Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Improve peel performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

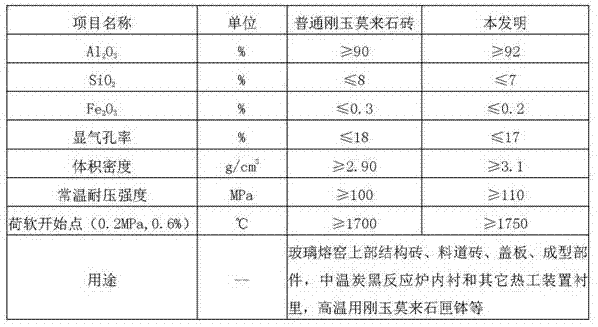

Corundum-mullite bricks capable of being used under high temperature and production method thereof

InactiveCN107056259AHigh hardnessImprove high temperature strengthCeramic shaping apparatusTunnel kilnBrick

The invention discloses corundum-mullite bricks capable of being used under high temperature. The corundum-mullite bricks comprise, by weight, 10-20 parts of fused white corundum granule, 5-10 parts of fused white corundum fine powder, 10-20 parts of fused mullite granule, 5-10 parts of fused mullite fine powder, 5-20 parts of alumina powder and 10-20 parts of kaolin. A production method of the corundum-mullite bricks includes: mixing and grinding raw materials, performing aging and back grinding, performing compression molding, sintering to obtain finished-product bricks and the like. Green bricks obtained after the compression molding are subjected to sintering and heat preservation under 1450-1500 DEG C in a high-temperature tunnel kiln for 10-20 hours, naturally cooled for 48-52 hours and discharged from the kiln to obtain the finished-product bricks. The produced corundum-mullite bricks have the advantages that the hardness, melting point, high-temperature strength, erosion resistance, thermal shock resistance, peeling off resistance and wear resistance of the bricks can be increased evidently, cracking and peeling off during high temperature and cooling can be prevented, and the service life of the corundum-mullite bricks is prolonged.

Owner:辉县市东方耐火材料有限公司

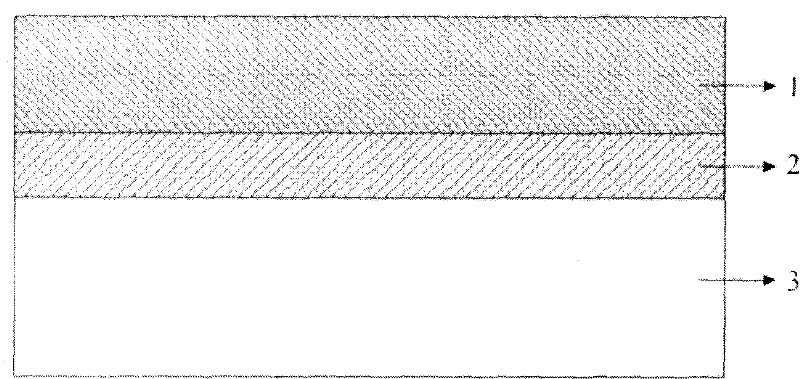

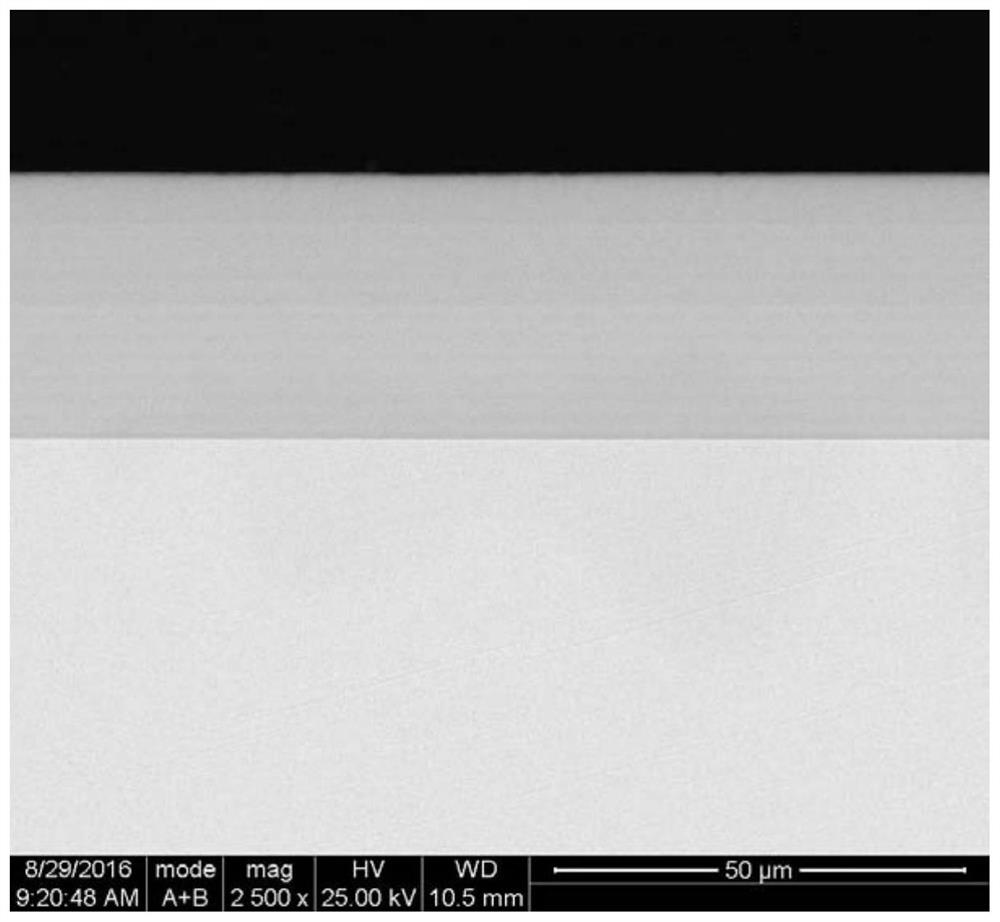

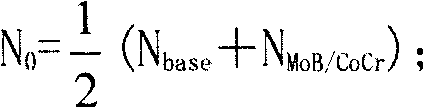

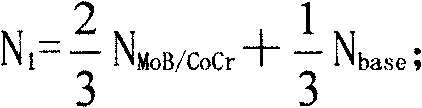

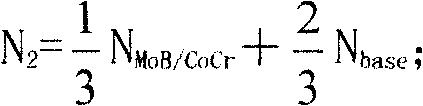

Anti-melting aluminum-silicon alloy corrosion gradient protective coating for solar thermal power generation, and preparation thereof

InactiveCN102191449AIncrease stressImprove peel performanceMolten spray coatingLayered productsPorositySilicon alloy

The invention relates to an anti-melting aluminum-silicon alloy corrosion gradient protective coating for solar thermal power generation, and a preparation method thereof, in particular to an MoB / CoCr gradient protective coating for the inner wall of an aluminum-silicon alloy energy-storage material container for solar thermal power generation, and a preparation method thereof. The MoB / CoCr gradient protective coating is composed of a MoB / CoCr surface protective coating with the thickness of 130mu m and the heat expansion coefficient of 9.2*10<-6> / K and a Co-based alloy buffering transition coating with the thickness of 60mu m and the heat expansion coefficient of 12.5*10<-6> / K. The MoB / CoCr gradient protective coating is spray-painted on a 310S substrate through low-pressure plasma spray painting. Shown by implementation on specimens, the MoB / CoCr gradient protective coating is well matched with the 310S substrate, so that the stress cracking and peeling resisting capabilities of the coating are improved, and the number of thermal shock resisting times reaches 70; the MoB / CoCr gradient protective coating has low porosity, the MoB / CoCr surface protective coating has a porosity of 1.13%, and the buffering transition coating has a porosity of 0.84%; and both the MoB / CoCr surface protective coating and the MoB / CoCr coating powder material contain only two phases of CoMo2B2 and CoMoB.

Owner:GUANGDONG UNIV OF TECH

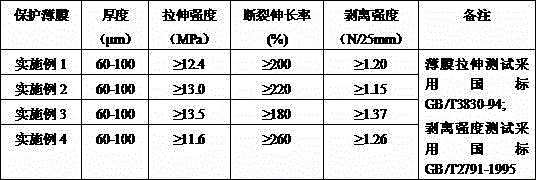

Manufacturing method of heat-shrinkable auto-adhesive vacuum plating protective film

ActiveCN104788867AViscosity stabilityGood adhesionFlat articlesFilm materialEnvironmentally friendly

The invention discloses a manufacturing method of a heat-shrinkable auto-adhesive vacuum plating protective film. The manufacturing method comprises the following steps: (1) firstly, synthesizing polyvinyl polyacrylate; (2) then, performing melt blending on the polyvinyl polyacrylate, polyethylene resin, a first initiator and an antioxidant according to a weight proportion, extruding and granulating, and finally performing extrusion film blowing and UV curing to obtain the heat-shrinkable auto-adhesive vacuum plating protective film. The manufactured protective film wraps a local part, required to be protected, of a vacuum plating component in a heat shrinkage way; in a vacuum plating process, the surface of the film does not crease and deform, the adhesion force is stable, the attachment property is good, the re-peeling performance is excellent, the phenomenon of adhesive residue is avoided, and the barrier and mechanical properties are excellent; the heat-shrinkable auto-adhesive vacuum plating protective film is an excellent vacuum plating protective film material which is non-toxic, environmentally-friendly, safe and practical.

