Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Guarantee the quality of sintering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

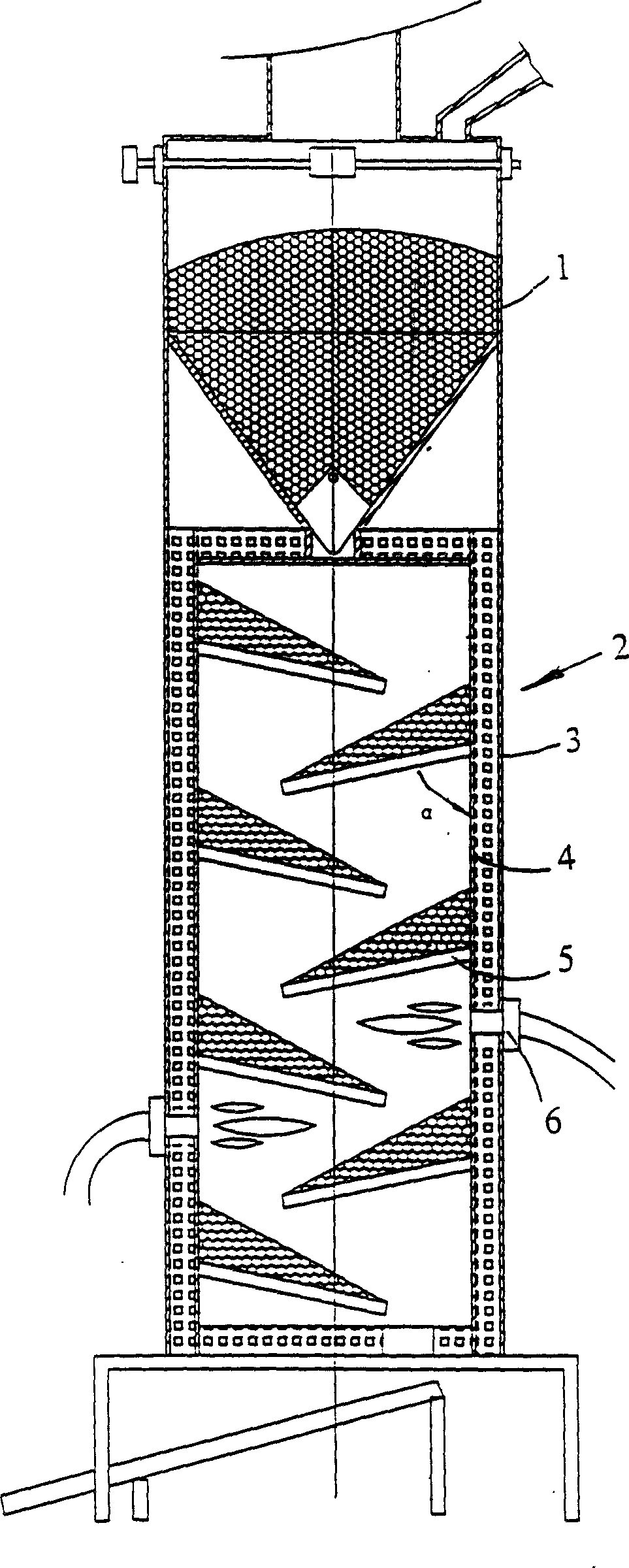

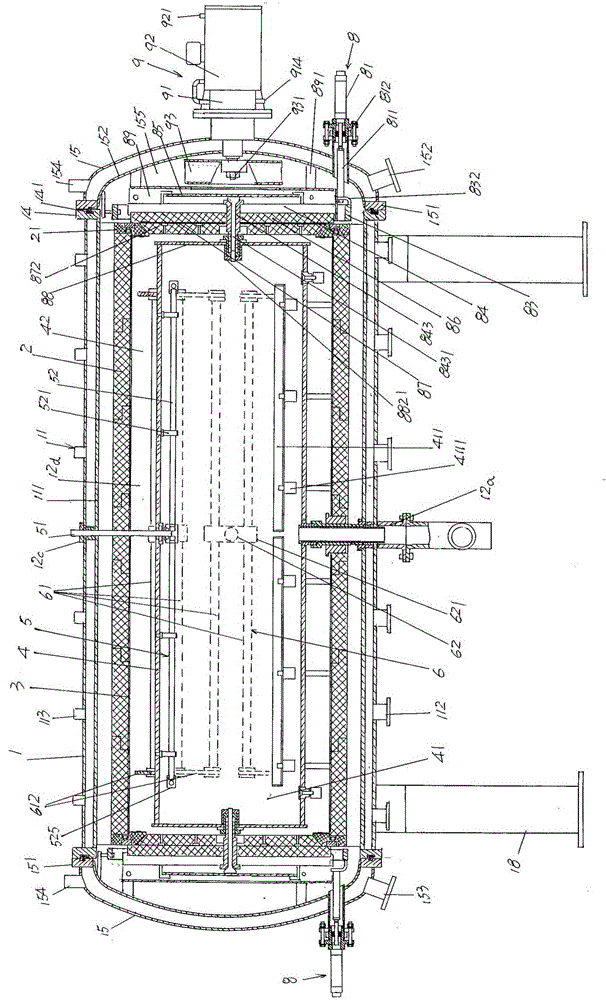

Stepwise grog burning furnace

The present invention relates to a clinker sintering clinker, including a vertical cylinder. Said vertical cylinder includes an external cylinder; an inner liner; two or more staggering mutually fishback pans which are mounted in the inner cavity of the outer cylinder, tightly abuts on the silo and approaches the bottom, with a distance therebetween; and more than two staggering mutually combustion nozzles or other heat source entrances mounted between the fishback pans. Said furnace stove utilizes a countercurrent mode between the falling materials and the ascending air and the heat source, takes full advantage of the possesses high thermal efficiency due to the hot gas and the clinker residual heat after a sintering, and utilizes to facilitate free fall from top to bottom or rolling of the sintered materials. Then the contact between the materials and gas are increased, the heat exchange rate is improved, and the production is increased; at the same time, the sintering quality and the homogeneity thereof of the clinker are ensured, and the material is not easy to block. Said furnace stove has a simple structure and few auxiliary equipments, has a small volume and low first cost, is convenient to examine and repair.

Owner:蒋明学

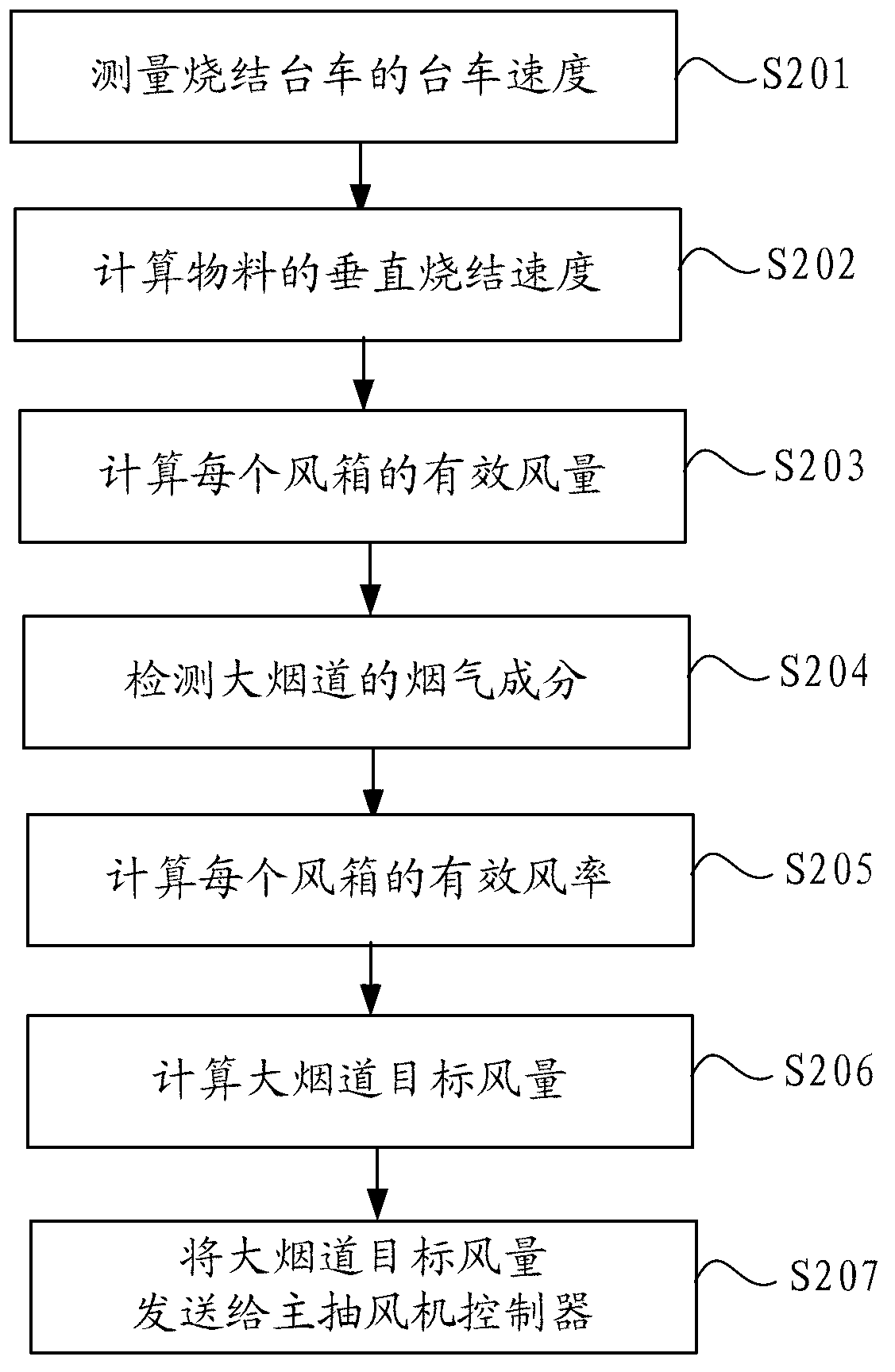

Method and system for controlling air quantity of main draft fan of sintering machine

ActiveCN103017533AReduce energy consumptionGuarantee the quality of sinteringFurnace typesAir volumeLayer thickness

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Method for preparing zirconia ceramic casing for optical fiber connector

InactiveCN1699278AGuarantee the quality of sinteringGuaranteed roundnessCoupling light guidesOptical fiber connectorYttrium

The invention discloses a method for preparing zirconia ceramic casing for optical fiber connector by using domestically made zirconium dioxide powder containing 3 mol% of yttrium oxide as the raw material, the process comprises the following steps, (1) granulation: employing atomizing granulation technique to treat the zirconium oxide powder with secondary particles whose average grain diameter is between 1.0-3.0 um containing yttrium oxide, reaching a specific surface area of 12-35m2 / g, (2) moulding: employing a resilient die vibration charging method and isostatic compaction with a forming pressure of 60-200 MPa, (3) firing: employing a silicon-molybdenum rod electric furnace at a firing temperature of 1380-1480 deg. C, the firing cycle is 48-50 hours.

Owner:TIANJIN URBAN CONSTR COLLEGE +1

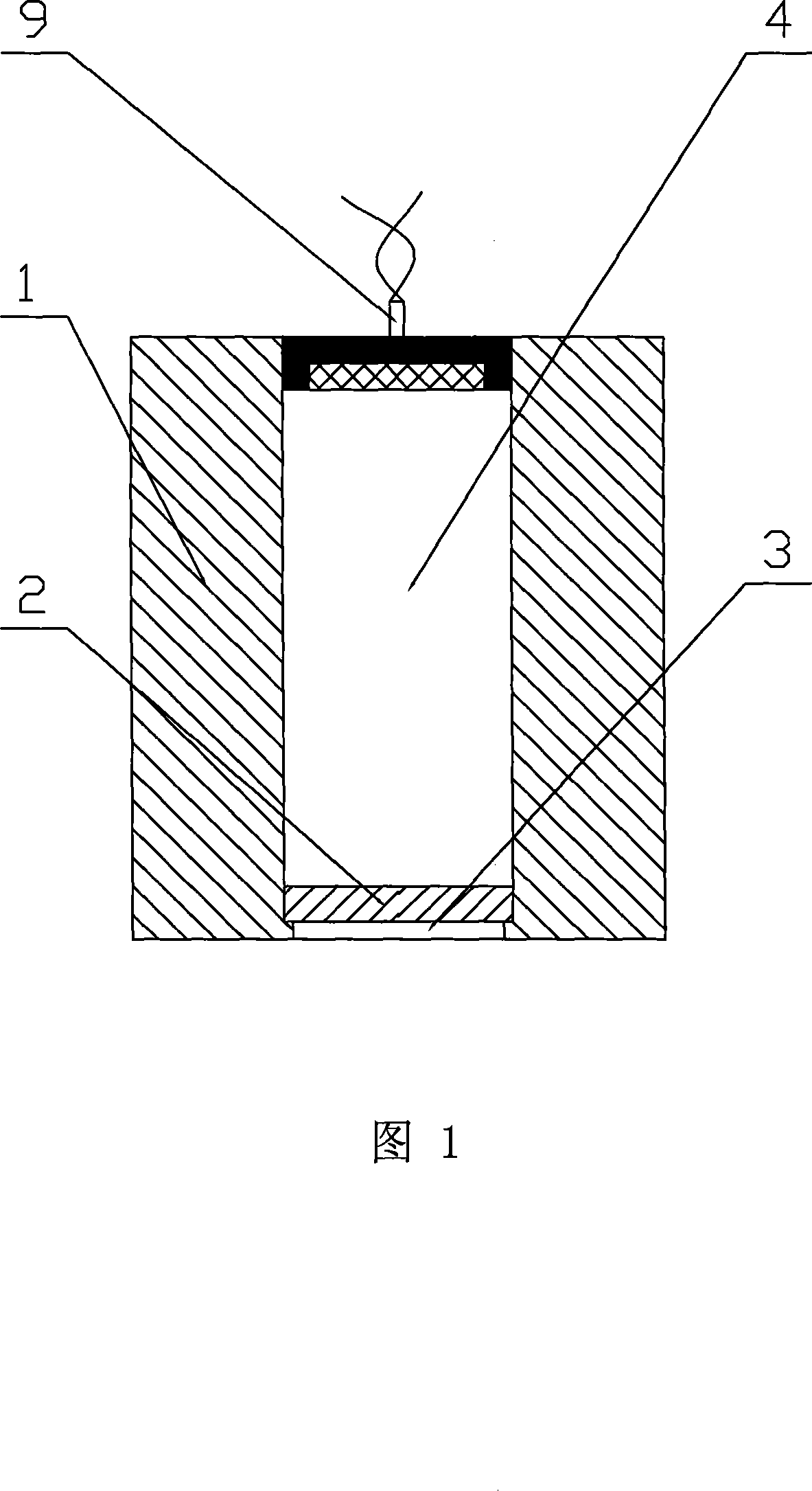

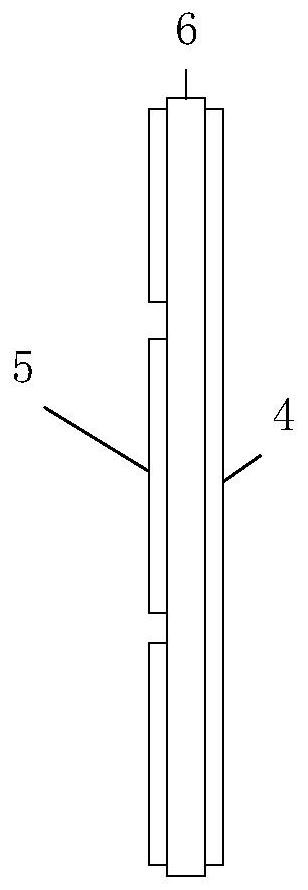

Flat plate exploder capable of improving velocity of flyer

ActiveCN101234428AReduce the sparse effectIncrease pressureBlasting cartridgesEngineeringVolumetric Mass Density

The invention discloses a plate explosion device which can improve the speed of a flyer, which is provided with a dielectric liner (1) with a bottom sealing and with a density of 0.9 to 2g / cm <3>. The bottom sealing is provided with a central hole (3) with a diameter smaller than the flyer (2), the flyer is arranged on the central hole (3) and an explosive cylinder (4) is positioned on the flyer (2) and is connected with an internal wall of the dielectric liner (1). The height of the dielectric liner (1) is higher than the height of the explosive cylinder (4), namely, 30 to 140mm. An external diameter of the dielectric liner is 2 to 3 times bigger than the diameter of the explosive cylinder (4). The plate explosion device reduces the sparse effect of the explosion products to the surroundings, therefore enlarge the pressure to the flyer by the explosion products, as a result, the flying speed is accelerated and the pressure of the flyer reduces from the center to the outer edge. Therefore, the flyer keeps plate flying and the impact received by the powder is even, which guarantees the powder calcinations or compounding quality.

