Method for preparing difluorophosphates

A technology of difluorophosphate and hexafluorophosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of increasing labor and time costs, increasing the difficulty of purification and separation, and increasing the difficulty of purification. Residence time, increase the effect of mass transfer and heat transfer, the effect of excellent mass transfer and heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

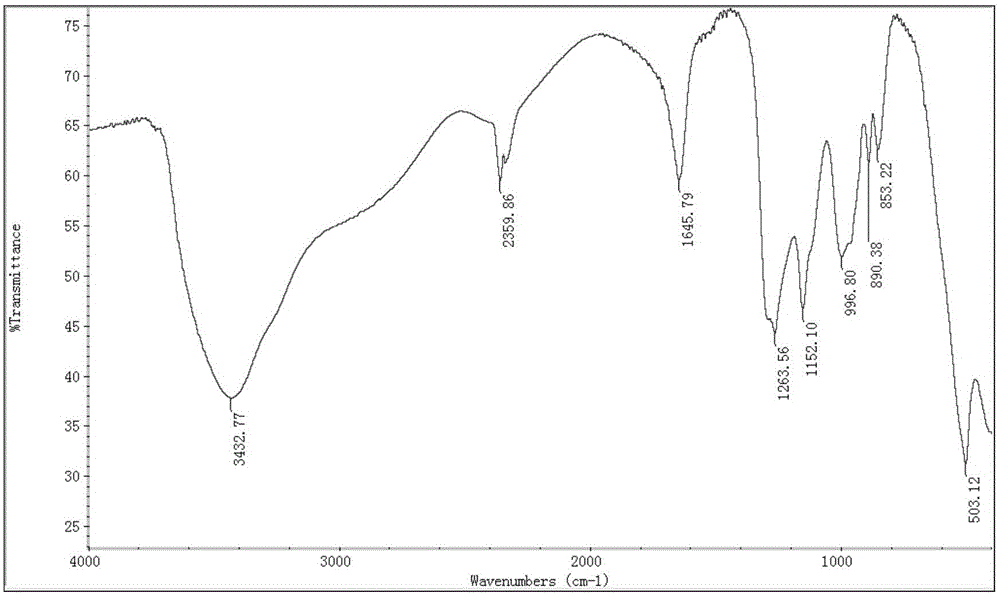

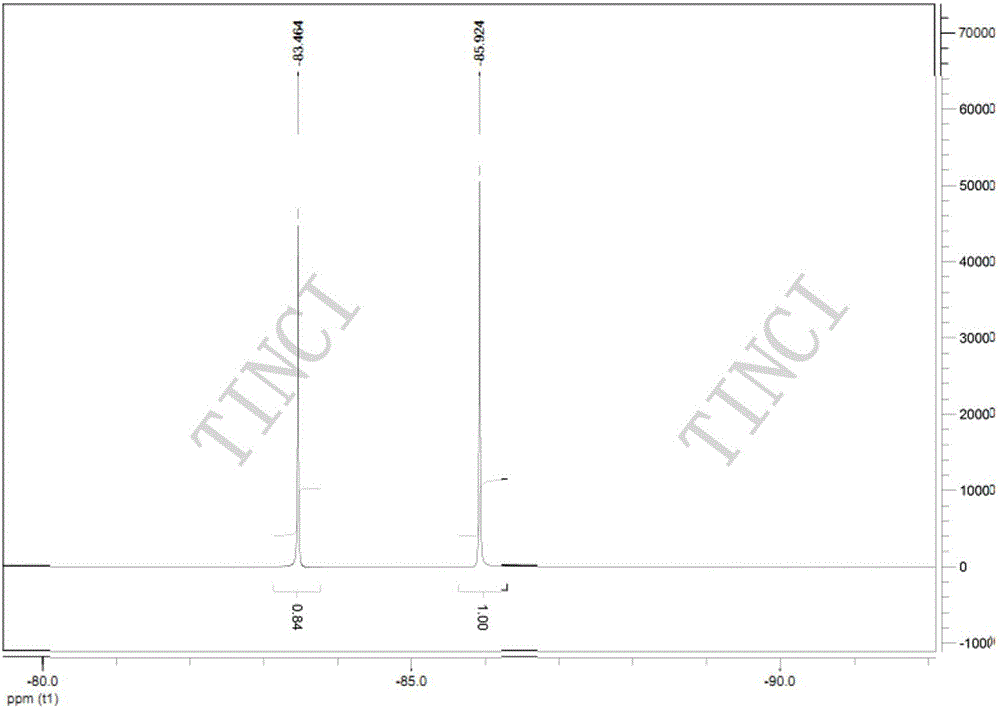

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto. The raw materials used in the following examples are commercially available unless otherwise specified.

[0028] The preparation method of difluorophosphate comprises the following steps: prepare 300g of hexafluorophosphate solution in a container, add a certain amount of cyclosiloxane or acetal in another container, and (use a metering pump to set a certain metering ratio) into the microchannel The reactor reacts at a constant temperature, and the obtained reaction solution is filtered through a membrane, then concentrated and dried to obtain a difluorophosphate solid. The raw materials and parameters of specific examples are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com