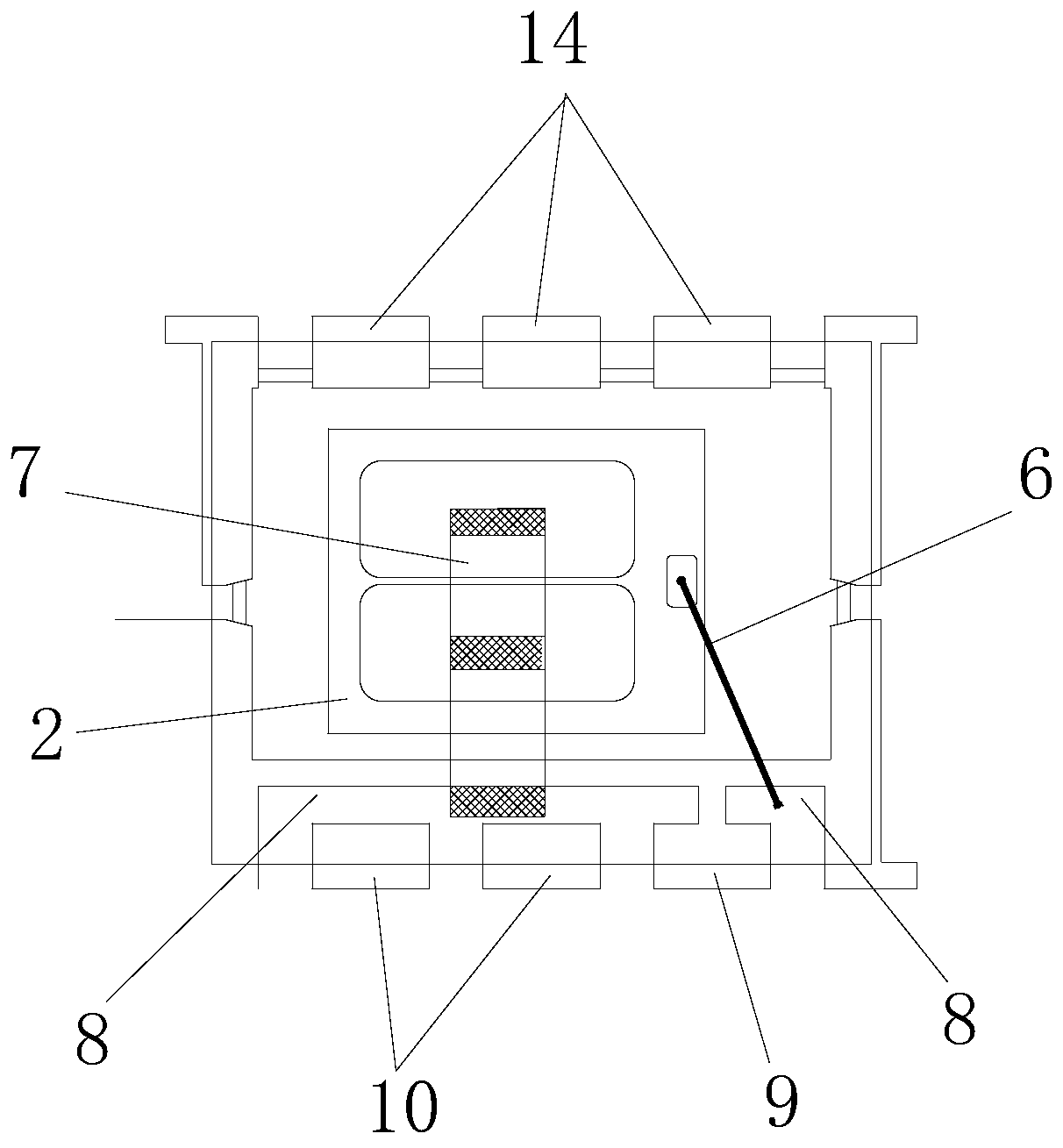

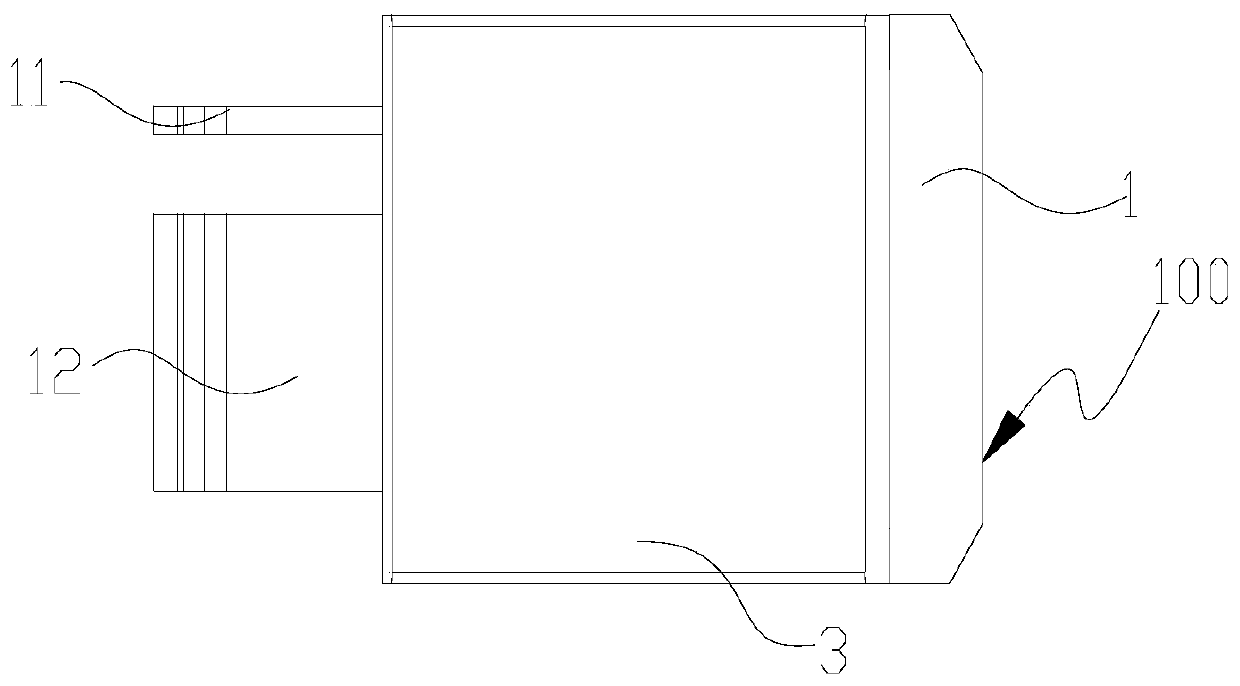

A packaging device for a full-spectrum LED packaged light source

ActiveCN111640838BLower package thermal resistanceAccelerate the lossSemiconductor devicesEngineeringHeat sink

The invention discloses a packaging device for a full-spectrum LED packaged light source. Aiming at the problem of poor heat dissipation performance and affecting luminous performance, the following solution is proposed, including a light-emitting chip, and both sides of the outer wall of the bottom of the light-emitting chip are fixedly connected with bumps , a silicon carrier is fixedly connected to the bottom outer wall of the bump, a heat sink is fixed on the bottom outer wall of the silicon carrier by bolts, the light-emitting chip is inverted on the top outer wall of the heat sink, and the two outer walls of the heat sink are The bases are fixed by bolts on the top of the heat sink, a lamp cup is clamped on the top outer wall of the heat sink, the lamp cup is covered on the outer side of the light-emitting chip, and the surface of the lamp cup is coated with a phosphor layer. The invention enables the heat to be transformed layer by layer, from heat to mechanical vibration, and then into the energy compressed by the shock-absorbing spring, thereby forming a damping force, and finally dissipating in the atmosphere. The whole process is extremely short, but the heat is quickly dissipated. It makes the cooling effect of the device better and stronger.

