Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Guaranteed Purity Requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

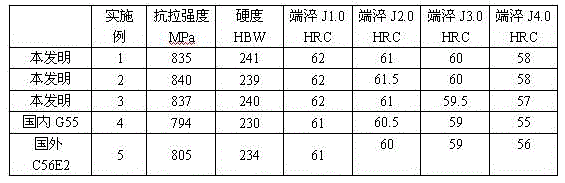

Steel for carbon hub bearing of microalloying car and production method thereof

InactiveCN105568134AGuaranteed normal growthImprove composition segregationRolling contact bearingsHubsChemical compositionMetallurgy

The invention relates to steel for a carbon hub bearing of a microalloying car. The steel comprises the following chemical components: 0.45-0.70% of C, 0.10-0.50% of Si, 0.30-0.70% of Mn, 0.20-0.60% of Cr, P not more than 0.025%, 0.003-0.030% of S, Mo not more than 0.1%, Ni not more than 0.2%, Al not more than 0.04%, Cu not more than 0.3%, Ca not more than 0.001%, Ti not more than 0.003%, O not more than 0.001%, As not more than 0.04%, Sn not more than 0.03%, Sb not more than 0.005%, Pb not more than 0.002%, and the balance of Fe and inevitable impurities. A production method comprises an electric furnace or a converter-refining out of the furnace-VD or RH vacuum degassing-continuous casting-continuous rolling-sawing-cooling in heap-finishing-surface and internal flaw detection-packing. The steel for the hub bearing improves the mechanical performance, the element segregation and the structure uniformity, and belongs to a brand new hub bearing steel type.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

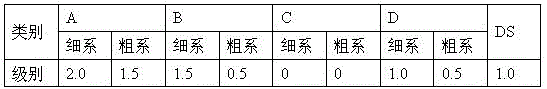

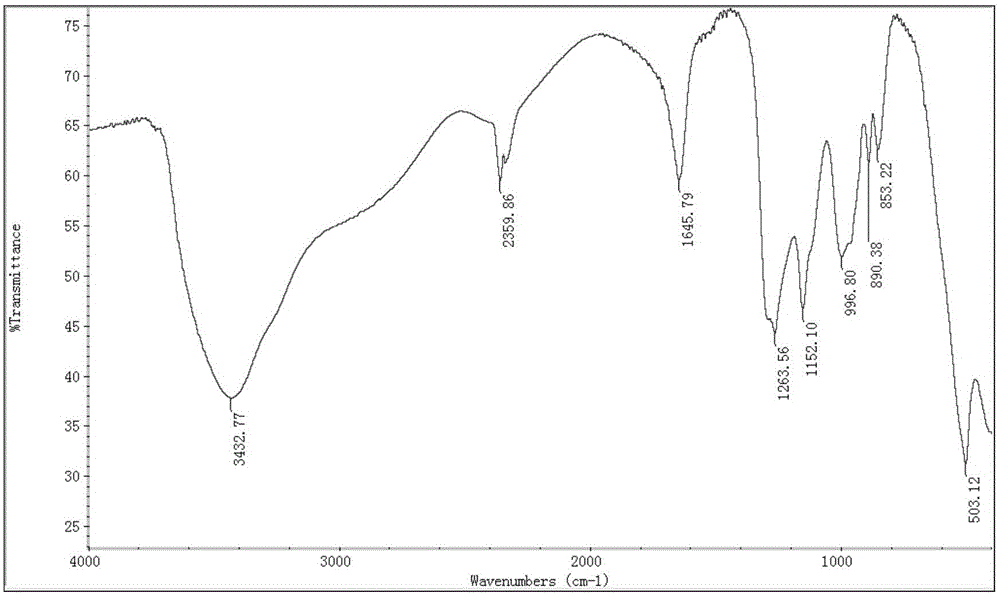

Method for preparing difluorophosphates

The invention belongs to the technical field of lithium-ion batteries and particularly relates to an efficient method for preparing difluorophosphates. The method comprises the following steps: metering a hexafluorophosphate solution with the concentration being 5wt% to 50wt% and a cyclosiloxane or an acetal, then, introducing the metered materials to a microchannel reactor, carrying out a reaction for 60 to 900 seconds at the temperature of 20 DEG C to 150 DEG C, carrying out membrane filtration on an obtained reaction solution, and then, carrying out concentrating and drying, thereby obtaining a corresponding difluorophosphate product. The method disclosed by the invention has the advantages that the process route is simple, the raw materials are readily available, the reaction efficiency is high, the energy consumption is low, the product purity is high, and the like.

Owner:JIUJIANG TINCI ADVANCED MATERIALS CO LTD

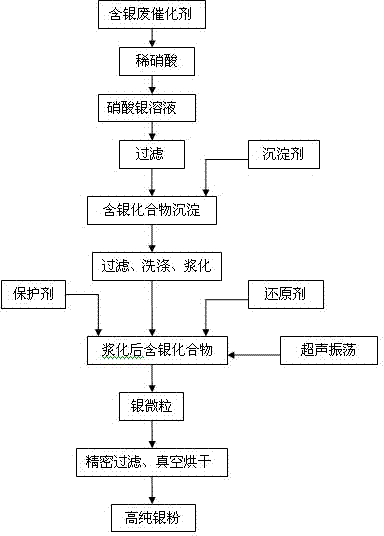

Method for producing high-purity silver powder by using silver-containing dead catalyst

InactiveCN103074500AHas a variety of characteristicsSolve the problem of energy consumptionProcess efficiency improvementDispersityPolyethylene glycol

The invention discloses a method for producing high-purity silver powder by using a silver-containing dead catalyst, and belongs to the technical field of noble metal refining. The method comprises the following steps: the silver-containing dead catalyst is used as a raw material, silver is dissolved and converted to silver nitrate solution by dilute nitric acid; a precipitant is added in the silver nitrate solution after the filtration; a silver-containing compound precipitate is pulped after being filtered and washed; one or two reagents are randomly chosen from hydrazine hydrate, hydrogen peroxide, sodium borohydride, formic acid, ascorbic acid, glucose, fatty aldehyde, fatty amine and formaldehyde as reducing agent; any one reagent is chosen from polyvinylpyrrolidone, cetyl trimethyl ammonium bromide, lauryl sodium sulfate, polyethylene glycol and between as a protective agent; silver ions are reduced to silver particles under the condition of ultrasonic oscillation; and the silver particles are precisely filtered, and are dried in vacuum to obtain the high-purity silver powder product. The method has the benefit that the high-purity silver powder product with high purity, high dispersity and high activity can be obtained, and has the advantages of stable product performance, high recovery rate and environmental friendliness.

Owner:HOOTECH

Preparation method for high-purity submicron lithium carbonate

ActiveCN105399115AImprove conversion efficiencyShorten the production cycleLithium carbonates/bicarbonatesPhysical chemistryIon exchange

The invention relates to the technical field of chemical separation and purification, especially to a preparation method for high-purity submicron lithium carbonate. The preparation method comprises the following steps: dissolving a crude lithium carbonate product in high-purity water to prepare lithium carbonate slurry; allowing the lithium carbonate slurry to enter a rotary packed bed and introducing CO2 gas into the rotary packed bed so as to prepare lithium bicarbonate liquid; allowing the lithium carbonate liquid to successively pass through a pretreated calcium-magnesium ion exchange resin apparatus and boron ion exchange resin apparatus so as to allow a second solution to be formed after removal of impurities containing calcium, magnesium and boron in the lithium bicarbonate liquid; uniformly mixing the second solution with a dispersant so as to form a third solution and adding the third solution into the rotary packed bed for a reaction so as to produce lithium carbonate precipitate; and drying the lithium carbonate precipitate so as to obtain a high-purity submicron lithium carbonate product. The preparation method employs crude lithium carbonate of the lithium salt industry as a raw material for preparation of the high-purity submicron lithium carbonate; and the raw material is more widely and easily available and cost for the raw material is greatly reduced.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Method for producing tetraammine chloride crystals by taking ethanol as solvent

InactiveCN102502894AAvoid introducingGuaranteed Purity RequirementsRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsFiltrationPetrochemical

The invention discloses a method for producing tetraammine chloride crystals by taking ethanol as a solvent, belonging to the technical field of petrochemical industry. The method comprises the following steps of: dissolving and transforming simple substance platinum serving as a raw material into a stable +4 valent chloroplatinic acid solution with royal water, and performing niter driving and acid driving treatment; controlling the final point of a reaction system to reduce the +4 valent chloroplatinic acid solution into a +2 valent chloroplatinous acid solution in a metastable state by taking hydrazine hydrate as a reducing reagent; adding ammonia water for aminating, complexing and coordinating the +2 valent chloroplatinous acid solution, and transforming into a tetraammine chloride solution; controlling the concentration of the tetraammine chloride solution, mixing the tetraammine chloride solution with ethanol serving as a crystalizing reagent, crystallizing, and quickly crystalizing and separating tetraammine chloride out of the solution; and performing suction filtration and drying to obtain a tetraammine chloride crystal product. The method has the beneficial effects of capability of ensuring the purity requirement of the product, stable and reliable product quality, high yield, mild reaction condition, easiness, practicability and environmental friendliness.

