Structural adhesive containing quartz sand, preparation method and application thereof

A technology of quartz sand and structural adhesive, which is applied in the direction of building construction, building maintenance, non-polymer adhesive additives, etc., can solve the problem of lack of new structural adhesives, etc., and achieve the effect of improving the reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

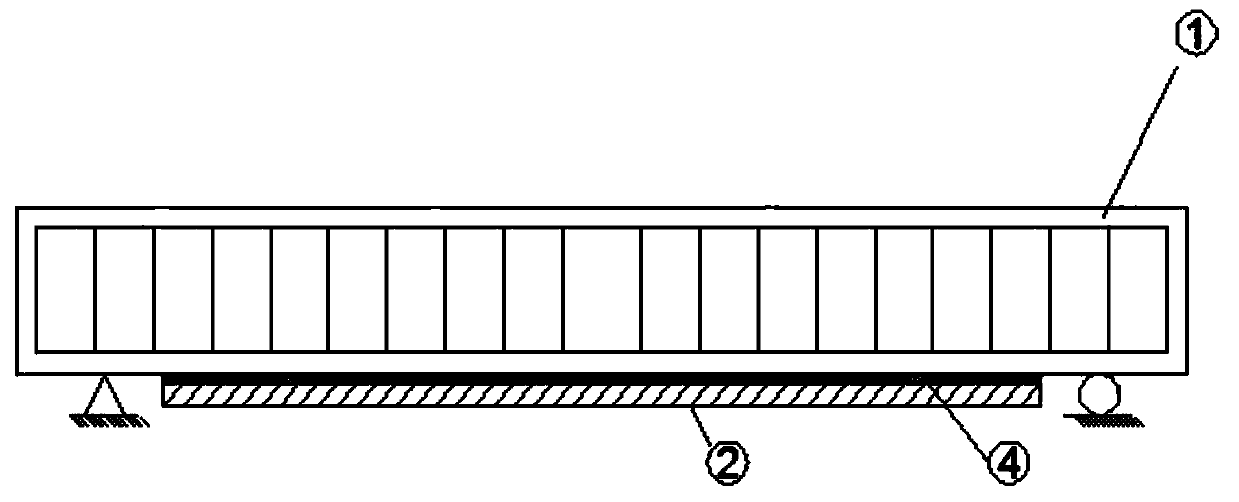

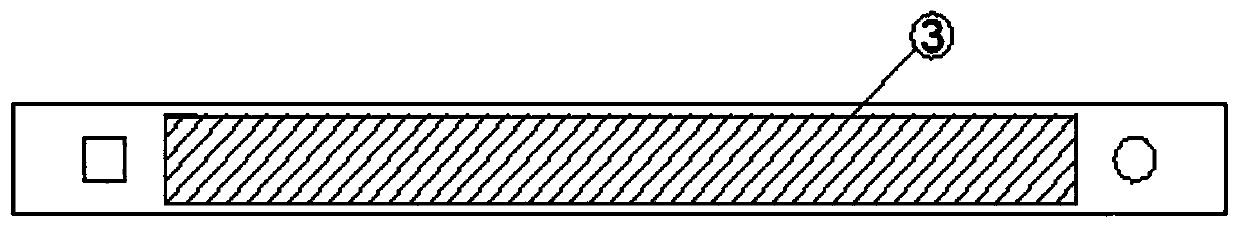

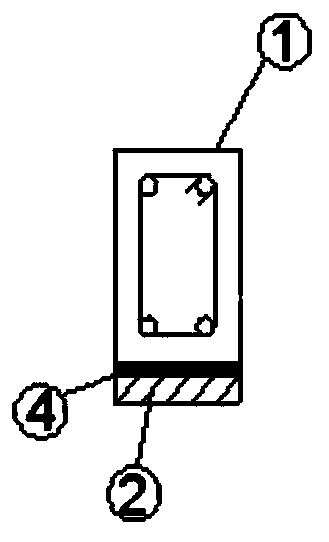

Image

Examples

Embodiment 1

[0022] A structural adhesive containing quartz sand, which is composed of the following components in parts by weight: 2 parts of adhesive, 2 parts of curing agent, 2 parts of quartz sand, and 0.7 parts of steel fiber; the adhesive and curing agent are JGN type two-component adhesive steel Reinforce the structural glue, the specification of quartz sand is 300 mesh, the diameter of steel fiber is 0.08mm, and the length is 2mm.

[0023] Concrete preparation method is implemented according to the following steps:

[0024] Weigh 2 parts of adhesive, 2 parts of curing agent, 2 parts of quartz sand, and 0.6 parts of steel fiber; pour the weighed adhesive and curing agent into a clean container, stir well until the color is uniform, and then add quartz sand into it and steel fibers, fully stirred evenly to obtain the structural glue containing quartz sand.

Embodiment 2

[0026] A structural adhesive containing quartz sand, which consists of the following components in parts by weight: 1 part of adhesive, 3 parts of curing agent, 2 parts of 150-mesh quartz sand, and 0.5 part of steel fiber; the adhesive and curing agent are JGN type two-component Bond steel to reinforce structural glue, the specification of quartz sand is 200 mesh, the diameter of steel fiber is 0.08mm, and the length is 2mm. The specific preparation method is the same as in Example 1, except that the formula in Example 1 is changed into the formula in Example 2.

Embodiment 3

[0028] A structural adhesive containing quartz sand, which is composed of the following components in parts by weight: 3 parts of adhesive, 1 part of curing agent, 2 parts of quartz sand, and 0.6 parts of steel fiber; the adhesive and curing agent are JGN type two-component adhesive steel Reinforce the structural glue, the specification of quartz sand is 150 mesh, the diameter of steel fiber is 0.08mm, and the length is 2mm.

[0029] The specific preparation method is the same as in Example 1, except that the formula in Example 1 is changed into the formula in Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com