Owner:SHENZHEN CHANGFANG GRP CO LTD

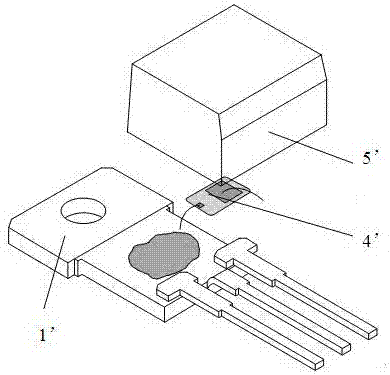

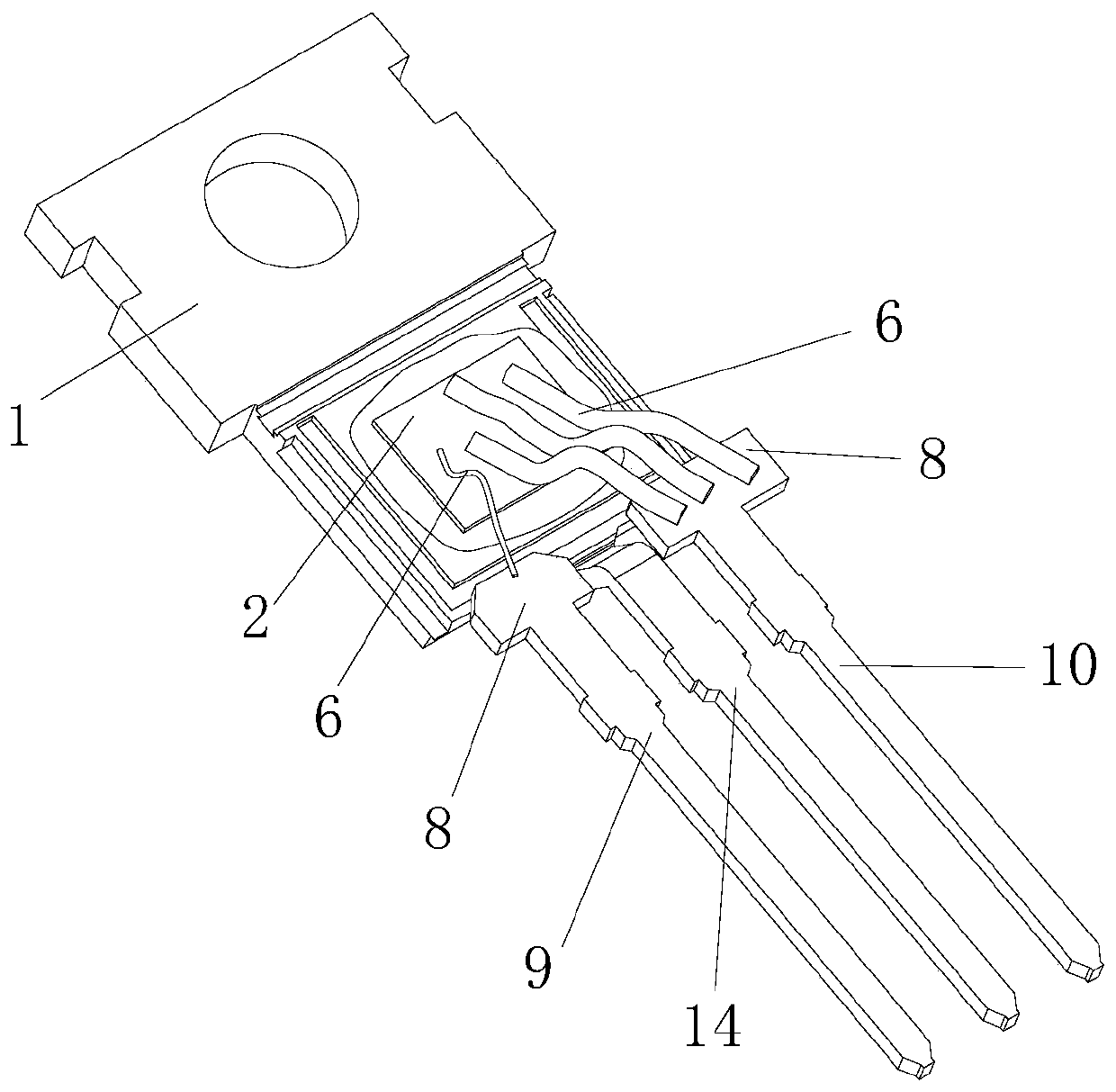

Novel plastic packaging structure for power MOS

PendingCN106887391AEasy to assembleLower package thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionEngineering

The invention relates to a novel plastic packaging structure for a power MOS. The novel plastic packaging structure comprises a frame, a chip, and a packaging body. The frame is a copper frame having two parts; one part of the copper frame is used as a piece of slide glass and is connected with a back electrode of a device and a pin is led out to form electrical connection; and the other part of the copper frame is a cooling back panel for realizing a heat radiation function; and the two parts are isolated from each other by a high-thermal-conduction isolation layer, so that the two parts of the copper frame are in physical connection. According to the invention, because the slide glass and the cooling panel are independent parts isolated from each other and the slide glass is used for electrical connection and the cooling panel is used for providing a cooling channel, PCB assembling becomes convenient and the packaging thermal resistance of the power MOS can be reduced, and the security working zone at an application terminal is enhanced; and advantages of high power and low power consumption of the power MOS are fully realized.

Owner:SHANGHAI CHANGYUAN WAYON MICROELECTRONICS

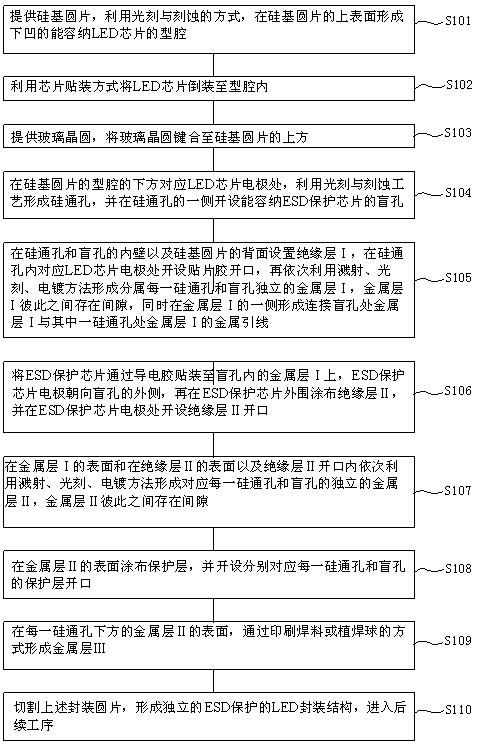

A kind of LED encapsulation structure of ESD protection and encapsulation method thereof

