Steel for carbon hub bearing of microalloying car and production method thereof

A technology of micro-alloying and hub bearings, applied in bearings, hubs, manufacturing tools, etc., can solve problems affecting product performance, uneven bearing structure, and reduced bearing service life, so as to improve quality and secondary dendrite arm spacing Improve and reduce the effect of central carbon segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with embodiment the present invention is described in further detail.

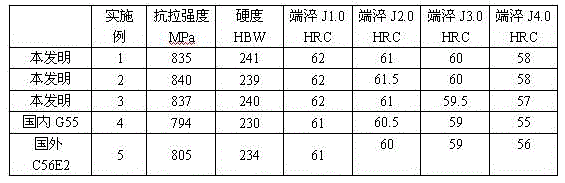

[0045] The chemical composition (wt%) of carbon hub bearing steel in each embodiment of the present invention and (as a comparison) G55 and foreign C56E2 hub bearing steel used in the market is shown in Table 2 and Table 3,

[0046] Table 2

[0047]

Example

C

Si

mn

P

S

Cr

Mo

Ni

Al

this invention

1

0.56

0.30

0.58

0.013

0.004

0.35

0.01

0.03

0.015

this invention

2

0.57

0.28

0.59

0.011

0.004

0.35

0.02

0.04

0.017

this invention

3

0.57

0.28

0.58

0.013

0.004

0.36

0.01

0.03

0.018

Domestic G55

4

0.55

0.27

0.80

0.012

0.001

0.08

0.01

0.03

0.022

Foreign C56E2

5

0.56

0.28

0.79

0.010

0.002

0.10

0.01

0.03

0.01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com