Owner:WUXI HAITE NEW MATERIAL RES INST

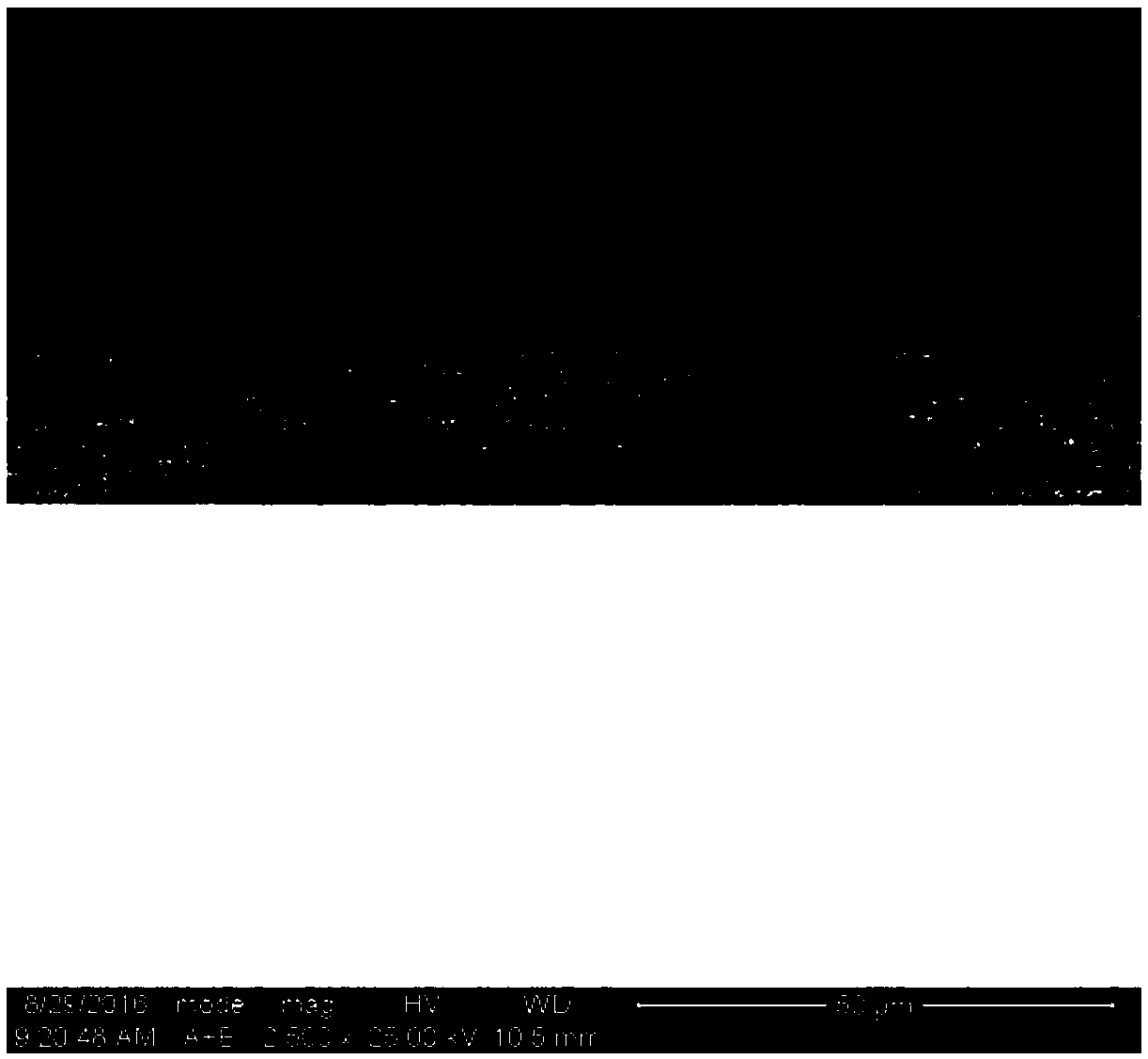

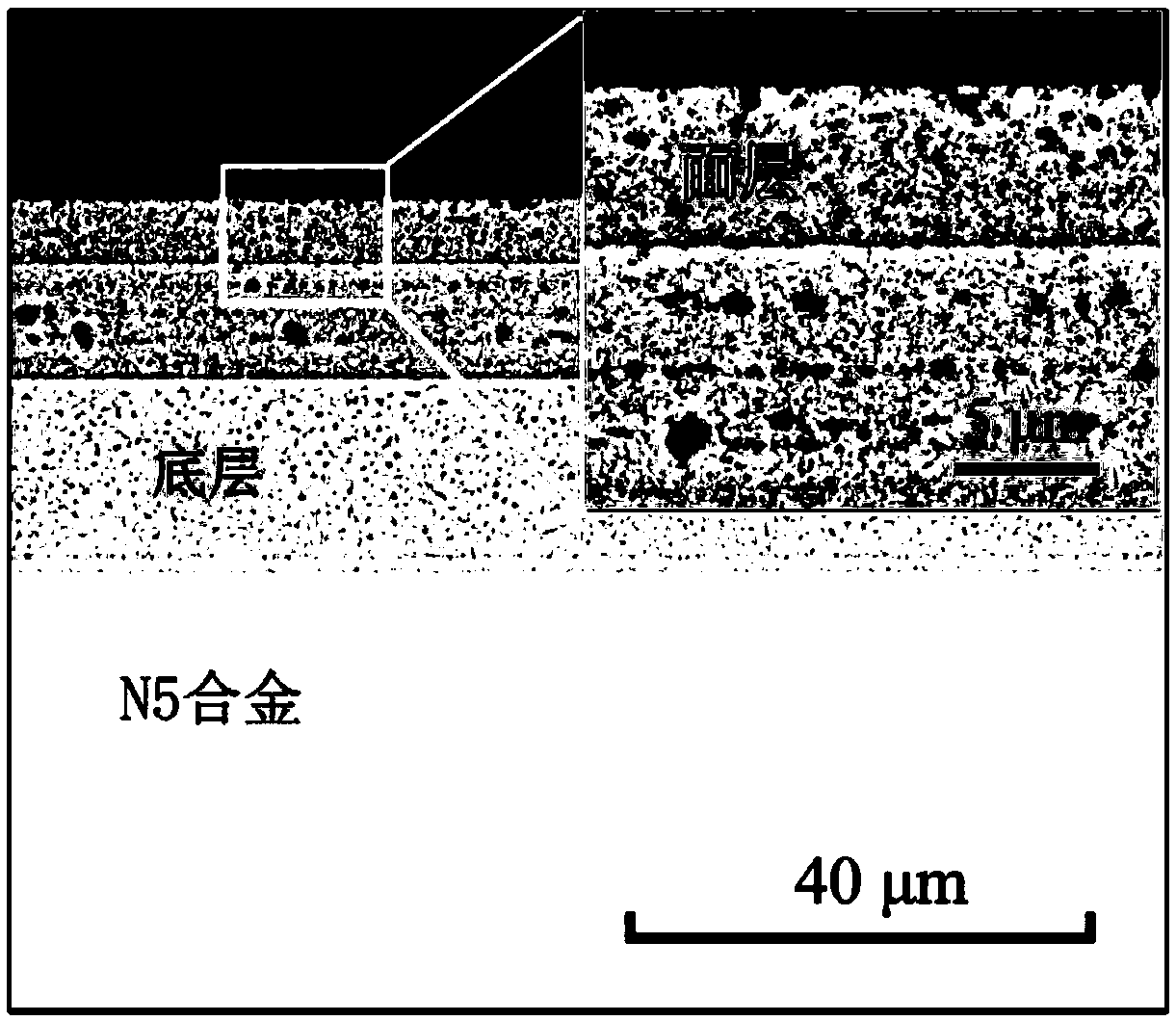

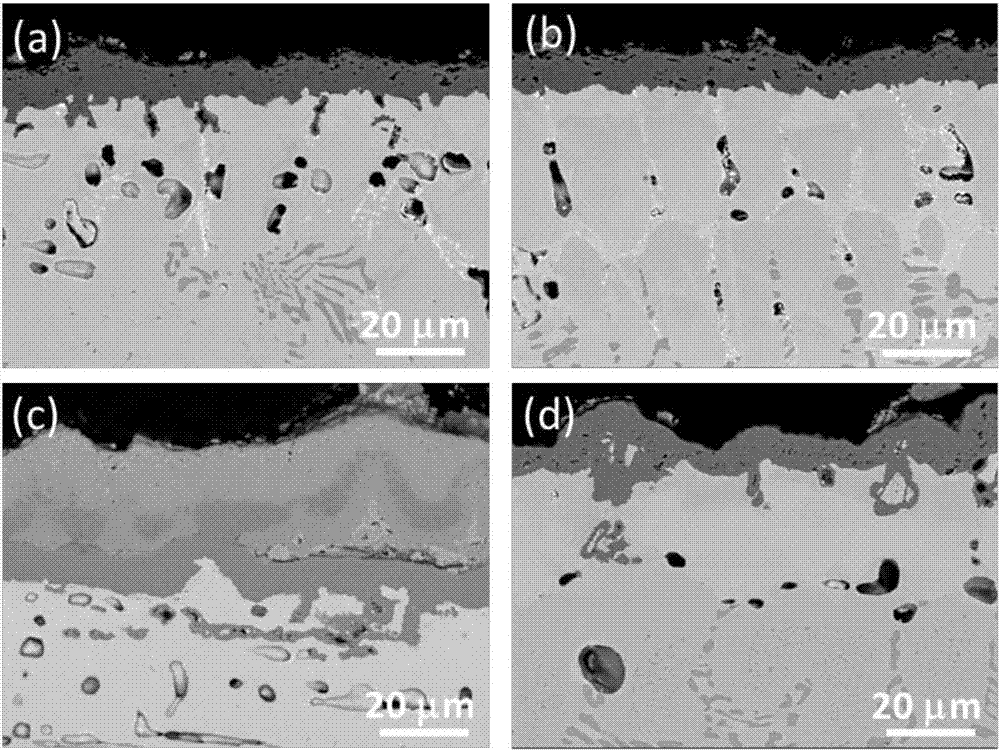

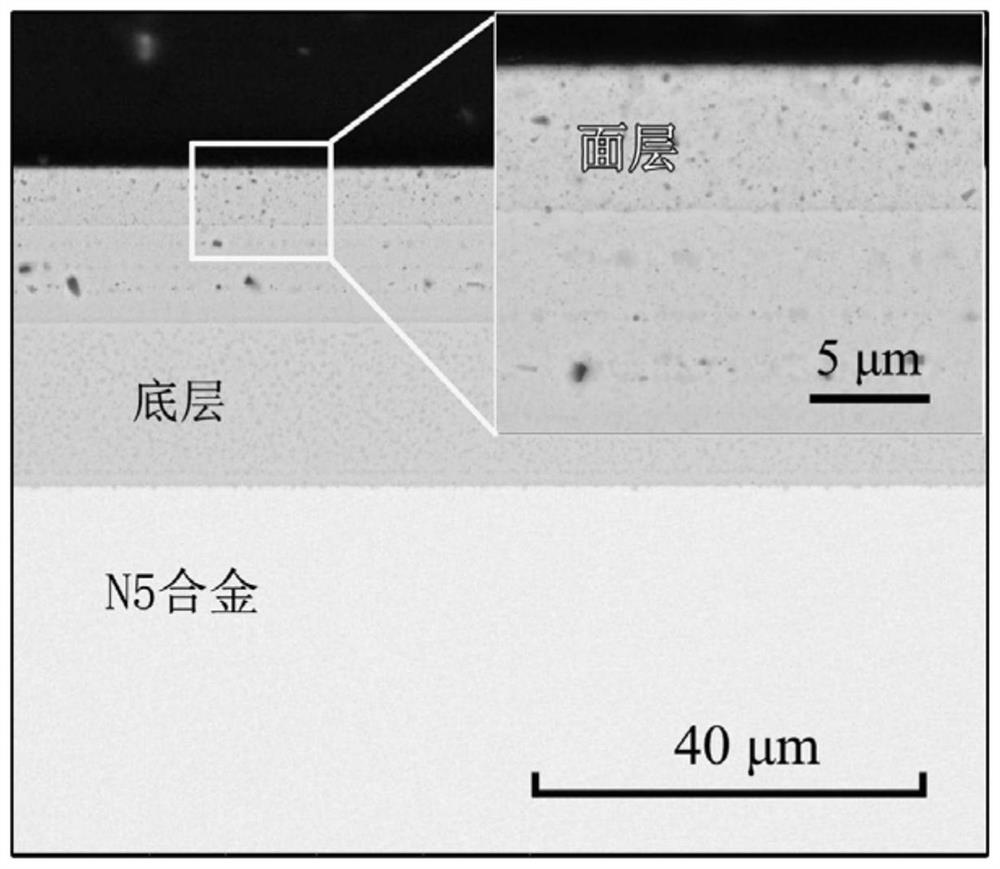

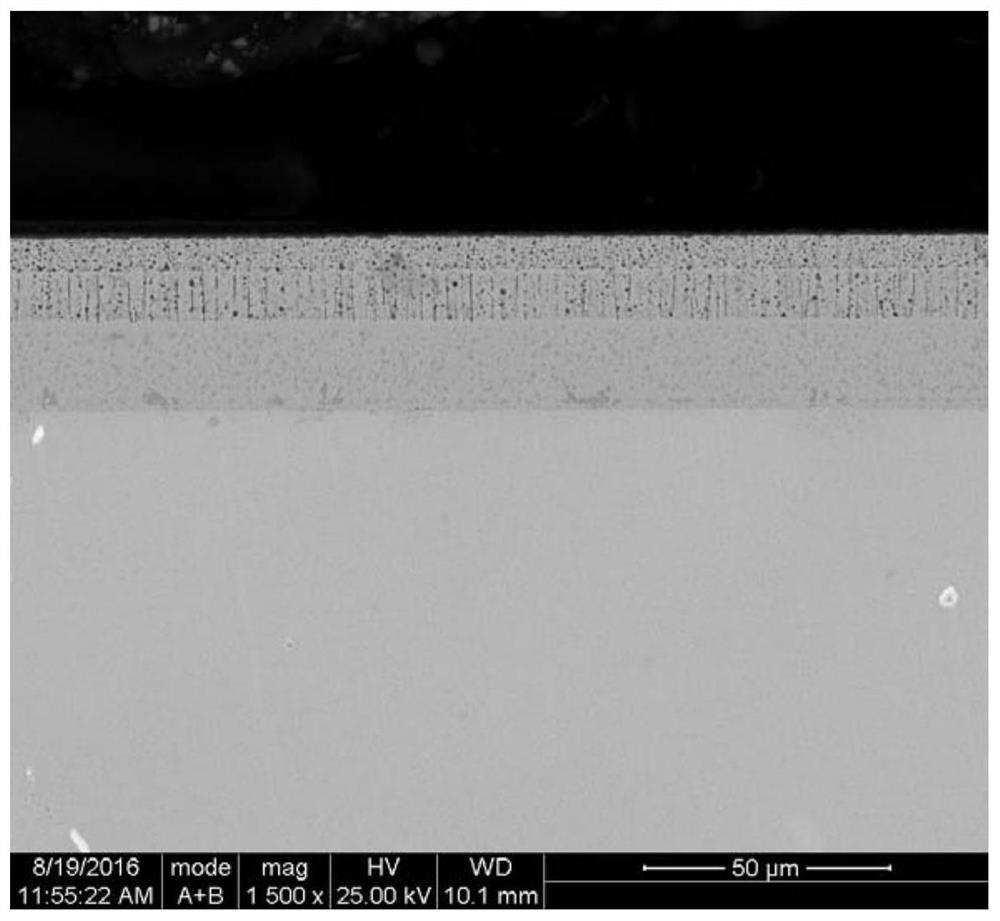

Composite metal ceramic coating for high-temperature alloy protection and preparing method of composite metal ceramic coating

ActiveCN108796461AAlleviate thermal expansion coefficient differencesReduce thermal stressVacuum evaporation coatingSputtering coatingSputteringCrystal structure

The invention discloses a composite metal ceramic coating for high-temperature alloy protection and a preparing method of the composite metal ceramic coating. The coating comprises a face layer and abottom layer with a nano columnar crystal structure. The face layer comprises at least two metal ceramic sub layers, and a metal parent phase and a dispersed distribution nitride ceramic phase are specifically included. In the direction from the surface of the composite metal ceramic coating to an alloy matrix, the doping amount of the nitride ceramic phase is gradually reduced, and the distribution interval of the volume fraction of the nitride ceramic phase is 0.1-60%. According to the preparing method of the coating, magnetic control sputtering is adopted for preparing a bottom layer coating, and then, non-balance reaction magnetic control sputtering is utilized for preparing the face layer of the doped ceramic phase. Through the structure, the heat expansion coefficient of the coatingis gradually increased from top to bottom, jumping changes of the heat expansion coefficient on the coating / oxide film interface are reduced, accordingly, the heat stress in an oxide film in the heatcirculation process is relieved, and the capability of oxide film peeling resisting of the coating in the heat circulation is enhanced.