ActiveCN103618041BReduce the risk of electrostatic breakdownGuaranteed anti-static shock capabilitySolid-state devicesSemiconductor devicesSemiconductor packageEngineering

Owner:JIANGYIN CHANGDIAN ADVANCED PACKAGING CO LTD

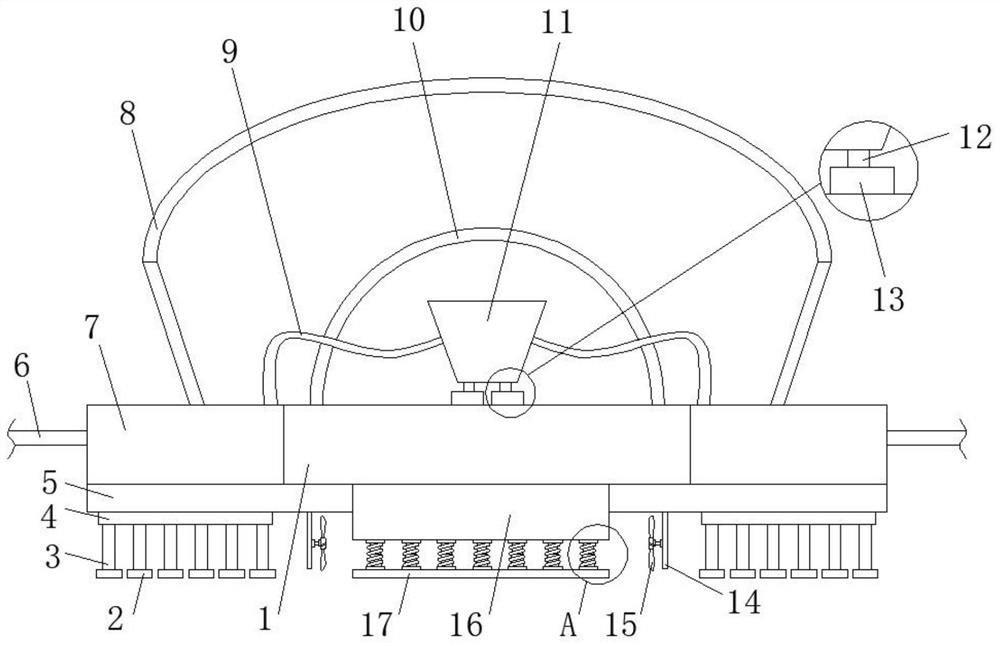

Packaging device of full-spectrum LED packaging light source

ActiveCN111640838ALower package thermal resistanceAccelerate the lossSemiconductor devicesHeat sinkLuminescence

The invention discloses a packaging device of a full-spectrum LED packaging light source. Directed at the problem of poor heat dissipation performance and influencing on luminescence property, the invention provides a solution as follows: the packaging device includes a light-emitting chip, salient points are fixedly connected to two sides of the outer wall of the bottom of the light-emitting chip, silicon carriers are fixedly connected to the outer walls of the bottoms of the salient points, a heat sink is fixed to the outer walls of the bottoms of the silicon carriers through bolts, the light-emitting chip is reversely buckled on the outer wall of the top of the heat sink, bases are fixed to the outer walls of the two sides of the heat sink through bolts, a lamp cup is connected to the outer wall of the top of the heat sink in a clamped mode, the lamp cup covers the light-emitting chip, and the surface of the lamp cup is coated with a fluorescent powder layer. Heat is converted layerby layer into mechanical vibration, and then mechanical vibration is converted into the energy of damping spring compression, a damping force is formed and finally dissipated into the atmosphere, thewhole process is extremely short, heat is dissipated rapidly, and the heat dissipation effect of the device is better and stronger.

Owner:SHENZHEN CHANGFANG GRP CO LTD

A high-strength anti-blue LED packaging material

InactiveCN106832775BGood light transmissionImprove mechanical propertiesSemiconductor devicesPolymer sciencePolymer chemistry

The invention relates to the technical field of LED electronic products, in particular to a high-strength anti-blue-ray LED packaging material. The high-strength anti-blue-ray LED packaging material comprises the components in parts by weight: 60-70 parts of polysulfone modified epoxy resin, 23-25 parts of bisphenol formaldehyde / resorcin copolymerization epoxy resin, 5-8 parts of polydimethylsiloxane, 0.1-1 parts of modified or unmodified melanin, 0.1-0.3 parts of hydroquinone, 5-8 parts of styrene modified alkyd resin and 3-10 parts of modified sea-foam stone powder. The prepared high-strength anti-blue-ray LED packaging material has the advantages that blue ray blocking performance is very high, and blue rays can be effectively filtered, so that the transmitting light is much softer and human eyes can be protected against being injured to a certain extent. Meanwhile, the high-strength anti-blue-ray LED packaging material has the advantages of high light transmission performance and smaller influence on color temperature; and moreover, the packaging thermal resistance value can be reduced as much as possible. The prepared high-strength anti-blue-ray LED packaging material provided by the invention also realizes a high mechanical property.

