Metal anticorrosive coating and preparation method and application thereof

A metal anti-corrosion and metal product technology, applied in structural elements, building components, buildings, etc., can solve problems affecting metal anti-corrosion coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

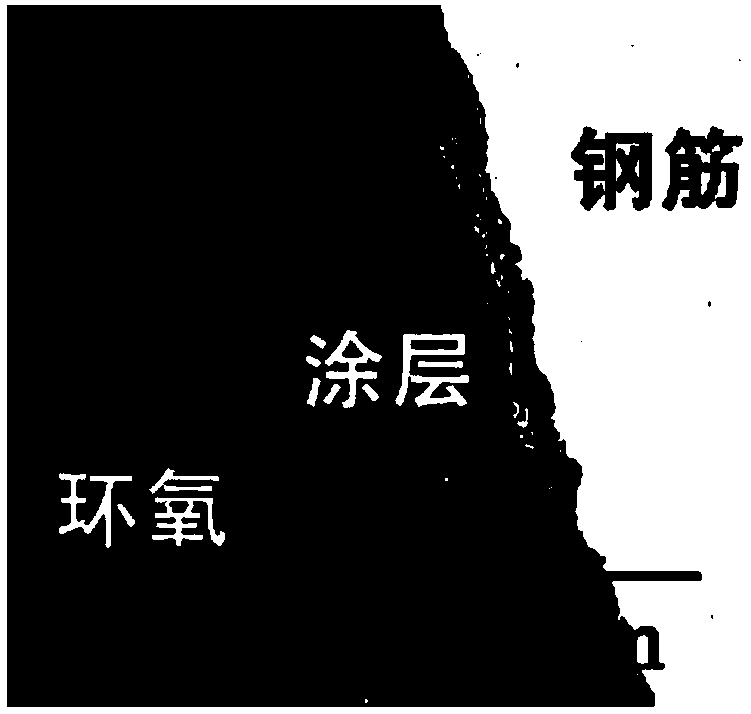

[0071] Embodiment 1: Preparation of double-layer thermal expansion coefficient gradient structure coating

[0072] 1) Grinding for the first time: weighing enamel powder, thermal expansion regulator, flux, adhesive, the content of said enamel powder is 40-90 parts, preferably 60-75 parts; the content of thermal expansion regulator is 5-90 parts 40 parts, preferably 10 to 25 parts; the content of flux is 1 to 20 parts, preferably 5 to 12 parts; the content of binder is 0.5 to 12 parts, preferably 2 to 6 parts, and the content is in weighing scale. and ground into powder.

[0073]2) Prepare the mixture: mix and stir the above four raw materials with water to obtain the mixture;

[0074] 3) grinding for the second time: the mixture obtained in step 2) is dried and ground into powder;

[0075] 4) High-temperature reaction: react the mixture obtained in step 3) in a high-temperature furnace at 600° C. for 15 minutes;

[0076] 5) The third grinding: grinding the mixture after hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com