Inversion type encapsulation structure and manufacturing method thereof

A packaging structure, flip-chip technology, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of high heat generation of power devices, unfavorable heat dissipation of power devices, etc., to reduce the thermal resistance of packaging , shorten the process cycle, avoid the effect of leakage and crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A specific implementation of a flip-chip packaging structure and a packaging method provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

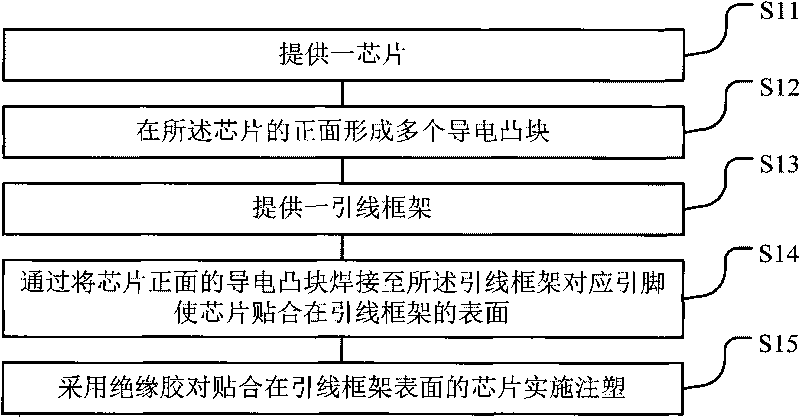

[0025] attached figure 1 Shown is a schematic diagram of the implementation steps of the method described in this specific embodiment, including: step S11, providing a chip; step S12, forming a plurality of conductive bumps on the front surface of the chip; step S13, providing a lead frame; step S14 , by welding the conductive bumps on the front of the chip to the corresponding pins of the lead frame, so that the chip is attached to the surface of the lead frame; step S15, using insulating glue to perform injection molding on the chip attached to the surface of the lead frame.

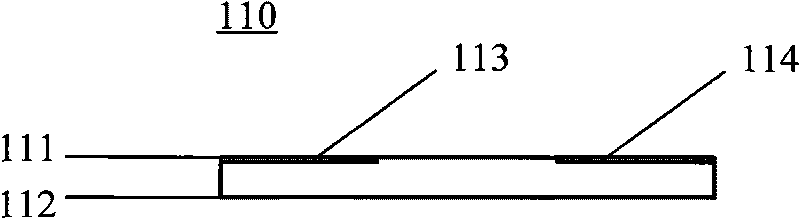

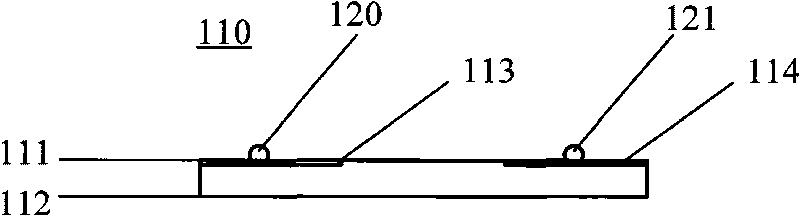

[0026] attached figure 2 to attach Figure 8 Shown is the process schematic diagram of above-mentioned method.

[0027] attached figure 2 As shown, referring to step S11, a chip 110 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com