Owner:杭州科翼科技有限公司

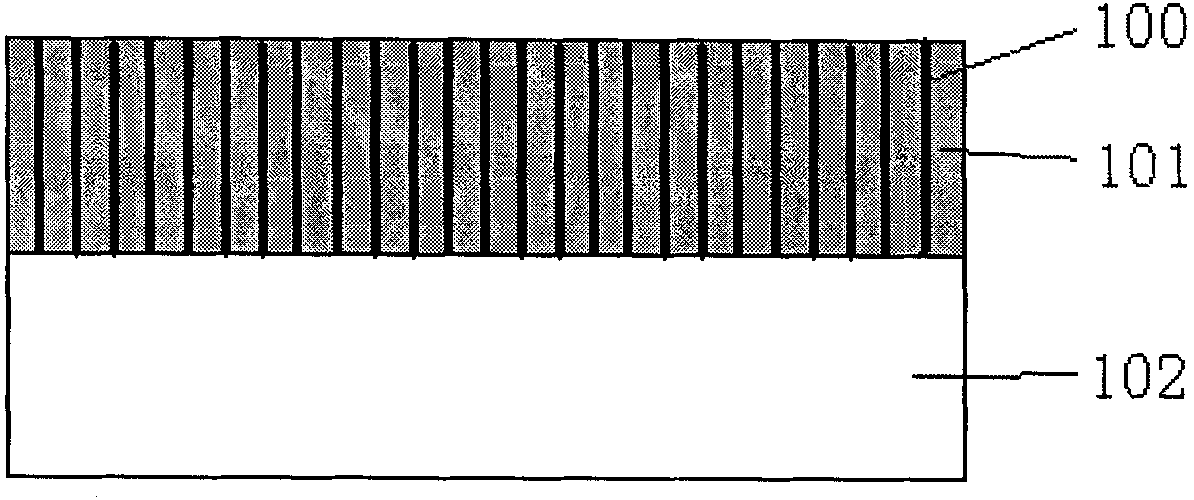

LED packaging structure and manufacturing method thereof

InactiveCN104900785ALower package thermal resistanceReduce manufacturing costSemiconductor devicesFluorescenceLed packaging

The invention relates to the technology of LED packaging, and provides an LED packaging structure comprising fluorescent supports and inverted LED chips. The fluorescent supports are supports formed by doping fluorescent substance in light-transmitting material. Each light-transmitting support is provided with a groove. The inverted LED chips are fixed on the bottom surfaces of the grooves in a way that the light-emitting surfaces of the inverted LED chips face the direction of the grooves, and the electrode surfaces of the inverted LED chips are back to the direction of the grooves. The invention also provides a manufacturing method of the LED packaging structure. The manufacturing method comprises the steps that S1, the supports are manufactured: the light-transmitting material is selected and the fluorescent substance is doped in the light-transmitting material to manufacture the supports, and one groove is formed on each support; and S2, die-bonding is performed: the inverted LED chips are selected and are fixed on the bottom surfaces of the grooves in the way that the light-emitting surfaces of inverted LED chips face the direction of the grooves, and the electrode surfaces of the inverted LED chips are back to the direction of the grooves. The LED packaging structure is used for packaging the LED chips so that packaging thermal resistance is substantially reduced.

Owner:厦门多彩光电子科技有限公司

Packaging structure for system heat dissipation and packaging process

PendingCN110808233AImprove thermal conductivityImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesMemory chipEngineering

The invention discloses a packaging structure for system heat dissipation and a packaging process. The packaging structure in the present invention includes: a substrate; an active chip mounted on thesubstrate; a memory chip mounted on the active chip; a thermal conductor, wherein the thermal conductor and the memory chip are mounted on the same side of the active chip, and a second TSV interconnected with the active chip is disposed on the thermal conductor; and a packaging body packaging the active chip, the memory chip and the thermal conductor on the substrate, wherein one end of the second TSV on the thermal conductor is interconnected with the active chip, and the other end of the second TSV is exposed on the surface of the packaging body. The packaging structure enlarges the heat dissipation path of the packaging structure itself, thereby significantly improving the heat dissipation performance.