Owner:大连鑫凯多晶金刚石科技有限公司

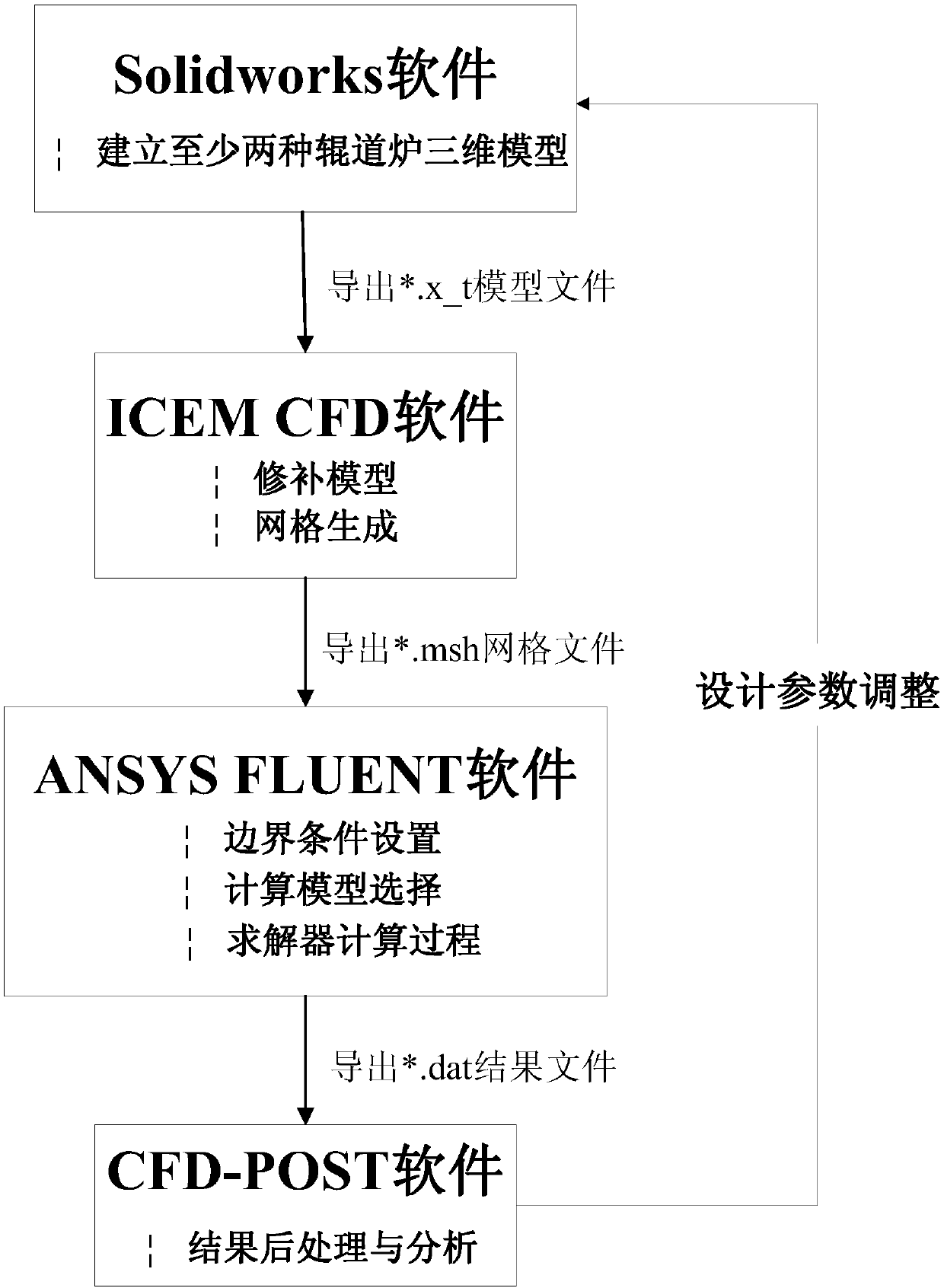

Electric heating roller furnace structure optimization method

InactiveCN107341291AGuarantee the quality of sinteringReduce design costDesign optimisation/simulationSpecial data processing applicationsTemperature differenceEngineering

The invention discloses an electric heating roller furnace structure optimization method. The method comprises the steps of S01, building multiple roller furnace body models with different design parameters; S02, importing the roller furnace body models into ICEM CFD software, performing model repair and grid division, and importing a grid file generated after the grid division into ANSYS Fluent software; S03, setting material property parameters, calculating boundary conditions and selecting a calculation model in the ANSYS Fluent software, initializing a calculation domain and performing calculation by utilizing a solver; and S04, importing a result file obtained by the in the ANSYS Fluent software into CFD-POST, performing comparative analysis on dimensionless temperature difference coefficients of furnace chamber center sections of the models, and taking the roller furnace body model with the relatively small temperature difference coefficient as an optimal scheme. The electric heating roller furnace structure optimization method has the advantages of low cost, short optimization time and the like.