Owner:HOOTECH

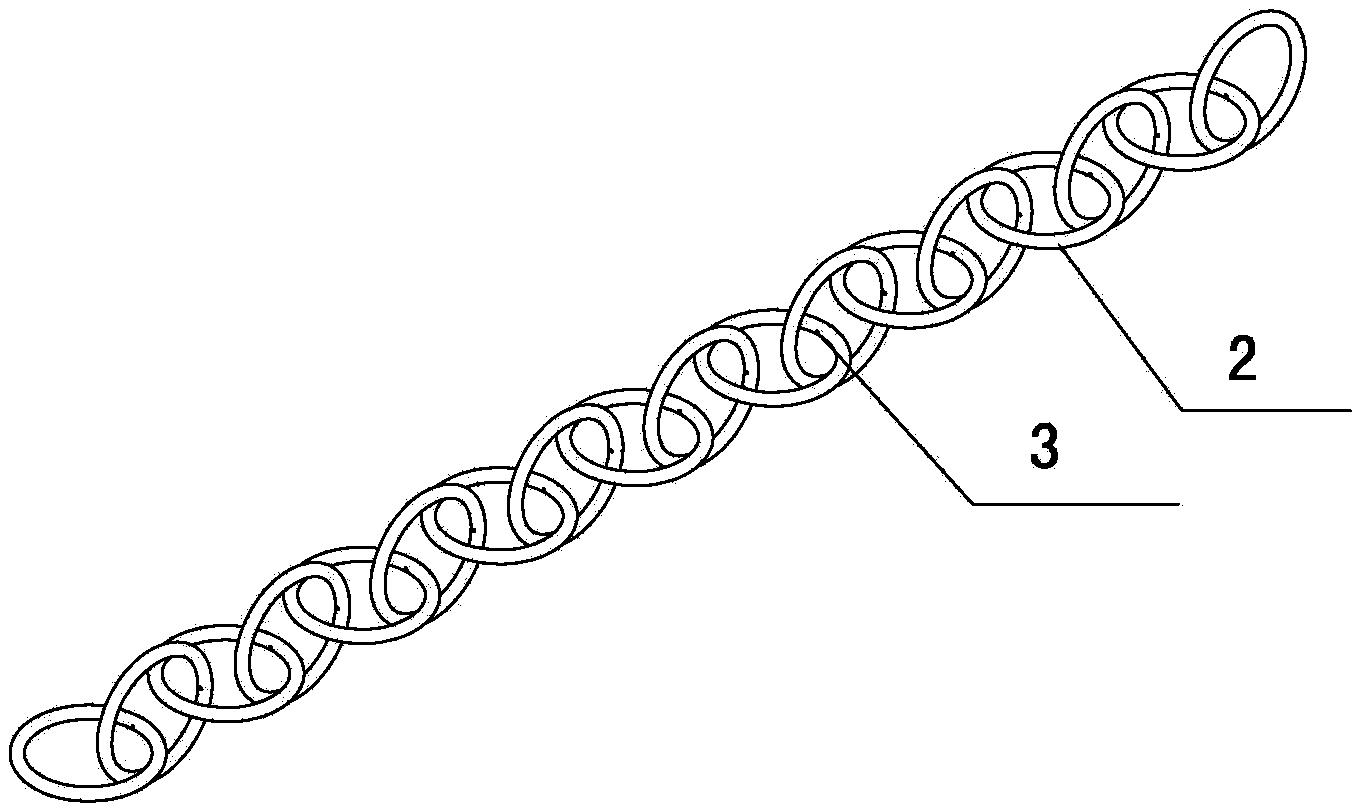

Seamless chain accessory processing method

ActiveCN103892528ARealize seamless processingGuaranteed aestheticsFoundry mouldsFoundry coresWaxPunching

The invention discloses a seamless chain accessory processing method. The method comprises the following steps: (1) manufacturing a silver mask; (2) manufacturing a casting mould; (3) manufacturing a wax mould; (4) finishing the wax mould; (5) binding a copper wire; (6) racking; (7) cleaning the wax mould; (8) performing primary electroforming; (9) performing primary electroforming cleaning; (10) performing secondary electroforming; (11) performing secondary electroforming cleaning; (12) punching; (13) dewaxing; (14) performing dewaxing cleaning; (15) removing silver; (16) performing silver removal cleaning. According to the method, seamless processing of chain accessories can be realized, the attractive appearance of the product can be guaranteed to the greatest degree, and the purity requirements of the product can be effectively met.

Owner:深圳市凯恩特珠宝首饰有限公司

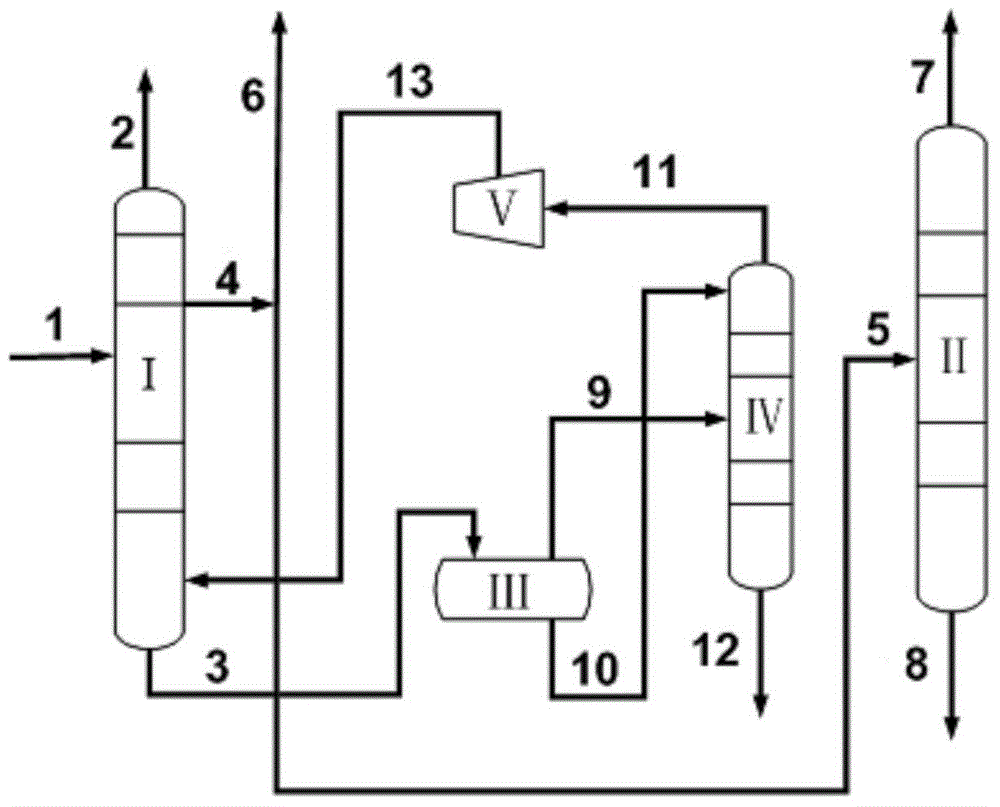

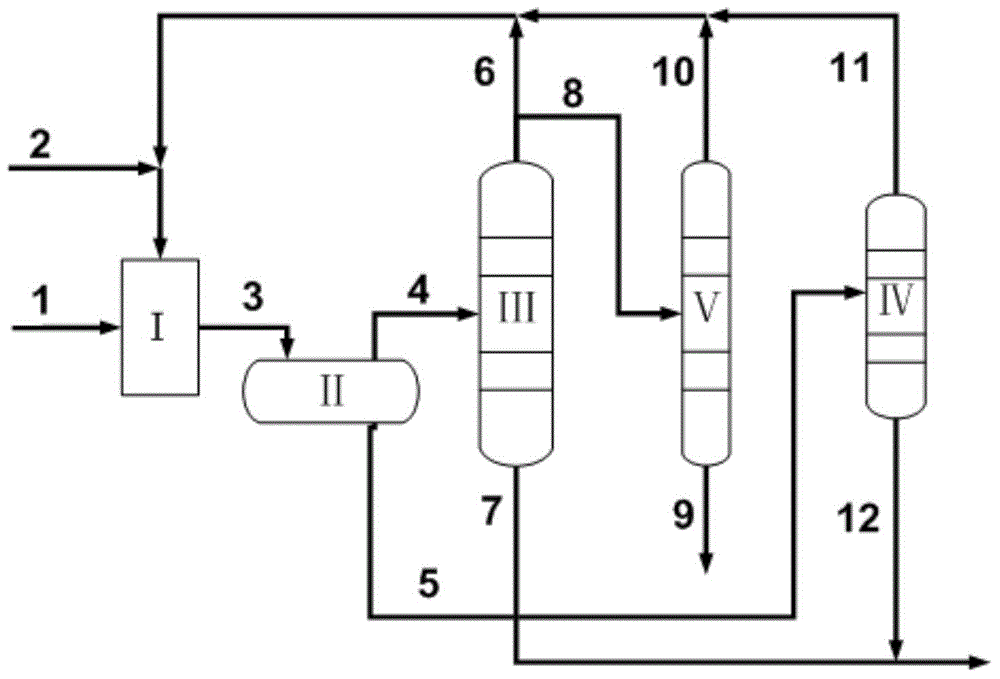

Propylene recovery method

ActiveCN105272806AReduce the amount of feedGuaranteed separation effectDistillation purification/separationHydrocarbonsHigh energyHigh pressure

The present invention relates to a propylene recovery method. A purpose of the present invention is mainly to solve the high energy consumption in the prior art. According to the present invention, the propylene recovery refining process containing the high pressure propylene recovery tower, the low pressure propylene recovery tower and the depropanization tower is used to well solve the problem in the prior art, and the method can be used for the propylene recovery through the propylene oxide device in the industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production equipment of epoxypropane

ActiveCN105315238AReduce the amount of feedGuaranteed separation effectOrganic chemistryProcess engineeringHigh pressure

The invention relates to a production equipment of epoxypropane. The production equipment is mainly used for solving a problem of the prior art that energy consumption is high. The production equipment comprises a reactor, a high pressure propylene recovery tower, a low pressure propylene recovery tower, and a depropanizing tower, wherein operation pressure of the high pressure propylene recovery tower ranges from 0.5 to 3.5MPa as gage pressure, and operation pressure of the low pressure propylene recovery tower ranges from 0.1 to 0.4MPa as gage pressure. The production equipment is capable of solving the problem preferably, and can be applied to industrial production of epoxypropane.