Owner:SHANGHAI XIANFANG SEMICON CO LTD +1

Method for construction of high power LED multilayer gradient material cooling channel

InactiveCN101281944BImprove cooling effectImprove stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesGradient materialThermal coefficient

The invention provides a construction method for a high power LED multilayer gradient material heat dispersion channel, which includes steps: 1) GaN-base LED chip preparation: etching a GaN-base LED epitaxial wafer by dry process to form a L shape and expose N-GaN layer surface; vaporizing a indium tin oxide current expansion layer on surface of the P-GaN, vaporizing P, N electrodes and plating pure gold on the P, N electrode; 2) Cu fast heat diffusion board preparation: preparing a L-shaped Cu board, sputtering a layer of Ti or Cr by magnetic control to be used as a adhesive layer; sputteringa layer of AlN on the Ti layer by magnetic control to be used as a insulated layer; vaporizing a layer of thin gold and plating a layer of thick pure gold; 3) pure gold bonding by thermocompression bonding: upside-down mounting the LED chip on the Cu fast heat diffusion board. By employing Au-Au-AlN-Ti multilayer material with high thermal conductance and gradient changed thermal coefficient of expansion to construct the heat dispersion channel between the LED and the Cu fast heat diffusion board, heat diffusion problem of high power LED is resolved, heat diffusion capability and stability ofdevice is increased.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Single-substrate multi-chipset high-power LED (Light-Emitting Diode) encapsulation one-step bonding method

InactiveCN102157630BSolve driftReduce failure rateSolid-state devicesSemiconductor devicesScreen printingFree cooling

The invention relates to a single-substrate multi-chipset high-power LED (Light-Emitting Diode) encapsulation one-step bonding method, belonging to the technical field of multi-chipset high-power LED encapsulation. The invention solves the problem that the whole bonding time is too long as multiple chipsets are sequentially spliced in the traditional multi-chipset high-power LED encapsulation technology. The method comprises the following steps of: cleaning a substrate, a chip carrying platform, a multi-chip suction nozzle and a supporting platform; placing the substrate on the supporting platform; determining positions of chips to be bonded on the front of the substrate, and placing multiple chips to be bonded on the chip carrying platform corresponding to the positions of the chips to be bonded; uniformly coating soldering paste on the positions of the chips to be bonded by adopting screen printing, and then simultaneously picking up multiple chips to be bonded with the multi-chip suction nozzle; heating the back of the substrate, enabling multiple chips to align with the positions to be bonded and then attached to the soldering paste, continuously heating for 5-10s, naturally cooling to room temperature, and removing the multi-chip suction nozzle, thus the bonding process is completed. The invention provides an encapsulation bonding method.