Owner:JINAN UNIVERSITY

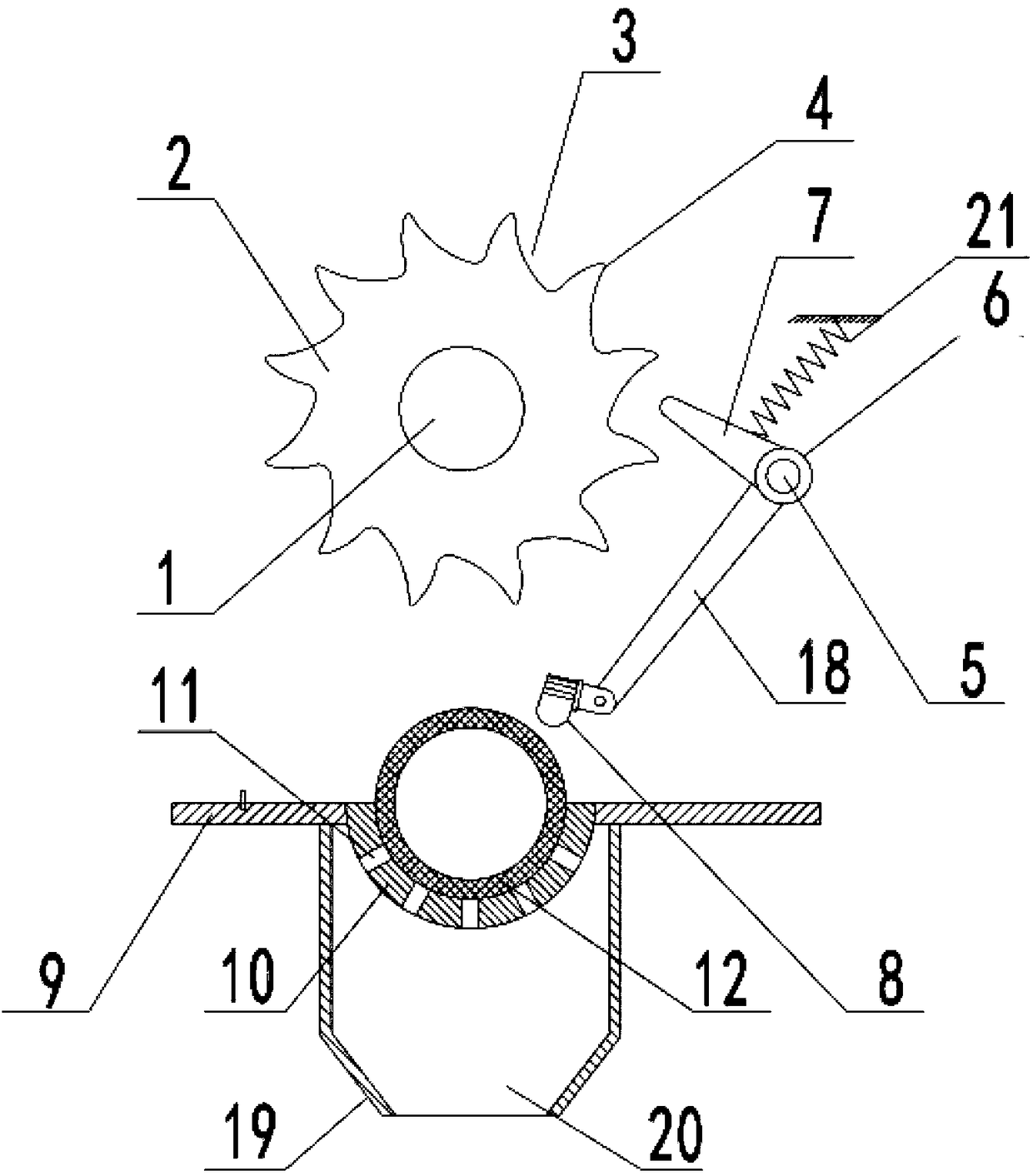

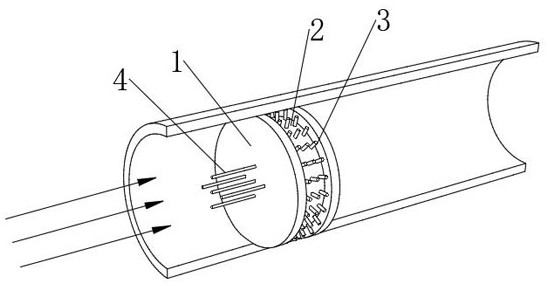

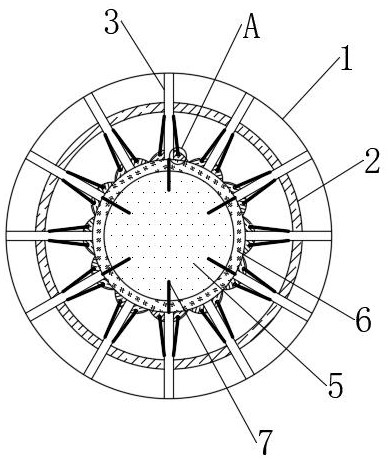

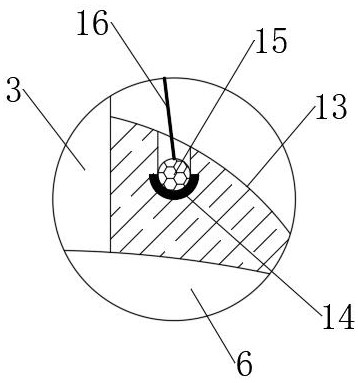

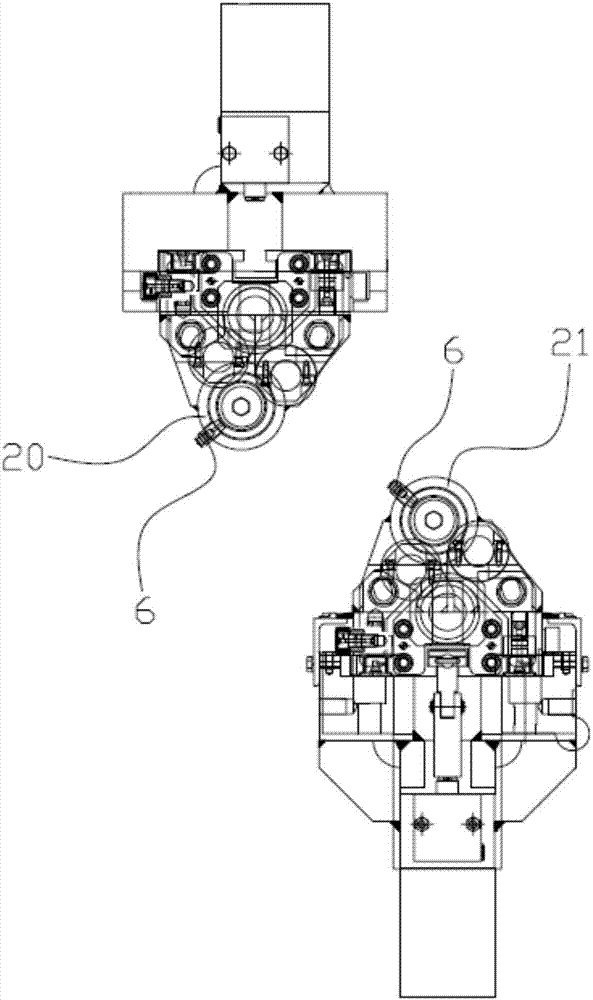

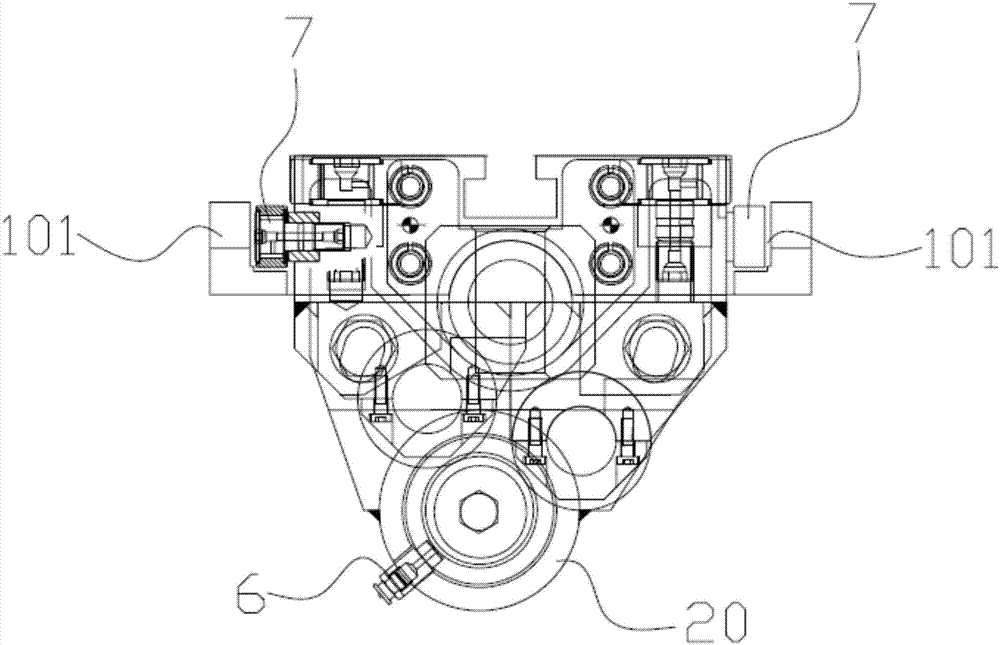

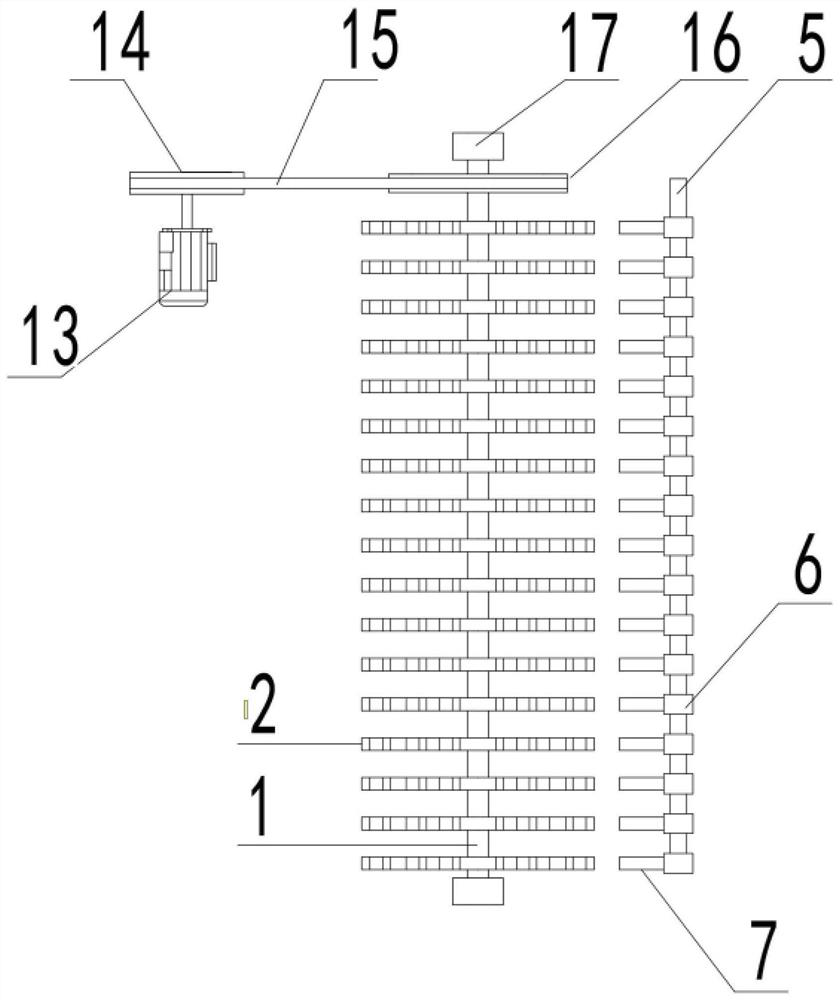

Filter element impurity knocking and peeling device

ActiveCN108771913AImprove peel performanceSimple structureDispersed particle filtrationTransportation and packagingEngineeringMechanical engineering

The invention discloses a filter element impurity knocking and peeling device. The filter element impurity knocking and peeling device comprises a rotary shaft, power discs, a driving rod, knocking heads, a working tabletop, a filter element placement plate and a driven rod, wherein the power discs are mounted on the rotary shaft; a plurality of teeth are arranged on the outer circumferences of the power discs; each tooth is of an arc-shaped bulge structure; the adjacent teeth are in gap connection; a fixed shaft is arranged at the position of one side of the rotary shaft; the fixed shaft is parallel to the rotary shaft; the fixed shaft is provided with a shaft sleeve which rotates independently; the driving rod and the driven rod are fixed on the outer side face of the shaft sleeve. The filter element impurity knocking and peeling device disclosed by the invention has the beneficial effects that a plurality of groups of the power discs and the knocking heads are arranged and a filterelement can be subjected to all-directional knocking; the dust and impurity peeling effect is improved; a filter element can rotate for a certain angle under the knocking of the knocking heads, so that the filter element can rotate while being knocked, and the peeling effect of dust and impurities is improved; a whole structure is simple and the filter element impurity knocking and peeling deviceis convenient to operate and has very strong practicability.

Owner:李冰雪

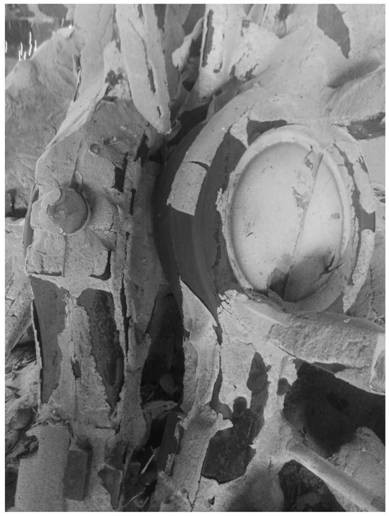

Manufacturing method of self-adhesive protective film for vacuum plating

The invention discloses a manufacturing method of a self-adhesive protective film for vacuum plating. The manufacturing method comprises the following steps: weighing the following raw materials in parts by weight: 100 parts of polyethylene resin, 2-15 parts of acrylate monomer, 0.2-5.0 parts of a first processing additive, and 0.2-1.0 part of a second processing additive; firstly, dissolving the acrylate monomer and the first processing additive in a solvent to obtain a solution, then uniformly mixing the solution with polyethylene resin and the second processing additive in a blender, realizing in-situ grafting and extrusion granulation in an extruder, finally film-forming the prepared grafted granules through a blow molding or tape-casting method directly. The manufacturing method is simple in process; the manufactured protective film is vacuum-plated in a local position, needing to be protected, of a part; during vacuum plating, the surface of the film has no wrinkle and no deformation, is stable in adhesion, good in attachment property and re-peeling performance, has no residue phenomenon; the protective film is excellent in barrier and mechanical properties, non-toxic, environment-friendly, safe and practical, and is an excellent vacuum-plated protective film material.