Owner:CHINA PETROLEUM & CHEM CORP +1

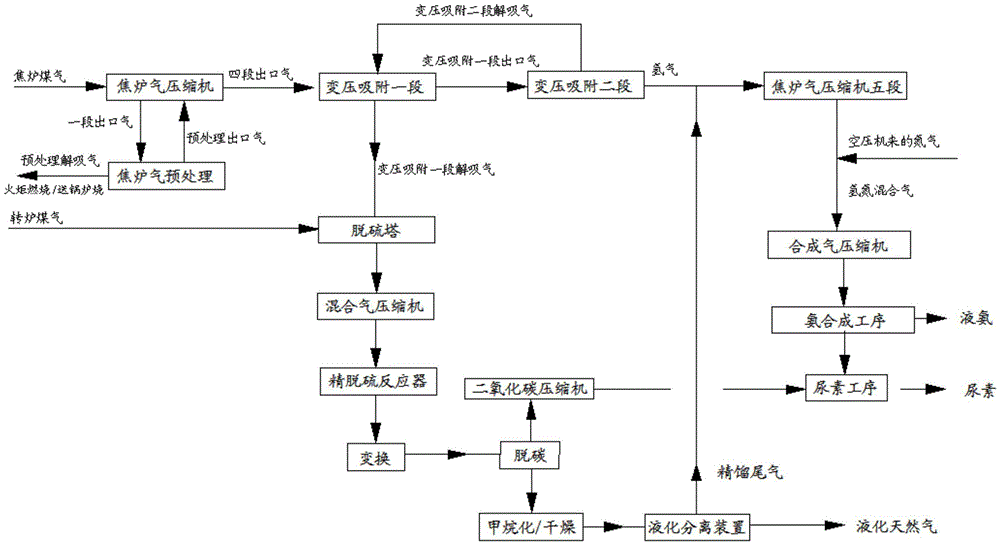

Urea separation and purification method

InactiveCN104151202AGuaranteed Purity RequirementsUrea derivatives preparationOrganic compound preparationPurification methodsCombustion

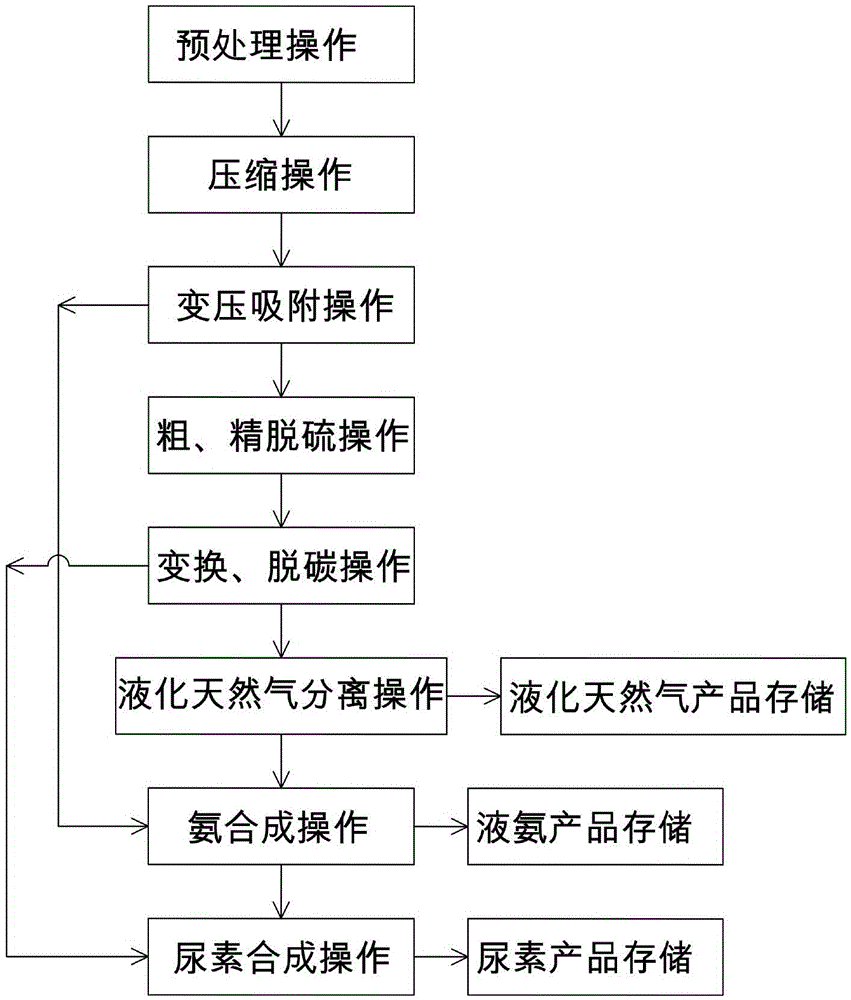

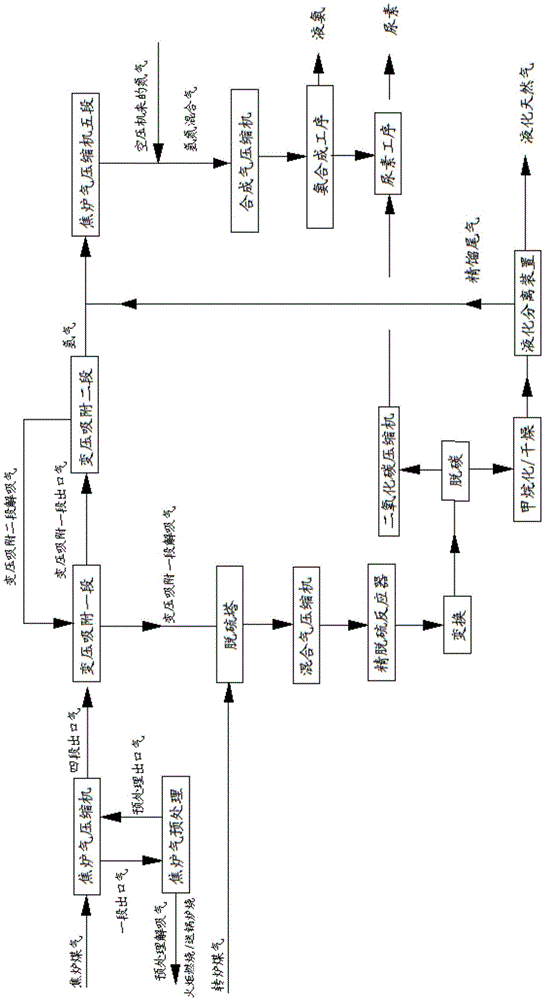

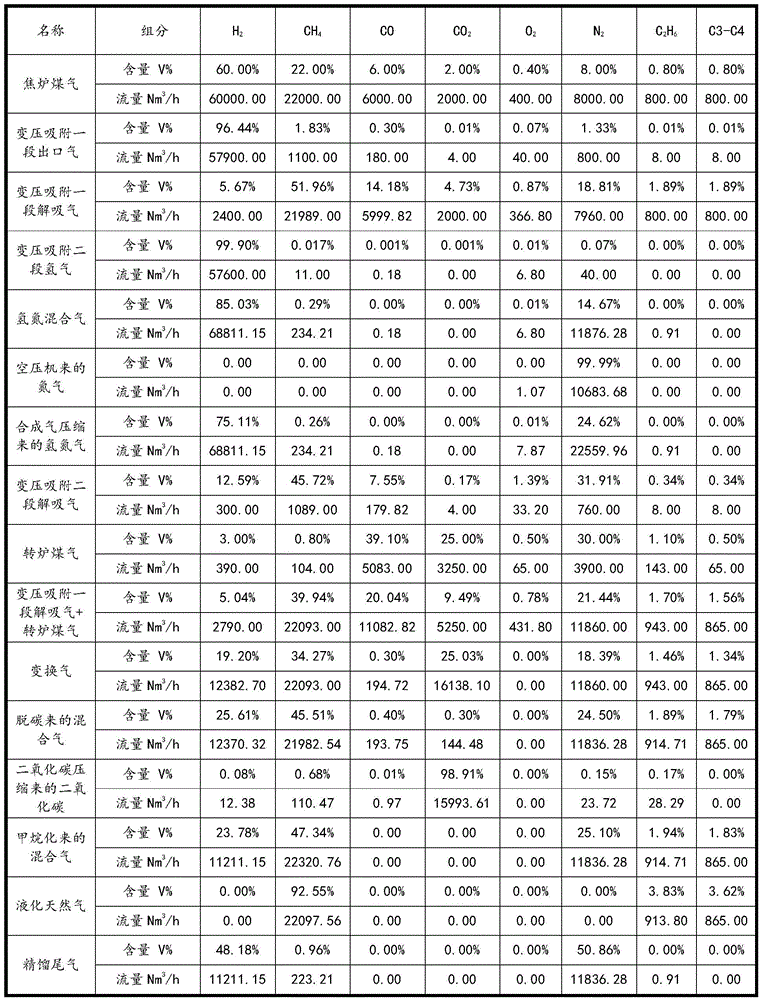

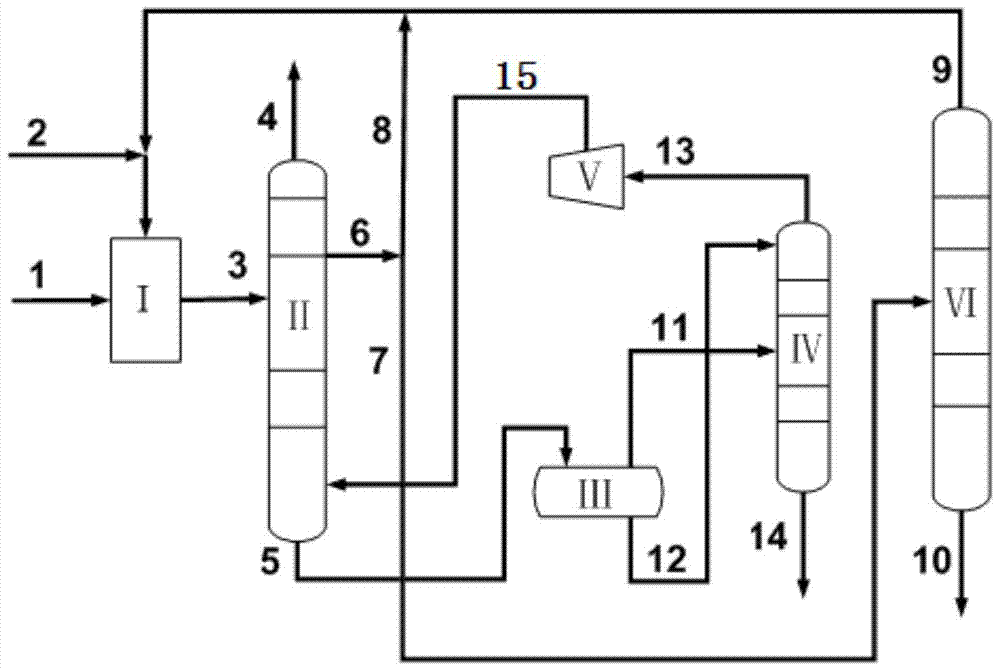

The invention discloses a urea separation and purification method which comprises the following steps: a pretreatment operation is performed; coke oven gas feed gas is transported to an oil removal tower for tar removal operation, and when the content of the tar is removed to 23 mg / m<3> or less, the coke oven gas is sent into a first section of a coke oven gas compressor for pressurization operation; the pressurized coke oven gas is subjected to pretreatment operation, and when the content of the tar is removed to 5.5 ppm or less and the content of naphthalene is removed to 1 mg / m<3> or less, the coke oven gas is sent into a second section of the coke oven gas compressor for pressurization operation; the pretreated coke oven gas is transported to a boiler for combustion, or is unloaded after combustion by a torch. The method can be applied to the urea preparation technology field; and with application of the method, gas of mixed feed gas in the preparation process can be effectively controlled, so as to ensure purity requirements of the finally-produced urea.

