A kind of LED encapsulation structure of ESD protection and encapsulation method thereof

A technology of ESD protection and LED packaging, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of reducing LED luminous performance, high thermal resistance, affecting the conversion of electricity into light efficiency, etc., to reduce the risk of electrostatic breakdown, Effects of expanding application fields and improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

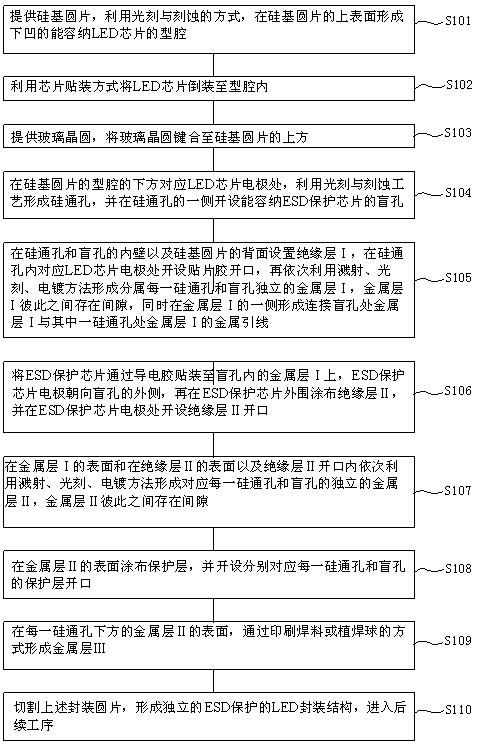

[0074] see figure 1 A kind of LED encapsulation method of ESD protection of the present invention comprises the following steps:

[0075] Executing step S101: providing a silicon-based wafer, and forming a concave cavity capable of accommodating LED chips on the upper surface of the silicon-based wafer by means of photolithography and etching;

[0076] Execute step S102: Flip-chip the LED chip into the cavity by chip mounting;

[0077] Executing step S103: providing a glass wafer, and bonding the glass wafer to the top of the silicon-based wafer;

[0078] Executing step S104: using photolithography and etching processes to form through-silicon vias at the corresponding LED chip electrodes under the cavity of the silicon-based wafer, and opening blind holes capable of accommodating ESD protection chips on one side of the through-silicon vias;

[0079] Step S105 is executed: an insulating layer I is provided on the inner wall of the through-silicon via and the blind via and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com