Owner:WUXI HAITE NEW MATERIAL RES INST

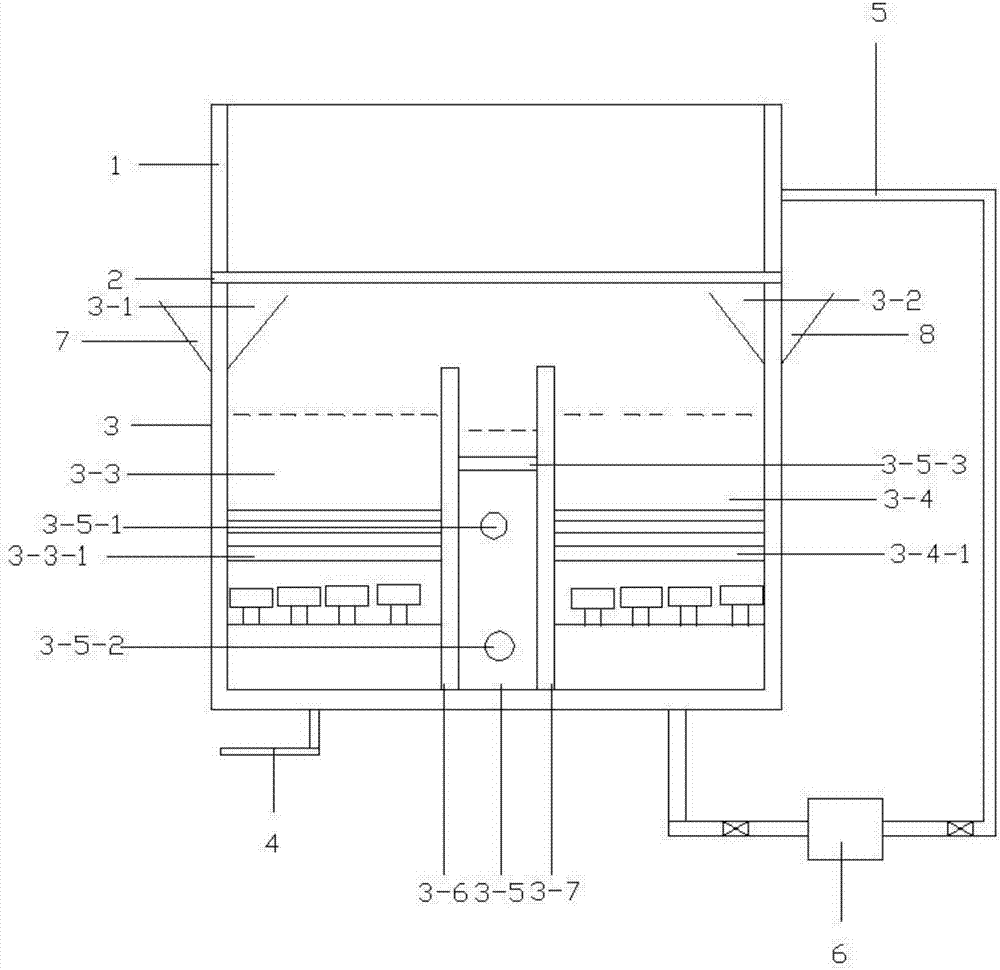

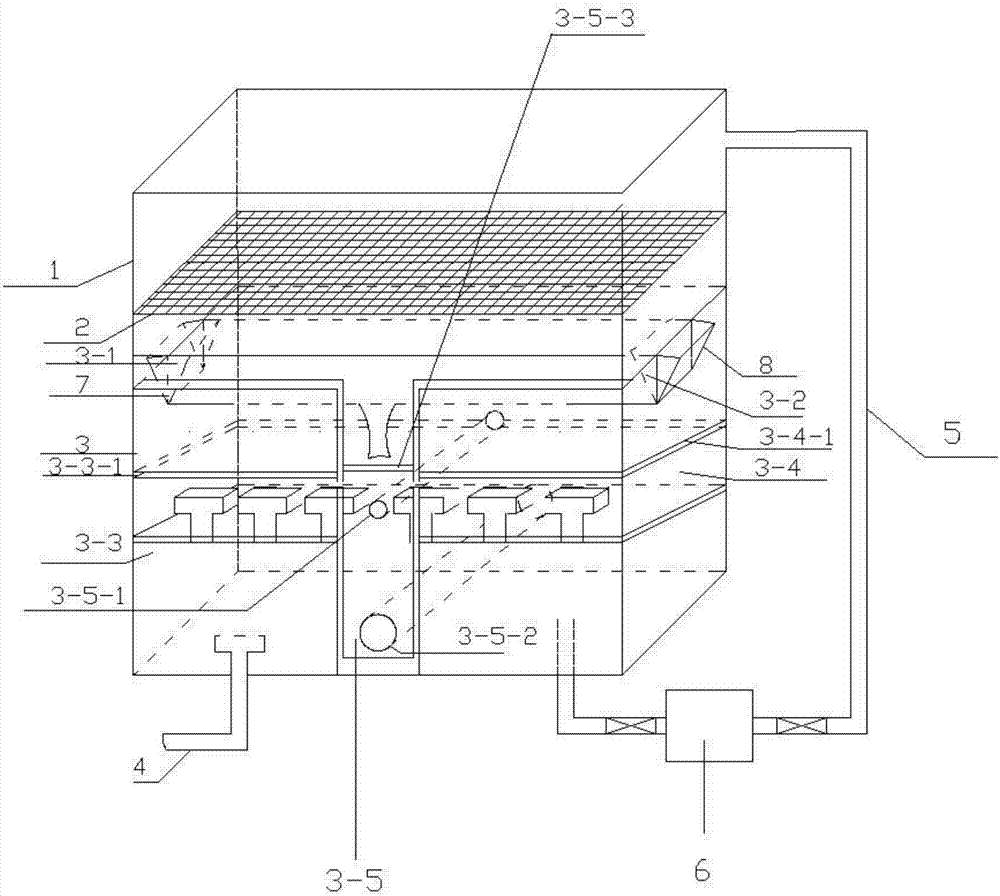

Fish tank with filtering device

InactiveCN107182888AImprove peel performanceImprove pollution interception effectPisciculture and aquariaWater qualitySewage

The invention discloses a fish tank with a filtering device. The fish tank with the filtering device comprises a fish tank, wherein the fish tank bottom is a first baffle with filtering holes; a filtering tank is disposed under the first baffle; a first V-shaped groove and a second V-shaped groove are formed in two opposite side walls of the filtering tank; a first baffle and a second baffle are disposed vertically inside the filtering tank; the filtering tank is successively divided by the first baffle and the second baffle into a first filtering groove, a water-gas distribution groove and a second filtering groove; the first filtering groove is located under the first V-shaped groove; the second filtering groove is located under the second V-shaped groove; bottoms of the first filtering groove and the second filtering groove communicate with the bottom of the water-gas distribution groove; a water backflow pipe is disposed on the bottom of the filtering tank; a water outlet end of the water backflow pipe communicates with the fish tank; a water pump is disposed on the water backflow pipe; and a sewage pipeline is disposed on the bottom of the filtering tank. According to the invention, use is convenient; and silt, iron rust, suspended solids, algae, bacteria, inorganic matters and other pollutants in water are disposed by a sterilization lamp and a filtering pool at the same time, so that water quality purification can be achieved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

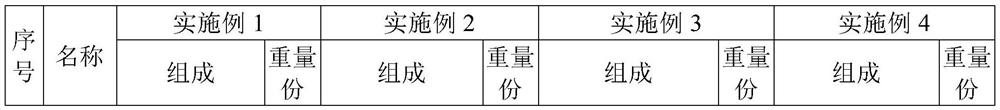

Anti-crack modified quartz-based mica powder full mold paint and preparation method thereof

InactiveCN105817572AImprove dispersion stabilityImprove crack resistanceFoundry mouldsFoundry coresOxideCarbonization

The invention discloses anti-crack modified quartz-based mica powder full mold paint. The anti-crack modified quartz-based mica powder full mold paint is prepared from, by weight, 100-102 parts of quartz powder, 0.9-1.1 parts of modified starch, 0.9-1.1 parts of carboxymethylcellulose, 2.4-2.6 parts of sodium bentonite, 0.9-1 part of mica powder, 0.8-0.9 part of tetrapod-like zinc oxide whiskers, 0.9-1.1 parts of silica sol, 10-13 parts of ethanol, a proper amount of water, 0.4-0.5 part of nano spherical aluminum oxide, 0.7-0.8 part of straw powder and 4-5 parts of sodium hydroxide solution with the concentration being 20-25w%. According to the anti-crack modified quartz-based mica powder full mold paint, the nano spherical aluminum oxide and the straw powder are used, and the straw powder is modified, so that the crack resistance of the paint is improved; in addition, the nano spherical aluminum oxide is used for modification, so that the heat resistance of the straw powder is improved, and the situation that sudden carbonization occurs during casting, a large amount of gas is released, and consequentially air holes of a casting are caused is avoided; and furthermore, the strength and smooth finish of the paint after sintering are improved, and the spalling resistance is improved.

Owner:MAANSHAN XINGLONG FOUNDRY CO LTD

Fluorescent protective film and preparation method thereof

InactiveCN104788700AMeet the needs of useSelf-adhesiveLuminescent paintsTectorial membraneFluorescence

The invention discloses a fluorescent protective film and a preparation method thereof and belongs to the field of packaging industry. The fluorescent protective film comprises a base material layer and a functional coating, wherein the base material layer is made of PE (Poly Ethylene) and has a thickness of 30-60 microns; the functional coating has a thickness of 15-25 microns and comprises the following components in parts by mass: 50-70 parts of acrylic resin, 6-12 parts of polyacrylate, 3-7 parts of nano-titanium dioxide, 4-8 parts of dicumyl peroxide, 0.5-2 parts of aluminate fluorescent powder and 15-25 parts of deionized water. The fluorescent protective film disclosed by the invention is stable in viscous force, good in attachment property, good in re-peeling property and good in fluorescence property, and not only is the aesthetic property of the fluorescent protective film improved, but also a certain identification effect is achieved; therefore, the fluorescent protective film is a good composite functional protective film.

Owner:SUZHOU DINGLI PACKAGING

Scratch-resistant protective film and preparation method thereof

The invention discloses a scratch-resistant protective film and a preparation method thereof and belongs to the field of packaging industry. The scratch-resistant protective film comprises a substrate layer and a functional coating, wherein the substrate layer is PE which is 30-60 microns in thickness and the functional coating is 15-25 microns in thickness. The functional coating comprises the following components in parts by mass: 50-70 parts of organic silicon resin, 6-12 parts of polyisocyanate, 3-7 parts of nanotitanium oxide, 4-8 parts of a silane coupling agent, 0.5-2 parts of a graphite powder and 15-25 parts of deionized water. The scratch-resistant protective film disclosed by the invention is stable in viscous force and good in adhesiveness and re-peeling property, has a good wear-resistant and scratch-resistant performance, and can be effectively used for preventing household appliances from being physically scratched, so that the service lives of the household appliances are prolonged.

