Jet nozzle of concentrate

A nozzle and concentrate technology, applied in the field of copper smelting flash furnace concentrate nozzle, can solve the problem that it is difficult to achieve uniform material distribution, and achieve the effect of ensuring the reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

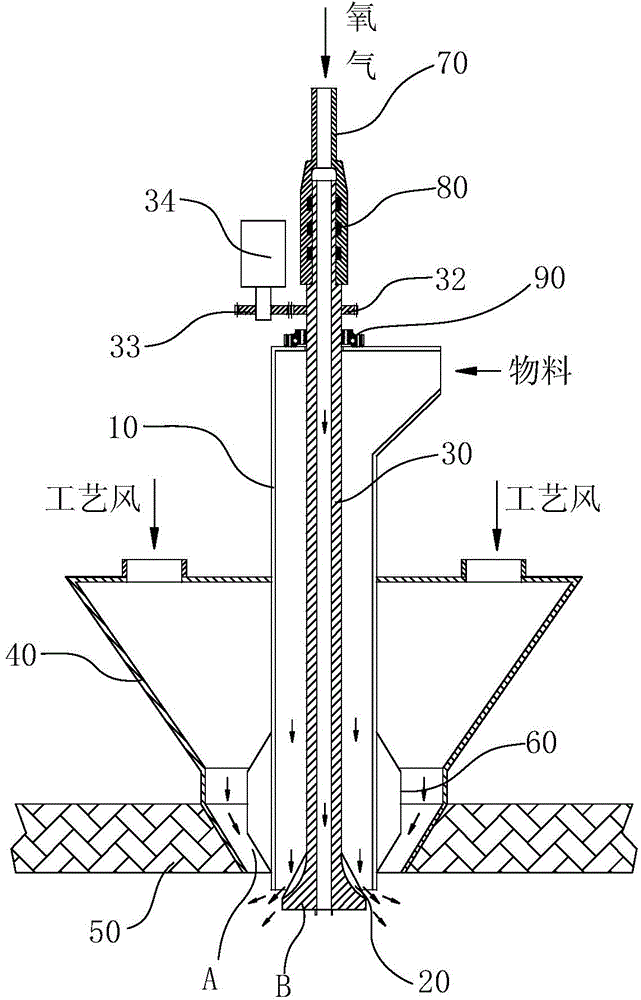

[0008] In conjunction with accompanying drawing, the present invention will be further described:

[0009] A concentrate nozzle, comprising a water-cooling sleeve 10, a distributor 30 is arranged inside the water-cooling sleeve 10, a rotary paddle 20 is arranged on the distributor 30 where the discharge end of the lower pipe end of the water-cooling sleeve 10 is located, and a driving mechanism The distributor 30 is driven to rotate to provide kinetic energy for dispersion to the passing materials.

[0010] The rotary paddle 20 provided at the lower part of the distributor 30, when feeding the concentrate material, the material is delivered from the upper pipe end of the water-cooled casing 10, and the material falls under its own gravity, and the centrifugal force formed by the rotary paddle 20 makes The materials are dispersed, so that the concentrate materials are in a uniform suspension state. After entering the flash furnace, the gas phase and the solid phase are fully mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com