Composite cermet coating for superalloy protection and preparation method thereof

A composite metal and ceramic coating technology, applied in the direction of metal material coating process, coating, vacuum evaporation plating, etc., to achieve the effect of reducing thermal stress, relieving thermal stress, and strong resistance to thermal cycle spalling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

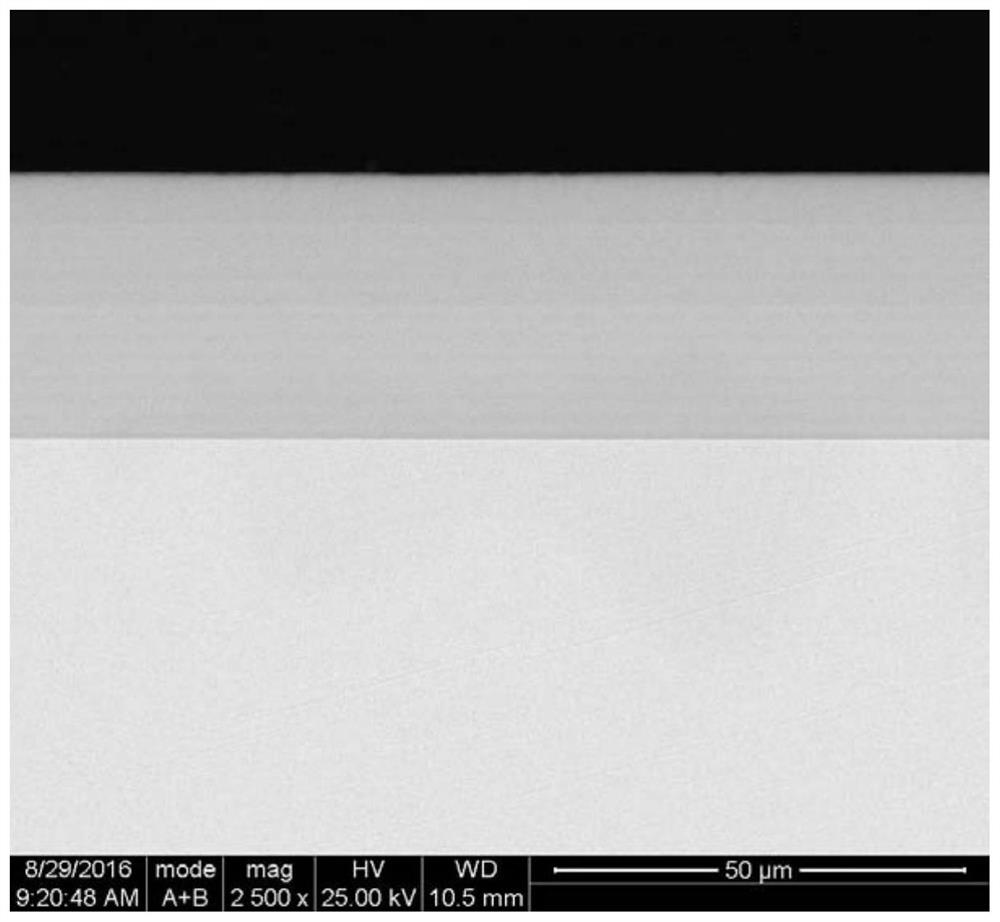

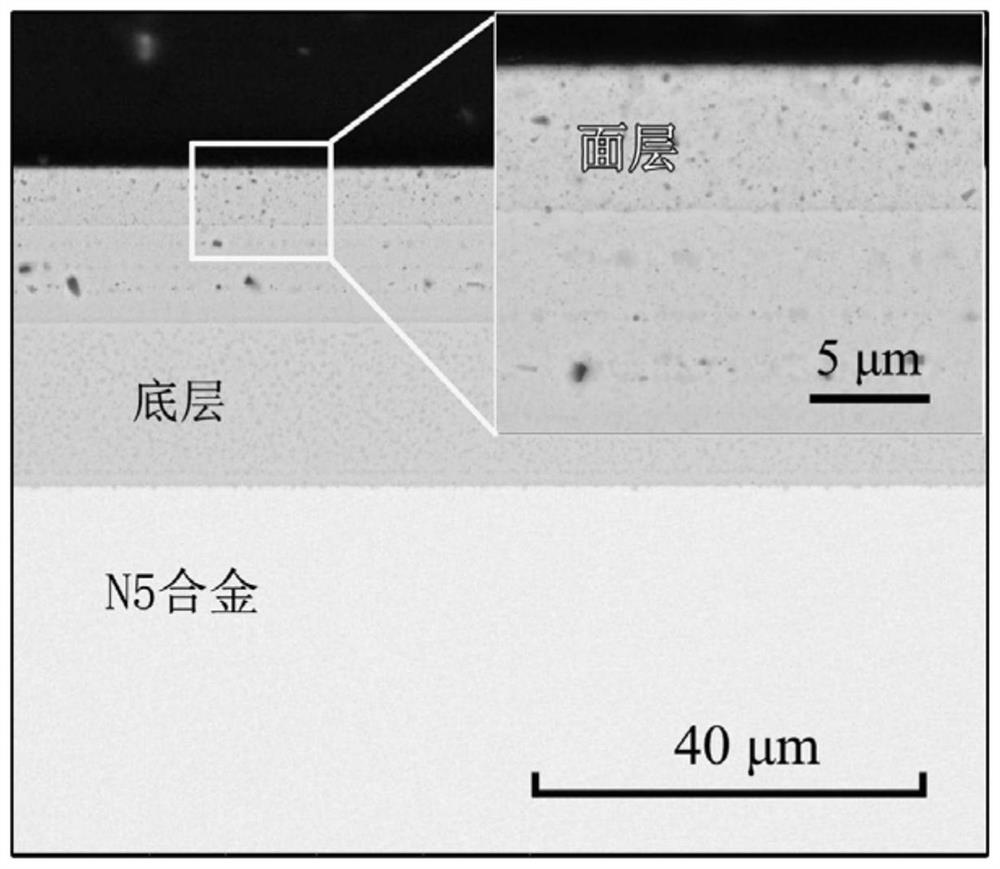

[0046] Taking the second-generation single crystal superalloy N5 as the alloy matrix sample, the nanocrystalline NiCrAlYHfSi bottom layer was prepared on the surface of the alloy N5 by magnetron sputtering, and then the reaction gas N2 , and by controlling N 2 The flux in the deposition process is used to prepare the surface layer of the composite cermet coating, and the specific preparation process is as follows:

[0047] (1) Prepare N5 single crystal alloy and NiCrAlYSiHf target material by vacuum smelting method, the target material composition is: 25wt% Cr, 10wt% Al, 0.5wt% Y, 0.5wt% Hf, 0.5wt% Si, balance For you.

[0048] (2) Before coating, the alloy was polished with sandpaper, and then mechanically polished with a diamond polishing paste with a specification of 2.5 μm. Finally, the sample was ultrasonically cleaned with acetone and alcohol, and dried for later use.

[0049] (3) Prepare the bottom layer of nano-columnar crystal NiCrAlYHfSi on the surface of N5 alloy b...