Owner:SUZHOU DINGLI PACKAGING

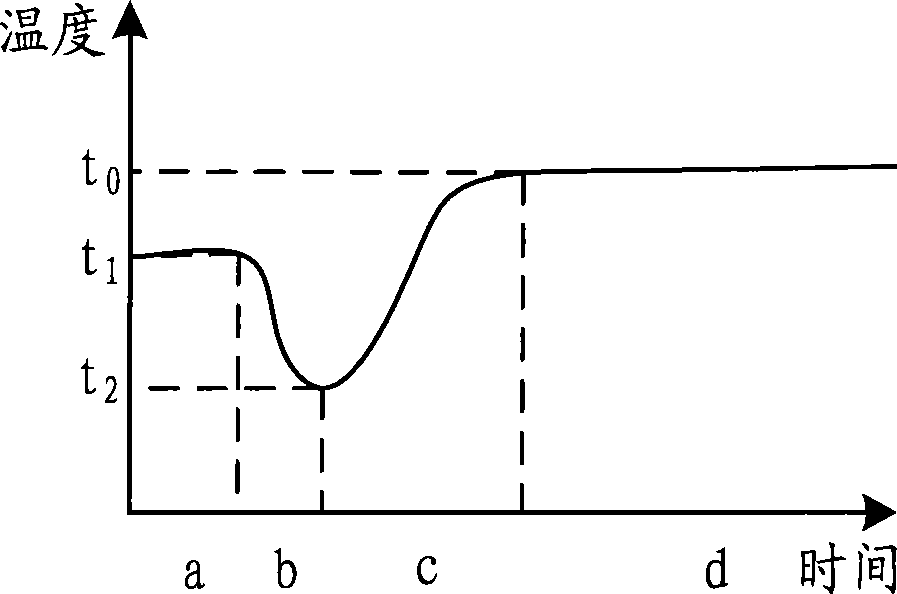

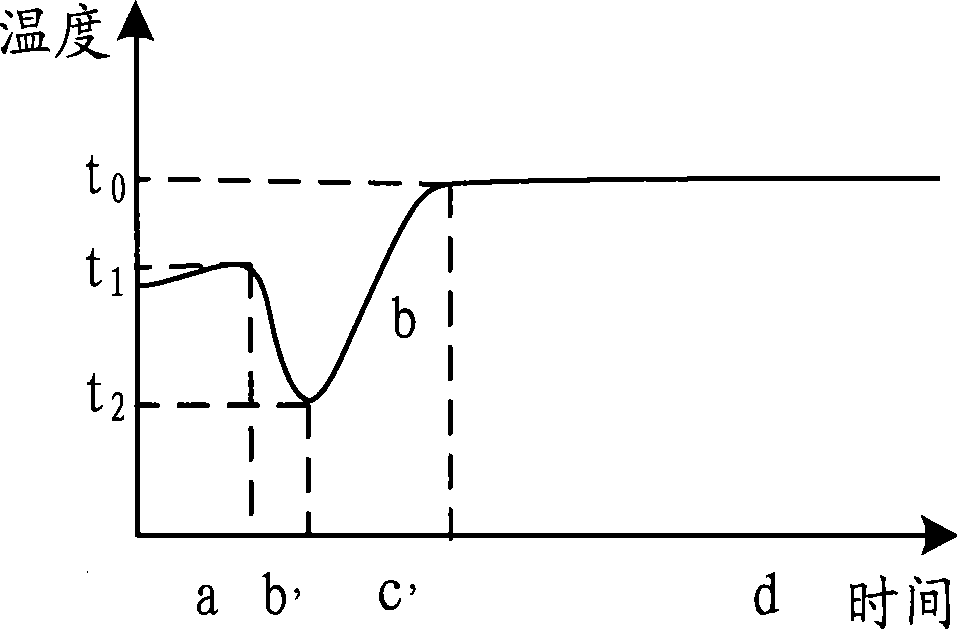

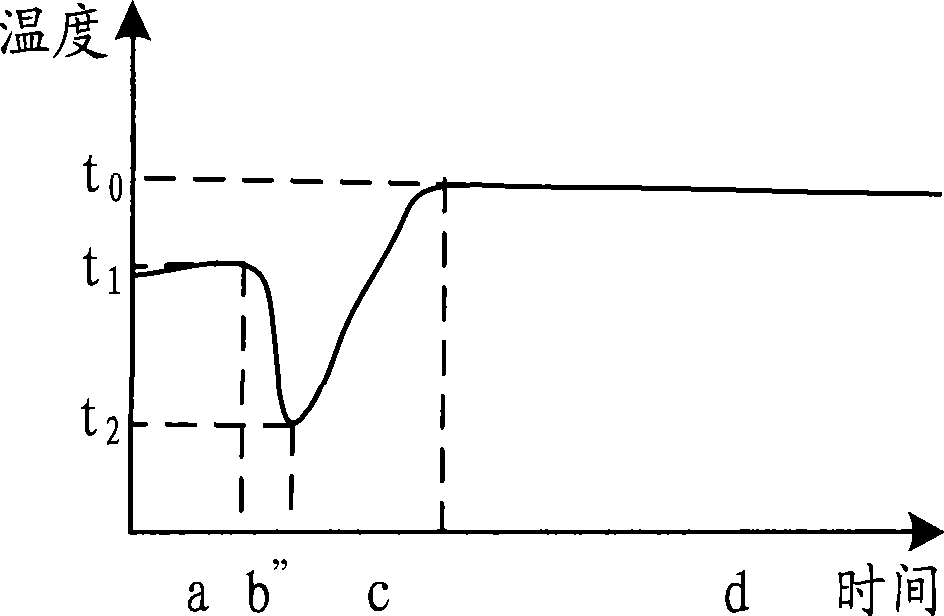

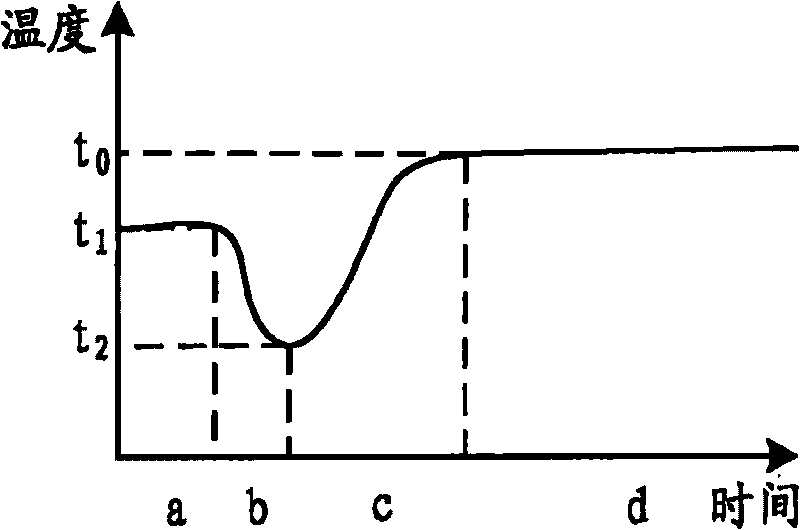

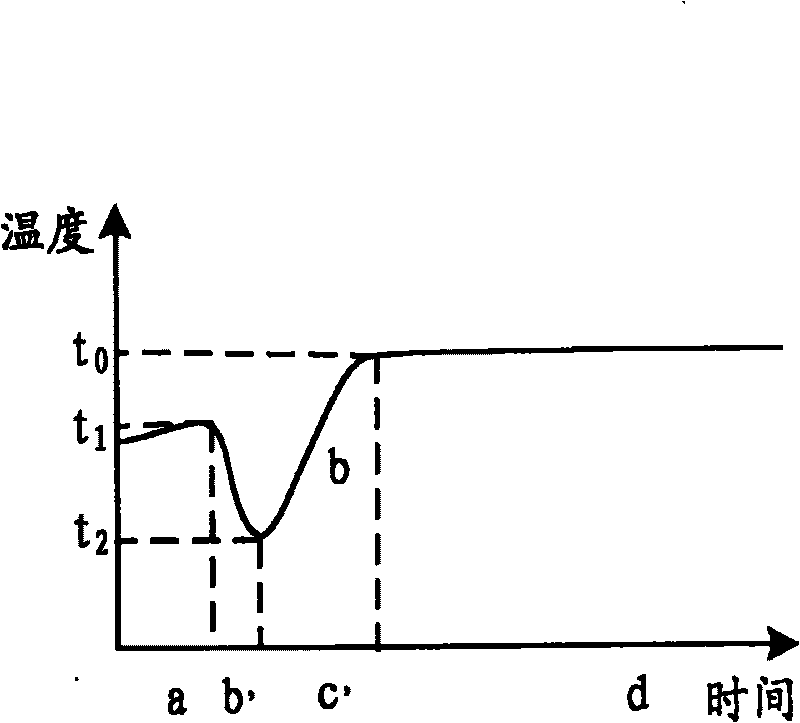

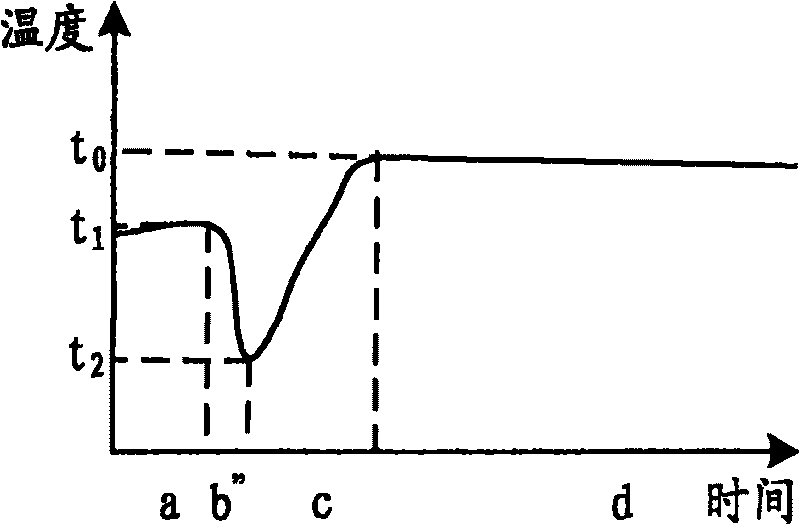

Precleaning method of reaction system

InactiveCN101391258AGood removal effectReduce time spent on pre-cleaningSemiconductor/solid-state device manufacturingCleaning using gasesVacuum pumpingReaction temperature

Disclosed is a pre-cleaning method of a reaction system, comprising: confirming a cooling region taking a first temperature and a second temperature as boundary values, wherein, the first temperature is higher than the second temperature; executing the pretreatment operation so as to make the temperature in the reaction system be the first temperature; executing the cooling operation from the first temperature to the second temperature; beginning to execute the vacuum pumping operation in the cooling process; executing the air suction and heating-up operation after the temperature is reduced to the second temperature so as to make the temperature in the reaction system be the reaction temperature at least. The invention can reduce the pre-cleaning time to improve the production efficiency, and can also enhance the micro-particle removing effect.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Quick-dry high-strength peelable film for radioactive surface decontamination and preparation method thereof

PendingCN113045984AHigh strengthExcellent peelabilityConjugated diene hydrocarbon coatingsPolyurea/polyurethane coatingsFiberEmulsion

The invention discloses a quick-dry high-strength strippable film for radioactive surface decontamination, which is prepared from the following raw materials in parts by weight: 20-30 parts of film forming matter, 30-40 parts of industrial alcohol, 5-10 parts of decontaminant, 5-10 parts of reinforced fiber, 0.4-1 part of dispersing agent, 0.1-1 part of defoaming agent, 1-2 parts of coalescing agent and 20-30 parts of deionized water, and the film forming substance is at least one of aliphatic polyurethane acrylic acid, polyisoprene high-elasticity emulsion, polypropylene glycol or waterborne polyurethane resin.

Owner:SICHUAN ENVIRONMENTAL PROTECTION ENG CO LTD CNNC

Alcohol-based coating for sand casting production of large steel casting and preparation method of alcohol-based coating

InactiveCN112338136AExtended sintering temperature rangeImprove peel performanceFoundry mouldsFoundry coresAlcoholFirming agent

The invention discloses an alcohol-based coating for sand casting production of a large steel casting and a preparation method of the alcohol-based coating. A formula comprises the following components of refractory powder, a binder, a high-efficiency suspending agent, a curing agent, an auxiliary agent A, an auxiliary agent B and methanol, and a high-quality casting paint is obtained through mixing, stirring, colloid milling and other treatment. The paint has the advantages of excellent high temperature resistance, excellent sand burning resistance, favorable paint layer stripping performanceand obvious cost benefit. When the coating is applied, the coating has excellent technical effects in the aspects of suspension, shear thinning, thixotropy, leveling property and the like, and the coating is not liable to blister and delaminate in the use process.

Owner:卢永光

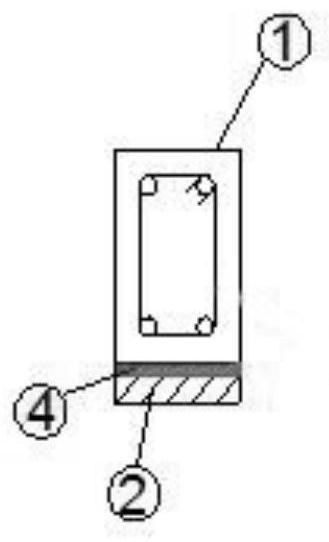

Strippable film

InactiveCN1359791AImprove peel performanceDoes not cause lanyard phenomenonCapsClosure capsPolyester resinCarvacryl acetate

Owner:SUMITOMO CHEM CO LTD

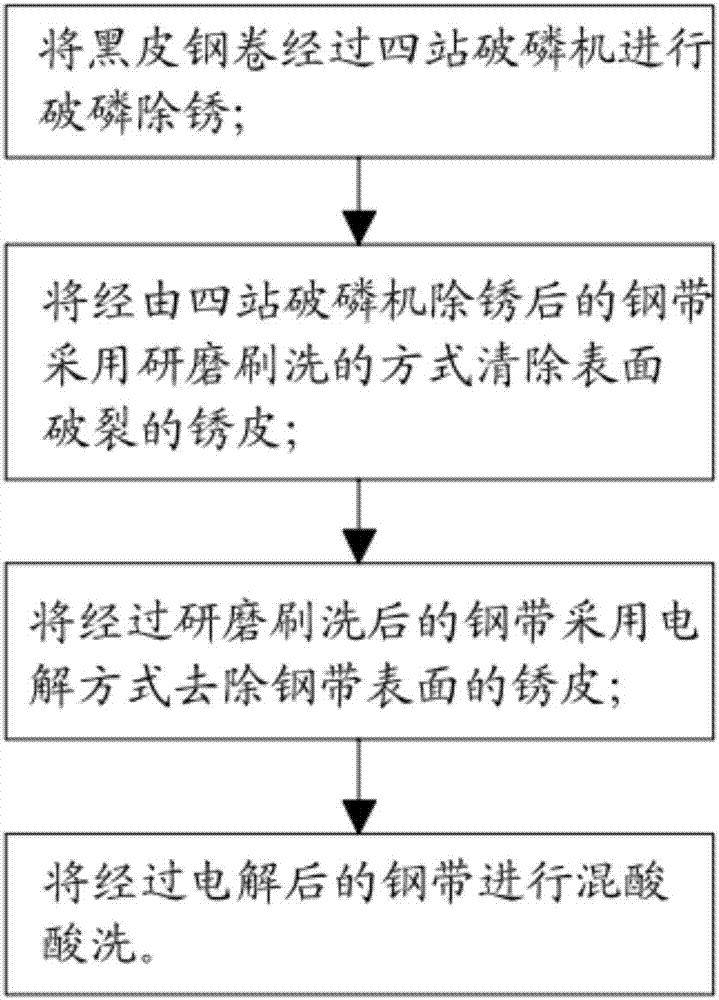

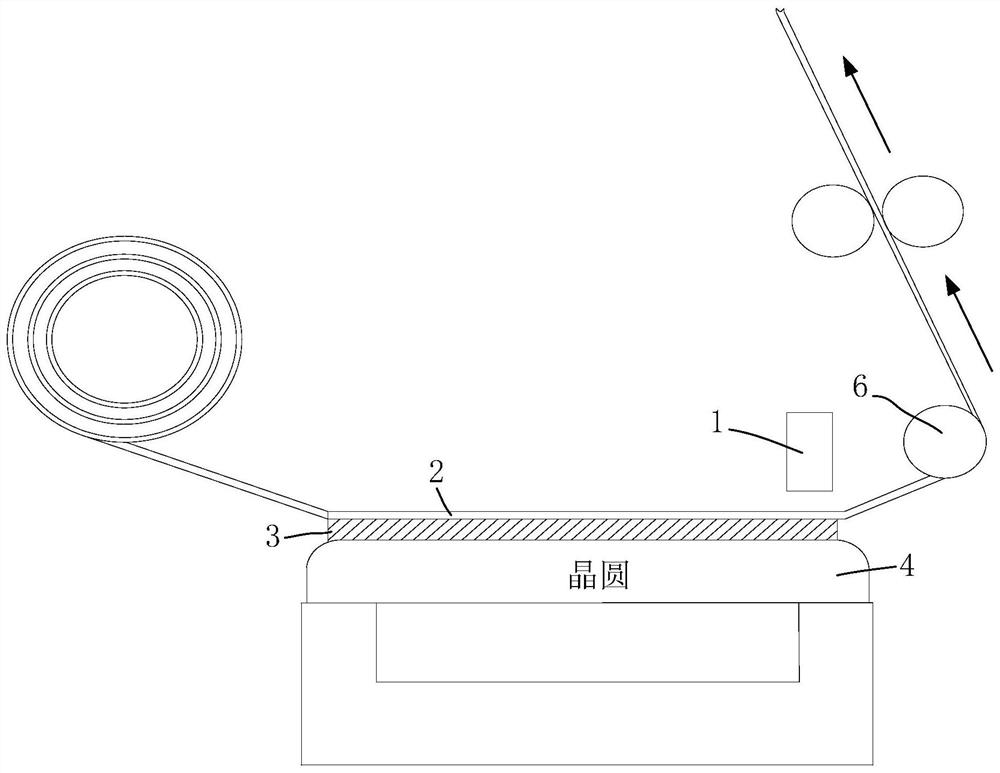

Rust removing technology for black-skin steel reel

InactiveCN107413771AImprove qualityIncreased crack openingMetallic material coating processesGrinding machinesElectrolysisEngineering

The invention provides a rust removing technology for a black-skin steel reel. The rust removing technology comprises the following steps that the black-skin steel reel is subjected to scale braking rust removing through a four-station scale breaker, a steel belt passes through two bending roller sets, the steel belt is bent through simultaneous operation of upper bending rollers and lower bending rollers, the elongation rate of the steel belt is increased, and the extension difference between rust scales and a base material is increased, so that the opening degree of cracks of the rust scales on the surface of the steel belt is increased, and meanwhile edge waves of the steel belt are eliminated; and then the steel belt passes through two straightening roller sets, and through simultaneous operation of upper straightening rollers and lower straightening rollers, C-shaped warped parts and L-shaped warped parts of the steel belt are eliminated; the rust scales cracked on the surface of the steel belt subjected to rust removing through the four-station scale breaker are removed in the mode of grinding and scrubbing; and the rust scales on the surface of the ground and scrubbed steel belt are removed in an electrolysis mode, during electrolysis, the rust scales on the surface of the steel belt are converted into sediments of Cr(OH)3 and Fe(OH)3 to be removed, and the rust scales on the surface of the steel belt are peeled off through O2 and H2 generated in the electrolysis process. According to the rust removing technology for the black-skin steel reel, the rust removing capacity of the whole technological process is reinforced, and the production efficiency is improved.

Owner:福建宏旺实业有限公司

Pipeline decontamination device and decontamination method for intelligent water affairs

InactiveCN112854427AImprove cleaning effectImprove efficiency and effectivenessSewer cleaningYarnSewage

The invention discloses a pipeline decontamination device and decontamination method for intelligent water affairs, and belongs to the technical field of intelligent water affairs. According to the pipeline decontamination device and decontamination method for the intelligent water affairs, normal water flow pressure serves as propulsive force to migrate in a pipeline, and a water suction pipe is used for directly absorbing water from water flow and conveying the water into an internal water storage bag. Then the water is conveyed to a water retention sleeve again through the main water guide fiber yarn, at the moment, a propelling pipe on a composite sewage disposal pipe absorbs the water and then chemically reacts to release a large amount of gas, the composite sewage disposal pipe is forced to leave the water retention sleeve by utilizing the counter-acting force of the gas, and the outer dispersion sewage disposal pipe is dispersed in a radial shape after being extruded by the inner wall of the pipeline, the inner wall of the pipeline is brushed, and meanwhile, dirt cleaning vibration balls in a storage pipe continue to move under the inertia effect to impact the inner wall of the pipeline, the dirt cleaning effect is improved based on the physical and chemical dual effects through the resonance effect and carried hydroxy tricarballic acid, and the efficiency and effect of dirt cleaning of the pipeline can be greatly improved.