Owner:湖南烁科热工智能装备有限公司

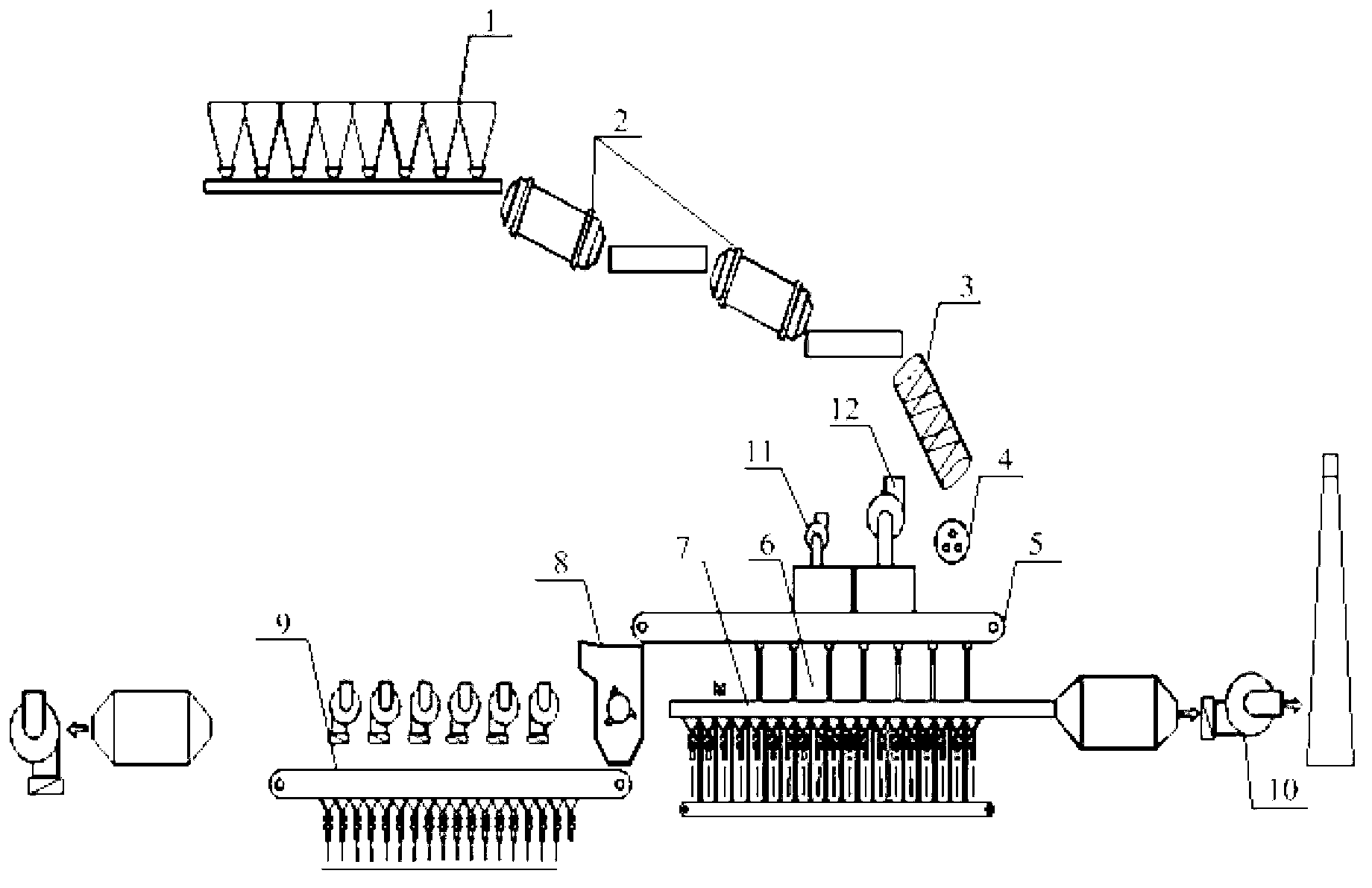

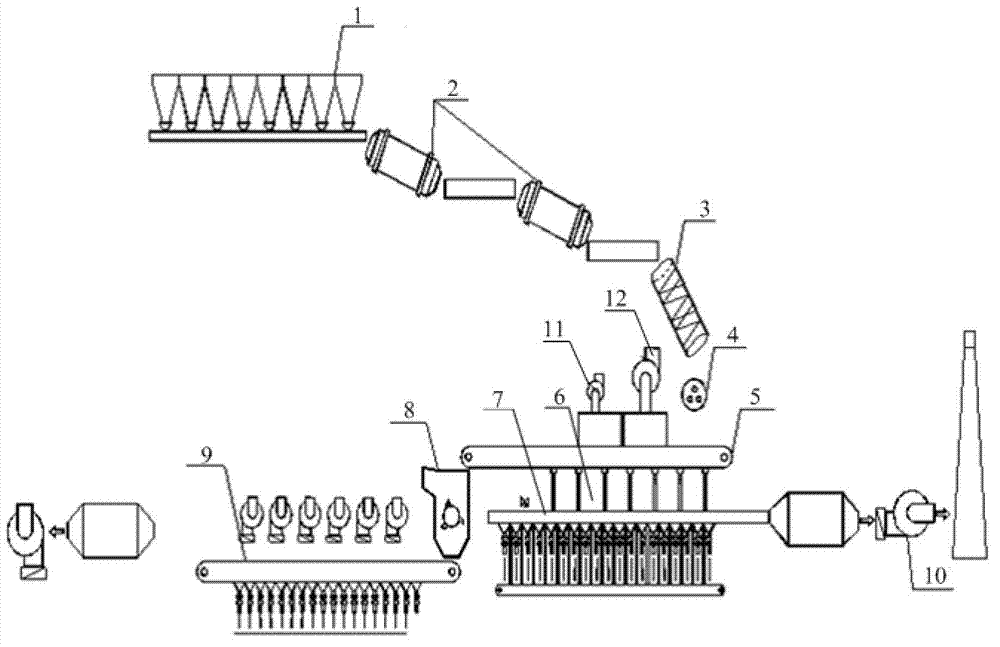

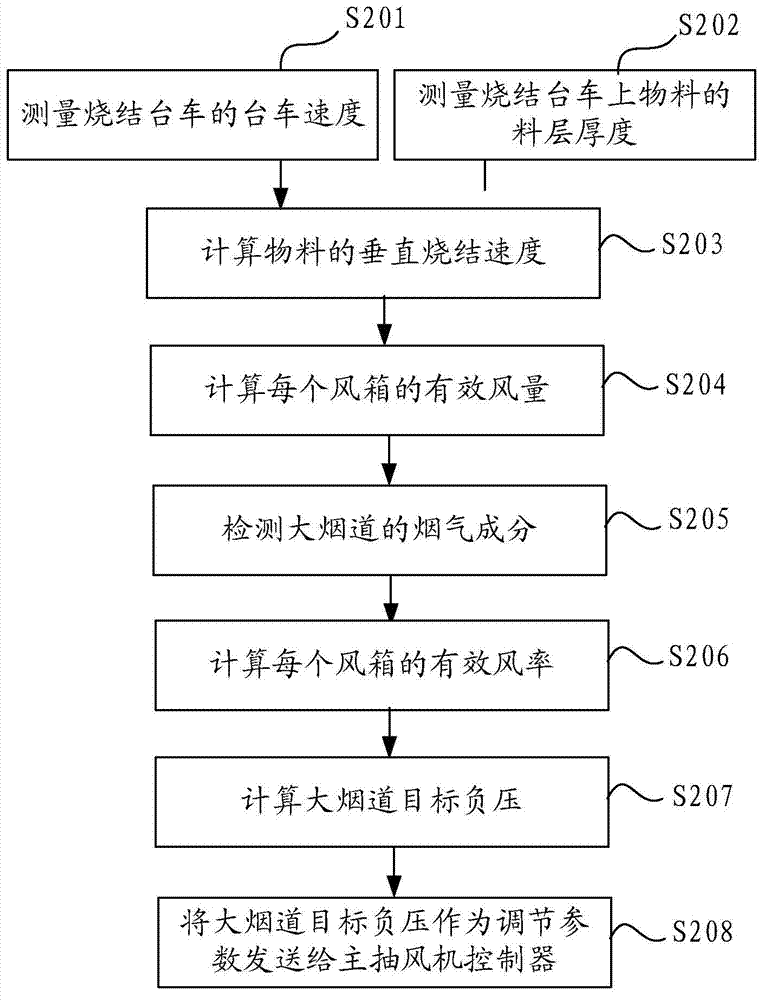

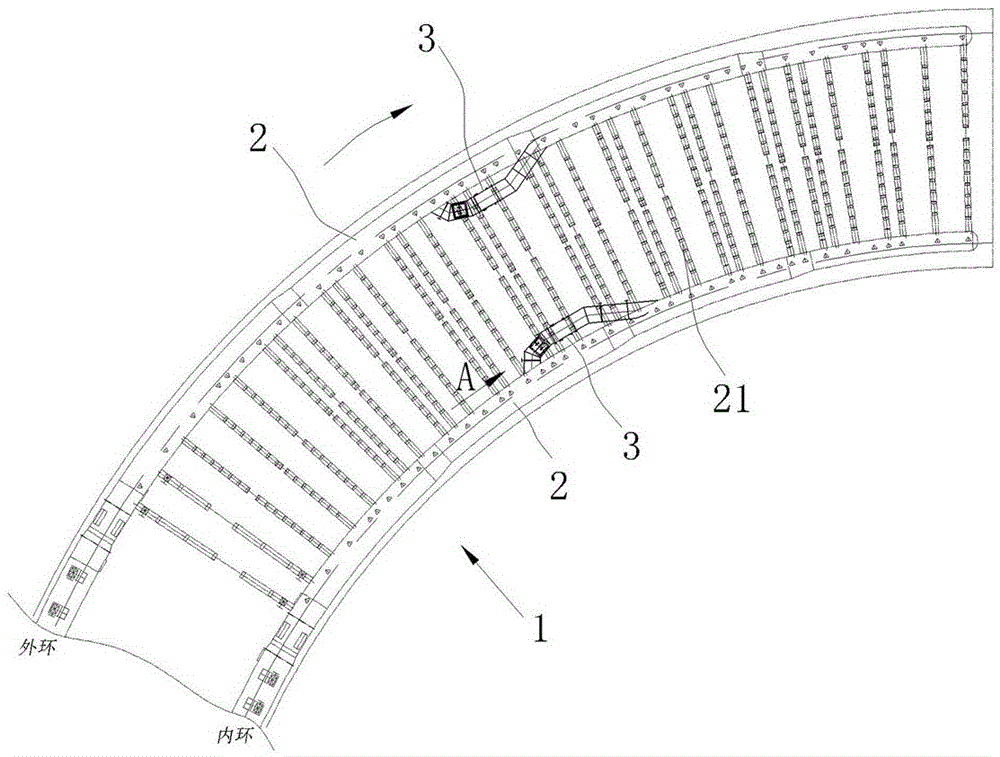

Air volume control method and air volume control system for main exhaust fan of sintering machine

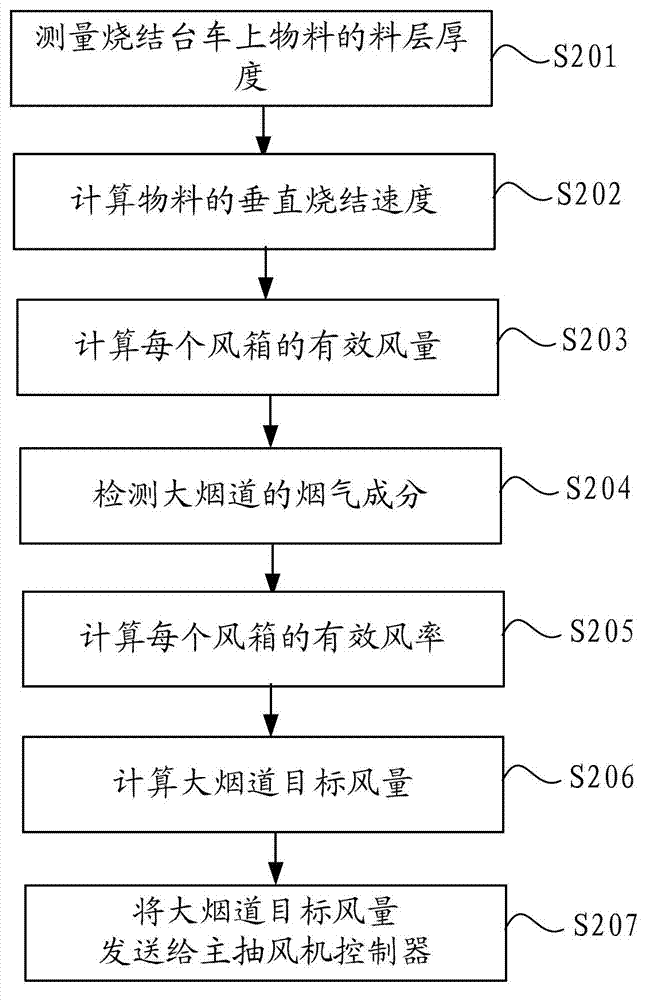

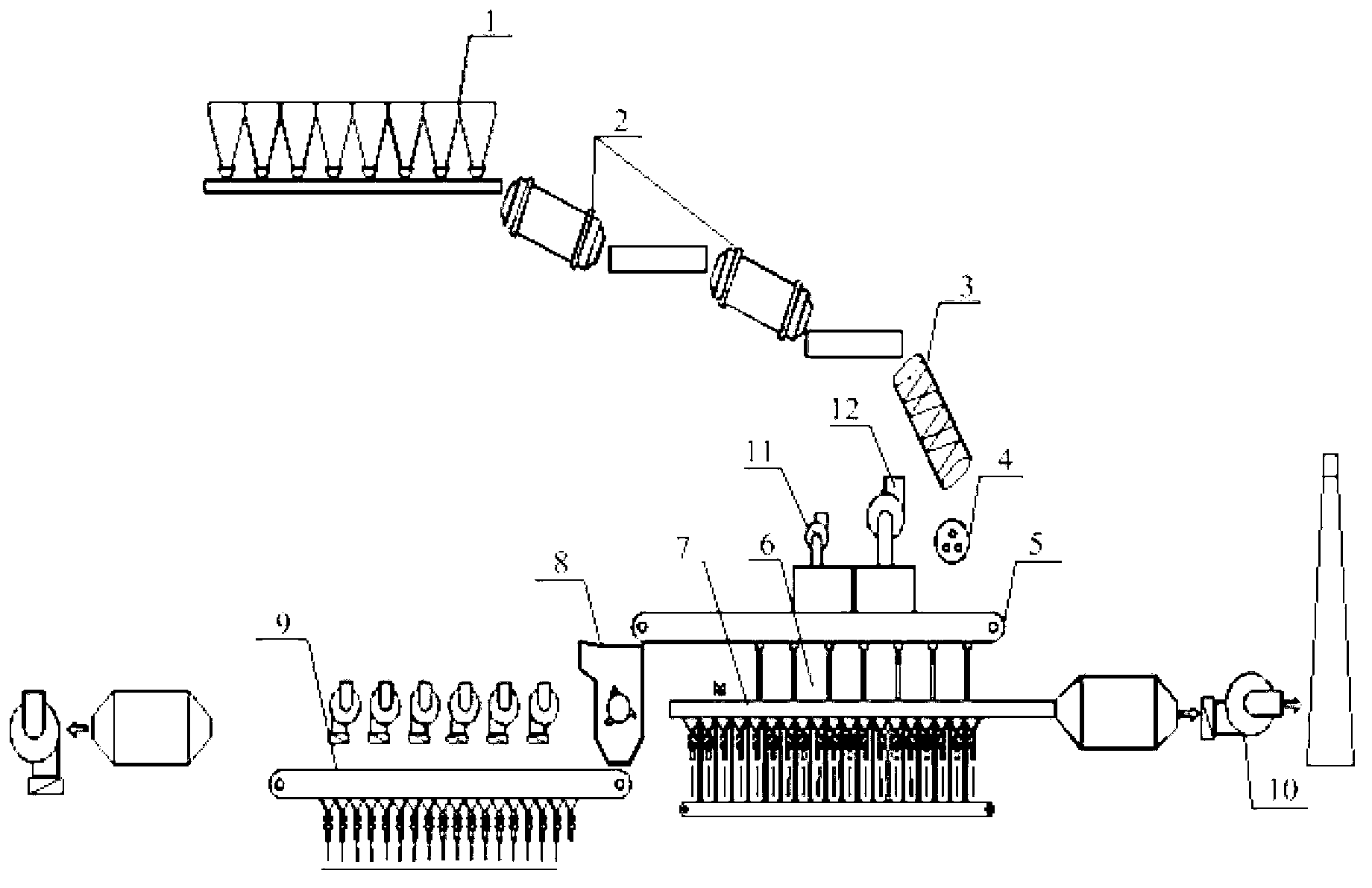

ActiveCN103033055AReduce energy consumptionGuarantee the quality of sinteringFurnace typesAir volumeFlue gas

The application discloses an air volume control method and an air volume control system for a main exhaust fan of a sintering machine. The method includes the following steps: the thickness of the material on a sintering pallet is measured, the vertical sintering speed of the material is calculated, and the effective air volume of each bellows is determined; the flue gas components of a large flue are detected; according to the detected flue gas components, the effective air rate of each bellows is calculated; the target large flue air volume is calculated; the target large flue air volume as a regulating parameter is sent to a main exhaust fan controller, and the main exhaust fan controller regulates the frequency of the main exhaust fan to change toward target frequency. After the material thickness is changed, the air volume of the main exhaust fan can be automatically and accurately regulated to match with the current material thickness, and under the premise of guaranteeing sintering quality, the energy consumption of the main exhaust fan can be reduced in the process of sintering.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD +1

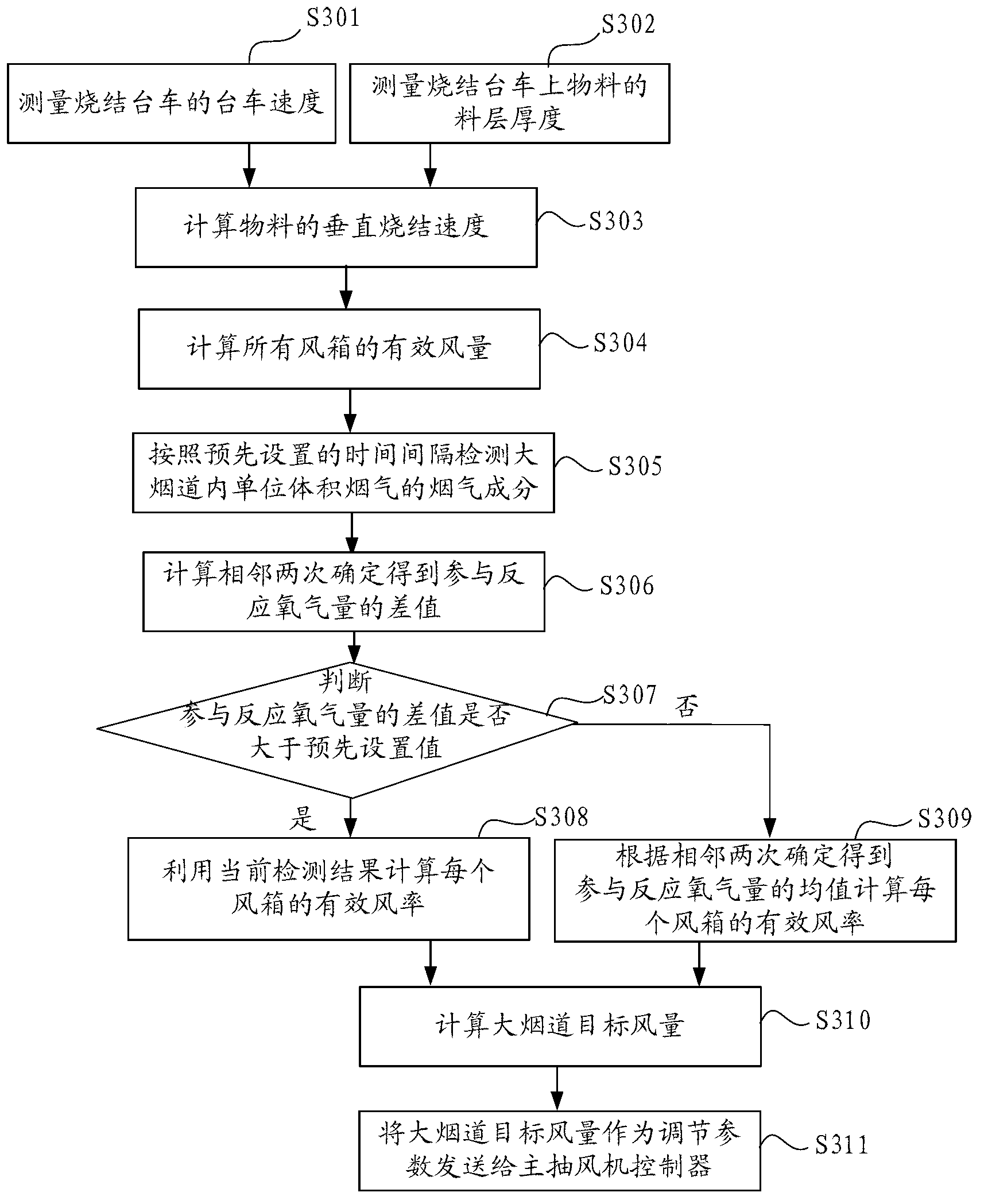

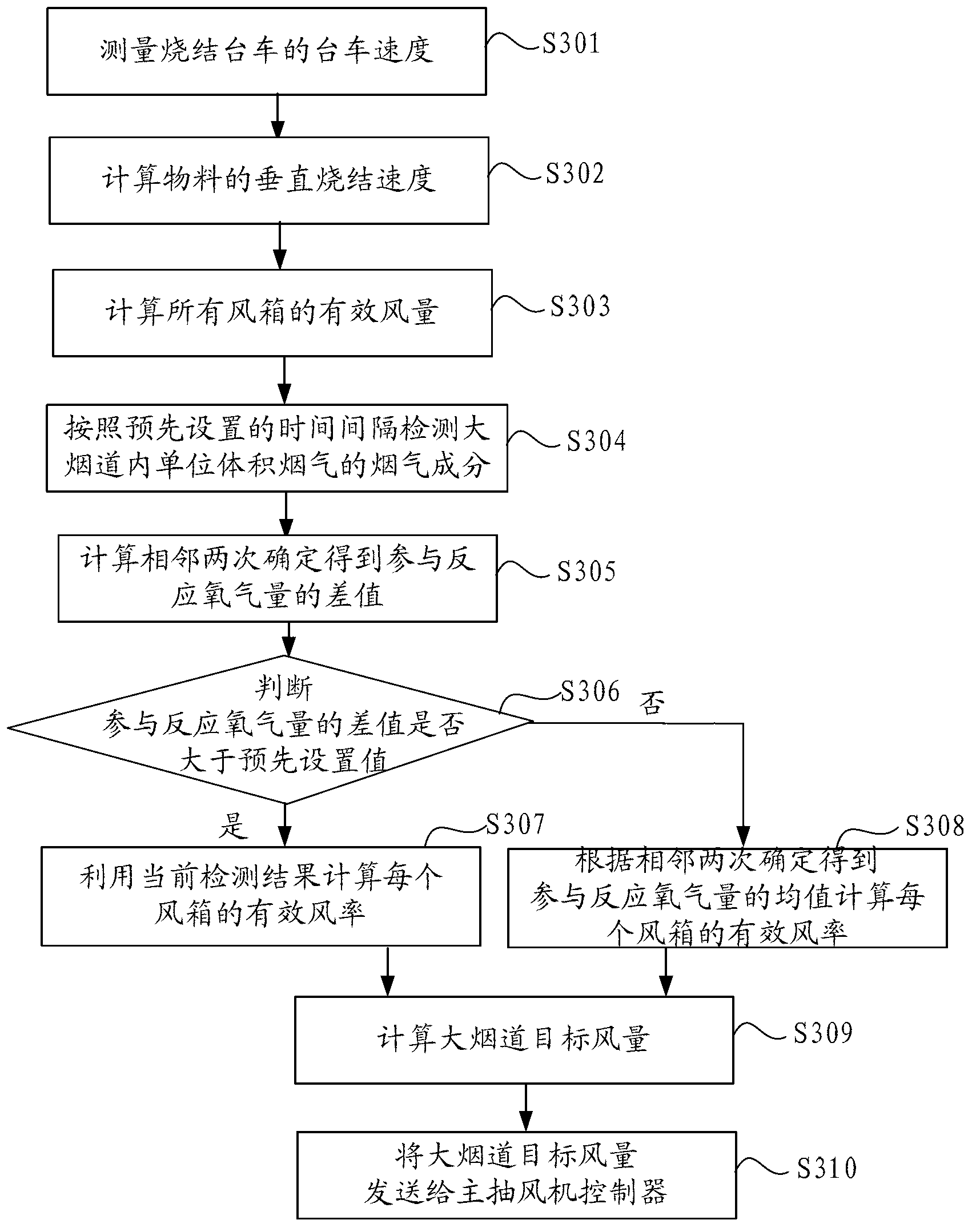

Method and system for controlling air quantity of main draft fan of sintering machine