Owner:GUIZHOU YIHUA CHEM

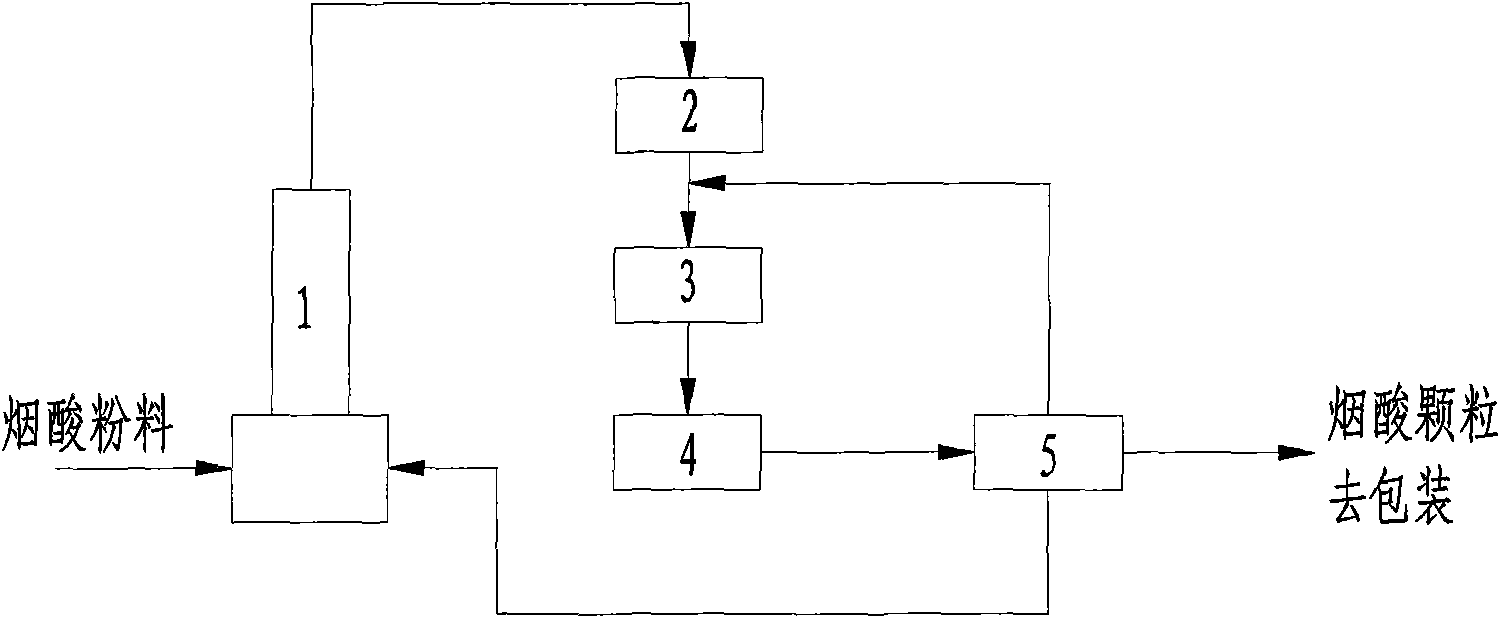

Granular niacin production method by extrusion and granulation

InactiveCN101565401AReduce granulation energy consumptionAvoid agglomeration and dust pollution problemsOrganic chemistryGranulation by material expressionNiacinPelletizing

The invention provides a production method of niacin / isonicotinic acid granules by extrusion and granulation, comprising the following steps: lifting a hopper to a measuring tank and measuring the materials in the hopper and tabletting the materials in a tablet machine, crushing, screening the tablets to obtain the granular niacin / isonicotinic acid product with grain size of 0.2-0.8mm, respectively returning the over-large or over-small granules into the crushing and measuring step. The niacin / isonicotinic acid granules prevents the defects of the niacin / isonicotinic acid powder produced by the prior production method such as severe dust pollution of package, application place due to over-small grain size and grains cluster phenomena in storage and transportation and provides the convenience for the use of the niacin / isonicotinic acid granules as additives.