Owner:何稳

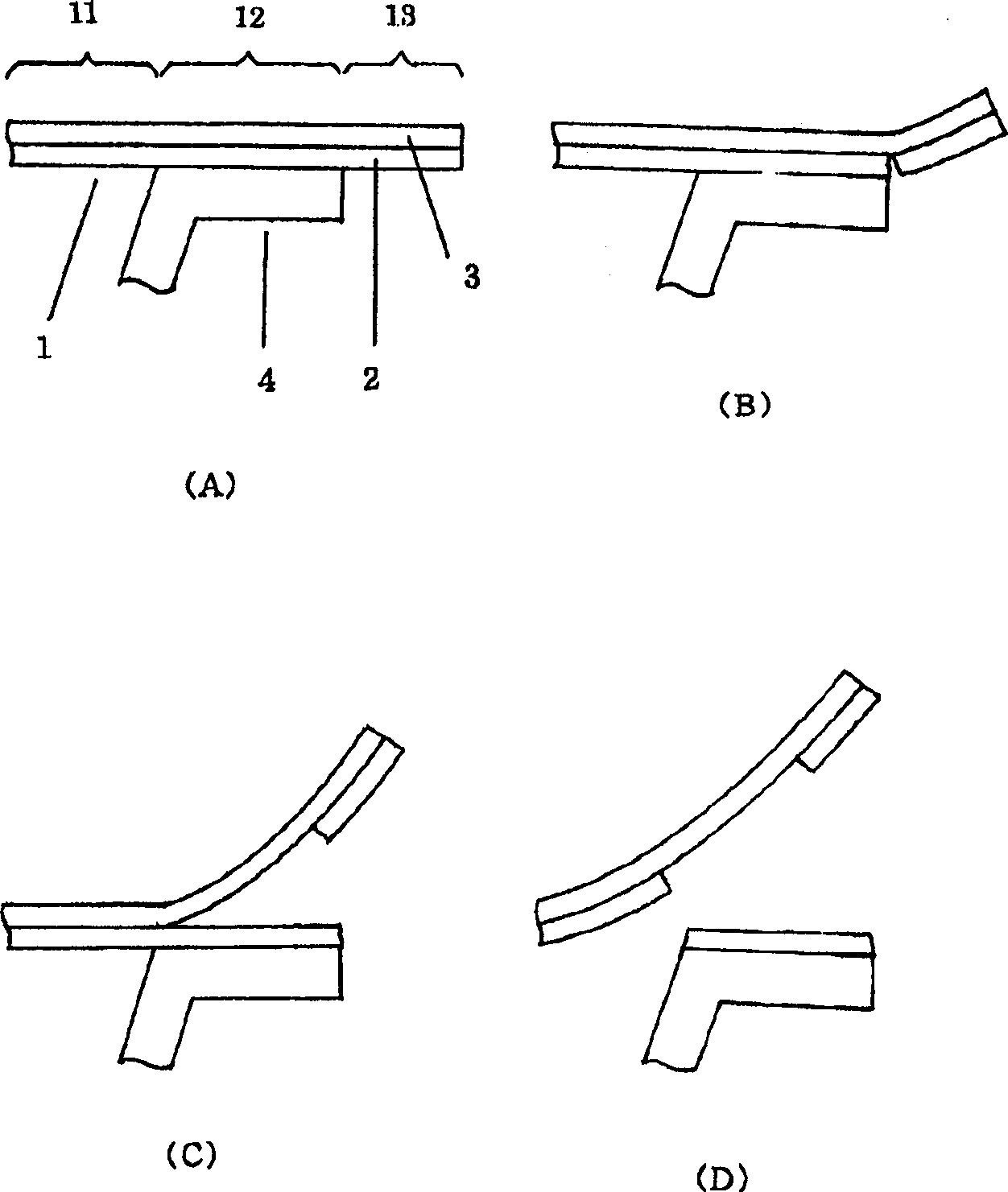

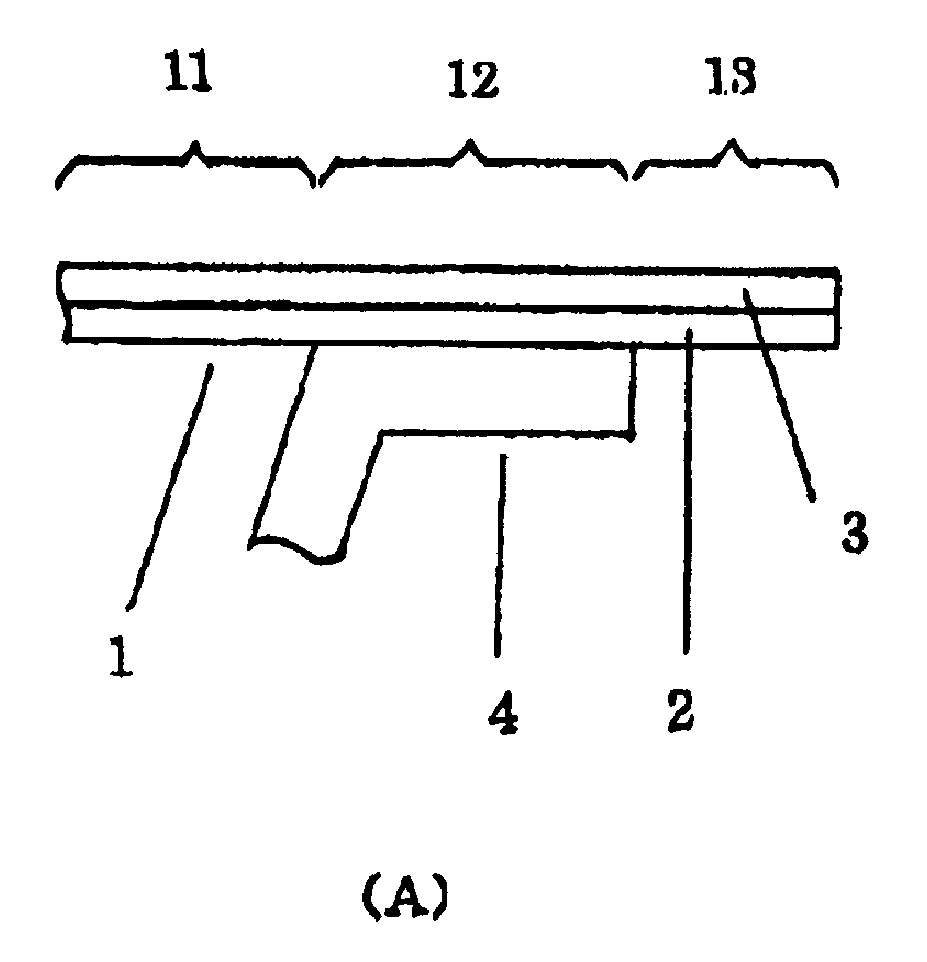

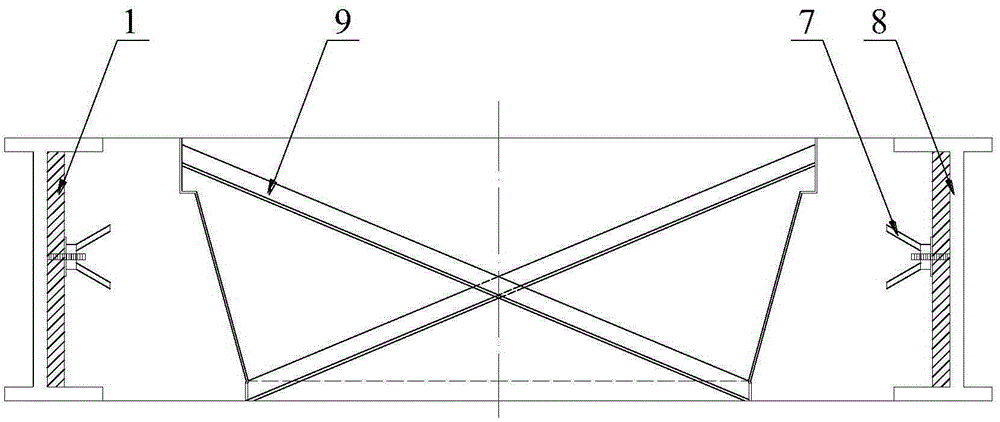

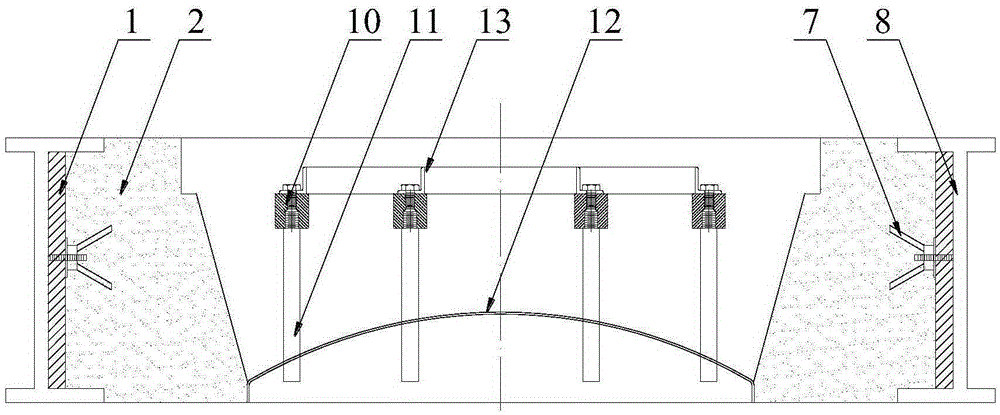

Arched load-bearing platform of a fluidized roaster and its pouring method

ActiveCN105241253BStable structureIncreased load-bearing capacityCharge supportsFiberCombustion chamber

The invention discloses an arch load-bearing platform of a fluidized roasting furnace and a pouring method thereof, comprising a main body of the load-bearing platform and a support platform, the main body of the load-bearing platform and the support platform are fastened together through an L-shaped fastening surface, and the main body of the load-bearing platform is composed of multiple layers. Different castable materials are poured in layers, and the layers are separated by hydrophobic fiberboards. The vent holes on the main body of the load-bearing platform are connected by wear-resistant and high-temperature resistant high-alumina ceramic tubes at the junction of different material layers; The water fiber board, the improvement of the matching structure between the main body of the load-bearing platform and the support platform, and the addition of different contents of steel fibers to the castables enable the arched load-bearing platform to reliably withstand the weight of the material itself in the roasting chamber and the high-frequency vibration load during fluidized roasting. It can also effectively prevent materials from falling into the lower combustion chamber from the roasting chamber.