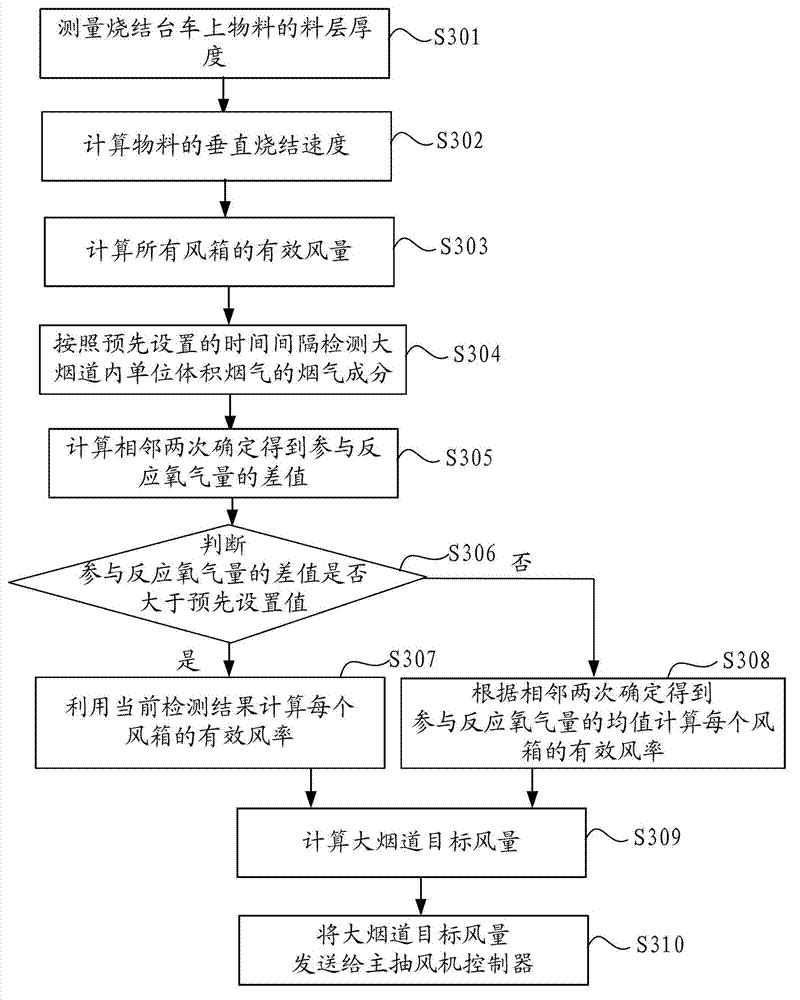

ActiveCN103017529AReduce energy consumptionGuarantee the quality of sinteringFurnace typesAir volumeControl theory

The invention discloses a method and a system for controlling the air quantity of a main draft fan of a sintering machine. The method comprises the steps of: measuring the trolley speed of a sintering trolley, calculating the vertical sintering speed of materials, and determining the effective air quantity of each air bellow; detecting smoke components of a big flue; calculating the effective air rate of each air bellow according to the detected smoke components; calculating the target air quantity of the big flue; and sending the target air quantity of the big flue to a main draft fan controller to serve as a regulating parameter, and regulating the frequency of the main draft fan to change towards a target frequency by the main draft fan controller. When the speed of the sintering trolley changes, the method can be used to regulate the air quantity of the main draft fan to be matched with the current trolley speed automatically and accurately, and thus reduce the energy consumption of the main draft fan in a sintering process on the premise of guaranteeing the sintering quality.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

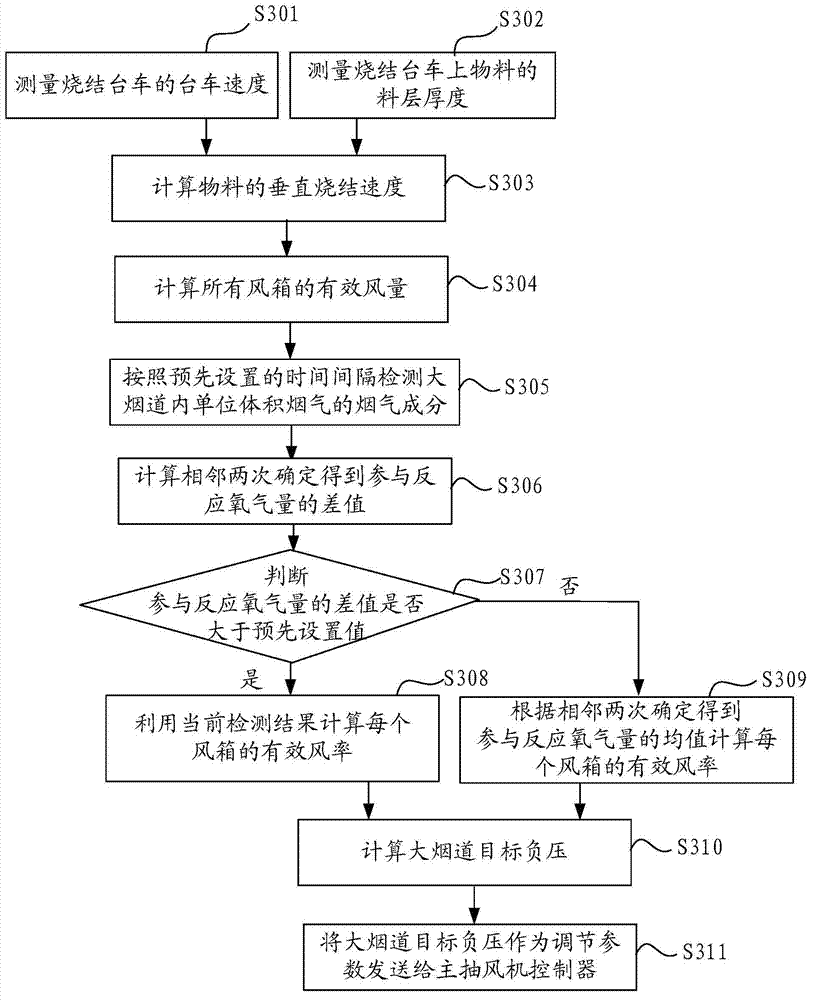

Negative pressure control method and negative pressure control system for main exhaust fan of sintering machine

ActiveCN103033054AReduce energy consumptionGuarantee the quality of sinteringFurnace typesAir volumeFlue gas

The application discloses a negative pressure control method and a negative pressure control system for a main exhaust fan of a sintering machine. The method includes the following steps: the thickness of the material on a sintering pallet and the speed of a sintering pallet are measured, the vertical sintering speed of the material is calculated, and the effective air volume of each bellows is determined; the flue gas components of a large flue are detected; according to the detected flue gas components, the effective air rate of each bellows is calculated; material resistance corresponding to the material thickness is queried; target large flue negative pressure is calculated; the target large flue negative pressure as a regulating parameter is sent to a main exhaust fan controller, the main exhaust fan controller regulates the frequency of the main exhaust fan to change toward target frequency, and the target frequency is equal to the frequency corresponding to the target large flue negative pressure. After the material thickness or the speed of the sintering pallet is changed, the negative pressure of the main exhaust fan can be automatically and accurately regulated to match with the current material thickness and the speed of the sintering pallet, and under the premise of guaranteeing sintering quality, the energy consumption of the main exhaust fan can be reduced in the process of sintering.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Device for maintaining overall temperature of working cylinder balanced and control method of device

InactiveCN105799175ATemperature controlAvoid cooling effectAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringHeat load

The invention discloses a device for maintaining the overall temperature of a working cylinder balanced and a control method of the device. The device mainly comprises a heating device, a heat preservation device, a detection device and a control unit and can achieve slow and balanced change of the temperature of an area where a forming workpiece is located. The control method of the device mainly comprises the following steps: calculating the position and the height of the forming workpiece in the working cylinder via slice preview; calculating the thickness and the shape of the forming workpiece via slice preview; and simulating the heat load data model of the working cylinder. The device and the control method can keep the change rate of temperatures of all areas to be consistent, can reduce warping deformation and defects of mechanical property caused by non-uniform heat dissipation of the forming workpiece due to sudden change of temperature, and can ensure the sintering quality of the forming workpiece.

Owner:湖南萌境智能三维技术有限公司

Alumina short fiber-reinforced magnesium oxide-based crucible and preparation method thereof

The invention discloses an alumina short fiber-reinforced magnesium oxide-based crucible which is excellent in chemical stability and thermal shock resistance, and can realize sintering at a low temperature and a preparation method thereof, the method comprises the following steps: (1) proportioning, by mass, 15% to 25% of nano-aluminum sol, 0.8% to 1.5% of a rheological agent, and balance of electro-fused magnesium oxide ceramic powder containing nano-lanthana and alumina short fiber, adding an appropriate amount of deionized water, uniformly mixing by ball milling, and vacuum degassing to obtain a ceramic slurry having a solid content of 70% to 80%; (2) preparing a crucible biscuit; (3) preparing a crucible blank; and (4) putting the magnesium oxide-based crucible blank in the aluminum sol for vacuum impregnation treatment, grinding the surface, drying, performing high-temperature secondary sintering at a temperature of 1400 to 1600 DEG C, and cooling in a furnace to room temperatureto obtain the magnesia-based crucible.