Embodiment 2

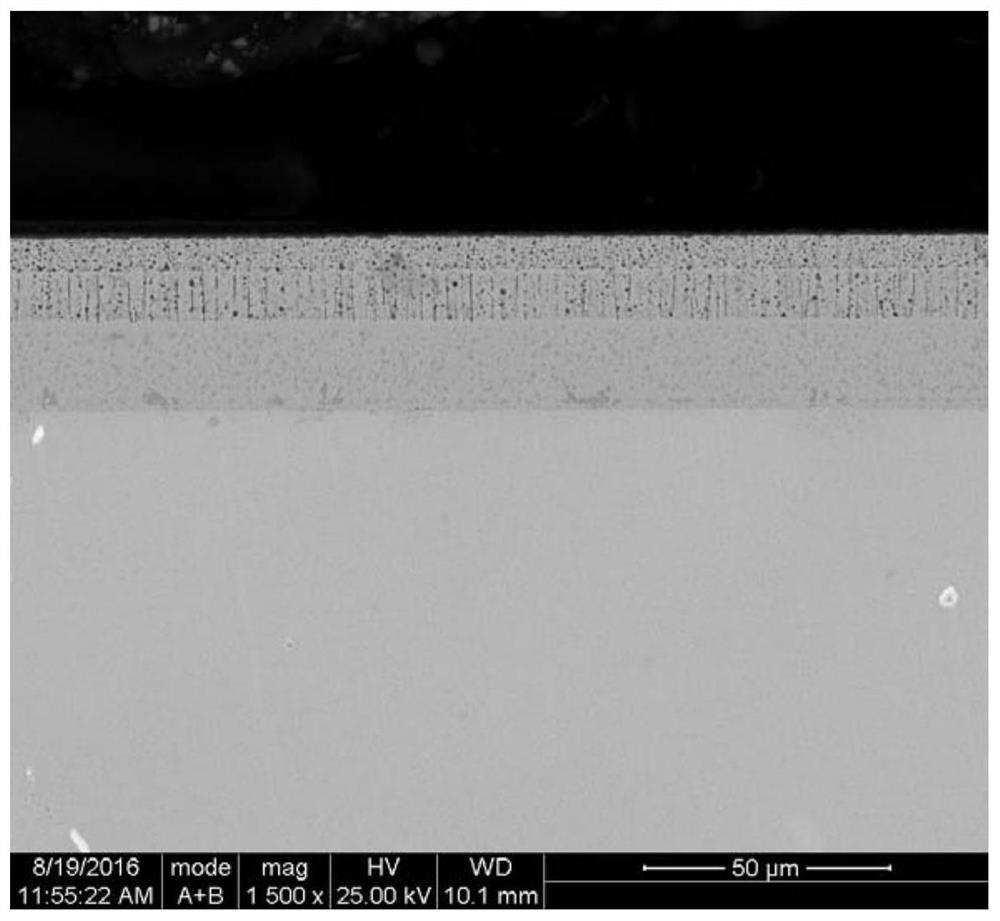

[0069] The experimental conditions and steps refer to Example 1. The difference from Example 1 is that the alloy matrix sample is K417G, and the N 2 The partial pressure is: 0.1Pa for the first 2 hours, and 0.12Pa for the next 1.5 hours; the total thickness of the surface layer is 12-14 μm, and the thickness of the bottom layer is 15-18 μm. The volume fractions of AlN are: 28vol.%, 15vol.%. Figure 5 It is the microscopic morphology of the surface layer of the coating at the nanometer scale, and it can be seen that the grain size of the surface layer is 4-10nm. The content of the main elements in the two sublayers of the coating containing nitrides detected by energy spectrum analysis is 59Ni–23Cr–11Al–7N (wt.%); 62Ni–23Cr–11Al–4N (wt.%). Figure 6 The SEM interface picture of its composite metal-ceramic coating oxidized at 1000°C for 100h, by Figure 6 It can be seen that there are obvious Cr at the interface between the coating and the alloy 23 C 6 A phase barrier layer ...

Embodiment 3

[0071] See Example 1 for the experimental conditions and steps. The difference from Example 1 is that the nickel-based superalloy K438 is used as the substrate, and the N 2 The partial pressure is 0.1Pa for the first 2h and 0.13Pa for the last 1.5h, and the total deposition is 3.5 hours; the total thickness of the surface layer is 10-12μm, and the thickness of the bottom layer is 15-18μm. Energy spectrum analysis shows that along the direction from the coating surface to the substrate sample, the main element contents in the two sublayers of the surface layer are 59Ni–22Cr–11Al–7N (wt.%) and 62Ni–24Cr–11Al–3N (wt.%) .%). After the coating was annealed at 1000 °C for 1 h, the main constituent phases were γ / γ' and AlN phases. The hardness of the coating was measured after the surface oxide was removed, and the hardness range was about 740±5HV. according to Figure 7 It can be seen that after the coating is oxidized at 1000°C for 100 hours, a continuous and dense aluminum oxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com