Owner:CMCU ENG

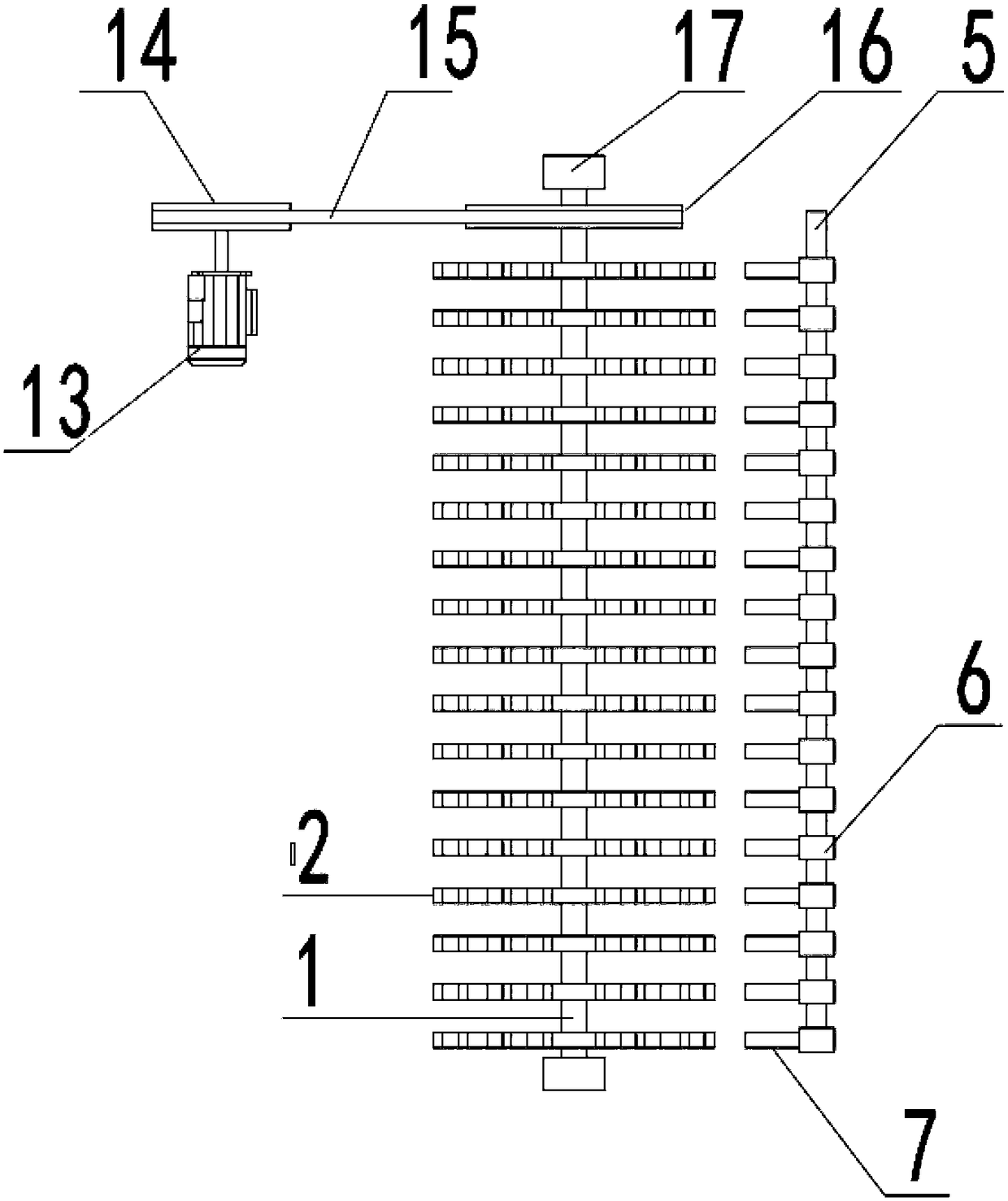

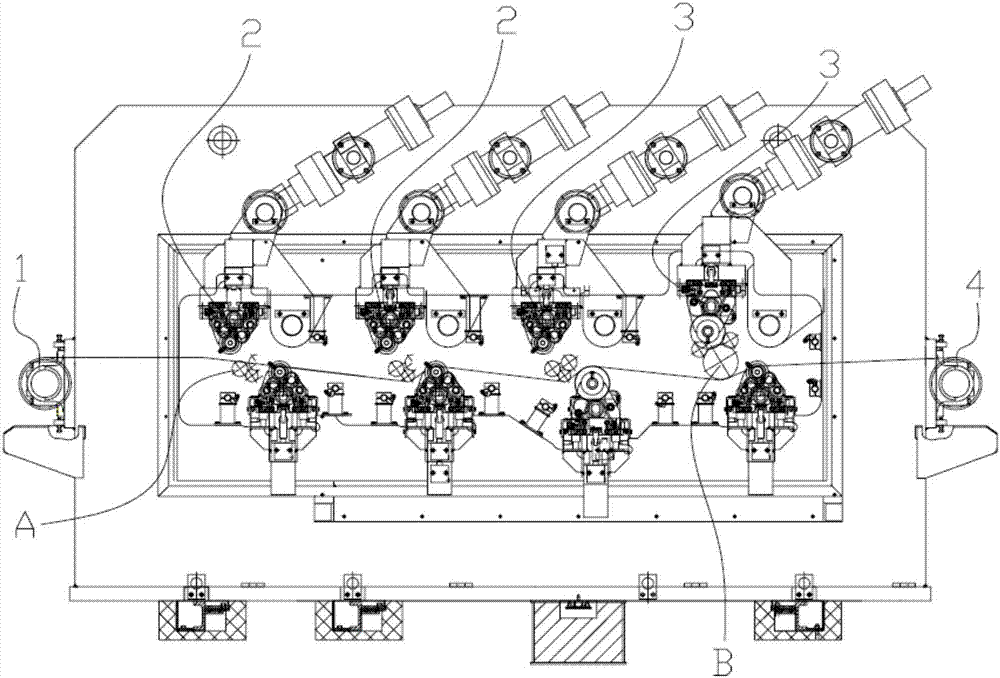

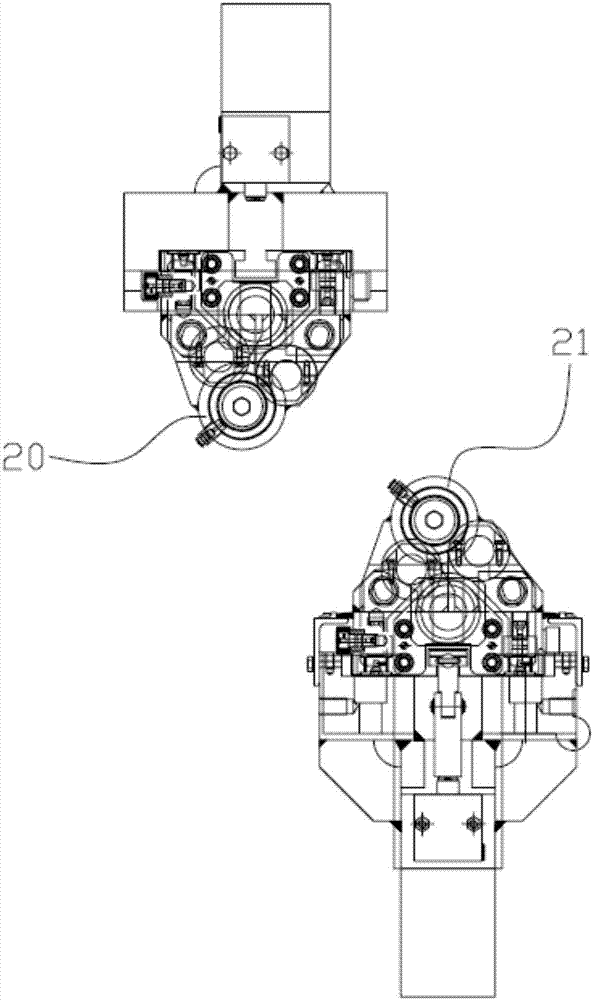

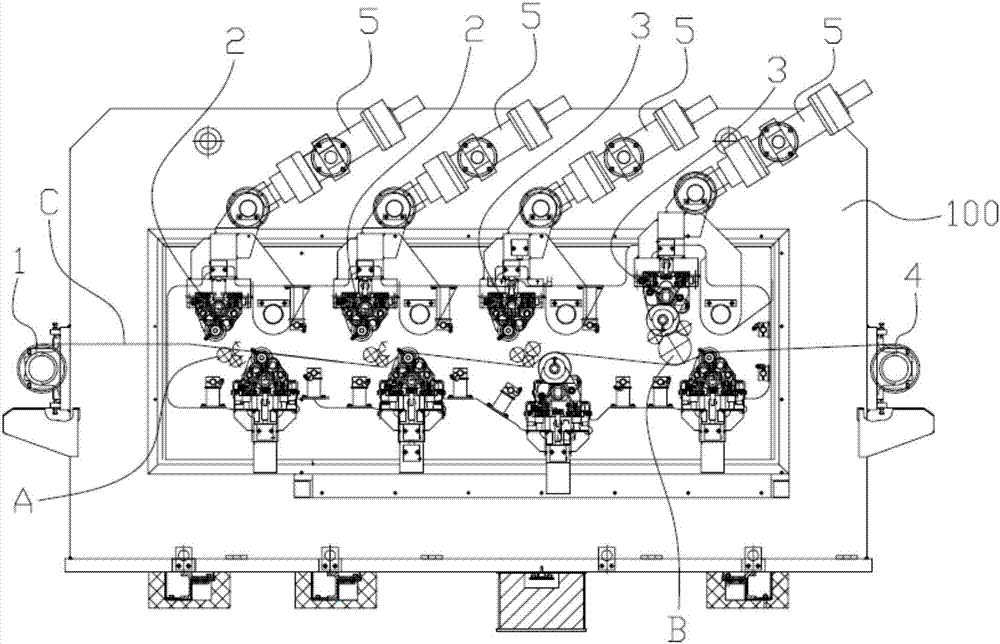

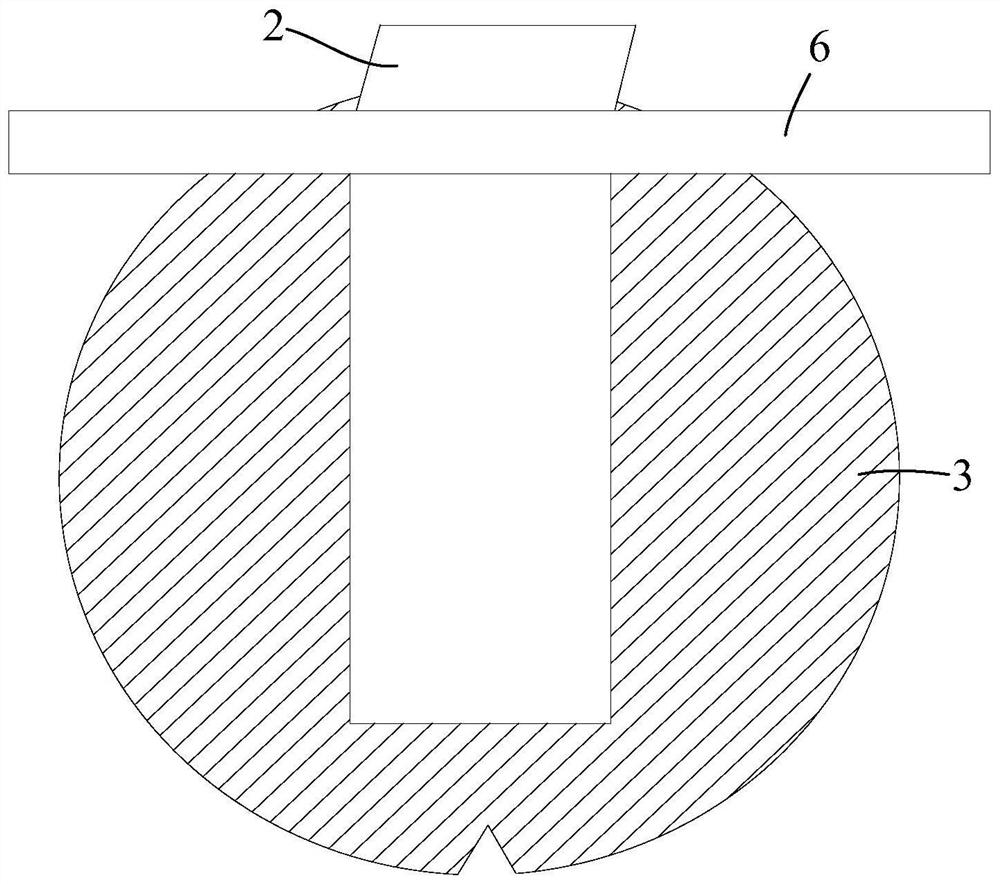

Four-station scale breaker

InactiveCN107413774AHigh elongationIncrease the difference in extensionCleaning processes and apparatusEngineeringSteel belt

The invention provides a four-station scale breaker which comprises a rack, two bending roller sets arranged on the rack and two straightening roller sets. Each bending roller set comprises an upper bending roller and a lower bending roller, wherein the diameter of the upper bending roller is equal to that of the lower bending roller; each straightening roller set comprises an upper straightening roller and a lower straightening roller, wherein the diameter of the upper straightening roller is larger than or smaller than that of the lower straightening roller; a steel belt passes through the two bending roller sets firstly, and the upper bending rollers and the lower bending rollers operate in a staggered mode, so that edge waves of the steel belt are eliminated while the steel belt is bent; and then the steel belt passes through the two straightening roller sets, the steel belt shape is adjusted through simultaneous operation of the upper straightening rollers and the lower straightening rollers, and C-shaped warped parts and L-shaped warped parts of the steel belt are eliminated. According to the four-station scale breaker, the extension difference between scales on the surface of a raw material steel reel and a base material can be effectively increased, the product quality is improved, and the production efficiency is improved.

Owner:福建宏旺实业有限公司

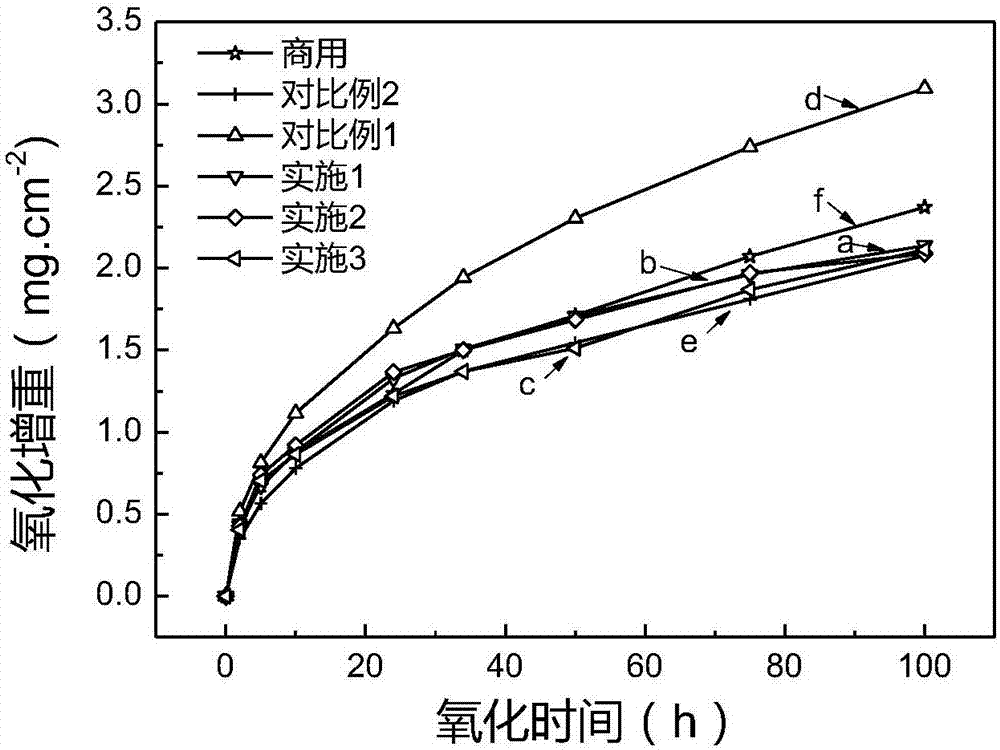

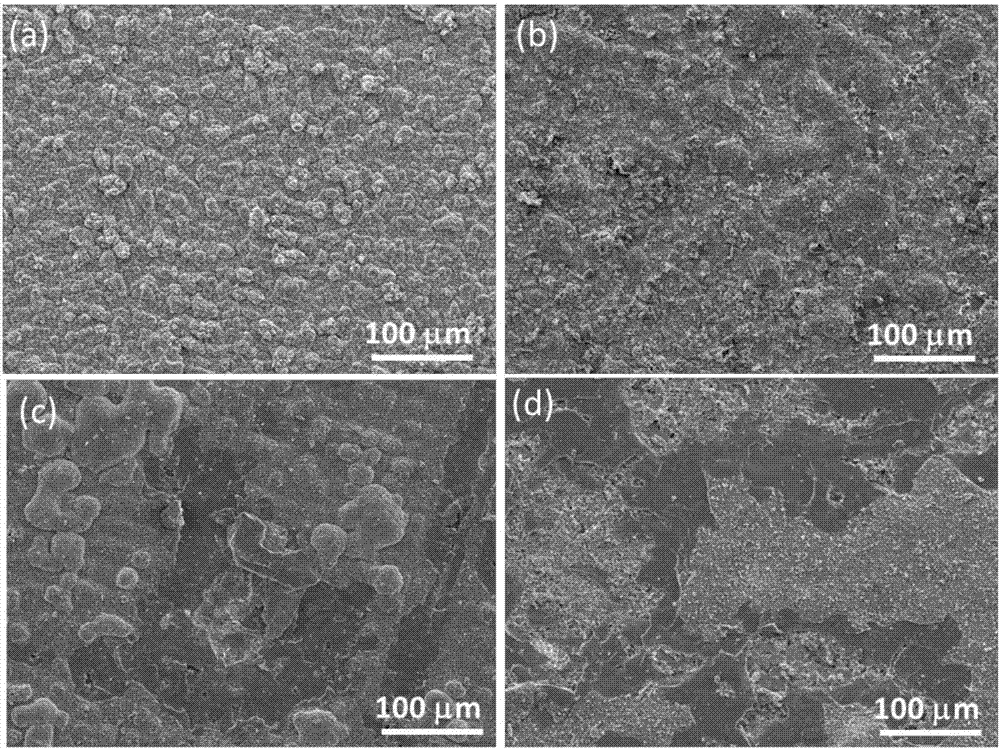

Niobium-containing high-carbon nickel-iron-based alloy and preparation method thereof