Owner:FENGYANG L S NET FORMING CO LTD +1

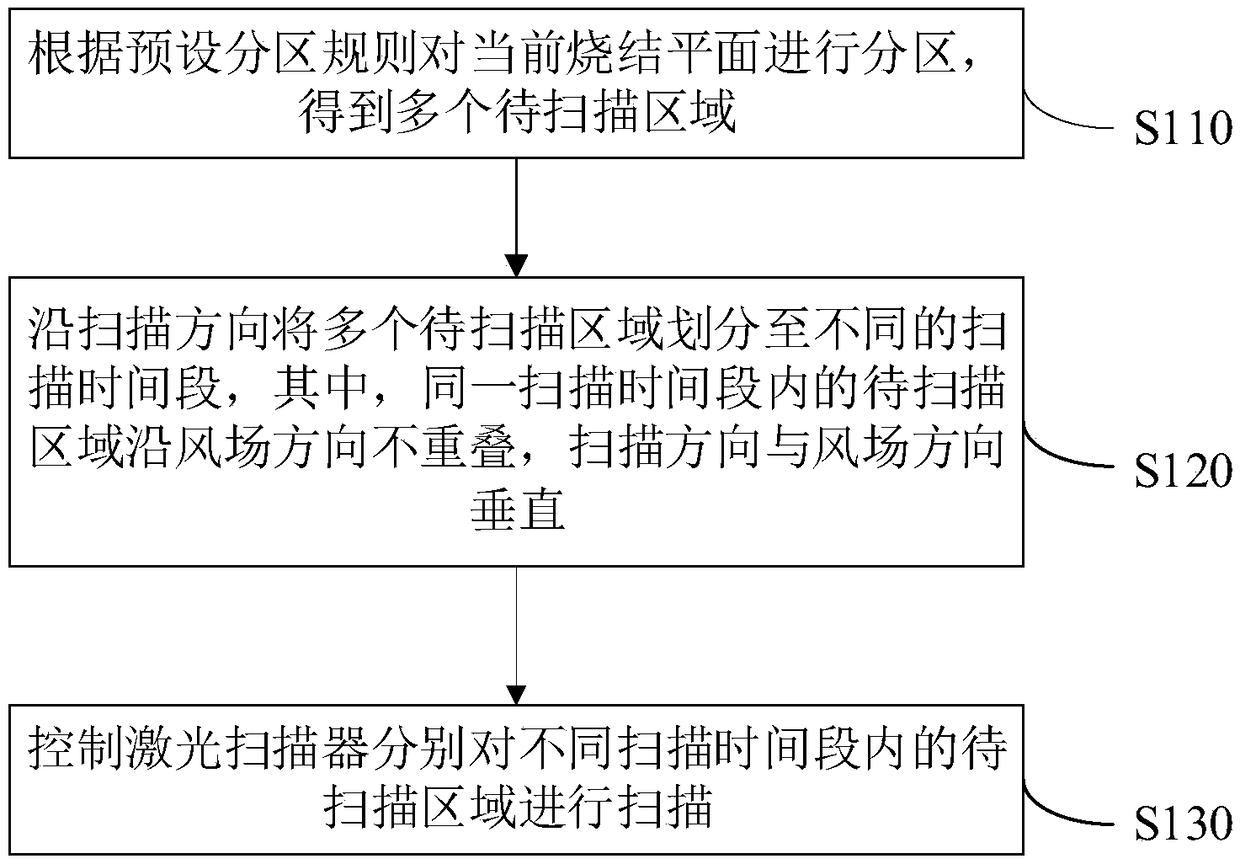

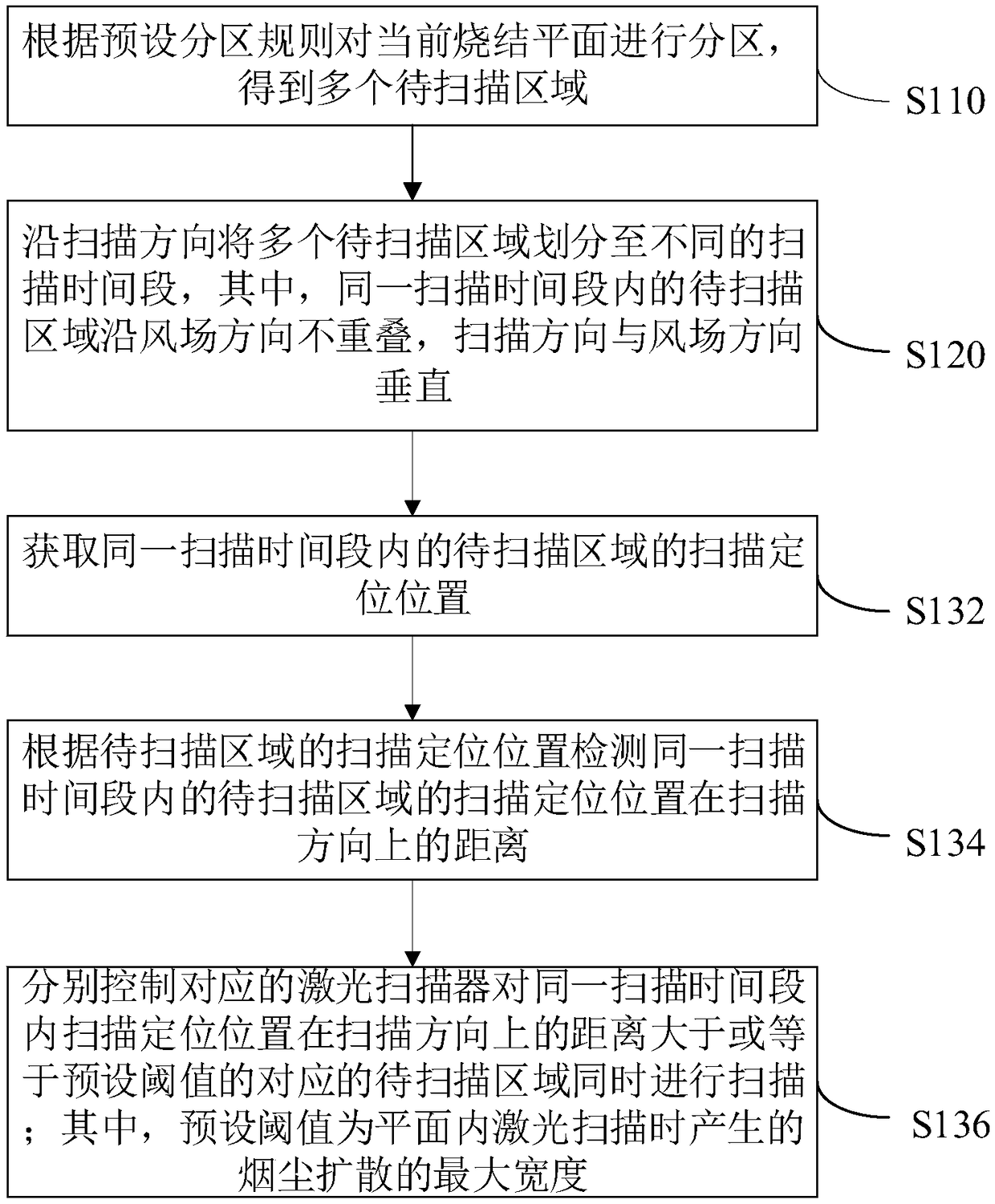

Multi-galvanometer scanning control method, device, computer device and storage medium

ActiveCN108790180AAvoid it happening againGuarantee the quality of sinteringAdditive manufacturing apparatusManufacturing data aquisition/processingTime segmentGalvanometer

The invention relates to a multi-galvanometer scanning control method, device, a computer device and a storage medium. The current sintering plane is divided according to a preset partition rule, so as to obtain a plurality of regions to be scanned, dividing the regions to be scanned into different scanning time periods in the scanning direction, wherein the regions to be scanned in the same scanning time period do not overlap along the direction of the wind field, the scanning direction is perpendicular to the direction of the wind field, the laser scanner is controlled to respectively scan the to-be-scanned area in different scanning time periods. A plurality of regions to be scanned are divided into different scanning time segments in the scanning direction, the dividing principle is that the to-be-scanned area in the same scanning time period does not overlap in the direction of the wind field, the laser scanner is controlled to carry out scanning on the to-be-scanned area in different scanning time periods, so that smoke generated during laser scanning can be prevented from passing through a laser starting path, the laser energy and the sintering quality are guaranteed to themaximum extent, and the laser scanning effect is not influenced.

Owner:HUNAN FARSOON HIGH TECH CO LTD

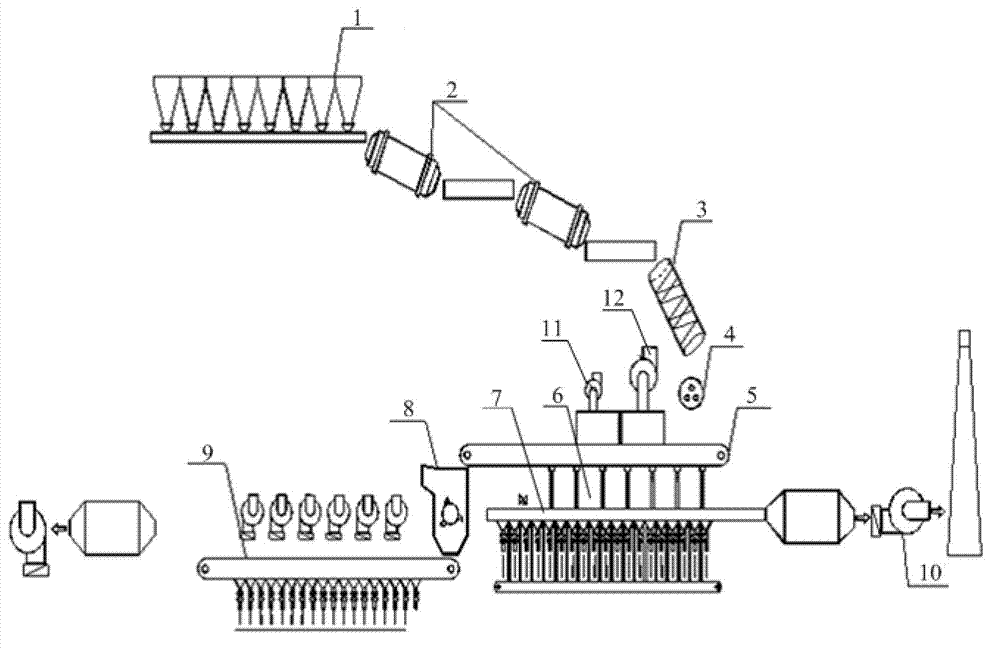

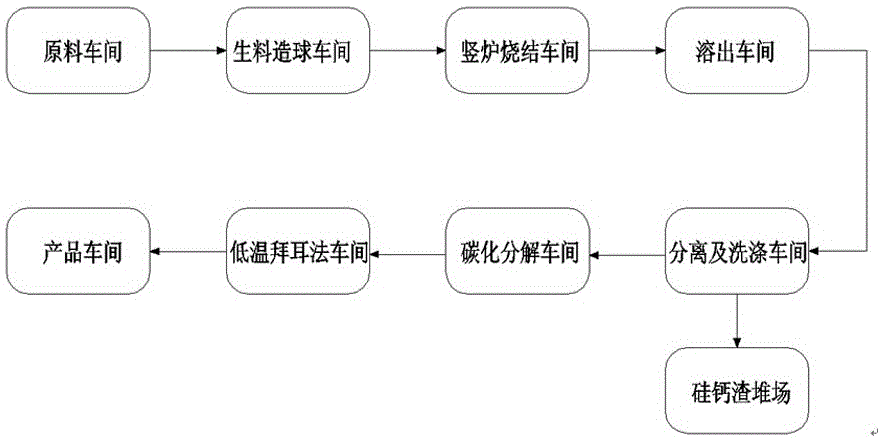

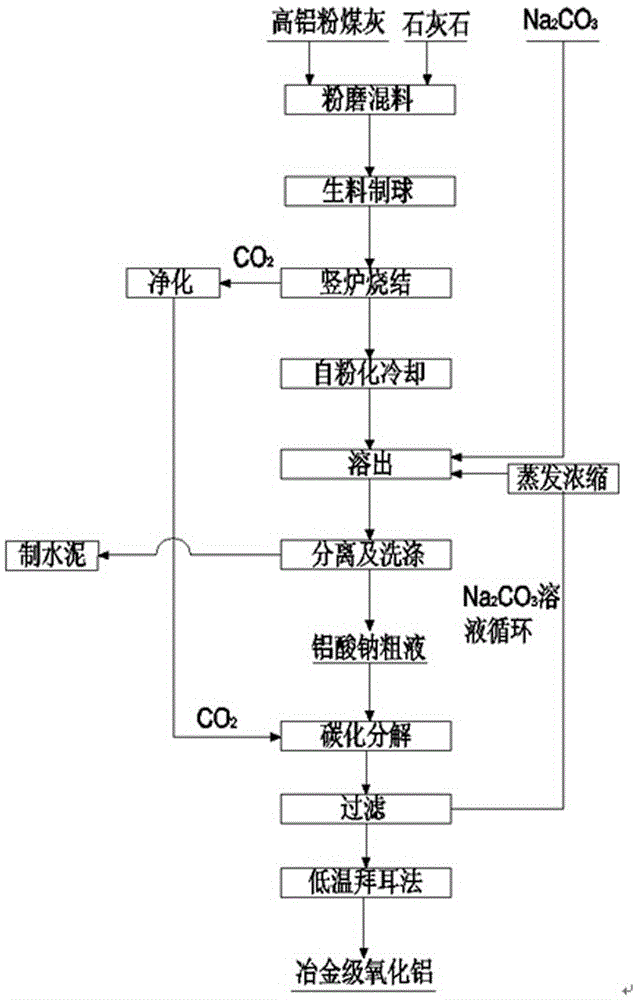

Method for extracting aluminum oxide from coal ash on basis of lime sinter process

InactiveCN105753024AHigh temperatureLarge outputAlkaline-earth metal silicatesAluminium oxides/hydroxidesShaft furnaceCalcination

The invention discloses a method for extracting aluminum oxide from coal ash on basis of a lime sinter process.The method includes steps: (1) grinding and mixing; (2) raw material balling; (3) shaft furnace calcining; (4) autogenous pulverizing and cooling; (5) dissolving out; (6) separating and washing; (7) carbonizing and decomposing; (8) filtering; (9) treating according to a low-temperature Bayer process, so that metallurgical aluminum oxide is obtained.The method has the advantages that by shaft furnace calcinations, energy consumption is greatly reduced, and production cost is evidently reduced; by the method, sintering under high-temperature large-scale operating conditions can be realized easily, product sintering quality is guaranteed, and the method is suitable for large-scale industrial production.

Owner:JIUQUAN IRON & STEEL GRP

Production of ceramic double-pipe with jargonia for fibre optical connector

InactiveCN1818731AGuarantee the quality of sinteringGuaranteed roundnessCoupling light guidesElastic vibrationOptical fiber connector

A method for preparing zirconium oxide ceramic sleeve used on optical fiber connector includes applying zirconium oxide powder containing 3mol% yttria as raw material granulating zirconium oxide powder to let it have specific area of 12-35 m2 / g by atomizing technique of granulation ,forming granulated zirconium oxide material to be required shape by elastic vibration model with pressure of 60-200Mpa ,firing formed material with temperature of 1380-1480 deg.c for period of 48-50 hr. by silicon-molybdenum bar electronic furnace for obtaining final produce.

