High-power COB-packaged LED structure and wafer-level manufacturing process thereof

A technology of LED structure and manufacturing process, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of high unit lumen cost, poor packaging light color consistency, poor reliability, etc., to reduce the number of packaged chips and reduce unit lumens Cost, the effect of increasing the luminous flux of a single core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0036] See attached figure 1 to attach Figure 9 As shown, this embodiment provides a wafer-level manufacturing process for a high-power COB package LED structure, including the following steps in sequence:

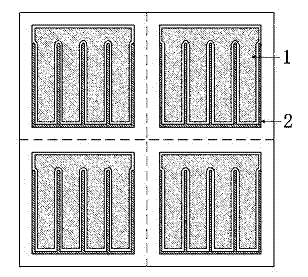

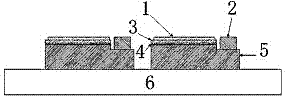

[0037] a) as attached figure 1 , 2 As shown, a p-type GaN layer 3, an active region 4, and an n-type GaN layer 5 are sequentially deposited on the epitaxial wafer of the sapphire substrate 6. After the chip is divided, the n-type GaN layer 5 is exposed in each chip unit to prepare chip electrodes. , to complete the sapphire wafer production;

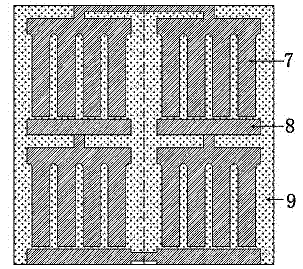

[0038] b) as attached image 3 , 4 As shown, wiring electrodes and interconnection lines are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com