The invention provides a niobium-containing high-carbon nickel-iron-based alloy and a preparation method thereof. The niobium-containing high-carbon nickel-iron-based alloy comprises the following chemical components of C, Cr, Fe, Nb, Mn, Co, a small amount of RE (Y or Ce) and Ni. The niobium-containing high-carbon nickel-iron-based alloy has a gamma phase and a carbide phase formed by Cr23C6, and the volume fraction of the carbide phase is 14%-20%. The niobium-containing high-carbon nickel-iron-based alloy and the preparation method thereof are characterized in that by adding a proper amount of Nb, the alloy has a low oxidation rate and high oxidation film peeling resistance under a high-temperature oxidation environment with the using temperature being lower than 1100 DEG C, and the alloy is suitable for manufacturing components such as high-temperature cracking pipes in petrochemical units and pulverized coal fired boiler overheater or reheater pipes. Besides, as for the alloy, a large amount of Fe replaces part of Ni, so that the production cost is low, and the remarkable price advantage is achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Composite cermet coating for superalloy protection and preparation method thereof

ActiveCN108796461BHigh coefficient of thermal expansionImprove peel performanceVacuum evaporation coatingSputtering coatingThermal dilatationSputtering

The invention discloses a composite metal ceramic coating for high-temperature alloy protection and a preparing method of the composite metal ceramic coating. The coating comprises a face layer and abottom layer with a nano columnar crystal structure. The face layer comprises at least two metal ceramic sub layers, and a metal parent phase and a dispersed distribution nitride ceramic phase are specifically included. In the direction from the surface of the composite metal ceramic coating to an alloy matrix, the doping amount of the nitride ceramic phase is gradually reduced, and the distribution interval of the volume fraction of the nitride ceramic phase is 0.1-60%. According to the preparing method of the coating, magnetic control sputtering is adopted for preparing a bottom layer coating, and then, non-balance reaction magnetic control sputtering is utilized for preparing the face layer of the doped ceramic phase. Through the structure, the heat expansion coefficient of the coatingis gradually increased from top to bottom, jumping changes of the heat expansion coefficient on the coating / oxide film interface are reduced, accordingly, the heat stress in an oxide film in the heatcirculation process is relieved, and the capability of oxide film peeling resisting of the coating in the heat circulation is enhanced.

Owner:JINAN UNIVERSITY

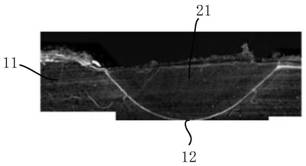

Film uncovering method

PendingCN113013080AAvoid risk of damageReduce adhesionSolid-state devicesSemiconductor/solid-state device manufacturingPolymer scienceSilicone tape

The invention relates to a film uncovering method which comprises the following steps: providing a substrate to which a protective adhesive tape is attached, forming a notch at the edge of the substrate, and enabling the protective adhesive tape to completely coincide with the notch; pressing the film uncovering adhesive tape on the protective adhesive tape in a non-thermal pressing manner; and using the film stripping mechanism for tearing the film uncovering adhesive tape from the notch position, and removing the protective adhesive tape from the substrate. Under the conditions of no heating and no auxiliary device, the protective adhesive tape is successfully removed from the substrate, the protective adhesive tape made of a soft material is conveniently selected to protect the substrate, the risk of damage to the substrate in the processing process is avoided, the product quality is ensured, and the film uncovering cost is reduced.

Owner:SEMICON MFG ELECTRONICS (SHAOXING) CORP

Precleaning method of reaction system

InactiveCN101391258BGood removal effectReduce time spent on pre-cleaningSemiconductor/solid-state device manufacturingCleaning using gasesVacuum pumpingReaction temperature

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A method to enhance the wear resistance of concrete in thermal environment

The invention provides a method enhancing abrasive resistance of concrete in thermal environments. The method enhancing abrasive resistance of concrete in thermal environments comprises spreading steel fibers on a concrete face layer about to solidify, and then performing floating and grinding scattering process to form crisscross steel fibers on the concrete face layer. The method enhancing abrasive resistance of concrete in thermal environments has the advantages of being capable of effectively restraining cracking of face layer concrete and capable of improving straining resisting capability, stripping resisting capability, breaking resisting capability and mechanical shock resisting capability. Besides, the method further has the advantages of being fast in construction and easy to operate, and constructed concrete is smooth in surface, corrosion-free, crack-free and abrasion resisting.

Owner:PANGANG GRP ENG TECH

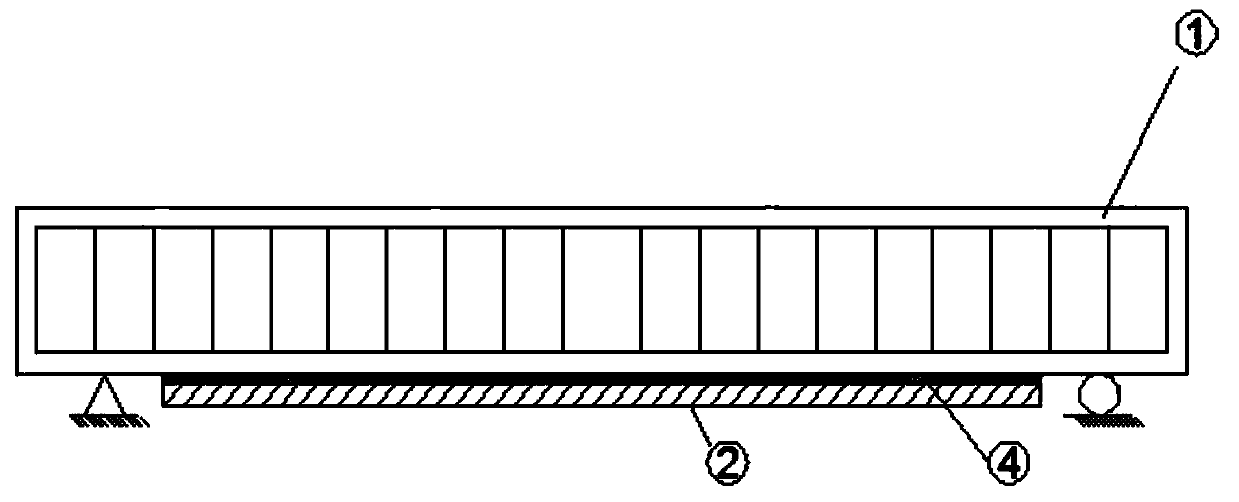

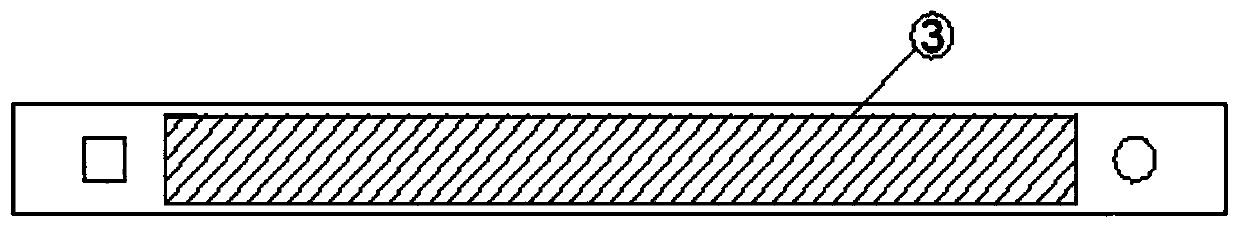

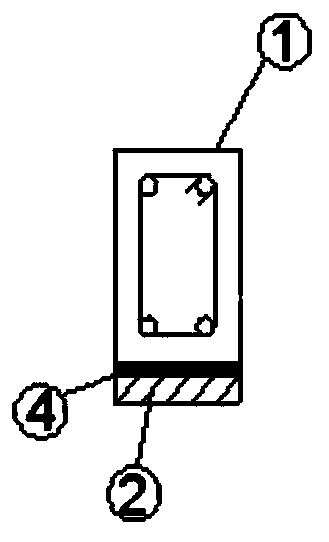

A kind of structural adhesive containing quartz sand, preparation method and application thereof

ActiveCN110272697BRaise the interface stressGood interface stress transfer effectNon-macromolecular adhesive additivesBuilding repairsAdhesive cementConcrete beams

The invention discloses a structural adhesive containing quartz sand. The structural adhesive is prepared from, by weight, 1-3 parts of an adhesive, 1-3 parts of a curing agent, 2.0-2.8 parts of quartz sand and 0.5-0.7 part of steel fibers. The invention also provides a preparation method and application of the structural adhesive containing the quartz sand. The structural adhesive containing the quartz sand is applied to a steel-bonded reinforced concrete beam so that the interface stress between a steel plate and a concrete beam in the steel-bonded reinforced concrete beam can be effectively improved, the steel plate can bear the load of a tension zone of the concrete beam to a greater degree, the effect of the adhered steel plate is fully played, and the reinforcing effect is improved.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Arched bearing platform of fluidized roaster and pouring method of arched bearing platform

ActiveCN105241253AStable structureIncreased load-bearing capacityCharge supportsFiberCombustion chamber

The invention discloses an arched bearing platform of a fluidized roaster and a pouring method of the arched bearing platform. The arched bearing platform comprises a bearing platform main body and a supporting table; the bearing platform main body is fastened with the supporting table through an L-shaped fastening surface; the bearing platform main body is formed through layered pouring from a plurality of layers of different castables, and the various layers are spaced by hydrophobic fiber plates; air holes formed in the bearing platform main body are connected by use of wear-resistant and high temperature-resistant high aluminum ceramic tubes at the junctions of different material layers; as the hydrophobic fiber plates are added, a cooperation structure of the bearing platform main body and the supporting table is improved and steel fibers different in content are added to the castables, the arched bearing platform is capable of reliably bearing the weight of materials in a roasting chamber and a high-frequency vibration load during fluidized roasting, and also capable of effectively preventing the materials from dropping into a combustion chamber at the bottom from the roasting chamber.

Owner:CMCU ENG

Structural adhesive containing quartz sand, preparation method and application thereof

ActiveCN110272697ARaise the interface stressGood interface stress transfer effectNon-macromolecular adhesive additivesBuilding repairsFiberAdhesive

The invention discloses a structural adhesive containing quartz sand. The structural adhesive is prepared from, by weight, 1-3 parts of an adhesive, 1-3 parts of a curing agent, 2.0-2.8 parts of quartz sand and 0.5-0.7 part of steel fibers. The invention also provides a preparation method and application of the structural adhesive containing the quartz sand. The structural adhesive containing the quartz sand is applied to a steel-bonded reinforced concrete beam so that the interface stress between a steel plate and a concrete beam in the steel-bonded reinforced concrete beam can be effectively improved, the steel plate can bear the load of a tension zone of the concrete beam to a greater degree, the effect of the adhered steel plate is fully played, and the reinforcing effect is improved.

Owner:EAST CHINA JIAOTONG UNIVERSITY

A knocking and stripping device for filter element impurity

ActiveCN108771913BImprove peel performanceSimple structureDispersed particle filtrationTransportation and packagingConvex structureEngineering

The invention discloses a device for knocking and stripping filter core impurities, which comprises a rotating shaft, a power disc, an active rod, a percussion head, a working table, a filter element placement plate and a passive rod. The power disc is installed on the rotating shaft, and the outer circumference of the power disc is There are a plurality of teeth on the top, the teeth are arc-shaped convex structures, and the gaps between adjacent teeth are connected. One side of the rotating shaft is provided with a fixed shaft, and the fixed shaft is parallel to the rotating shaft. A shaft sleeve that rotates independently of it is installed, and an active rod and a passive rod are fixed on the outer surface of the shaft sleeve. The beneficial effect of the present invention is that the filter element can be knocked in all directions by setting multiple sets of power discs and knocking heads. , improve the peeling effect of dust and impurities, and under the knocking of the beating head, the filter element can rotate at a certain angle, so that the filter element can be rotated while being knocked, and the peeling effect of dust and impurities is improved. The overall structure is simple, easy to operate, and has the advantages of Very practical.

Owner:李冰雪

Surface gradient protective coating and its preparing method

The invention relates to surface gradient protecting coat and manufacturing method. It uses protecting coat system design to adjust MoB and CoCr basis component content proportion without changing its essential component, make damping transition thermal spray coating material, and gain gradient thermal spray coating. The gradient protecting coat of the invention can obviously increase coating anti thermal shock property, and corrosion-resisting properties. Thus it can be used as surface protecting coat for the immerged and stable rollers used in continuous dip coating high aluminum zinc production line.

Owner:SHANGHAI BAOSTEEL EQUIP MAINTENANCE CO LTD

Curable composition

InactiveUS20210040258A1Good shape retentionThe implementation process is simpleLiquid surface applicatorsPolyurea/polyurethane coatingsPrepolymerComposite material

An object of the present invention is to provide a masking material having excellent peeling properties even if the drying step is reduced, preferably without the drying step. There is provided a curable composition a prepolymer (A) having a urethane / urea bond and at least two acrylic polymerizable groups, and solid particles (B), and having a viscosity at 40° C. of at least 10 Pa·s and at most 300 Pa·s.

Owner:SUNSTAR ENG AMERICAS INC

Manufacturing method of heat-shrinkable self-adhesive vacuum plating protective film

The invention discloses a manufacturing method of a heat-shrinkable auto-adhesive vacuum plating protective film. The manufacturing method comprises the following steps: (1) firstly, synthesizing polyvinyl polyacrylate; (2) then, performing melt blending on the polyvinyl polyacrylate, polyethylene resin, a first initiator and an antioxidant according to a weight proportion, extruding and granulating, and finally performing extrusion film blowing and UV curing to obtain the heat-shrinkable auto-adhesive vacuum plating protective film. The manufactured protective film wraps a local part, required to be protected, of a vacuum plating component in a heat shrinkage way; in a vacuum plating process, the surface of the film does not crease and deform, the adhesion force is stable, the attachment property is good, the re-peeling performance is excellent, the phenomenon of adhesive residue is avoided, and the barrier and mechanical properties are excellent; the heat-shrinkable auto-adhesive vacuum plating protective film is an excellent vacuum plating protective film material which is non-toxic, environmentally-friendly, safe and practical.

Owner:WUXI HAITE NEW MATERIAL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com