Reinforced aerobic granular sludge culture method

A technology of aerobic granular sludge and cultivation method, applied in the fields of environmental protection and sewage treatment, can solve the problems of long cultivation time of aerobic granular sludge, difficult formation of aerobic granular sludge, long formation time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

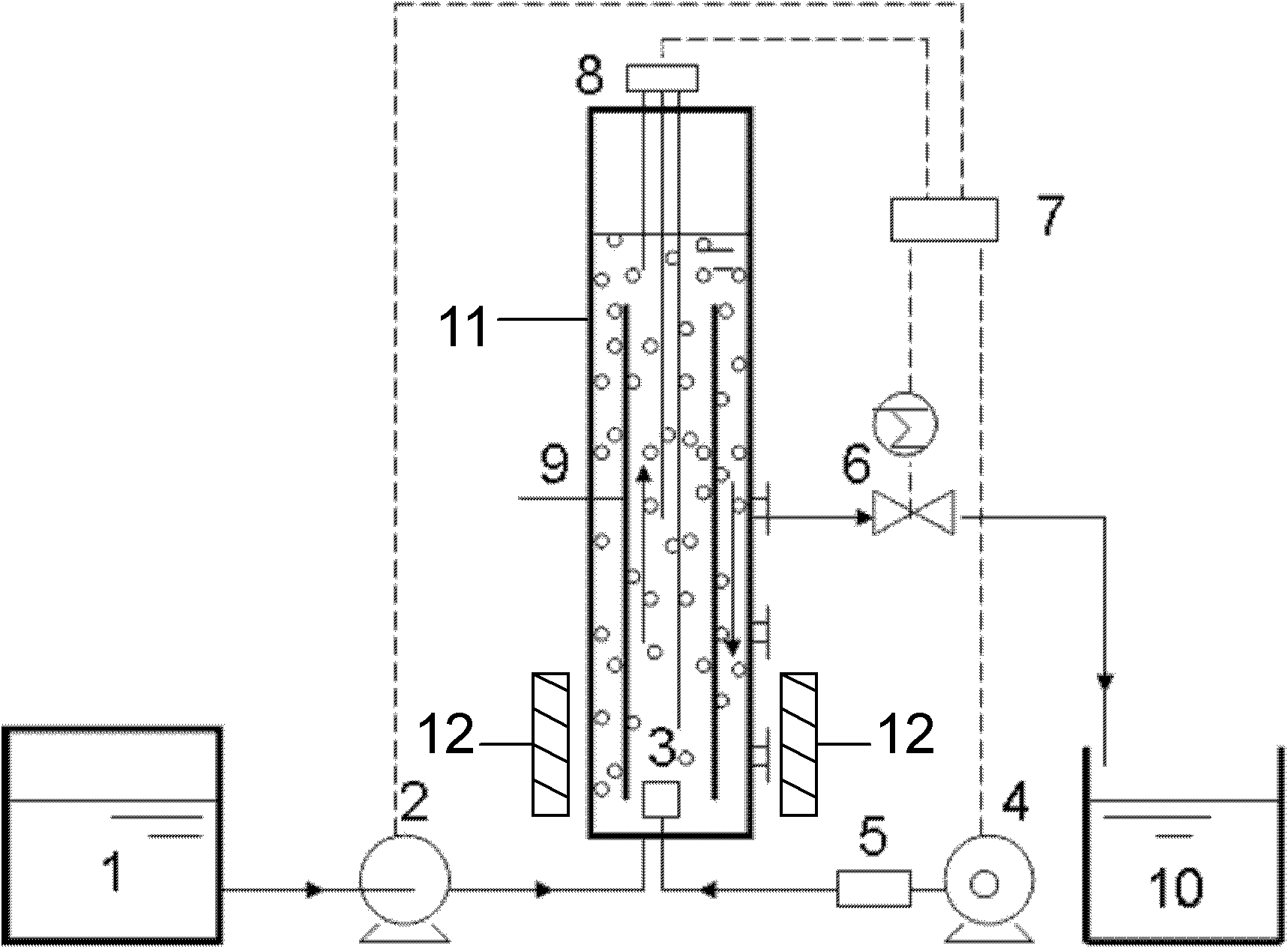

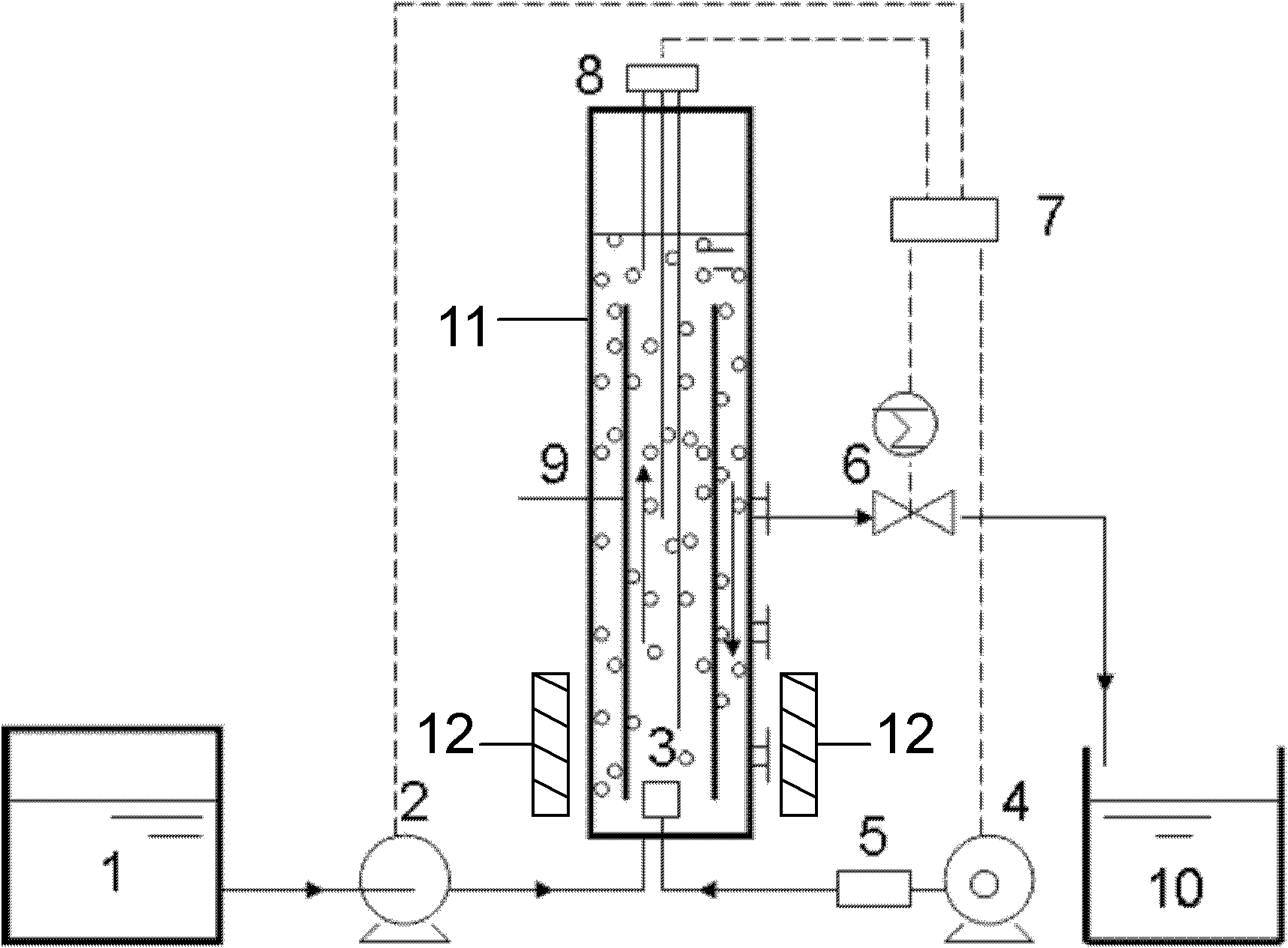

[0016] A gas-lift batch reactor is used, and two permanent magnets (25cm×100cm×150cm) are installed on the outer bottom of the gas-lift batch reactor, with a distance of 10cm between the two magnets to generate a statically stable magnetic field of 48.0mT.

[0017] The air-lift batch reactor consists of an inner tube 9 and an outer tube 11 with an effective volume of 3.5 L, an outer tube with a diameter of 10.0 cm and a height of 100 cm, an inner tube 9 with a diameter of 7.0 cm and a height of 70 cm, and a distance between the inner tube 9 and the outer tube 11 of 2 cm. The air enters the reactor through the microporous aeration head 3 installed in the center of the bottom of the reactor by the air pump 4, and the air flow formed pushes the liquid and granular sludge in the reactor to move upward in the inner pipe 9, and then downward between the inner and outer pipe walls After reaching the bottom of the reactor, it is pulled upward by the airflow again, so that the mixed liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com