Owner:HANGZHOU SHENGDA PHARMA

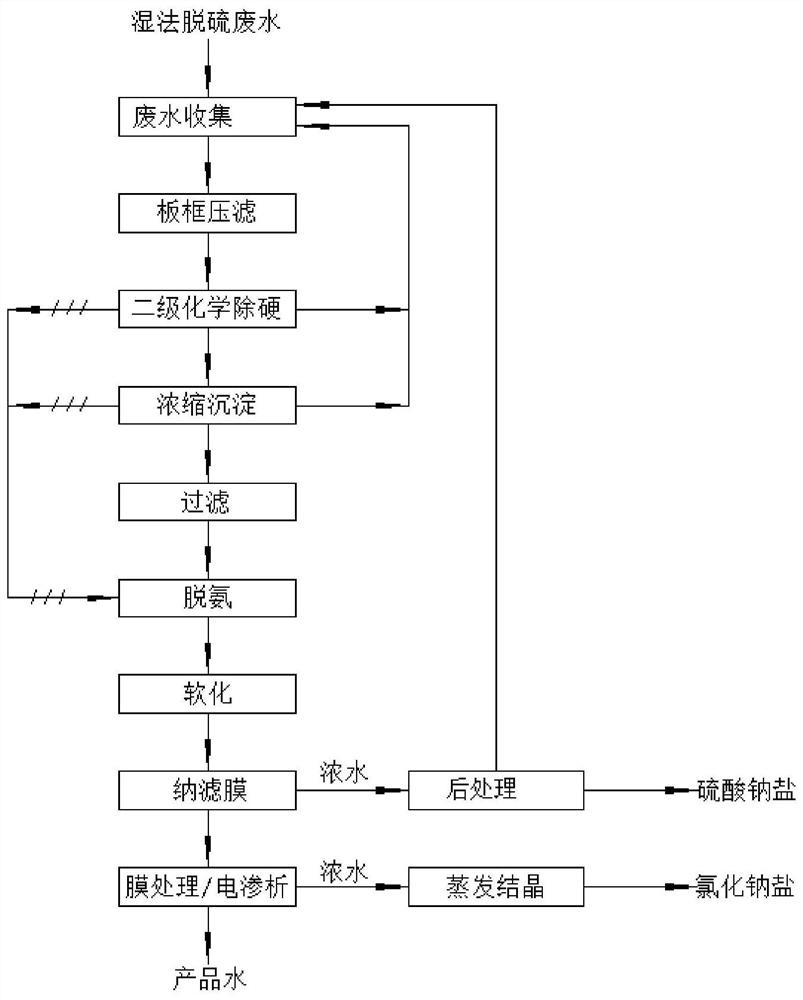

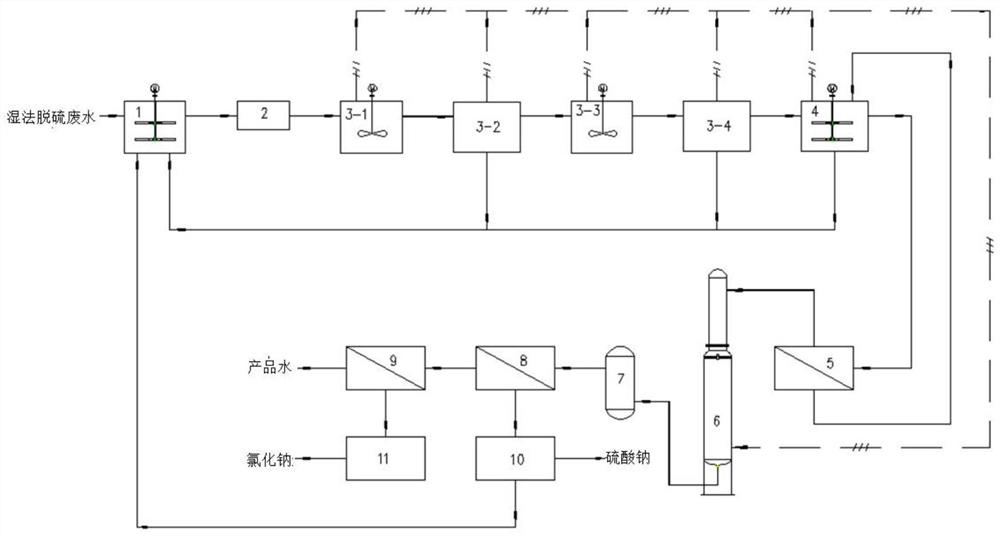

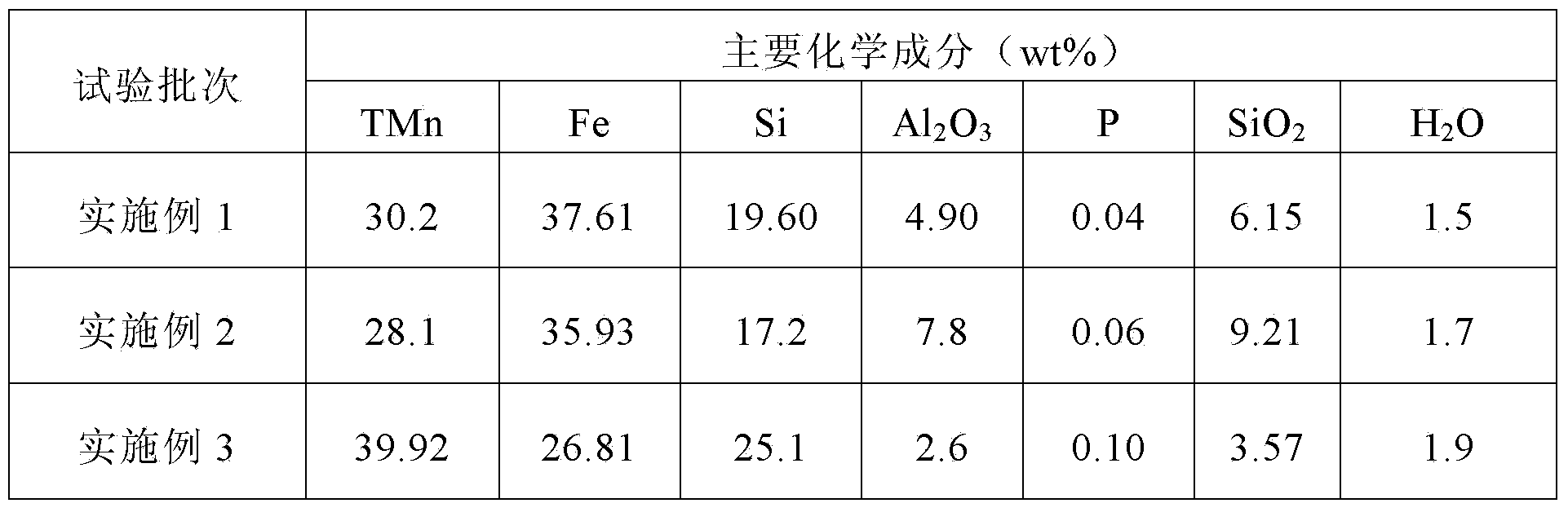

Steel wet desulphurization wastewater treatment system and method

PendingCN112794520AReduce operating burdenAchieve zero discharge treatmentAlkali metal sulfites/sulfates preparation formScale removal and water softeningNanofiltrationSULFATE ION

The invention discloses a steel wet desulphurization wastewater treatment system and method. The method comprises the following steps: carrying out plate-and-frame pressure filtration, secondary chemical hardness removal, concentration precipitation on steel wet desulfurization wastewater, conducting filtration treatment to remove impurities in the wastewater, carrying out deamination treatment to remove ammonia nitrogen in the wastewater, and carrying out softening treatment, nanofiltration membrane treatment, membrane treatment or electrodialysis treatment and evaporative crystallization treatment to obtain clear water and high-purity sodium sulfate and sodium chloride. According to the method, complex factors such as gypsum suspended solids, high hardness, high chloride ions, high ammonia nitrogen, high sulfate ions, fluorine ions, heavy metal ions and COD in the wastewater can be effectively removed, the obtained clear water can be recycled as industrial new water, and zero discharge treatment of the steel wet desulfurization wastewater is realized; and high-purity sodium chloride and sodium sulfate salt with certain economic recovery value are obtained, so that recycling of resources is realized.

Owner:中冶北方(大连)工程技术有限公司

304 stainless steel smelting method by AOD (argon oxygen decarburization) Converter

A 304 stainless steel smelting method by an AOD (argon oxygen decarburization) converter comprises 1) a silicon aluminum oxidation stage; 2) a main decarbonization stage; 3) a dynamic decarburization stage; 4) a reduction stage; and 5) desulfurization alloying; and is characterized in that: silicon mixed manganese ore balls are added in the reduction stage, the silicon mixed manganese ore balls are prepared by mixing and pressing manganese ore powder with a manganese percent content of 25-40% and ferrosilicon powder in a ratio of 7:3, the dosage of the silicon mixed manganese ore balls is 0.01-0.02 ton / ton steel, the silicon mixed manganese ore balls are averagely added in 2 to 3 times at intervals of 2 to 3 minutes; the decarbonization stage smelting temperature of the AOD converter is 1560 to 1620 DEG C; in the desulfurization alloying stage, lime is supplemented, and the lime adding amount is 0.04-0.06 ton / ton steel. According to the method, silicon mixed manganese ore is used for replacing manganese alloy, the production cost can be effectively reduced, the purity of molten steel can be ensured, manganese alloy production link can be directly omitted, and the pollution of the environment can be reduced.

Owner:BAOSTEEL STAINLESS STEEL

Device for recovery and refining of propylene

ActiveCN105330504AHigh purityReduce energy consumptionDistillation purification/separationHydrocarbonsEpoxideHigh energy

The invention relates to a device for recovery and refining of propylene, and mainly solves the technical problem of high energy consumption in the prior art. The invention solves the problems by using a propylene recovery device containing a high-pressure propylene recovery tower, a flash tank, a low-pressure propylene recovery tower and a depropanization tower, and can be used in industrial production of propylene recovery using a propylene epoxide plant.

Owner:CHINA PETROLEUM & CHEM CORP +1

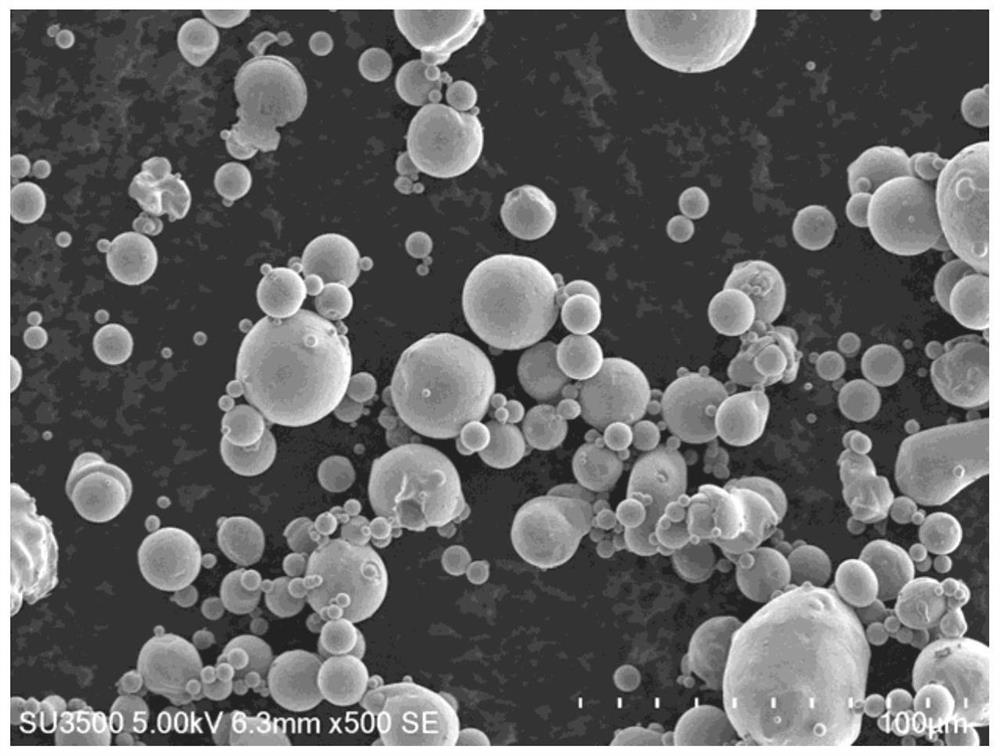

Iron-cobalt-tantalum alloy powder preparation method, iron-cobalt-tantalum alloy powder, and application

ActiveCN111957982ASolve the blockageHigh purityVacuum evaporation coatingSputtering coatingAlloyCobalt

The invention relates to an iron-cobalt-tantalum alloy powder preparation method, iron-cobalt-tantalum alloy powder, and an application. The iron-cobalt-tantalum alloy powder preparation method includes the steps that firstly, iron, cobalt, and tantalum are prepared according to a target atomic ratio and mixed; then the iron, the cobalt, and the tantalum are melted completely under the temperatureof 1650-1750 DEG C; and then atomizing is carried out under the action of inert gas, and the iron-cobalt-tantalum alloy powder is obtained. According to the preparation method, the melting temperature of an iron-cobalt-tantalum mixture is controlled at 1650-1750 DEG C, and the atomizing conditions are optimized, so that the purity of the prepared iron-cobalt-tantalum alloy powder is greater thanor equal to 99.95%, and the oxygen content is less than or equal to 600 ppm. The iron-cobalt-tantalum alloy powder with the particle size less than 150 meshes is obtained by sieving, which is conducive to the preparation of an iron-cobalt-tantalum alloy sputtering target material with high purity, high density, high bending strength and qualified magnetic flux. Tantalum scrap of a tantalum targetmaterial is used as a tantalum material for preparation, which realizes the transformation of waste into treasure.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Epoxy propane production method

InactiveCN105272939AReduce the amount of feedReduce energy consumptionDistillation purification/separationHydrocarbonsHigh energyTower

The invention relates to an epoxy propane production method, and is used for mainly solving the problem of high energy consumption in the prior art. The problem is better solved through adopting the technical scheme that the epoxy propane production method comprises the steps: a liquid material flow is generated from cumyl hydroperoxide and propylene in a reactor; the liquid material flow goes into a flash tank, a first light component material flow is obtained at a tank top, and a first heavy component material flow is obtained at a tank bottom; the first light component material flow goes into a high pressure propylene recovery tower, a second light component material flow is obtained at a tower top, and a second heavy component material flow is obtained at a tower kettle; the first heavy component material flow goes into a low-pressure propylene recovery tower, a third light component material flow is obtained at a tower top, and a third heavy component material flow is obtained at a tower kettle; a part of the second light component material goes into a depropanizing tower, a fourth light component material flow is obtained at a tower top, and a fourth heavy component material flow is obtained at a tower kettle; and a part of the second light component material flow except the part going into the depropanizing tower, the third light component material flow and the fourth light component material flow circulate back to the reactor. The epoxy propane production method can be used for industrial production of recovery of propylene with an epoxy propane device.

