Four-station scale breaker

A phosphorus machine and phosphorus breaking technology, which is applied in cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of high bending deformation resistance of steel strips, lower production efficiency, and small elongation, so as to increase the opening of cracks, The effect of improving product quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

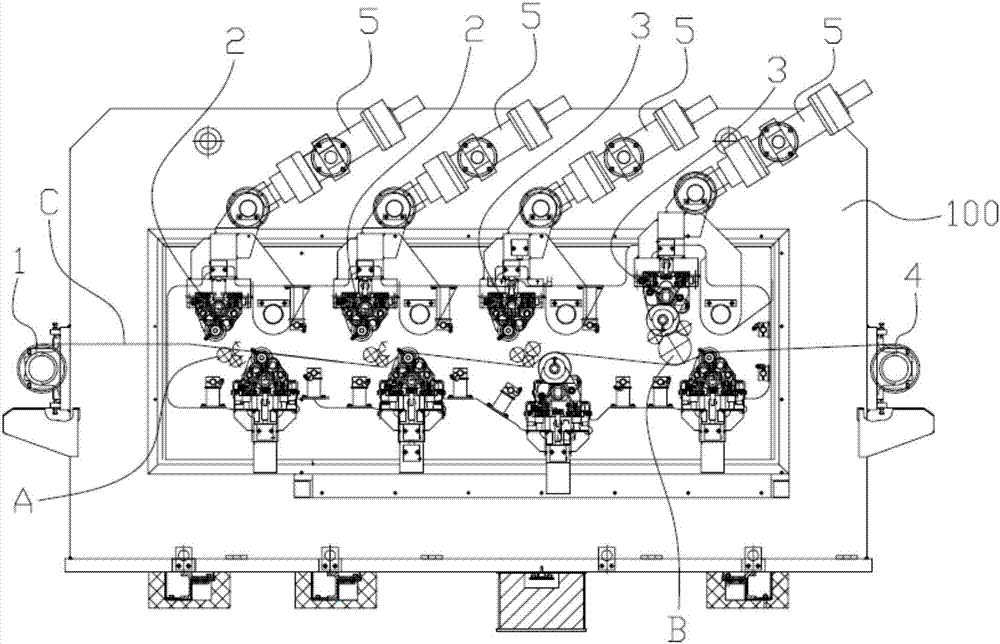

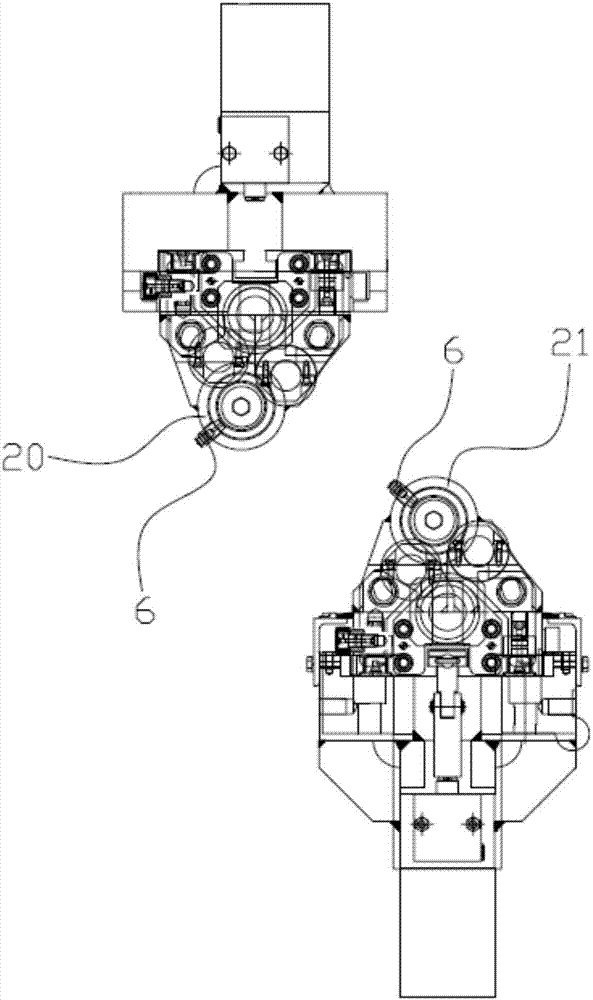

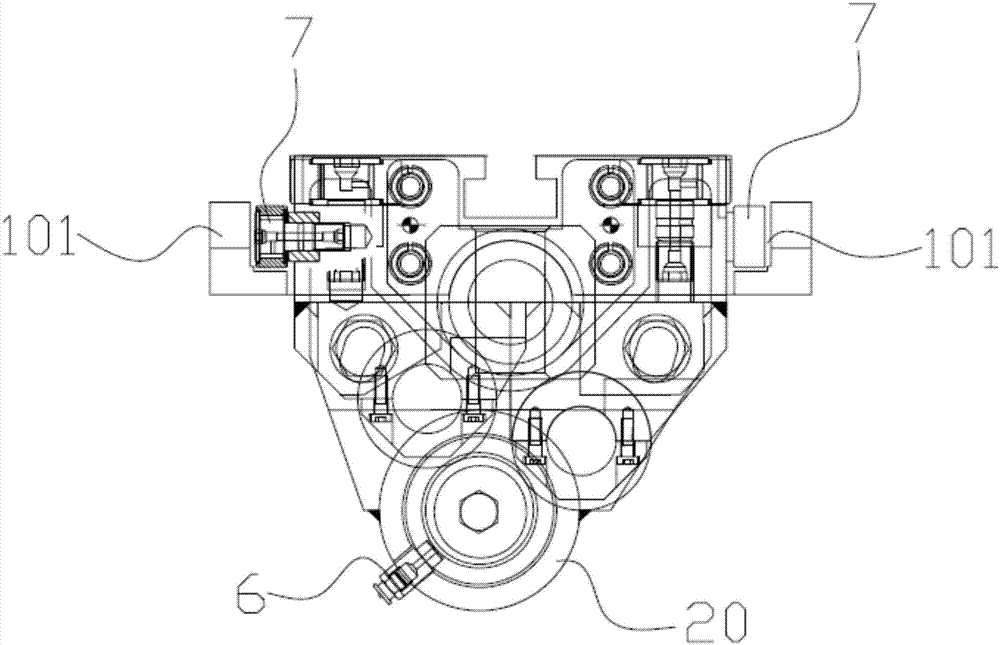

[0026] Such as figure 1 As shown, the four-station phosphorus breaker of the present invention includes a frame 100 , a first tension roller 1 disposed on the frame 100 , two bending roller groups 2 , two straightening roller groups 3 , and a second tension roller 4 .

[0027] Specifically, the first tension roller 1 is arranged on one side in the longitudinal direction of the frame 100, the second tension roller 4 is arranged on the other side in the longitudinal direction of the frame 100, two bending roller groups 2 and two straightening roller groups 3 It is arranged between the first tension roller 1 and the second tension roller 4 . The raw steel coil fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com