Novel plastic packaging structure for power MOS

A new type of high-power technology, applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems affecting product production efficiency, affecting device performance, and increasing device thermal resistance, so as to improve the safe working area and reduce Effect of package thermal resistance and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

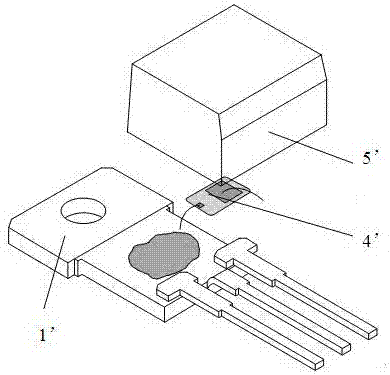

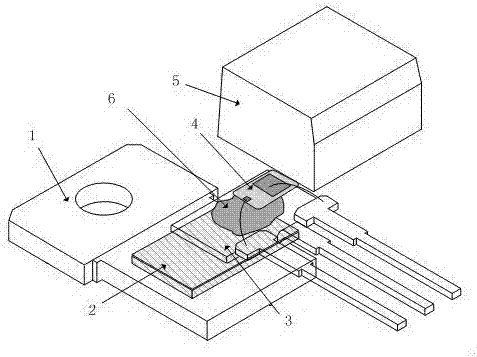

[0027] In order to better understand the packaging structure, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

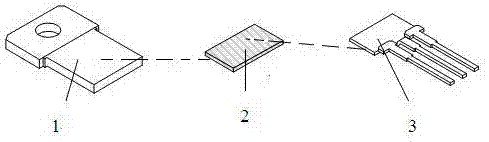

[0028] Such as Figure 2-4 As shown, a new type of plastic packaging structure suitable for power MOS includes a frame, a chip 2 and a package body, wherein the frame is a copper frame, and the copper frame is divided into two parts, one part is used as the carrier 3 and the device The back electrodes are connected and lead out pins to form an electrical connection, and a part is used to realize the heat dissipation backplane 1 of the heat dissipation function. The two are separated by a high thermal conductivity isolation layer, so that the two parts of the copper frame form a physical connection.

[0029] In this example, if Figure 4 As shown, the high thermal conductivity isolation layer adopts a ceramic isolation layer 2 covered with a copper layer on the upper and lower sides. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com