Rust removing technology for black-skin steel reel

A technology of steel coil and black skin, applied in the field of derusting process of black steel coil, can solve the problems of lowering the quality standard of cold-rolled final products, narrowing the usable range of cold-rolled products, and adverse effects on the quality of cold-rolled products, achieving The effect of increasing the crack opening, enhancing the rust removal ability and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

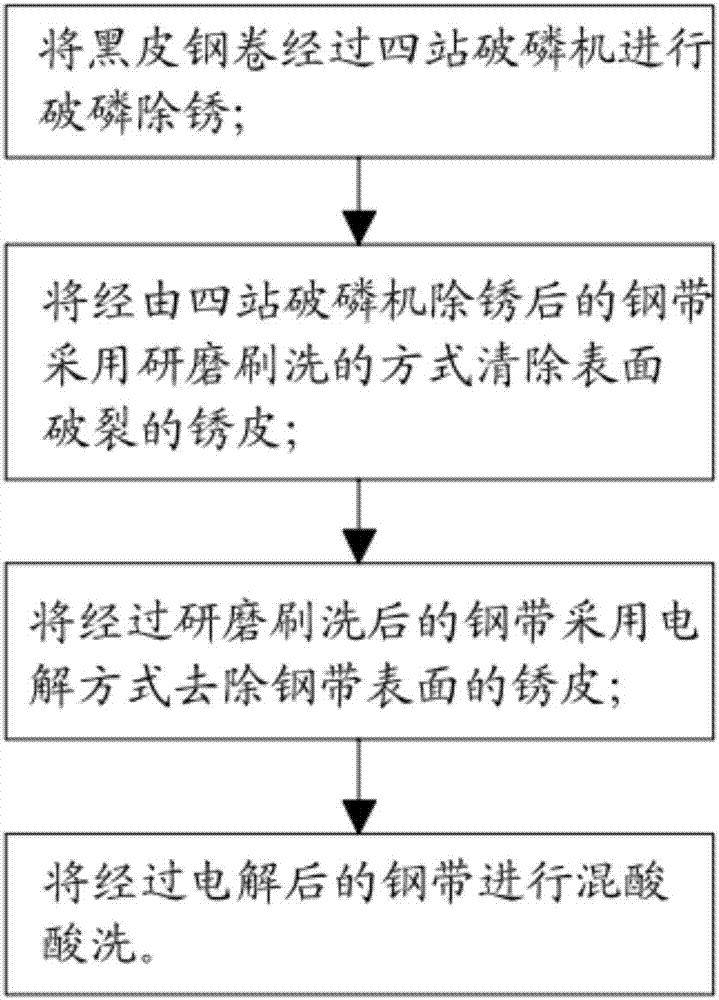

[0037] Please figure 1 and figure 2 , black steel coil derusting process of the present invention comprises the following steps:

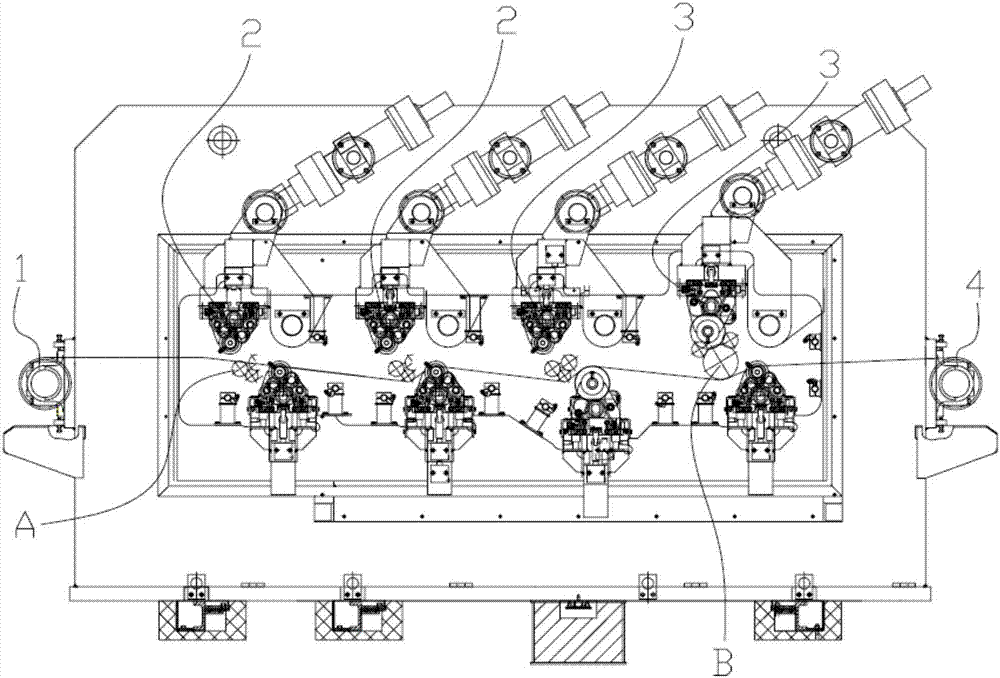

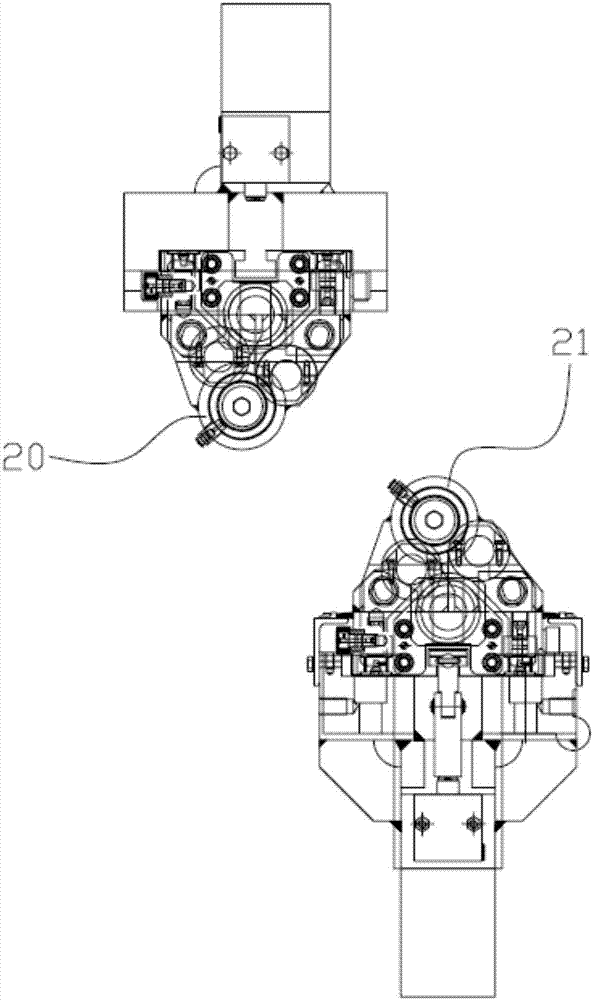

[0038] First of all, the black steel coils are broken through the four-station phosphorus breaker for phosphorus and rust removal; among them, the four-station phosphorus breaker includes the first tension roll 1, two bending roll sets 2, two straightening roll sets 3, and the second Tension roll 4; each bending roller group 2 comprises upper bending roller 20 and lower bending roller 21, and the diameter of upper bending roller 20 is equal to the diameter of lower bending roller 21, and each straightening roller group 3 comprises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com