LED thermal characteristic test method based on structure function

A technology of structure function and test method, applied in the field of LED light source structure, can solve the problems of limited spatial resolution, slow speed of infrared imaging method, and ignoring the test of device loss optical power, and achieves simple operation, short test time, improved The effect of packaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

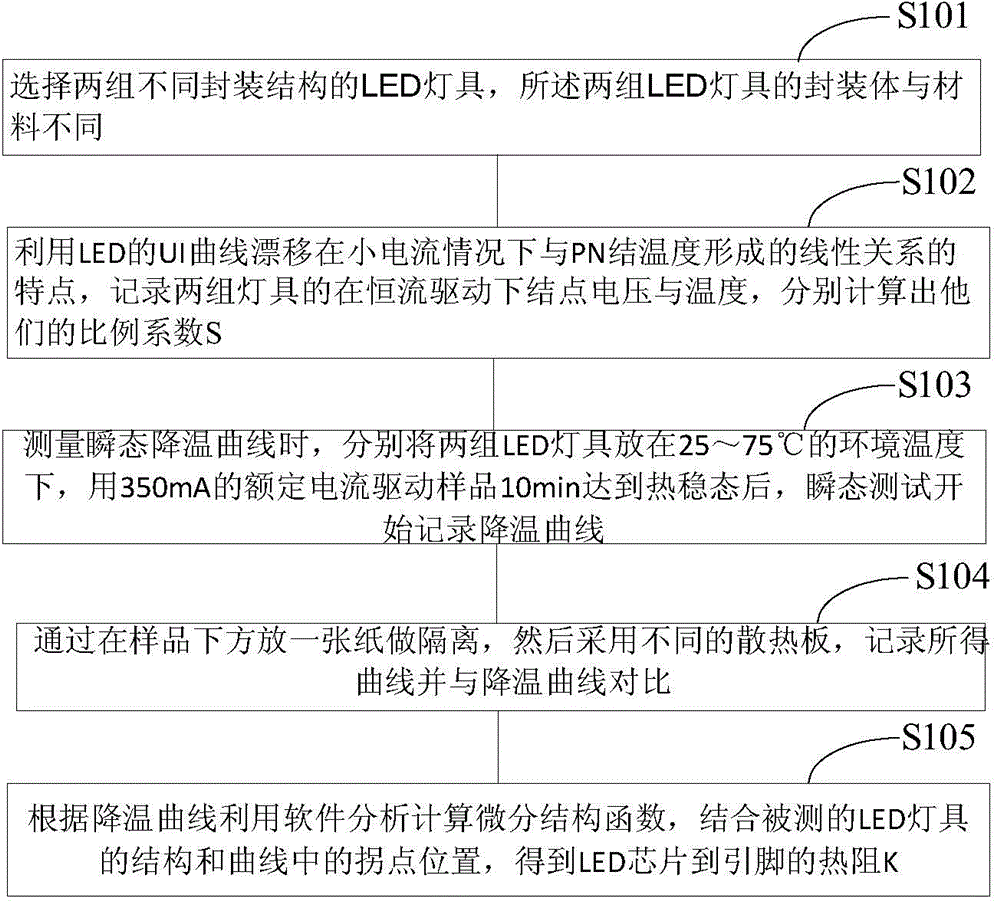

[0016] Such as figure 1 Shown, a kind of LED thermal characteristic test method based on structure function, described method comprises as follows:

[0017] (1) Select two groups of LED lamps with different packaging structures. The packages and materials of the two groups of LED lamps are different; for example, the first group is white LED, and its packaging structure is simple. The body is an imitation lumen structure; the second group is a yellow LED, and its packaging structure is similar to the first group of samples, but the packaging body and materials are different from the first group.

[0018] (2) Using the characteristics of the linear relationship between the U-I curve drift of the LED and the PN junct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com