High-power LED liquid cooled module lamp

A LED module, high-power technology, applied in cooling/heating devices, lighting devices, light sources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

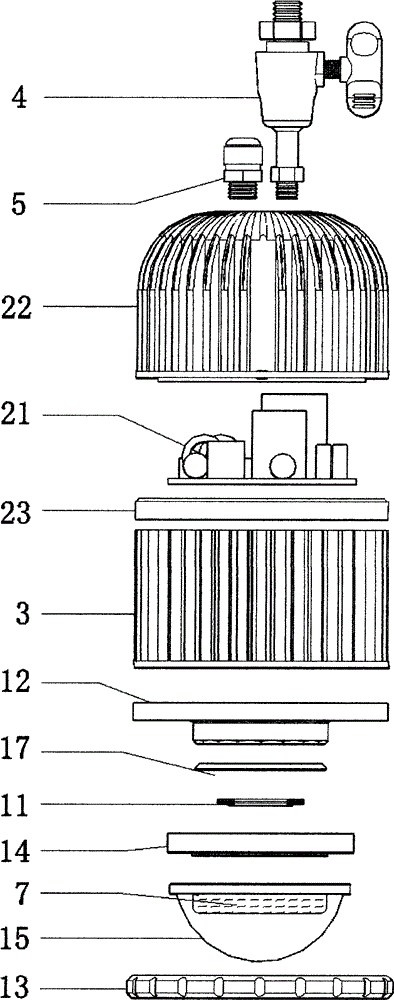

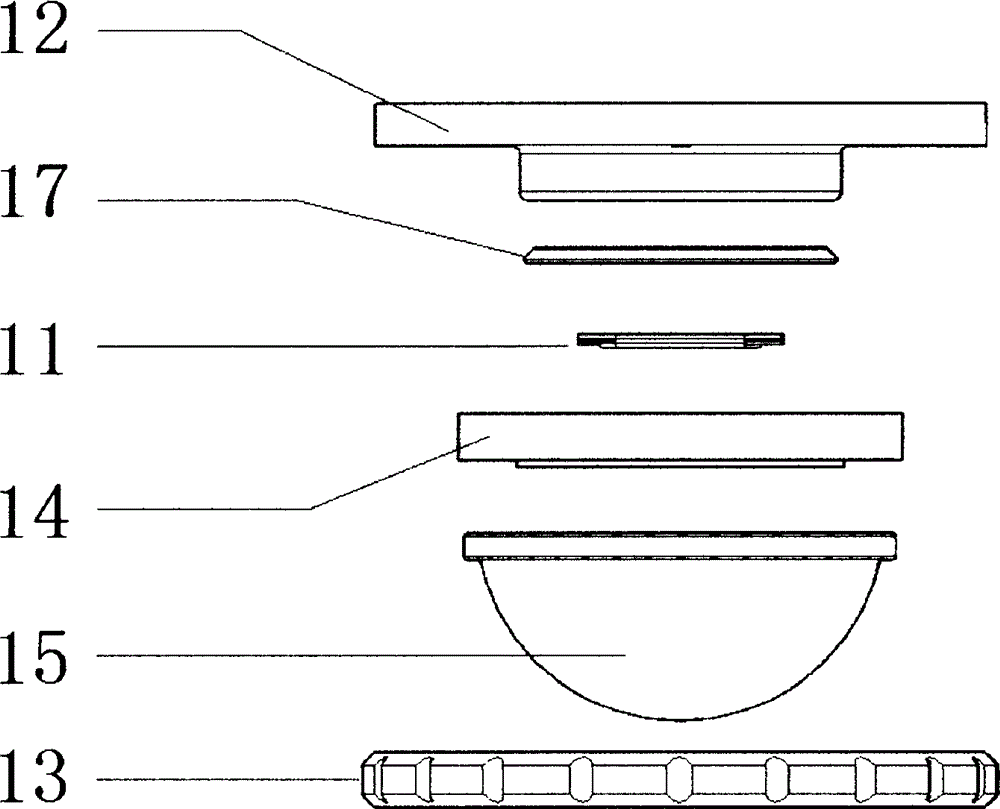

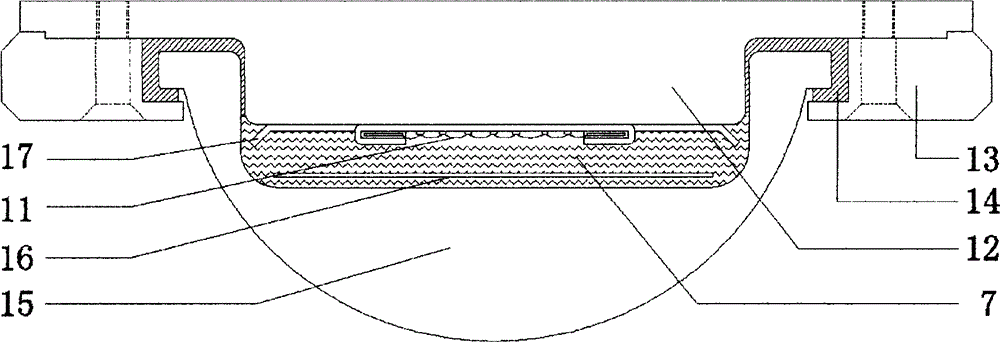

[0023] 1, in Figure 1-3 Among them, the LED light source, driving power supply, heat dissipation, light distribution and protection are integrated to form a five-in-one LED module light, which includes: [1] LED light source and [2] two independent closed systems of driving power, The cooling liquid 7 is injected respectively, and the LED light source 11 and the power supply 21 are soaked in it, and the heat energy of the LED light source 11 and the power supply 2 is transferred to the heat sink 3 through the heat flow ring and dissipated.

[0024] 1. The functions and beneficial effects of the above [1] LED light source closed system design are:

[0025] 1-1, the LED chip 113 quickly transfers heat to the outside through the heat flow ring, which further reduces the thermal resistance of the package of the LED light source 11 and prolongs the service life of the LED light source 11 .

[0026] 1-2, since the refractive index of the cooling liquid 7 is higher than that of air,...

Embodiment 2

[0044]The LED light source 11 is designed with a WFCOB light source 110, which includes: a base plate 111 punched with N grooves, and fluorine rubber tubes 115 are arranged on both sides to wrap the weldable metal sheet 112, and the base plate 111 is punched out on both sides. The weldable metal sheet 112 covered with insulating rubber tube 115 is punched and wrapped to form a dam, and the LED chip 113 is placed in it, and its positive and negative electrodes are welded to the positive and negative ends of the metal sheet 112. On the pad 114 outside the dam of the sheet metal 112 . A kind of WFCOB light source 110, compared with various light sources widely popular at present, its effect and beneficial effect of above-mentioned design are:

[0045] 1. Compared with the integrated light source:,

[0046] 1-1 adopts an all-metal integrated structure, which not only eliminates the injection molding process, but also completely solves the problem that the plastic PPA will turn ye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com