Owner:CHINA PETROLEUM & CHEM CORP +1

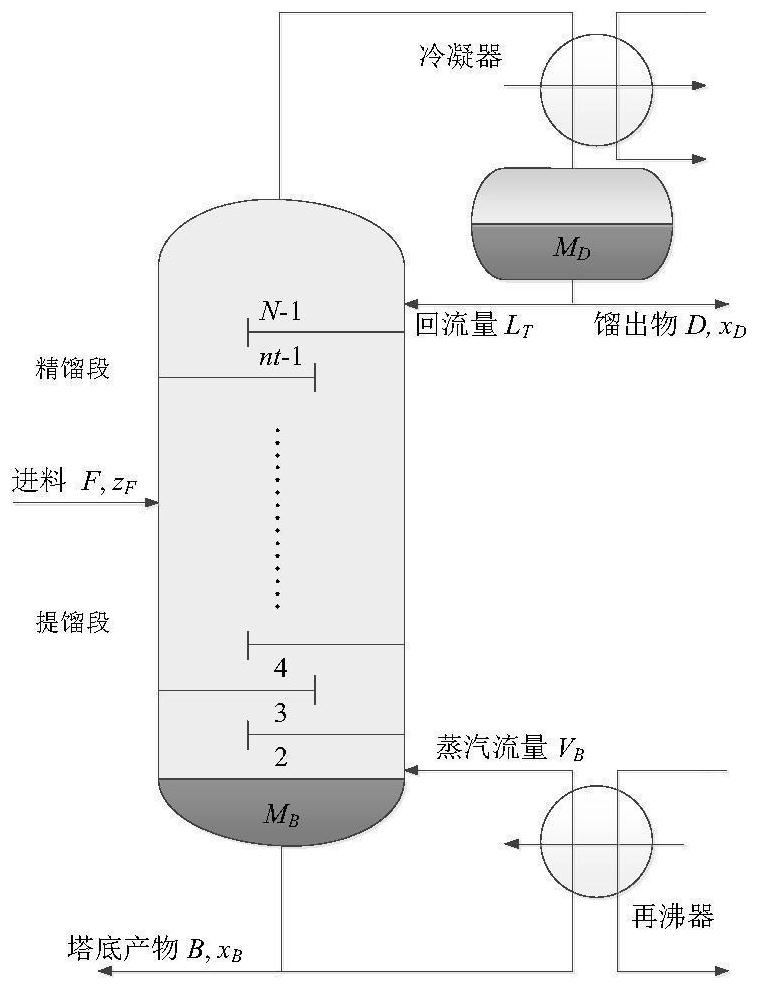

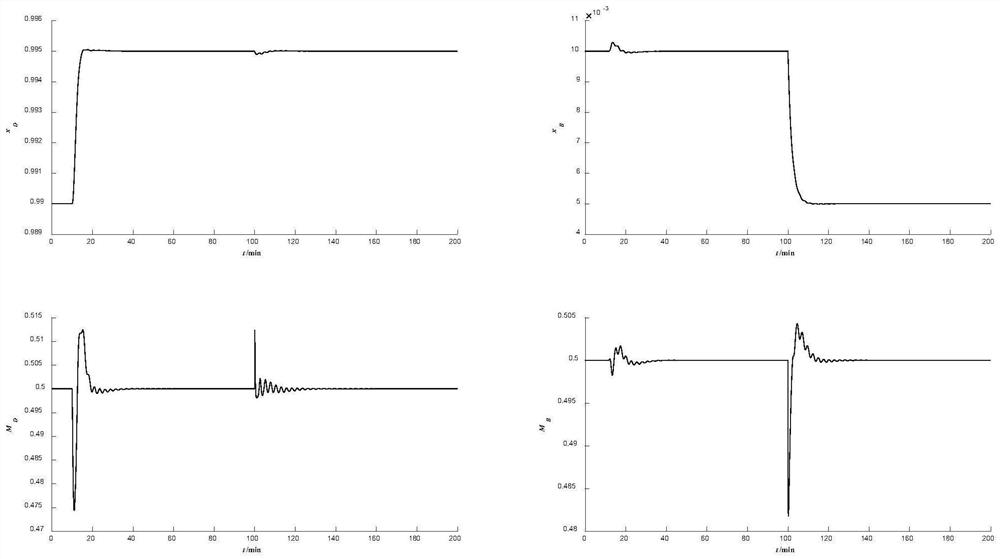

Active-disturbance-rejection control structure and control method for binary rectification process

ActiveCN114253130AObserve coupling effects in real timeImprove decoupling abilityChemical industryAdaptive controlLoop controlReboiler

The invention provides an active-disturbance-rejection control structure and a control method for a binary rectification process, and belongs to the technical field of energy-saving control of a chemical rectification process. The technical problems that various external disturbances exist in the existing rectification process, so that various states in the rectification tower are deviated, the process energy is wasted, and meanwhile, the product quality is influenced are solved. According to the technical scheme, the control structure for the product purity and quality of the binary rectifying tower comprises four control loops, namely a condenser liquid level control loop, a reboiler liquid level control loop, a tower top light component product concentration control loop and a tower bottom light component product concentration control loop; the control method comprises the step of realizing control of the four control loops by designing the four active-disturbance-rejection controllers. The control method has the beneficial effects that the degree of dependence of the control method on a mathematical model in the rectification process is low, the set value tracking of the concentration of the products at the tower top and the tower bottom can be realized, the purity of the products is ensured to be slightly influenced under the condition that the feeding flow or components are greatly disturbed, and the method has relatively strong robustness and stability.

Owner:NANTONG UNIVERSITY

Propylene recovery device

ActiveCN105272808AReduce the amount of feedGuaranteed separation effectDistillation purification/separationHigh energyEngineering

The invention relates to a propylene recovery device, and is used for mainly solving the problem of high energy consumption in the prior art. The problem is better solved through adopting a propylene recovery refining device comprising a high-pressure propylene recovery tower, a low-pressure propylene recovery tower and a depropanization tower, and the propylene recovery device can be used for industrial production of recovery of propylene with an epoxy propane device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing high performance metallic nickel powder using electrochemical passivation-loosing process

The invention relates to method which is adopted the electrochemistry purification-loosing to prepare the metal nickel powder. It prepares the high performance metal nickel powder by adopting the electrochemistry purification-loosing processing technology at first, then the oxidation reduction technology. The method is adopts the metal nickel plate with high purity to gain the foamed metal nickel with high porosity and purity after the processing of the electrochemistry purification-loosing. The foamed metal nickel is conducted oxidation treatment with dynamic gyration. The brittle nickel oxide foam is gained after the oxidation. Then the foamy nickel oxide is conducted multistage shearing crushing; the nickel oxide powder with different granularity is gained after the classification by sedimentation method. The nickel oxide powder is conducted reduction treatment in stages by cracked ammonia. Thus the high quality metal nickel powder with high purity, fine crystal grain, and small loosing ratio is produced. The advantages of the invention are that the non contaminant is discharged; it is good for the environmental protection; the process flow and the cost are reduced; and it can ensure the production of gaining the metal nickel powder with high performance. The metal nickel powder with high performance produced by the preparation method can be widely applied to the sintered metal product (hard alloy, diamond tool, nickel iron alloy product, nickel base product) stainless steel product, battery, and chemical industry product.

Owner:长沙市维优金属材料有限公司

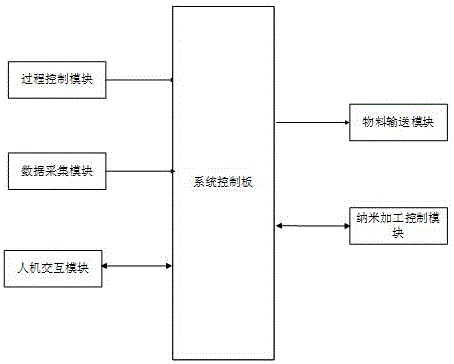

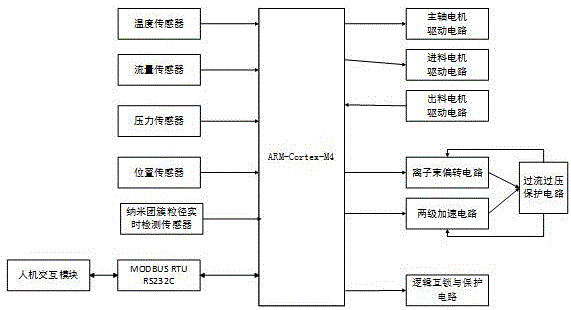

Cluster ion beam nanometer processing equipment control device and control method thereof

InactiveCN106829856AEnsure consistencyGuaranteed stabilityElectric discharge tubesNanostructure testingElectricityProcess equipment

The invention provides a cluster ion beam nanometer processing equipment control device and a control method thereof. The cluster ion beam nanometer processing equipment control device comprises a system control board, a human-computer interaction module, a process control module, a data acquisition module, a nanometer processing control module and a material conveying module, and the human-computer interaction module, the process control module, the data acquisition module, the nanometer processing control module and the material conveying module are electrically connected to the system control board respectively. The invention further provides a control method of cluster ion beam nanometer processing equipment. The particle size of the nanocluster is detected in real time, and the material is unloaded when a set condition is met. According to the cluster ion beam nanometer processing equipment control device and the control method thereof, the consistency and the stability of the particle size of the nanocluster are achieved, the component deviation and the phase contamination are reduced to the greatest extent, and the dynamic response performance of a system is drastically improved.

