Low-heat-resistance and high-light-efficiency light-emitting diode (LED) integrated light source

A technology with high luminous efficiency and low thermal resistance, applied in the direction of light source, point light source, fixed light source, etc., it can solve the problems of difficult structural design, too dense arrangement of LED chips, and inability to conduct and dissipate heat quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

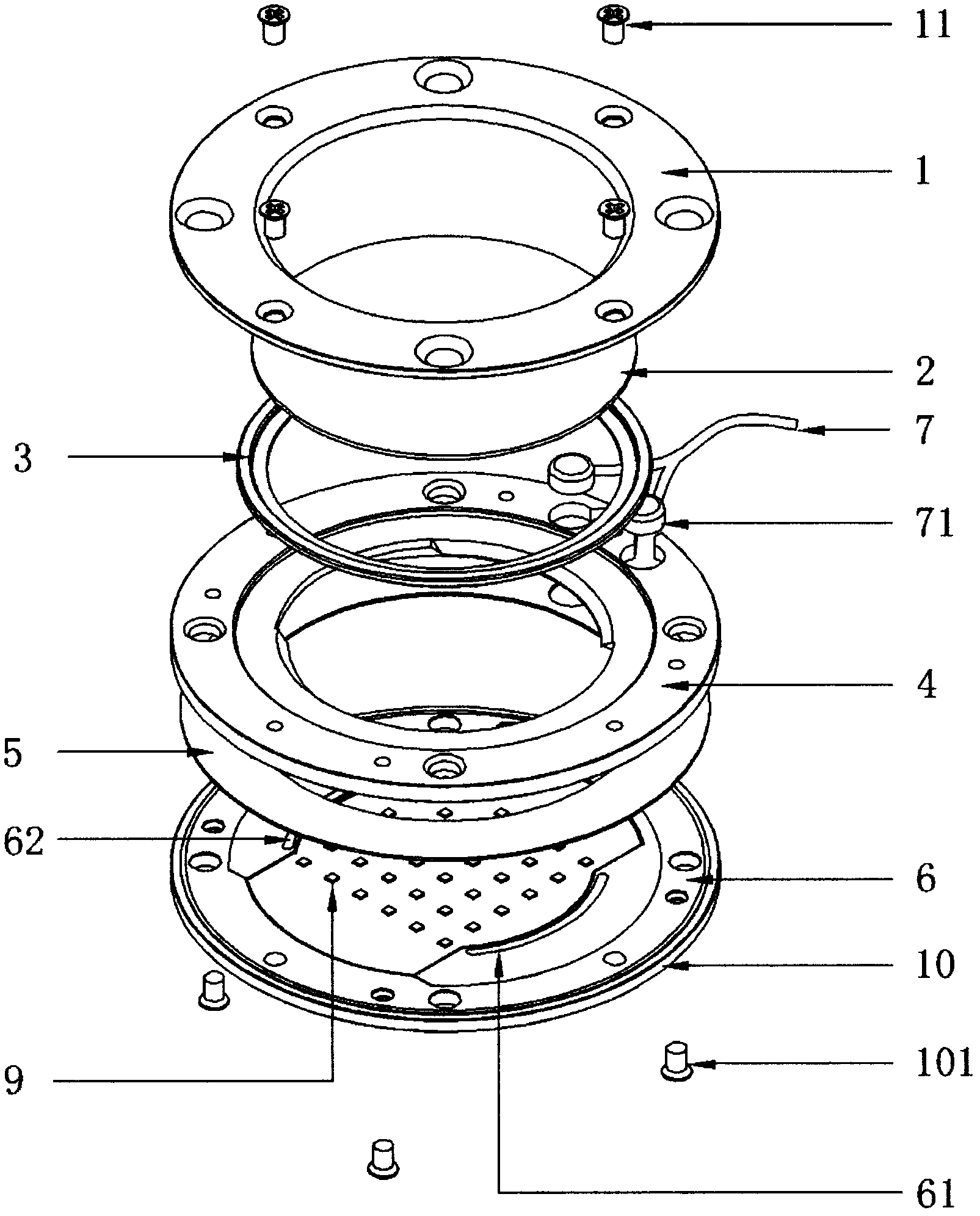

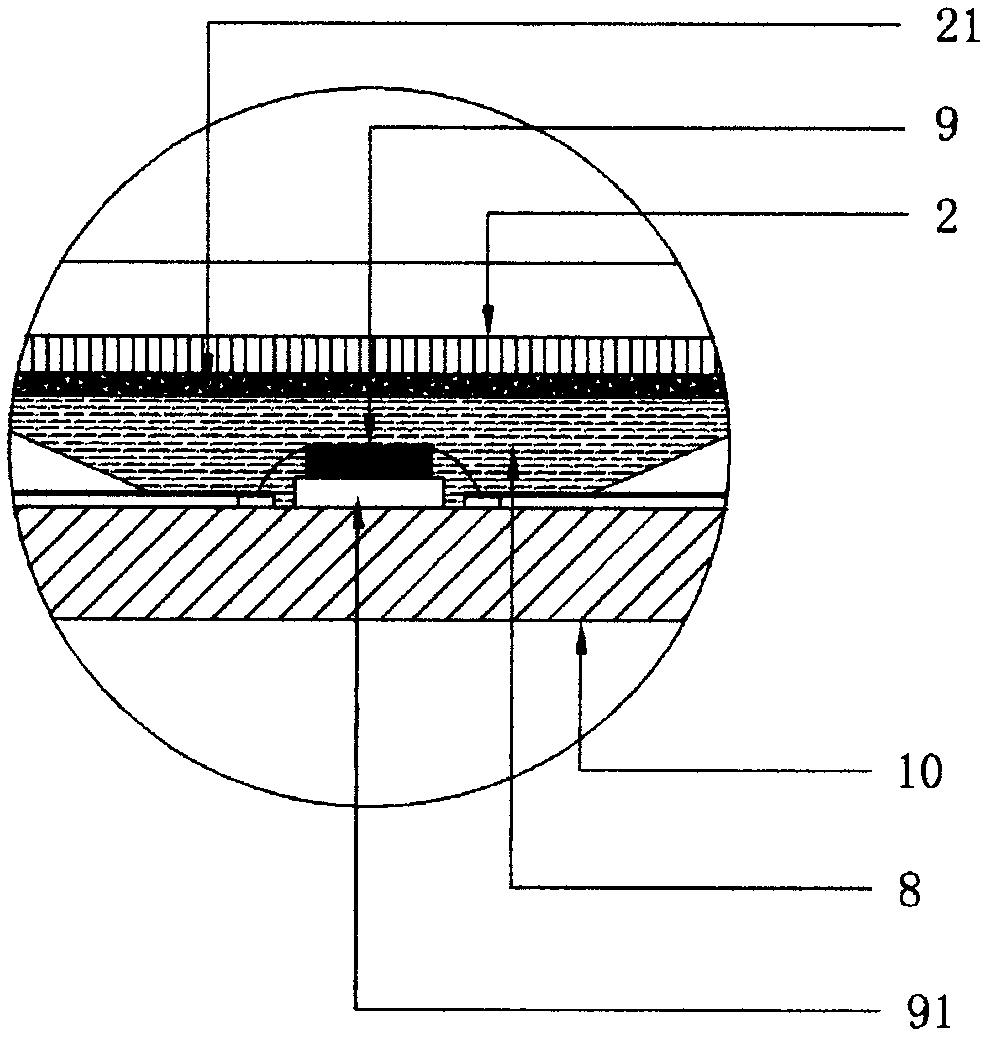

