Arched bearing platform of fluidized roaster and pouring method of arched bearing platform

A fluidized roasting and load-bearing platform technology, which is applied to furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of large maintenance costs and poor economic benefits, achieve good heat preservation effects, improve thermal efficiency, and improve resistance The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

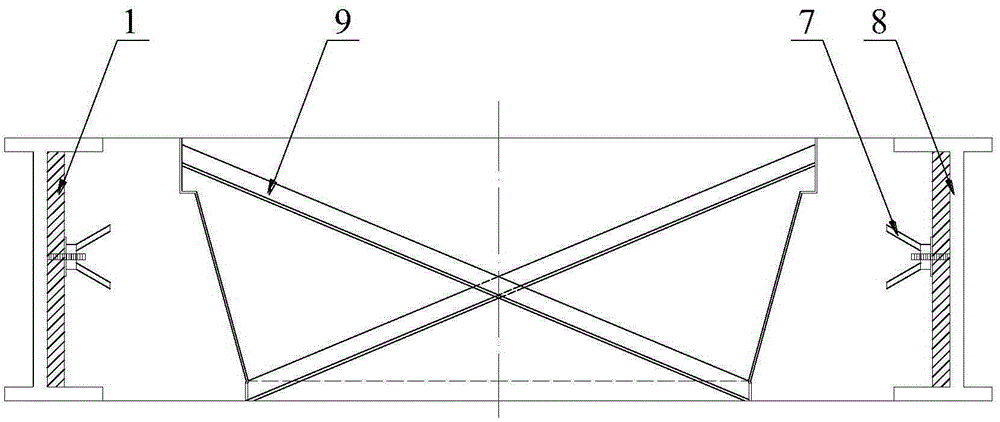

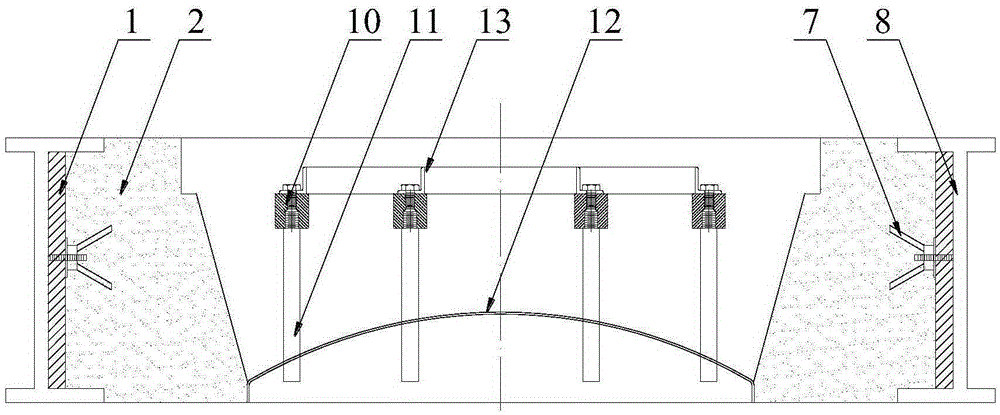

[0034] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0035] As shown in the figure, the arched load-bearing platform of the fluidized roaster in this embodiment includes a main body of the load-bearing platform and a support platform 2 for supporting the main body of the load-bearing platform, and the support platform 2 is arranged along the inner wall of the furnace shell 8 of the roaster , the main body of the load-bearing platform is arranged on the inner side of the support platform 2, and the main body of the load-bearing platform is provided with several ventilation holes 14 that communicate the roasting chamber with the combustion chamber; The layer is in the shape of a spherical arch, and a hydrophobic fiberboard 4 is provided between two adjacent casting layers; a high-alumina ceramic tube 6 is provided at the junction of different material layers in the vent hole 14, and a high-alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com