Owner:TIANJIN URBAN CONSTR COLLEGE

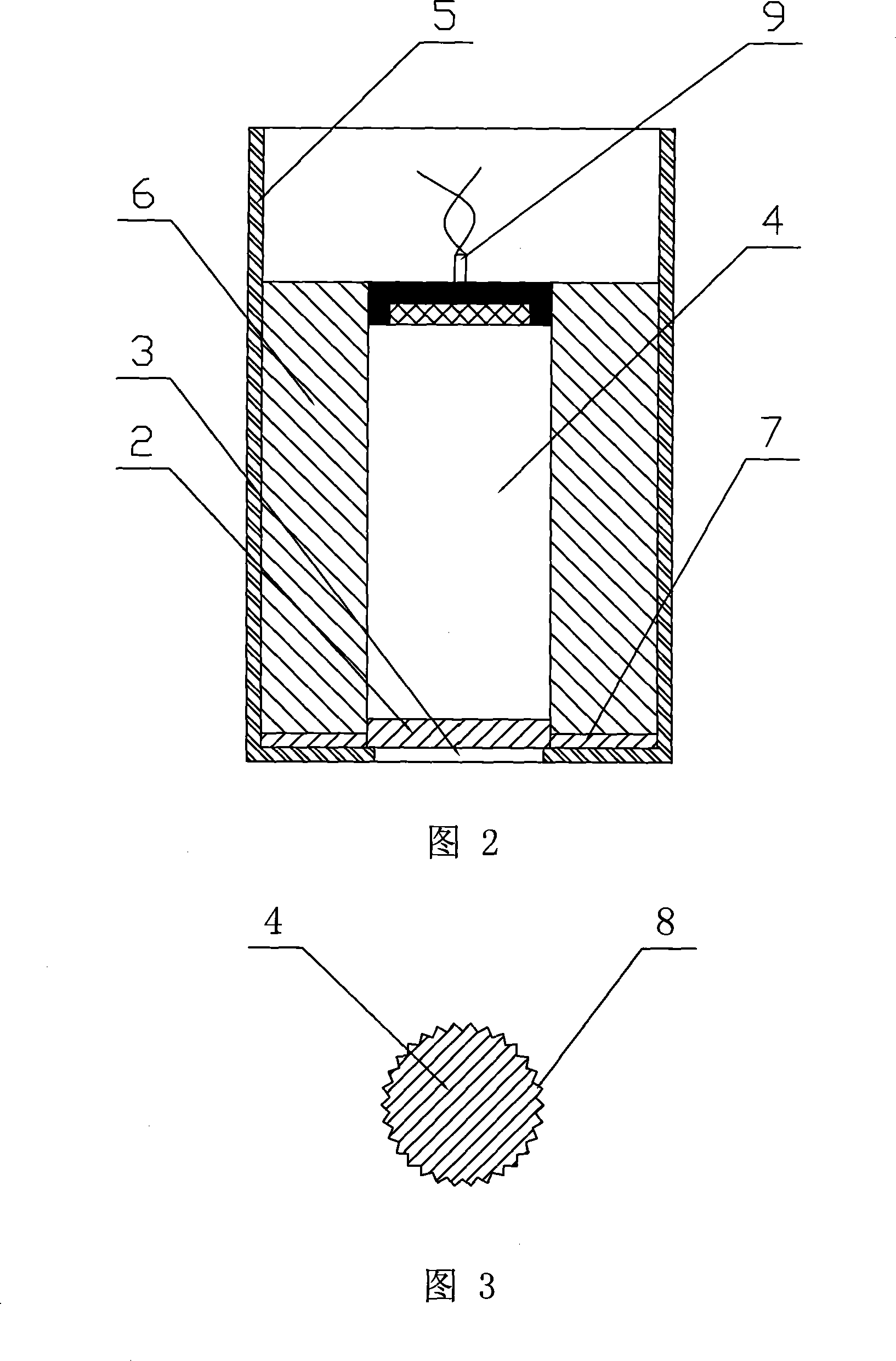

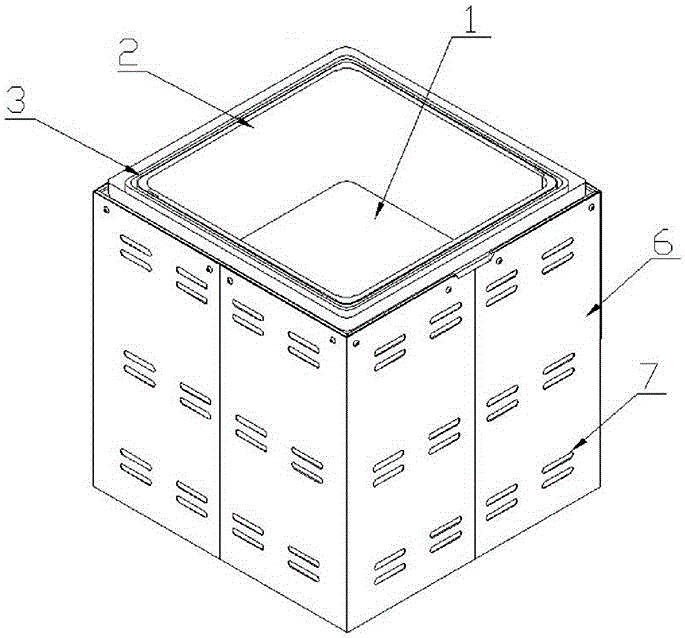

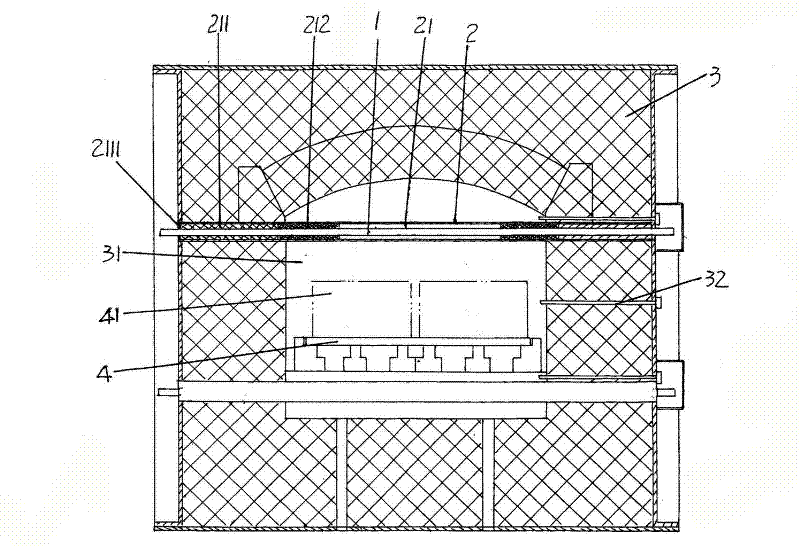

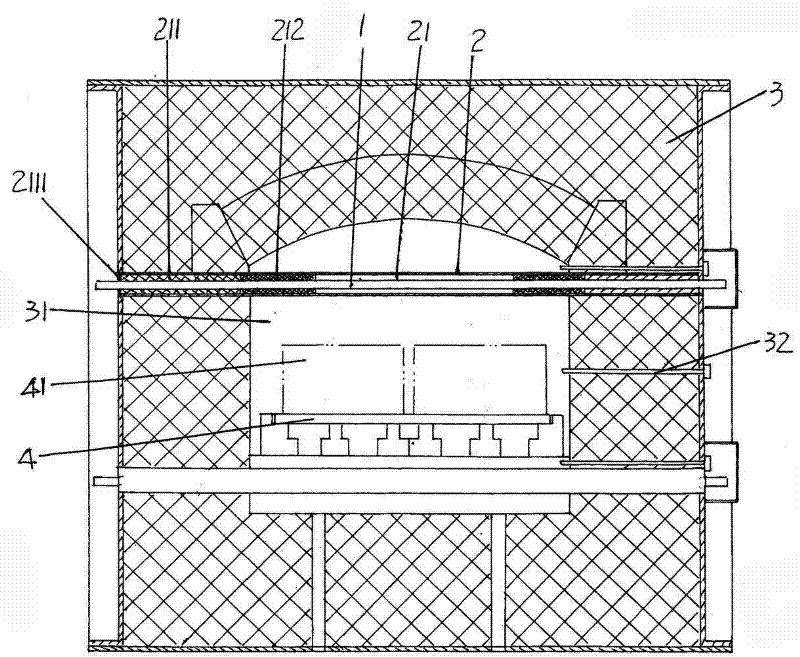

Fully-closed high temperature microwave sintering roller kiln

The invention discloses a fully-closed high temperature microwave sintering roller kiln, which aims to overcome the shortcomings of high noise, relatively poorer tightness and proneness to the occurrence of kiln arching of the conventional sintering kiln which is a gear drive mechanism. The fully-closed high temperature microwave sintering roller kiln comprises a closed kiln body consisting of a top plate, side plates and a bottom plate. Multi-layer fiberboards are arranged on the two sides and top part of the kiln body. A roller bed is arranged on the bottom plate of the kiln body, and is provided with a push plate for conveying materials. The push plate is driven by a roller bed drive system arranged in a cavity of the kiln body. The fully-closed high temperature microwave sintering roller kiln has a simple structure, low manufacturing cost, high tightness, high product sintering efficiency, high sintering quality and a wide sintering temperature range, is energy-saving, environmentally-friendly, safe and reliable and avoids the phenomenon of kiln arching.

Owner:湖南航天有限责任公司

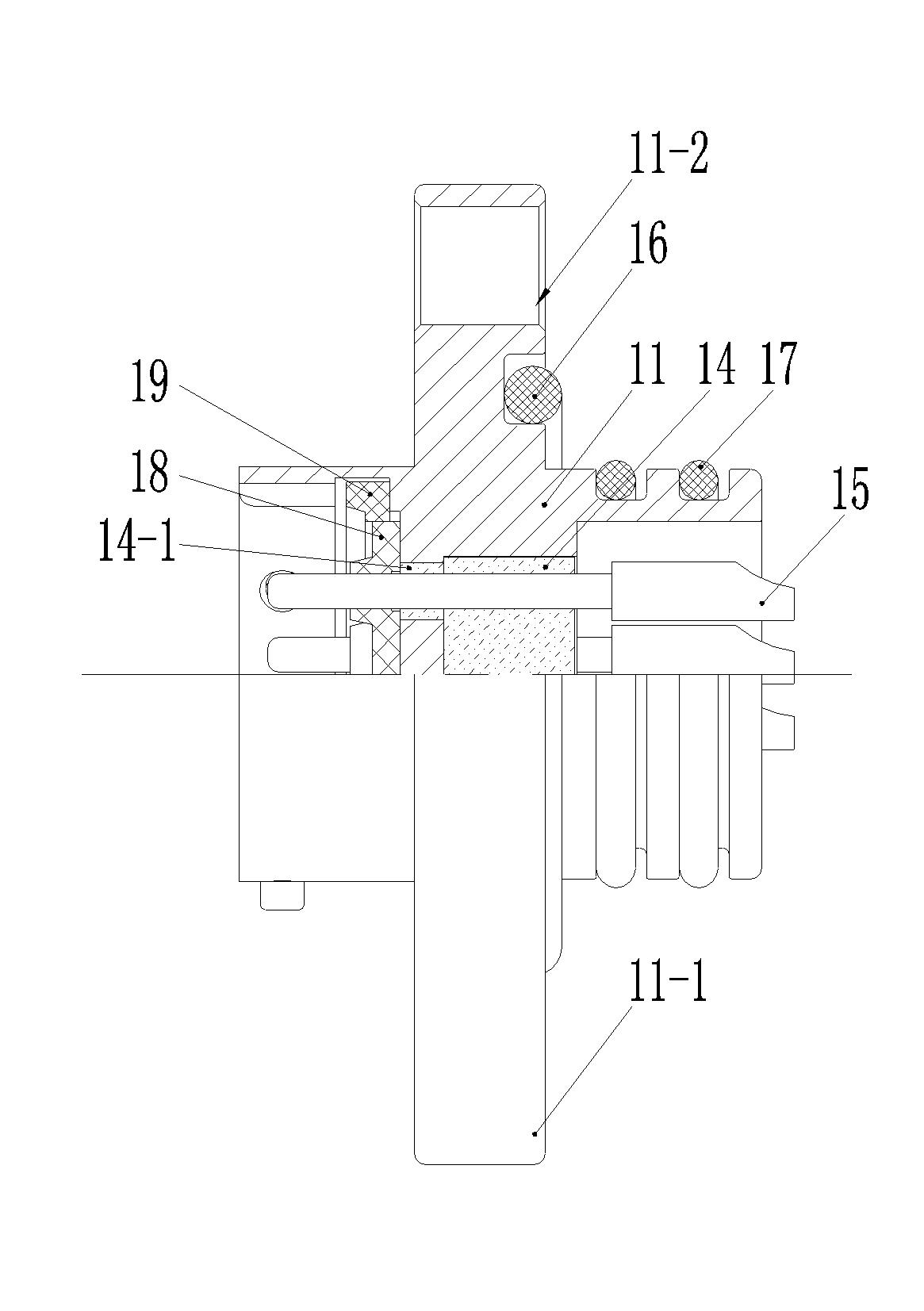

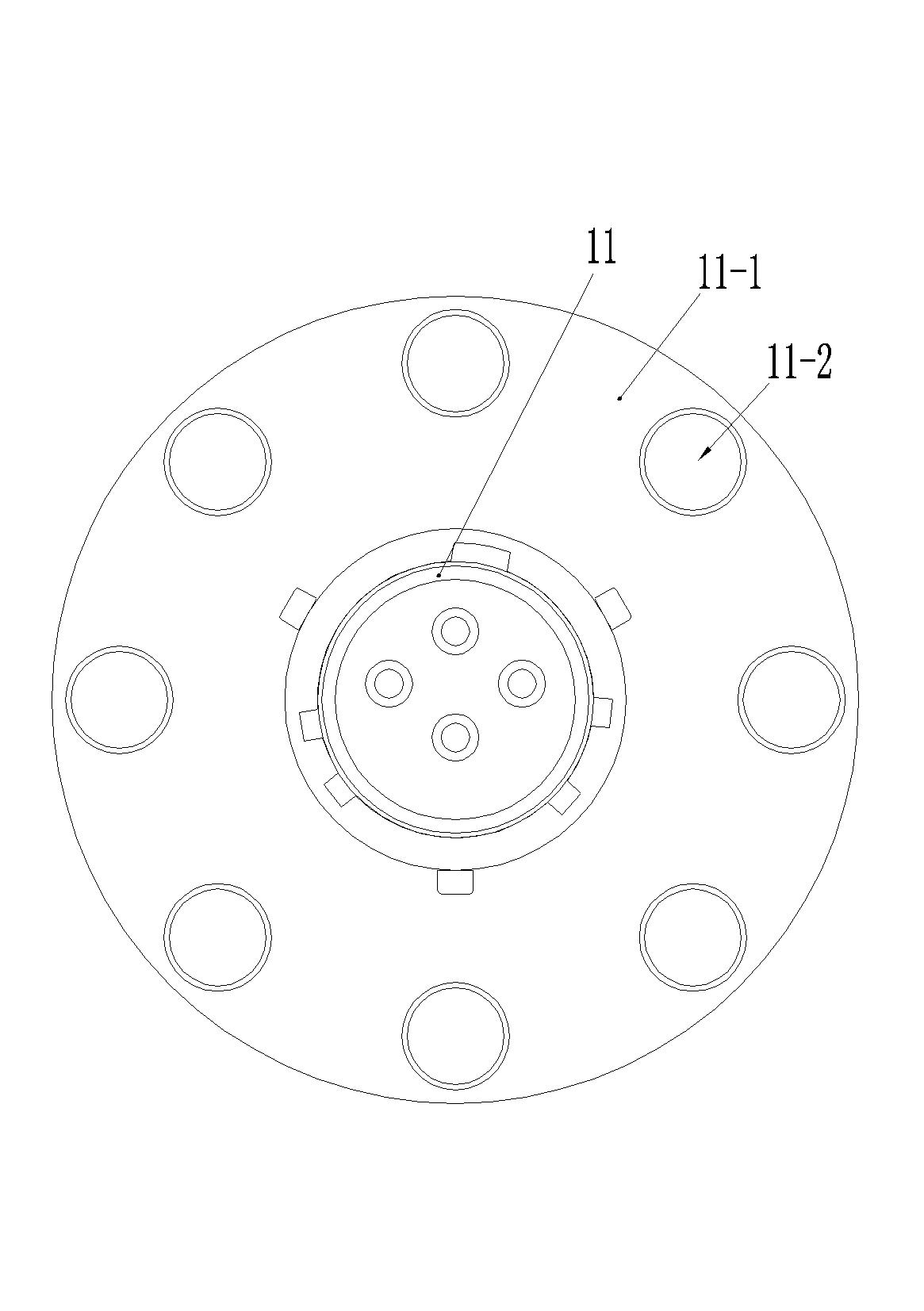

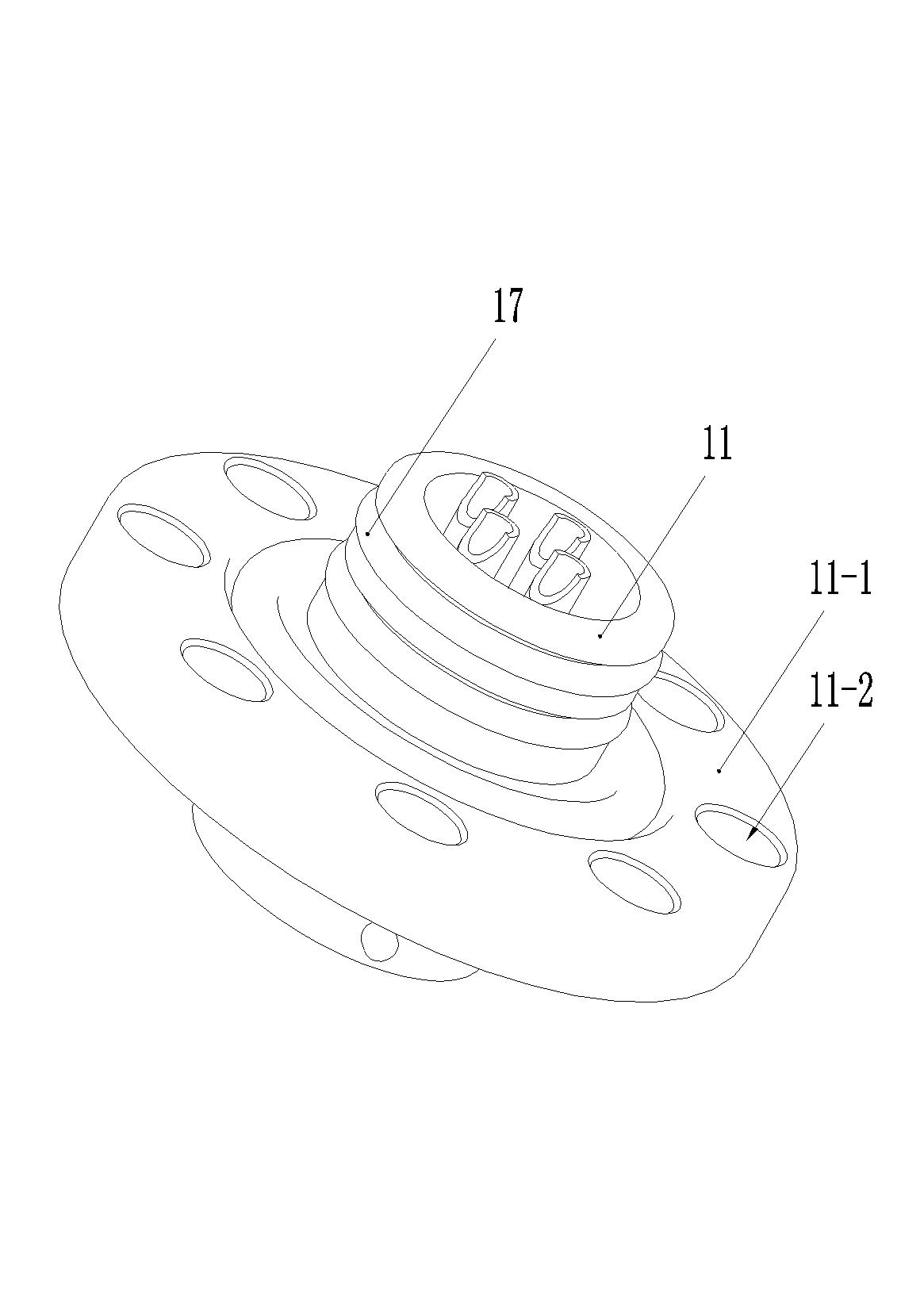

Sintered and sealed electric connector resistant to high pressure

InactiveCN102664329AImprove stress resistanceGuarantee the quality of sinteringCouplings bases/casesElectricityHigh pressure

