Hybrid packaging method and hybrid packaging structure applied to electronic device

A hybrid packaging and electronic device technology, applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of high production cost, low work efficiency, unstable performance, etc., to reduce costs, reduce packaging thermal resistance, chip Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In view of the deficiencies in the prior art, the inventor of this case was able to propose the technical solution of the present invention after long-term research and extensive practice. The technical solution, its implementation process and principle will be further explained as follows. Unless otherwise specified, the processing techniques adopted in the embodiments of the present invention can be known to those skilled in the art.

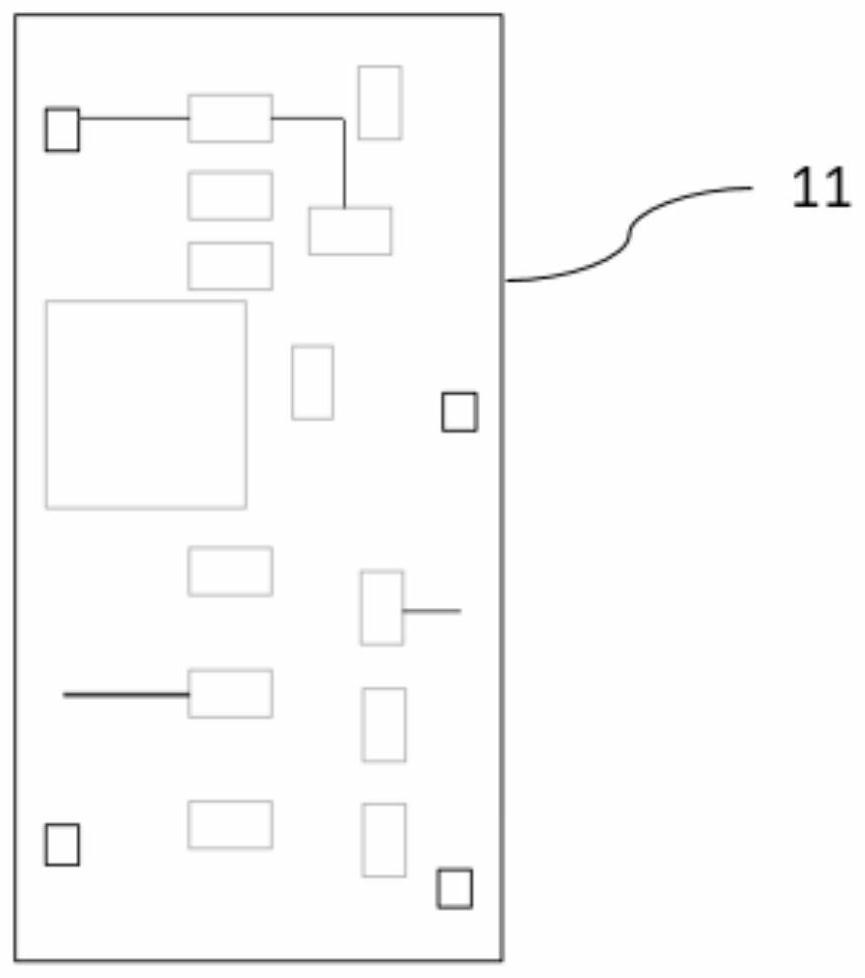

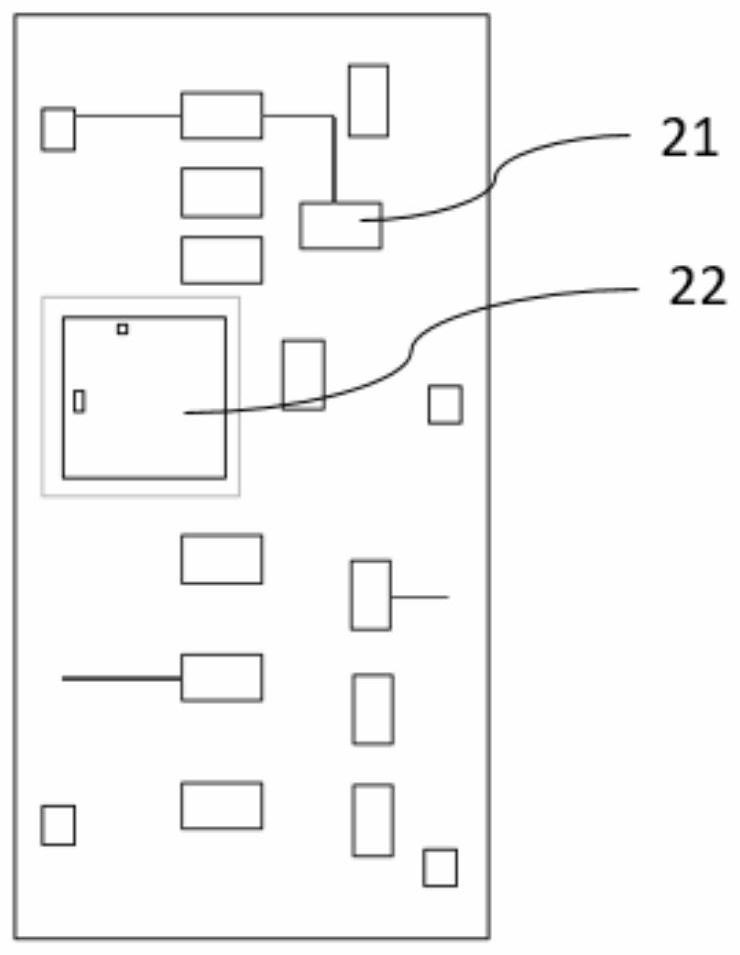

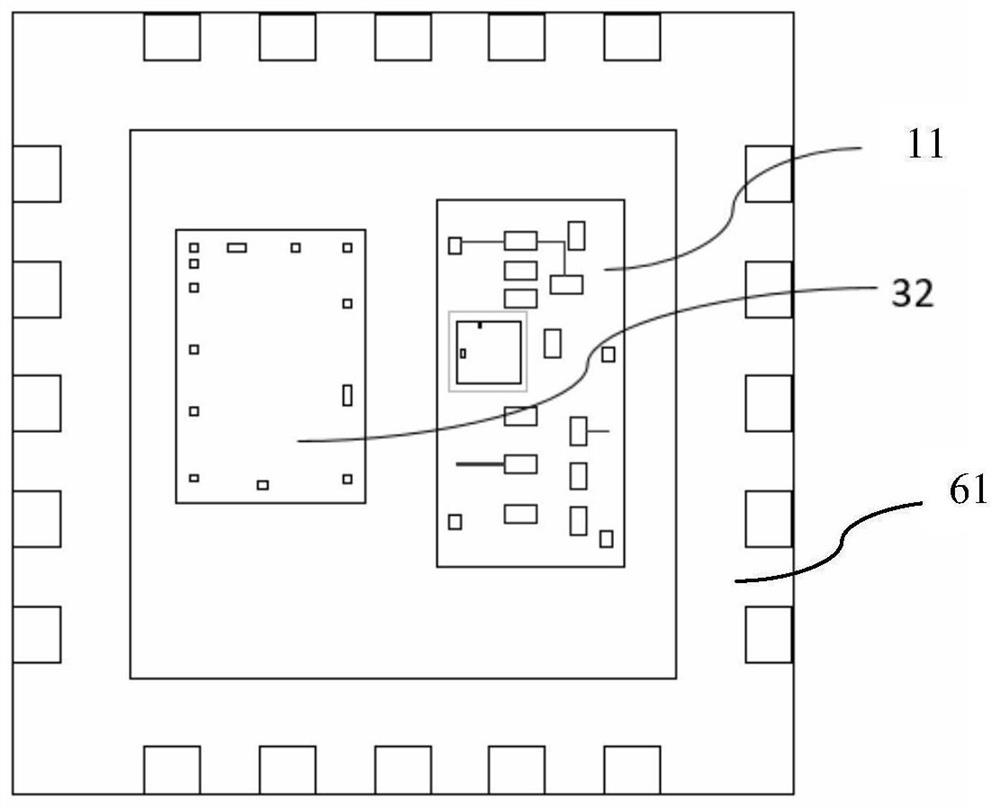

[0030] The hybrid package structure can not only realize chip integration, but also meet high heat dissipation requirements and reduce costs. The mixed production scheme of substrate and lead frame is a brand-new circuit integration, high heat dissipation hybrid (Hybrid) package form, plastic packaging The body contains die attached and laminate (laminate) (the substrate contains components and chips). Using the maximum limit space in the plastic package, it can match the circuit to achieve chip integration, high-demand chip heat dissipa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com