Owner:HARBIN INST OF TECH

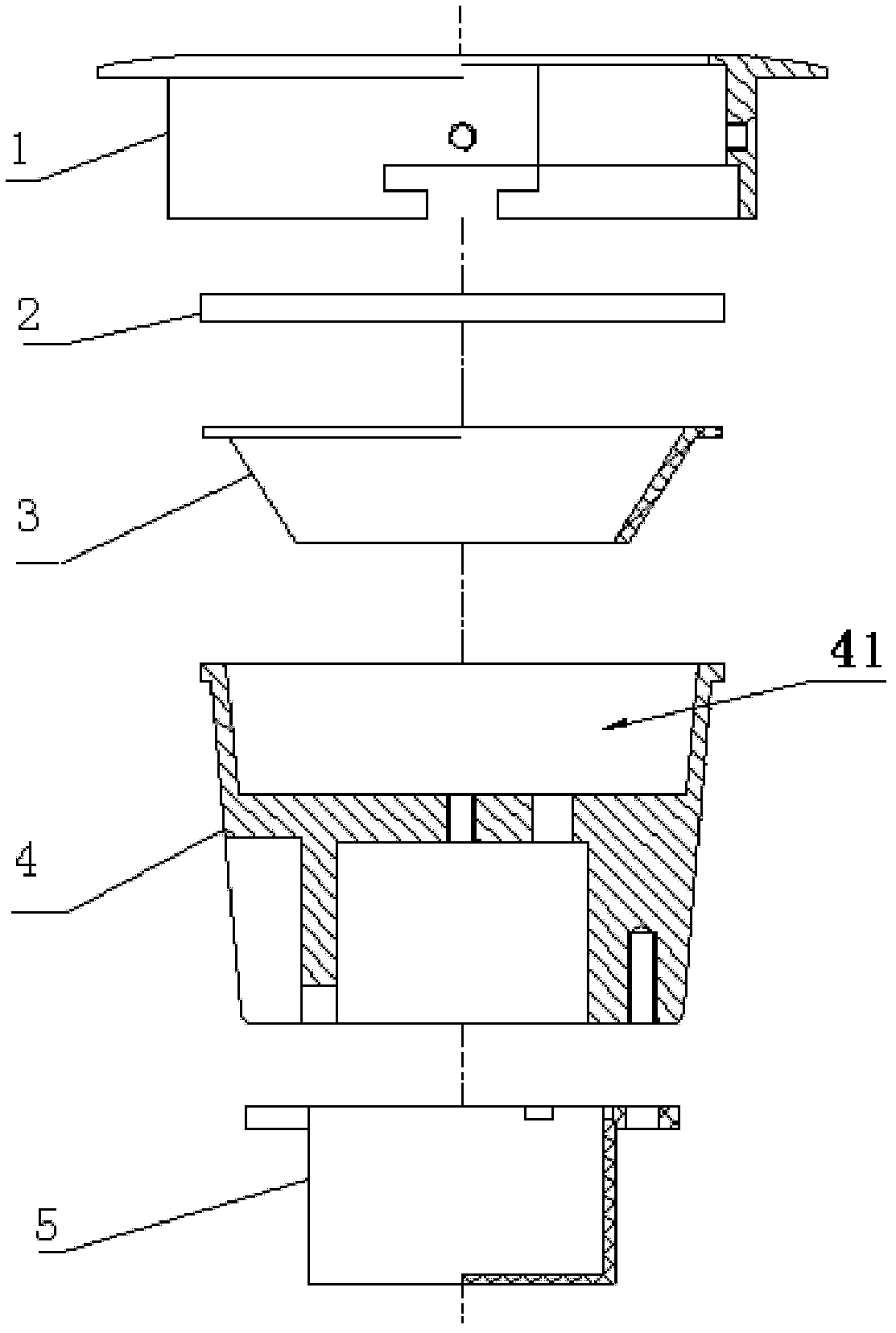

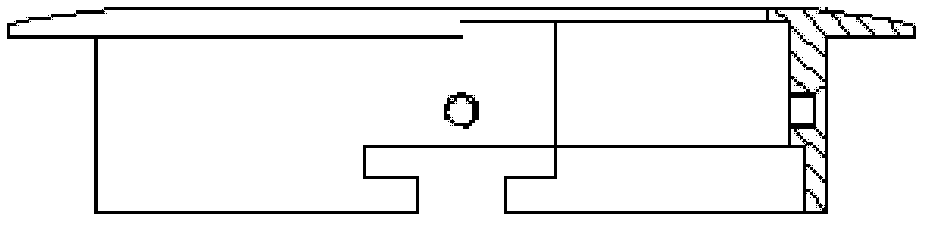

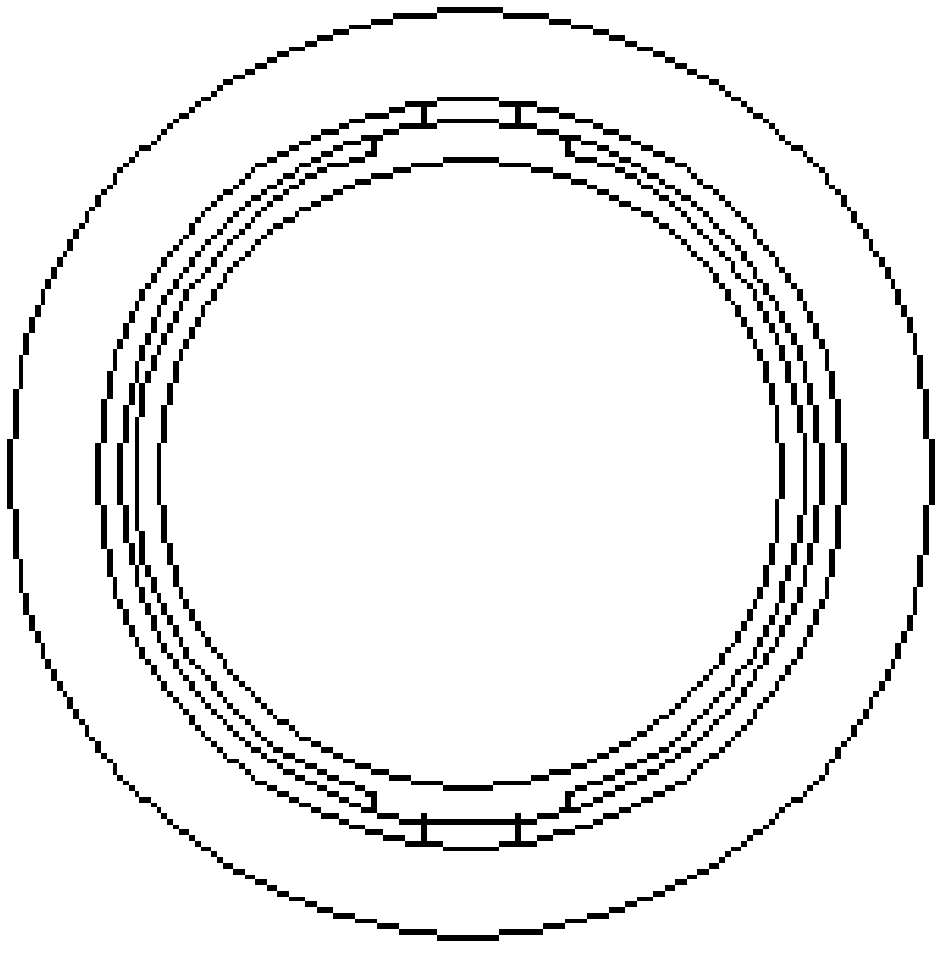

A packaging structure and packaging process in which welding, bonding and sealing are completed simultaneously