The invention relates to a sintered and sealed electric connector resistant to high pressure. The sintered and sealed electric connector comprises a metal shell, wherein a contact element is assembled inside the metal shell by a glass cake; the periphery of the glass cake is sintered and fixed with an internal wall surface of the metal shell; a bearing wall matched with the contact element in an insulating manner is integrally arranged between two ends of the contact element inside the metal shell; a through hole for the contact element to penetrate is formed in the bearing wall; the bearing wall is provided with an interface sealing body on one side adjacent to a plugging end of the electric connector, and the other side of the bearing wall is sintered and fixed with the glass cake; no matter which end of the connector is pressed, the bearing wall can share the pressure, so that the bearable pressure of the connector is not limited by the bonding strength between the glass cake and the shell any more; additionally, the adoption of the glass cake sintering is easier to guarantee the sintering quality in comparison with a glass tube sintering way, thereby solving the problem of poor pressure resistance performance of the prior electric connector adopting a sintered glass insulator on the primise of guaranteeing the sintering quality of the sintered glass insulator.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

A metal package rectifier diode and a manufacturing method thereof

ActiveCN108987363AIncreased high current toleranceImprove stability and reliabilitySemiconductor/solid-state device detailsSolid-state devicesRectifier diodesEngineering

A metal package rectifierdiode and a manufacturing method thereof are disclosed. Thediode comprise a die holder, a die assembly, a lead post and a tube cap. The tube holder and the tube cap respectively form a first electrode and a second electrode; The die assembly is welded on the pipe base, one end of the lead post is welded on the die assembly, and the other end is fixedly connected with the pipe cap; A lead post is arrange through that pipe cap, and the pipe cap is sealingly connected with the pipe seat and the lead post respectively; A lead post is for of a plurality of strands of metalwire, and a metal sleeve for fastening that metal wire is arranged at both ends. A manufacture method includes obtain an upper electrode sheet and a lower electrode sheet, sintering to form a die assembly and sintering seal welding. The diode can meet the use demand of more than 5A current, has strong heat dissipation ability, simple structure and ingenious design; Connection quality and conduction characteristics are guaranteed. The method ensures the sintering quality and reliability of the die assembly, ensures the good adhesion between the part and the solder, and realizes the stable, reliable and fast direct sintering of the die assembly with the bare copper pipe socket, the lead post and the red copper ring.

Owner:西安卫光科技有限公司

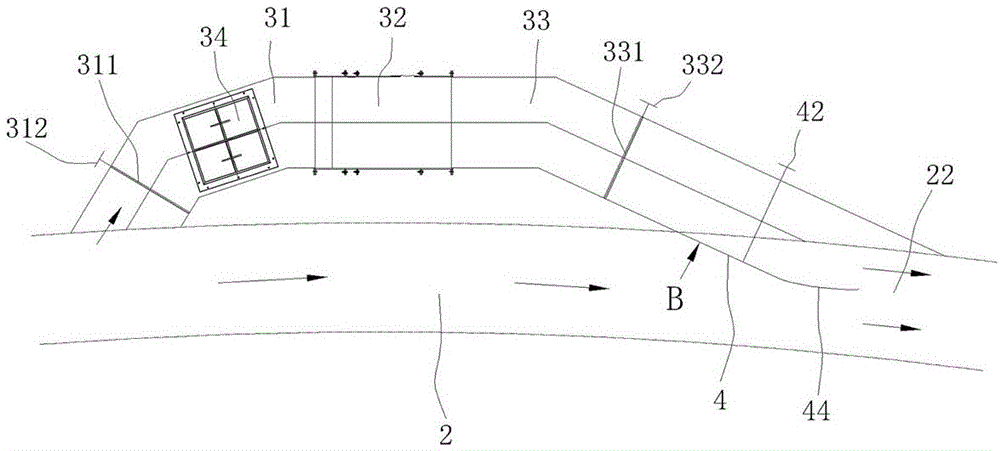

Air adding and pressurizing device of rotary kiln drying system

ActiveCN106017051AGuaranteed drying qualityGuarantee the quality of sinteringDrying gas arrangementsAir volumeAir temperature

The invention discloses an air adding and pressurizing device of a rotary kiln drying system and belongs to the technical field of tile kiln furnace equipment. The air adding and pressurizing device is used for solving the problem that the drying demand of raw tiles cannot be met due to the fact that existing rotary kiln drying systems are insufficient in wind supply. The air adding and pressurizing device is connected with part of a main heat supply air pipe in the rotary kiln drying system in parallel. The air adding and pressurizing device sequentially comprises an air inlet pipe, a fan and an air outlet pipe in the air supply direction. An air inlet adjusting brake is arranged at the end, close to the main heat supply air pipe, of the air inlet pipe. An external air inlet is formed in the air inlet pipe. An external air inlet adjusting brake is arranged in the position of the external air inlet. An air outlet adjusting brake is arranged at the end, close to the main heat supply air pipe, of the air outlet pipe. A converging adjusting brake is arranged at the joint of the air outlet pipe and the main heat supply air pipe. The air adding and pressurizing device is reasonable in design and convenient to operate, adjusting and control of the rotary kiln drying system to air amount, air temperature (temperature decrease) and air pressure can be ensured, and the drying quality and sintering quality of the tiles are ensured.

Owner:袁树芬

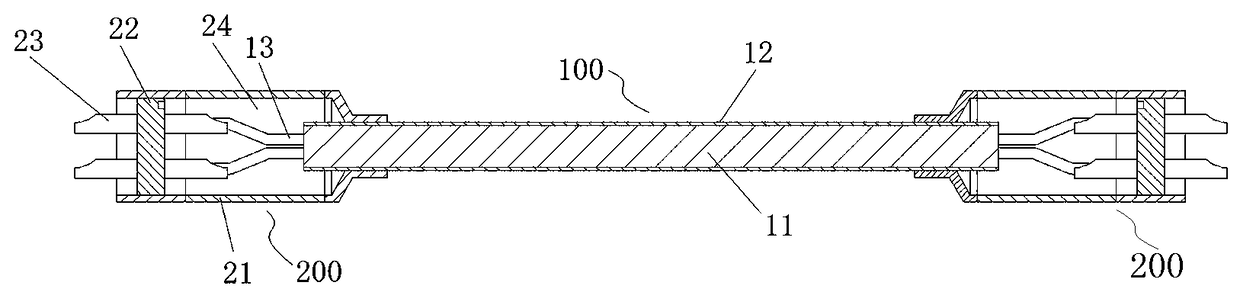

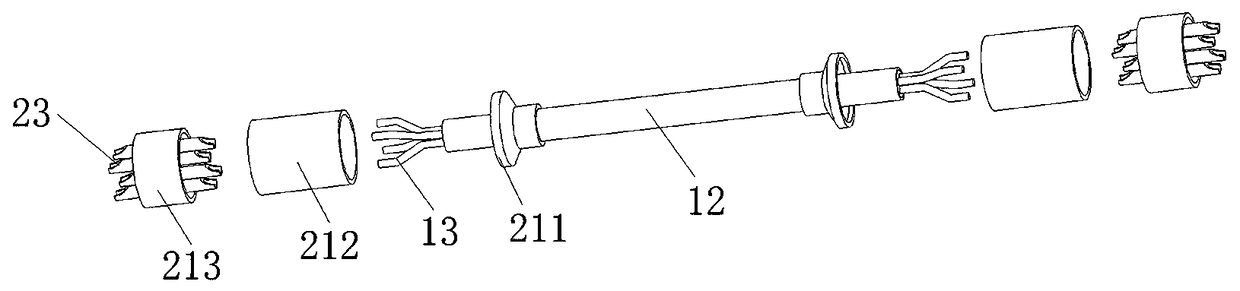

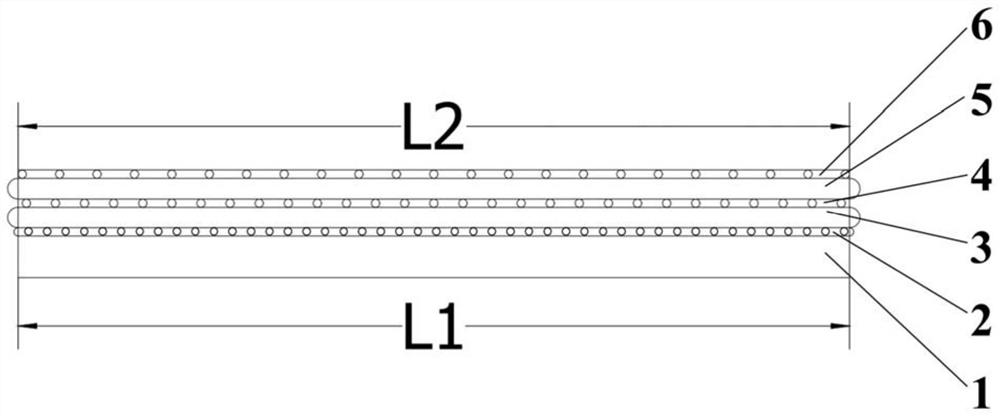

Mineral insulated cable subassembly

PendingCN109473204AImprove moisture resistanceImprove reliabilityClimate change adaptationInsulated cablesColloidHumidity

The invention relates to a mineral insulated cable subassembly. The mineral insulated cable subassembly comprises a mineral insulated cable having an outer sheath, an intermediate insulator and a corewire; a corresponding end of the mineral insulated cable is provided with a sealed adapter structure; the sealed adapter structure comprises an end sleeve sleeved out of a terminal of the core wire;a rear end of the end sleeve is welded and sleeved on the outer sheath; an adapter welding cup is sintered and fixed in front of the terminal of the core wire in the end sleeve through a glass disk; arear end of the adapter welding cup is connected with the terminal of the core wire in a welding manner; a front end of the adapter welding cup is an adapter end; a sealed filler chamber is disposedin the rear of the glass disk in the end sleeve; an insulating inorganic glue is poured into the sealed filler chamber to form an insulating potting colloid which wraps the corresponding core wire andthe adapter welding cup. The sealing for the ends is enhanced through the insulating potting colloid, the humidity resistance and reliability of the mineral insulated cable subassembly are improved,and the situations of poor sintering quality and poor waterproofness caused by direct sintering of the outer sheath and the core wire are avoided.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