Owner:佛山旋疯纳米科技有限公司

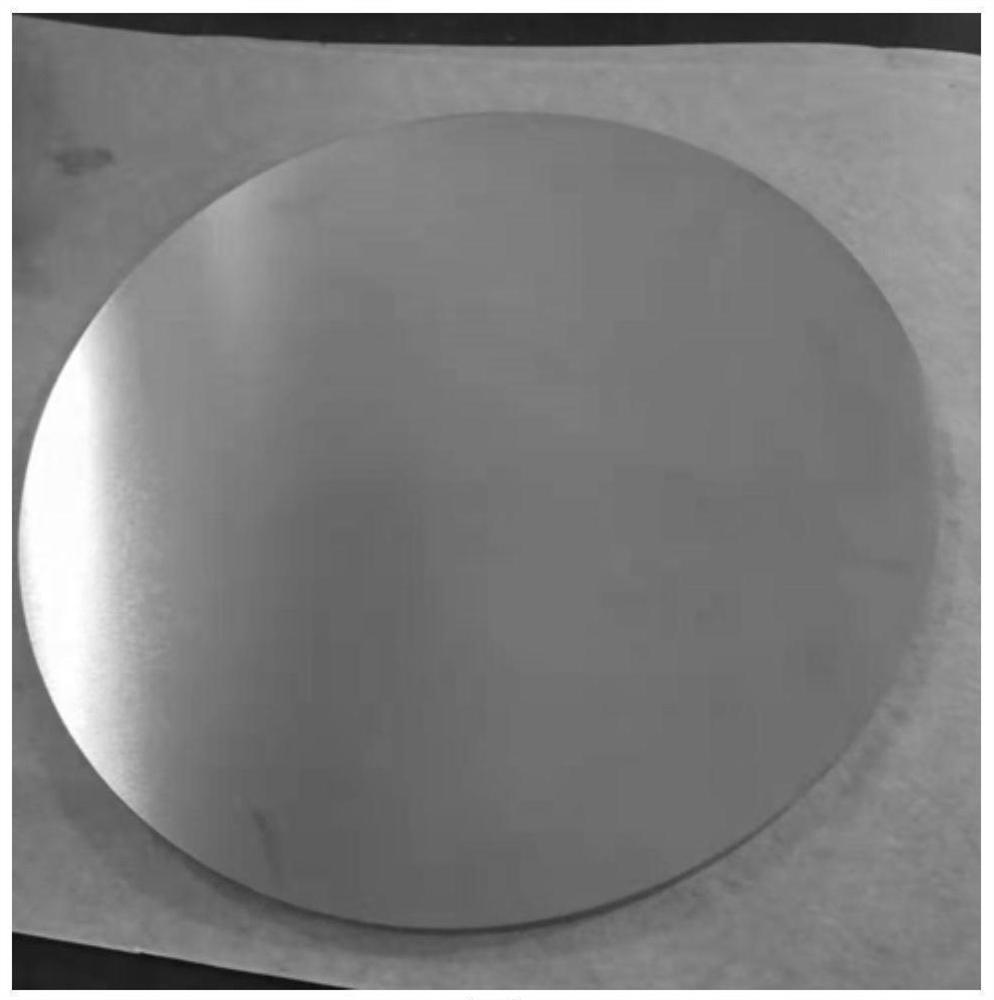

Titanium-nickel shape memory alloy target material and preparation method thereof

ActiveCN113234945AExtend your lifeGuaranteed Purity RequirementsVacuum evaporation coatingSputtering coatingSmelting processNickel alloy

The invention discloses a titanium-nickel shape memory alloy target material and a preparation method thereof. The preparation method of the titanium-nickel shape memory alloy target material comprises the following steps that S1, metal titanium and metal nickel are added into a container in an alternate tiling manner to be smelted, and alloy melt is obtained; S2, the alloy melt obtained in the S1 is cast, and cooling is carried out to obtain a target blank; and S3, the target blank is machined, and then the titanium-nickel shape memory alloy target material is obtained. According to the preparation method, the metal titanium and the metal nickel are added into the container in the alternate tiling manner to be smelted, so that the temperature in the smelting process is reduced, air suction in the smelting process is reduced, the purity requirement of the alloy is guaranteed, the smelting speed is increased, and the service life of a smelting furnace is prolonged. In addition, the titanium-nickel alloy target material prepared by the preparation method is uniform in component, low in content of impurities such as C and O, and high in purity.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

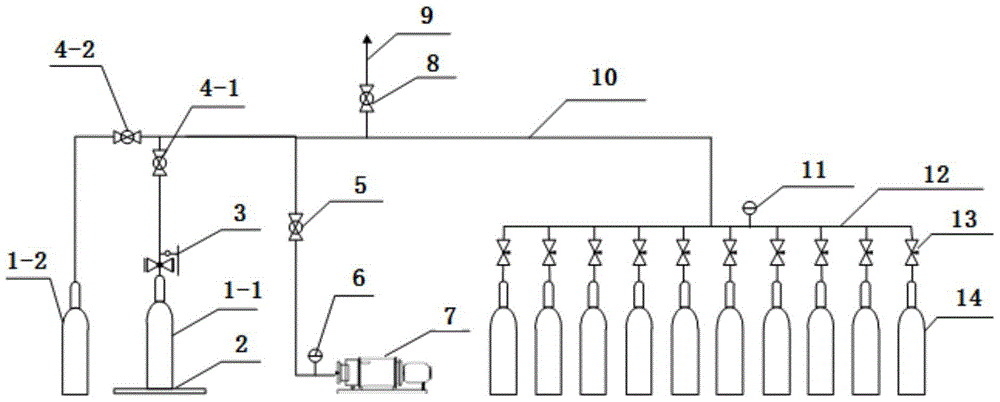

A device and method for preparing multi-bottle mixed gas

ActiveCN104888635BReduce mistakesImprove gas distribution accuracyMixer accessoriesMixing gases with gases/vapoursGas cylinderBottle

The invention discloses a device and method for preparing multi-bottle mixed gas, belonging to the field of mixed gas distribution. The device includes dilution gas raw material gas cylinders, component gas raw material gas cylinders, weighing devices, pressure reducing valves, first ball valves, second ball valves, high vacuum baffle valves, vacuum pressure gauges, vacuum pumps, venting control valves, exhaust Empty pipelines, raw material gas main pipelines, precision pressure gauges, product gas manifolds, needle valves, and product gas cylinders; the product gas manifold contains multiple gas pipelines, and the number of needle valves and product gas cylinders is the same as the number of gas pipelines. The quantity is equal. The steps of the method are as follows: Step 1, pipeline connection; Step 2, pipeline evacuation; Step 3, pipeline gas replacement; Step 4, mixed gas preparation; Step 5, pipeline evacuation. The low-concentration gas is prepared by using the device and method of the invention, which reduces the weighing error, improves the gas distribution accuracy, has fast gas distribution speed, is suitable for mass production, and saves the gas distribution cost. And the device is simple, and the method is easy to operate.

Owner:PERIC SPECIAL GASES CO LTD

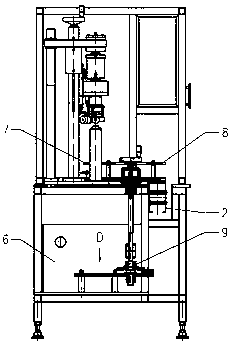

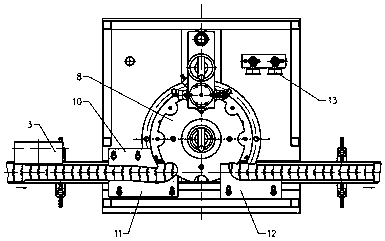

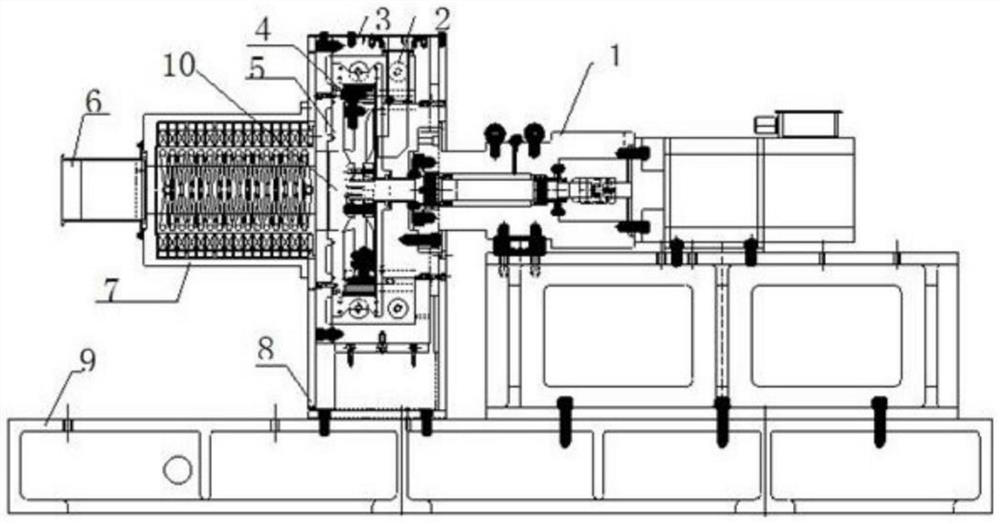

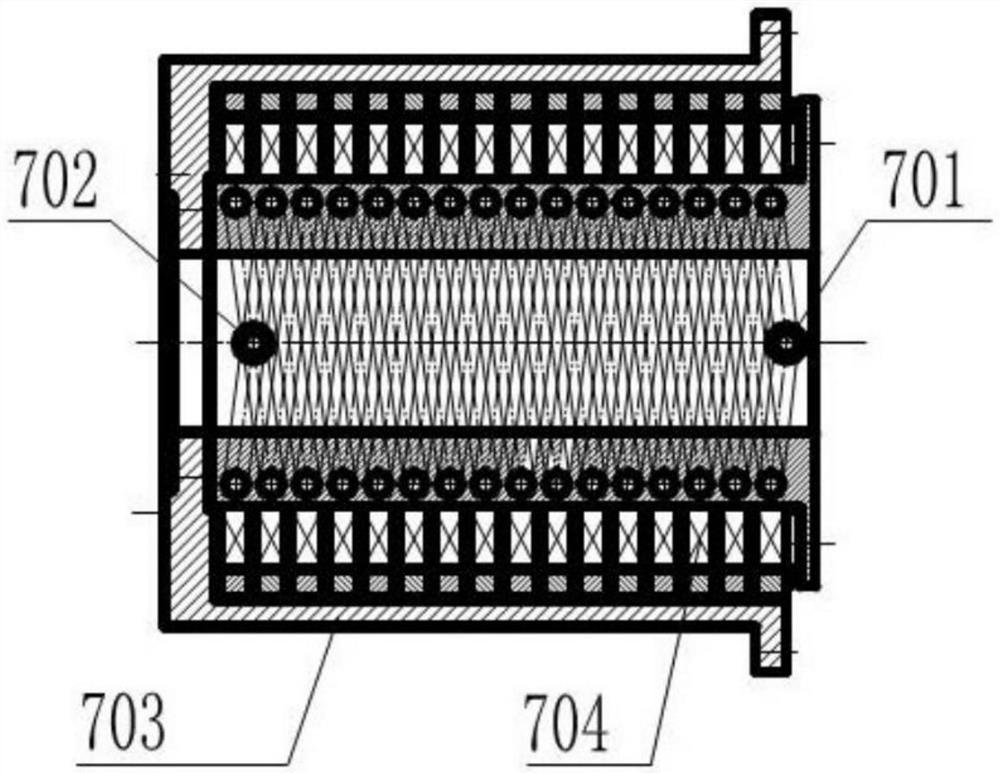

Fully Automatic High Purity Oxygen Under Cap Filling Machine

ActiveCN103090179BLow purityLess reduction in purityContainer discharging methodsContainer filling under pressureBiochemical engineeringHigh pressure oxygen

The invention relates to a fully automatic high-purity oxygen under-cap filling machine. It includes the frame, the upper cabinet on the frame, the conveying line passing through the frame, the control box installed on the side plate of the conveying line, the indexing star wheel assembly on the platen of the frame, and the guide plate for entering the tank Component 1, tank inlet guide plate component 2, tank outlet guide plate component, main body of under-cover filling machine, gas distribution device, electrical box and indexing mechanism in the frame. The present invention can automatically complete the aerosol tank with the aerosol valve into the can, lift the valve, vacuumize, fill the cover with low-pressure replacement oxygen, pump air, fill the cover with high-pressure oxygen, press the valve and seal, and leave the tank . The pumping and inflation times can be set. The oxygen purity after filling is less reduced, which can ensure that the finished aerosol fully meets the purity requirements of the medical oxygen standard.