ActiveCN104124215BReduce productionPackage structure is simpleSemiconductor/solid-state device detailsSolid-state devicesEngineeringAir tightness

The invention discloses a packaging structure and a packaging technology capable of synchronously completing welding, bonding and sealing. The packaging structure comprises a ceramic through cavity, two leading-out terminal cover plate, a seal ring and a chip, wherein the ceramic through cavity is brazed to the first leading-out terminal cover plate through welding flux, the seal connecting ting is brazed to the upper surface of the ceramic through cavity, one end of the chip is welded to the first leading-out terminal cover plate of the inner cavity of the ceramic through cavity while the other end of the chip is welded to the second leading-out terminal cover plate through welding flux, and meanwhile the second leading-out terminal cover plate is welded to the seal ring through welding flux. The first leading-out terminal cover plate, the ceramic through cavity, the seal ring, the welding flux and the second leading-out terminal cover plate jointly form the airtight packaging structure. The packaging technology comprises that the chip is welded and bonded to the first and second leading-out terminal cover plates, and the second leading-out terminal cover plate and the seal ring are fused and welded together through the welding flux at a time, wherein welding, bonding and sealing processes are synchronously completed.

Owner:JIANGSU PROVINCE YIXING ELECTRONICS DEVICE GENERAL FACTORY

Light emitting diode (LED) packaging structure

ActiveCN102255034BThe process path is simpleReduce package sizeSemiconductor devicesMetalLed packaging

The invention relates to a light emitting diode (LED) packaging structure. The LED packaging structure comprises an insulating substrate, an n-shaped layer, an active layer, a p-shaped layer; an isolating layer, a p electrode, an n electrode, a first back electrode and a second back electrode, wherein through holes are formed on both sides of the insulating substrate and are filled with conductive metal; the n-shaped layer is arranged on the insulating substrate, and a hole is formed in the n-shaped layer and is filled with conductive metal; the active layer is arranged on the n-shaped layer;the p-shaped layer is arranged on the active layer; the isolating layer is positioned on one side of the n-shaped layer, the active layer and the p-shaped layer and is used for covering a part of upper surface of the p-shaped layer; the p electrode is used for covering the isolating layer and covering a part of upper surface of the p-shaped layer; the n electrode is arranged on one side of the upper side of the n-shaped layer and is connected with the conductive metal in the through holes in the insulating substrate; the first back electrode is arranged on one side of the rear side of the insulating substrate and is connected with the p electrode through the conductive metal in the through holes in the insulating substrate; and the second back electrode is arranged on the other side of the rear side of the insulating substrate and is connected with the n electrode through the conductive metal in the through holes in the insulating substrate. A substrate of a device is formed by all the parts, and an optical element is packaged on the substrate to complete the production of the device.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Manufacturing method of led packaging structure

ActiveCN104900784BLower package thermal resistanceReduce manufacturing costSemiconductor devicesEngineeringDie bonding

The invention relates to the technology of LED packaging, and provides an LED packaging structure comprising light-transmitting supports, fluorescent glue and inverted LED chips. Each light-transmitting support is provided with a groove. The fluorescent glue at least covers the bottom surfaces of the grooves of the light-transmitting supports. The inverted LED chips are fixed on the fluorescent glue in a way that the light-emitting surfaces of the inverted LED chips face the direction of the grooves, and the electrode surfaces of the inverted LED chips are back to the direction of the grooves. The invention also provides a manufacturing method of the LED packaging structure. The manufacturing method comprises the steps that S1, the supports are manufactured: light-transmitting material is selected to manufacture the supports, and one groove is formed on each support; S2, the fluorescent glue is adhered; the fluorescent glue is adhered in the grooves of the supports; S3, drying is performed: the fluorescent glue in the grooves of the supports is solidified by drying; and S4, die-bonding is performed: the inverted LED chips are selected and are fixed on the fluorescent glue in the way that the light-emitting surfaces of inverted LED chips face the direction of the grooves, and the electrode surfaces of the inverted LED chips are back to the direction of the grooves. The LED packaging structure is used for packaging the LED chips so that packaging thermal resistance is substantially reduced.

Owner:厦门多彩光电子科技有限公司

Packaging structure and manufacturing method of a high-current power semiconductor device

ActiveCN106298722BReduce package resistanceLower package thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceSemiconductor chip

Owner:WUXI NCE POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com