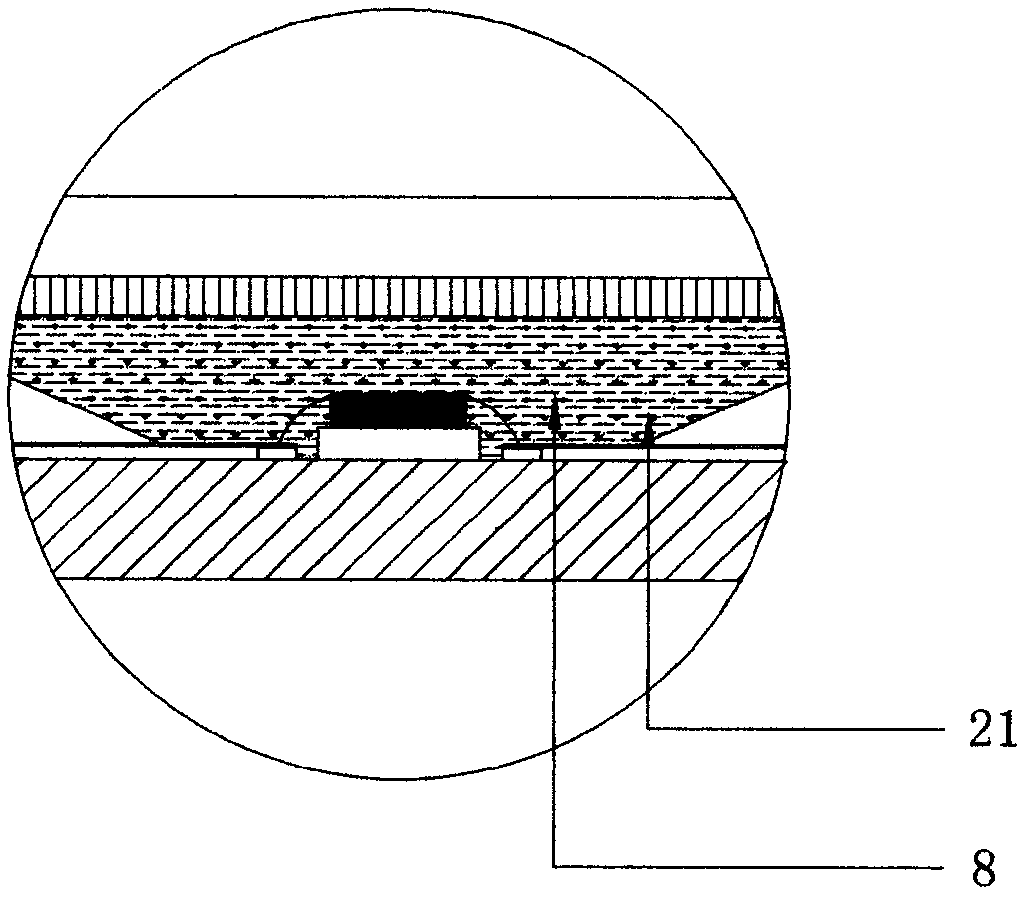

[0015] Example: see attached figure 1 , figure 2 , image 3 :

[0016] An LED integrated light source with low thermal resistance and high light efficiency, comprising a sealed casing 4, characterized in that the middle of the sealed casing 4 is a cavity, and the cavity is filled with a mixture of phosphor powder 21 and silicone oil 8, and is packaged on a heat-conducting substrate 10 The LED chip 9 is soaked in it, and sealed by the gland 1, the glass mirror 2, the rubber pad 3 by the gland screw 11.

[0017] The thermally conductive substrate 10 is a copper or aluminum metal substrate, which is combined with the circuit board 5 with adhesive backing to form a thermally conductive composite copper or aluminum substrate with circuit serial parallel function through hot pressing.

[0018] The LED chip 9 is composed of a number of LED chips distributed in an array and soldered or sealed with silver glue on the thermally conductive substrate 10, and its electrodes are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com