Owner:YANGZHOU MEIDA FILLING MACHINERY

Propylene oxide production method

ActiveCN105272941BReduce the amount of feedReduce energy consumptionDistillation purification/separationHigh energyHigh pressure

The invention relates to a production method of propylene oxide, which mainly solves the problem of high energy consumption in the prior art. The present invention comprises the following steps by adopting: a) cumene hydroperoxide and propylene react in a reactor to generate a liquid phase stream; b) the liquid phase stream enters a high-pressure propylene recovery tower, and the first light component stream is obtained at the top of the tower , the tower reactor obtains the first heavy component stream; b) the first heavy component stream enters the low-pressure propylene recovery tower, the tower top obtains the second light component stream, and the tower reactor obtains the second heavy component stream; c) the second The light component stream is divided into two parts, wherein a part of the stream enters the depropanizer, the top of the tower obtains the third light component stream, and the tower reactor obtains the third heavy component stream; d) the first light component stream, the second light component stream The technical scheme of removing the split part entering the depropanizer from the split stream and recycling the third light component stream back to the reactor solves this problem well, and can be used in the industrial production of propylene oxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Three-phase-type oxidoreduction metal chromium powder preparation technology

The invention discloses a three-phase-type oxidoreduction metal chromium powder preparation technology, a purification treatment technology is firstly conducted on a metal chromium plate, then an oxidoreduction technology is conducted, and thus high-performance metal chromium powder is prepared. According to the three-phase-type oxidoreduction metal chromium powder preparation technology, the metal chromium plate with high purity is adopted, after purification technology treatment is conduct, and foam metal chromium with high porosity and high purity is obtained; dynamic rotary oxidation treatment is conducted on the foam metal chromium, and fragile chromic oxide foam is obtained after full oxidation is conducted; then the spumescence chromic oxide is cut and crushed in a multistage mode,and chromic oxide powders with different particle sizes are obtained after sedimentation method is adopted to classify; grading reduction treatment is conducted on the chromic oxide powders by using cracked ammonia, and thus the high-quality metal chromium powder with high purity, fine particle size and small loose density is manufactured. The three-phase-type oxidoreduction metal chromium powderpreparation technology has the advantages that no pollutant is discharged, environmental protection is facilitated, the technologic process is shortened, the cost is lowered, and it can be ensured that the high-performance metal chromium powder is manufactured and obtained. The high-performance metal chromium powder manufactured through the preparation method can be widely applied to powder metallurgy products (hard alloys, diamond tools, ferrochrome products, chrome base products and the like), stainless steel products, batteries, chemical products and the like.

Owner:安建春

Method for improving performance of metal chromium powder by oxidation-reduction process

The invention discloses a method for improving the performance of metal chromium powder by an oxidation-reduction process. A metal chromium plate is first subjected to a purification treatment process, then an oxidation and reduction process is performed, and high-performance metal chromium powder is prepared. The method adopts the metal chromium plate with high purity, and the metal chromium plate is processed by the purification process to obtain foam metal chromium with high porosity and high purity; the foam metal chromium is subjected to dynamic rotary oxidation treatment, and fully oxidized to obtain brittle chromium oxide foam; then foam-shaped chromium oxide is subjected to multi-stage shearing and crushing, and chromium oxide powder of different particle sizes is obtained after grading is performed by a sedimentation method; and the chromium oxide powder is subjected to a graded reduction treatment by decomposing ammonia, and high-quality metal chromium powder with high purity, small crystal particles and a small specific ratio is obtained. The method has the advantages that no pollutant discharge is achieved, environmental protection is facilitated, the process flow is shortened, the cost is reduced, and the production of the high-performance metal chromium powder is ensured. The preparation method produces the high-performance metal chromium powder, and the high-performance metal chromium powder can be widely applied to powder metallurgy products (hard alloys, diamond tools, ferrochrome products, chromium-based product and the like), stainless steel products, batteries, chemical products and the like.

Owner:安建春

A kind of separation and purification method of urea

InactiveCN104151202BGuaranteed Purity RequirementsUrea derivatives preparationOrganic compound preparationPurification methodsCombustion

The invention discloses a urea separation and purification method which comprises the following steps: a pretreatment operation is performed; coke oven gas feed gas is transported to an oil removal tower for tar removal operation, and when the content of the tar is removed to 23 mg / m<3> or less, the coke oven gas is sent into a first section of a coke oven gas compressor for pressurization operation; the pressurized coke oven gas is subjected to pretreatment operation, and when the content of the tar is removed to 5.5 ppm or less and the content of naphthalene is removed to 1 mg / m<3> or less, the coke oven gas is sent into a second section of the coke oven gas compressor for pressurization operation; the pretreated coke oven gas is transported to a boiler for combustion, or is unloaded after combustion by a torch. The method can be applied to the urea preparation technology field; and with application of the method, gas of mixed feed gas in the preparation process can be effectively controlled, so as to ensure purity requirements of the finally-produced urea.

Owner:GUIZHOU YIHUA CHEM

A kind of production method of high plasticity high speed steel

ActiveCN103667731BImprove distributionImprove distribution uniformityIncreasing energy efficiencyIngotHot rolled

The invention provides a production method for high-plasticity high-speed steel. The production method comprises steps of selecting materials according to parts by weight of all elements of the high-speed steel to be prepared, and controlling the contents of harmful elements in the raw material; smelting by a vacuum induction melting furnace, casting so as to obtain a consumable electrode bar; remelting the consumable electrode bar by a vacuum consumable remelt furnace so as to obtain a high-speed steel remelting ingot, wherein a calcium iron wire is tied on the consumable electrode bar in vacuum consumable process; cogging the high-speed steel remelting ingot, then forging, hot rolling so as to obtain a high-speed steel coil rod, annealing the coil rod so as to obtain the high plasticity high-speed steel. The production method is simple and easy to control and can be used for preparing high-plasticity high-speed steel.

Owner:SOUTHEAST UNIV +2

Plants for the production of propylene oxide

ActiveCN105294604BHigh purityGuaranteed yieldDistillation purification/separationHigh energyHigh pressure

Owner:CHINA PETROLEUM & CHEM CORP +1

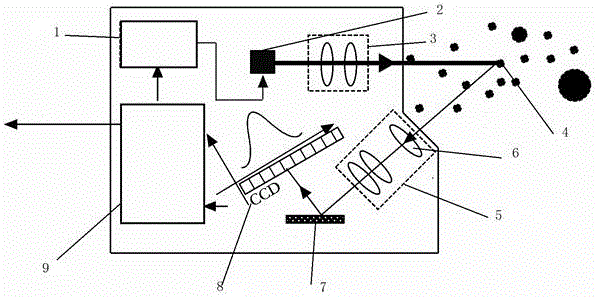

Cluster ion beam nanometer processing equipment and processing method thereof

PendingCN114141598AEnsure consistencyGuaranteed stabilityElectric discharge tubesNanotechnologyControl systemPhysical chemistry

The invention provides cluster ion beam nano-processing equipment. The cluster ion beam nano-processing equipment comprises a feeding device, a graded negative pressure generator, a spindle motor, a pressure cavity, a material pretreatment unit, a nano-cluster ion beam unit, a nano-cluster particle size real-time detection unit, a discharging device and an electrical control system, the invention also provides a cluster ion beam nano-processing method which comprises the following steps: pretreating the material, and grinding the material into a free abrasive material; the particle size of the free abrasive is detected in real time, and when the free abrasive reaches the submicron level, deflection, acceleration and collision processing are conducted, and the free abrasive is decomposed into nanoclusters; and detecting the particle size of the nanocluster in real time, and discharging when a set condition is met. According to the method, the particle size of the nanocluster is detected in real time, so that the consistency and stability of the particle size of the nanocluster are ensured; a processing mode of combining free abrasive pretreatment and nanocluster energy beam collision is adopted, so that the particle size and purity requirements of the nano material are ensured, and component deviation and phase pollution are reduced to the maximum extent.

Owner:广东如动纳米科技有限公司

Process for producing propylene oxide

The invention relates to a method for producing propylene oxide, which mainly solves the problem of high energy consumption in the prior art. The present invention adopts the following steps: CHP and propylene generate a liquid phase stream in the reactor; the liquid phase stream enters the middle part of the high-pressure propylene recovery tower, the first light component is obtained from the top of the tower, the first heavy component is obtained from the tower kettle, and the side line is obtained from the middle part of the tower Logistics; the side stream is divided into the first side stream and the second side stream; the first side stream enters the middle of the depropanizer, the second light component is obtained from the top of the tower, and the second heavy component is obtained from the bottom of the tower; the first heavy component enters the flash evaporation Tank, the third light component at the top of the tank, the third heaviest component at the bottom of the tank; the third light component enters the middle of the low-pressure propylene recovery tower, the third heaviest component enters the first tray at the top of the tower, and the fourth light component at the top of the tower Component, the fourth heavy component is obtained in the tower still; the fourth light component enters the high-pressure propylene recovery tower tower; the technical scheme of the second side stream and the second light component recycling back to the reactor solves this problem well, and can be used In the industrial production of propylene oxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com