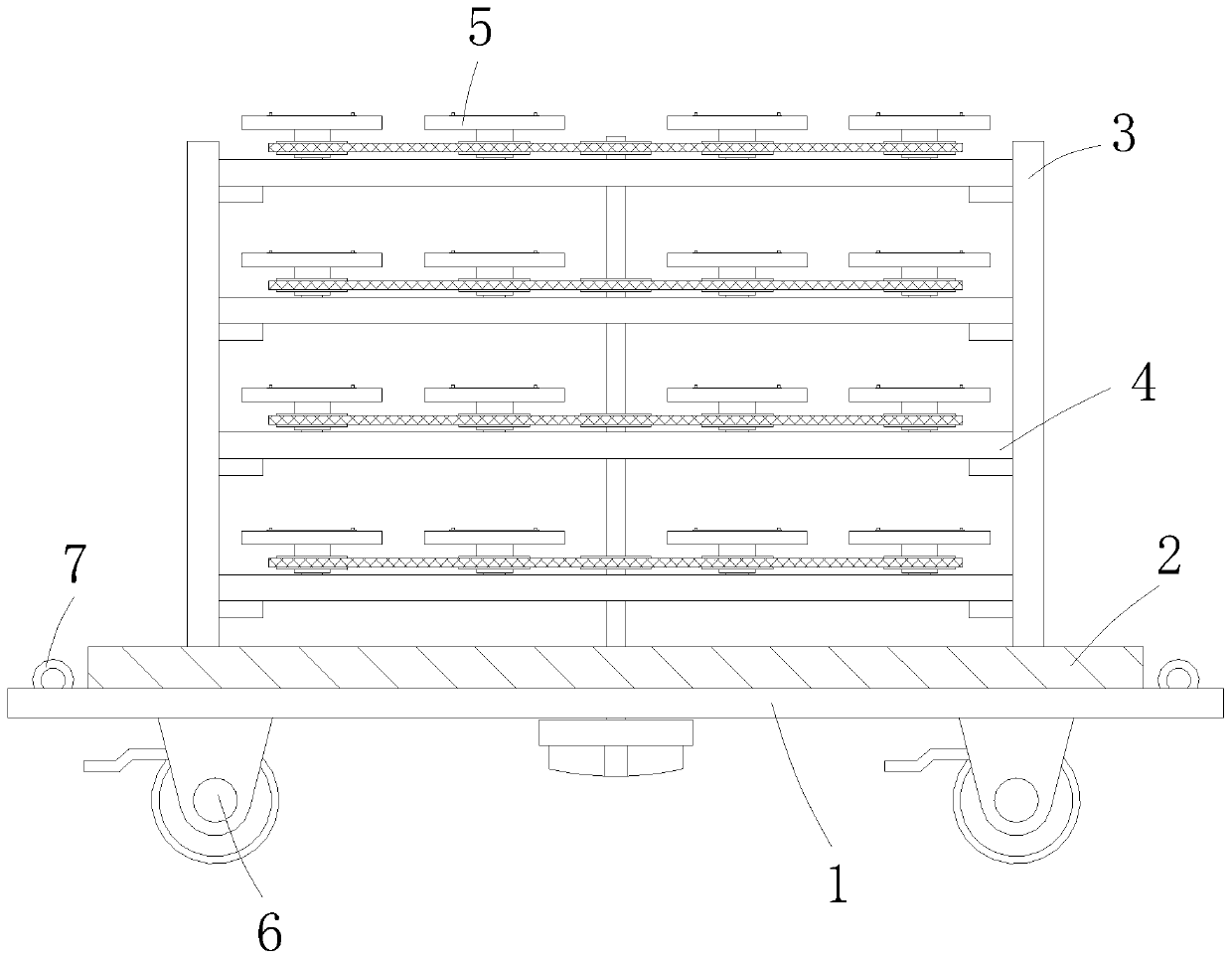

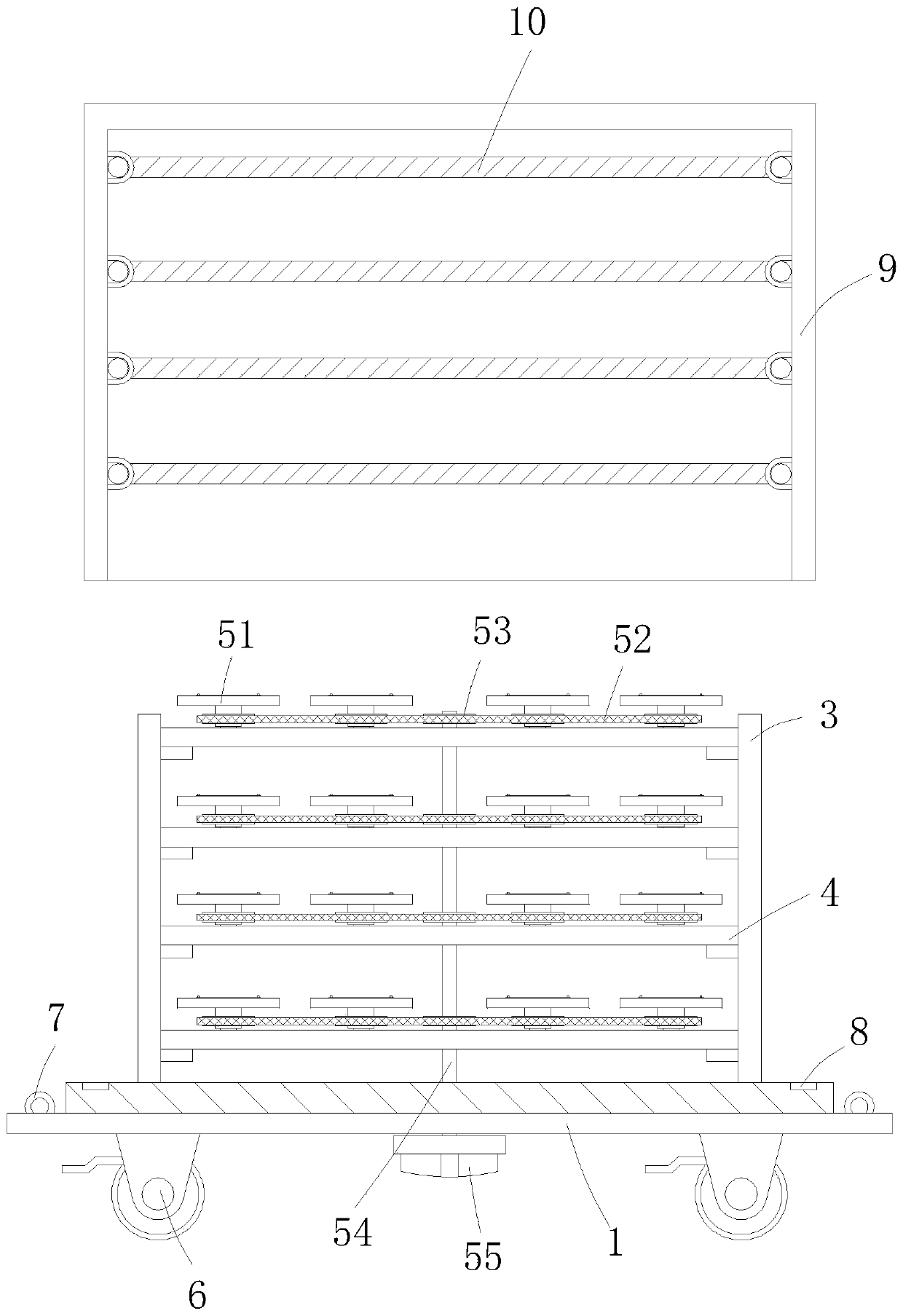

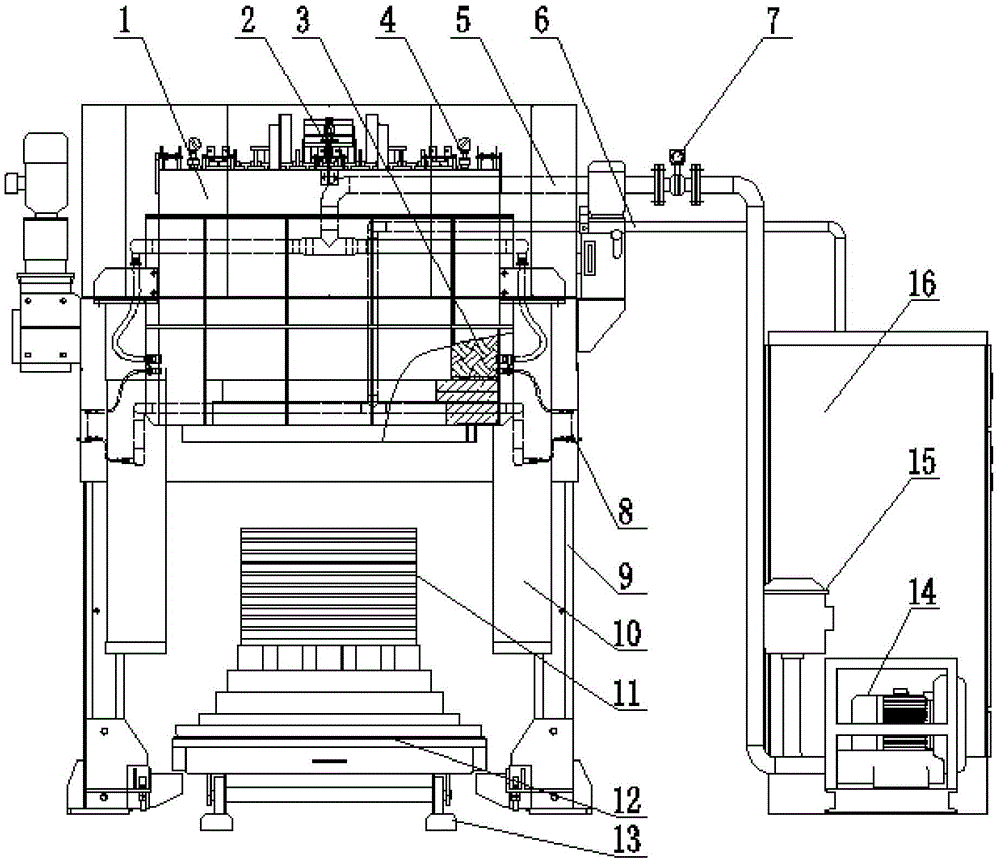

Support frame for sintering soft magnetic ferrite cores based on chain wheel transmission

ActiveCN111121468AImprove sintering qualityEasy to collectCharge supportsSoft magnetStructural engineering

The invention relates to the technical field of soft magnetic ferrite core production equipment, provides a support frame for sintering soft magnetic ferrite cores based on chain wheel transmission, and aims at solving the problems that soft magnetic ferrite core blanks on an existing support frame are vertically stacked on a burning bearing plate for high-temperature heating, the lower-layer blanks on the burning bearing plate are prone to bearing large pressure, stress is uneven, uneven heating is accordingly caused, and the soft magnetic ferrite core blanks deform. The support frame comprises a support bottom plate and a die assembly base installed at the upper end of the support bottom plate, four stand columns distributed in a matrix mode are fixedly installed at the upper end of thedie assembly base, a plurality of supporting blocks are installed on the opposite side walls of the four stand columns at equal intervals, a mounting plate is erected on the four supporting blocks located on the same horizontal plane, and a sintering dispersing mechanism is arranged on the mounting plate; and the sintering dispersing mechanism comprises a plurality of supporting columns arranged on the upper end face of the mounting plate in parallel. The support frame is particularly suitable for sintering placement of the soft magnetic ferrite cores, and has high social use value and application prospect.

Owner:天长市联嘉磁电科技有限公司

Sintering process method applicable to low-pressure bead sintering of double furnace

InactiveCN109249029AGuarantee the quality of sinteringUniform temperatureFurnace temperatureTemperature control

The invention discloses a sintering process method applicable to low-pressure bead sintering of a double furnace. The implementation scheme includes that heat-compensating temperature-control heatingmodules are arranged at upper, middle and lower positions in the center of a combustion chamber of the double furnace, to-be-sintered beads are placed and accumulated around the upper, middle and lower heat-compensating temperature-control heating modules to form triangular, quadrangular or annular bead accumulation areas which are heated and sintered by the upper, middle and lower heat-compensating temperature-control heating modules and original upper, middle and lower furnace temperature control heating modules in the furnace wall of the double furnace, and accordingly uniformity of internal and external heating temperature of the bead accumulation areas is guaranteed. Changing of an original process is avoided, a temperature control system automatically controls uniformity of the internal and external temperatures of the bead accumulation areas in sintering in the furnace, and accordingly temperature uniformity of each furnace portion in a sintering process is realized, and bead sintering quality is guaranteed.

Owner:GUILIN TEBON SUPERHARD MATERIAL

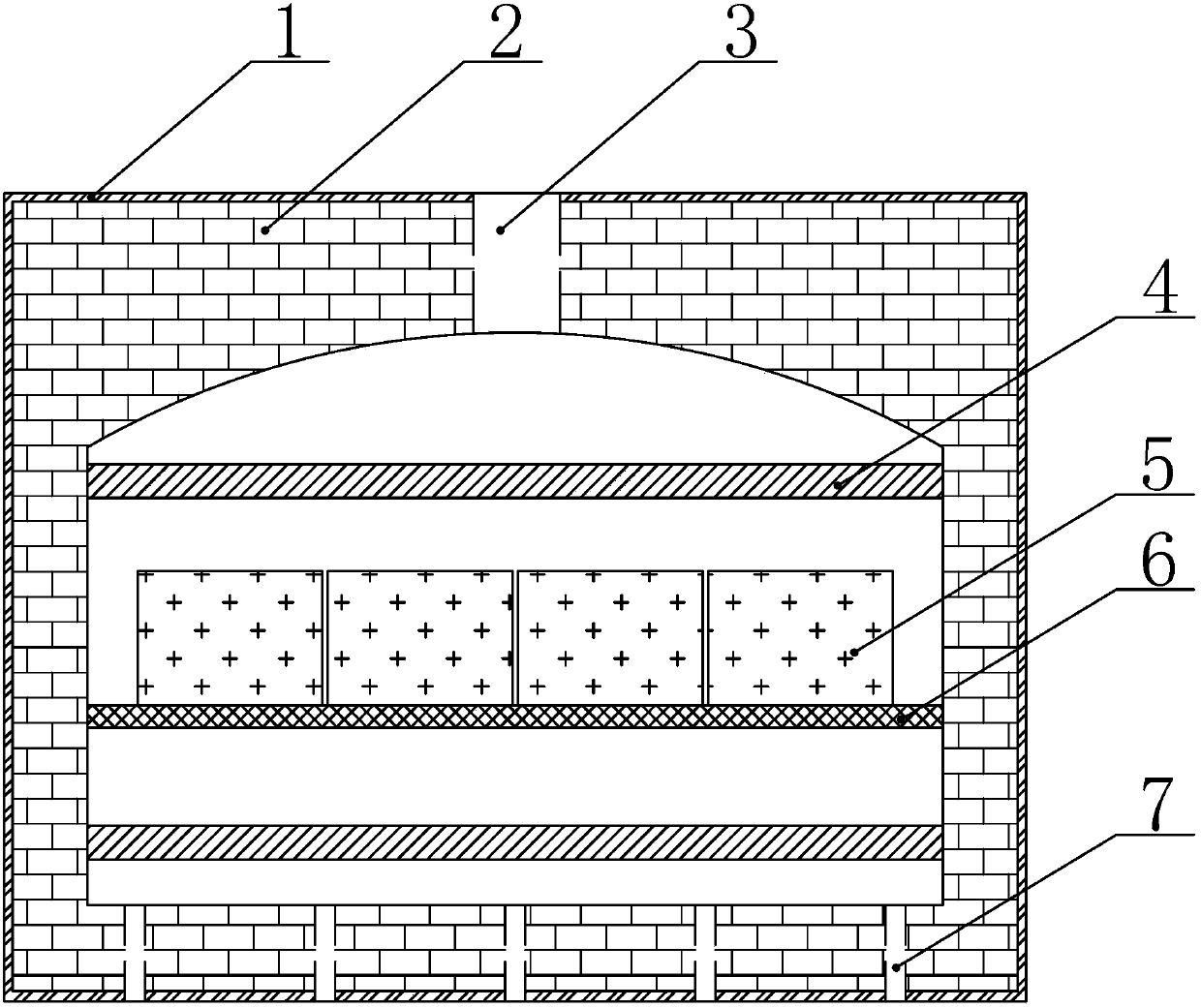

Furnace lining structure of high-temperature vacuum sintering furnace

ActiveCN105157417AImprove uniformityGuarantee the quality of sinteringMuffle furnacesMaintainance of heating chambersLine structureFiber

The invention relates to a furnace lining structure of a high-temperature vacuum sintering furnace, belonging to the technical field of high-temperature sintering furnaces. The high-temperature vacuum sintering furnace comprises a furnace shell, a furnace tube, a protective gas introduction mechanism and a furnace tube heating mechanism, wherein the furnace shell is provided with a furnace shell cooling mechanism; a furnace bed is arranged in the furnace tube cavity; the protective gas introduction mechanism is connected with a protective gas supply source through a pipeline; and the furnace tube heating mechanism is connected with a feed mechanism. The furnace lining structure comprises a furnace cylinder and a furnace cylinder inner sleeve, wherein a furnace cylinder door cover ring is respectively embedded in the left end and right end ports; the furnace cylinder inner sleeve is arranged in the furnace cylinder cavity and contacts the wall of the furnace cylinder cavity; a space is kept between the outer wall of the furnace tube and the furnace cylinder inner sleeve; the furnace cylinder is composed of a set of furnace cylinder sections; the furnace cylinder inner sleeve is a carbon fiber bushing; the furnace tube is prepared from graphitic carbon fibers; the inner wall of each furnace cylinder door cover ring is composed of a conical surface; one side of each furnace cylinder door cover ring is provided with a furnace cylinder embedding cavity; one side of the furnace cylinder door cover against the furnace cylinder is provided with a graphite ring caulking groove; a graphite ring is arranged in each graphite ring caulking groove; and the circumferential surface of the furnace cylinder door cover is matched with the conical surface. The furnace lining structure improves the sintering temperature uniformity of the product in the furnace tube cavity and ensures the sintering quality.

Owner:苏州汇科技术股份有限公司

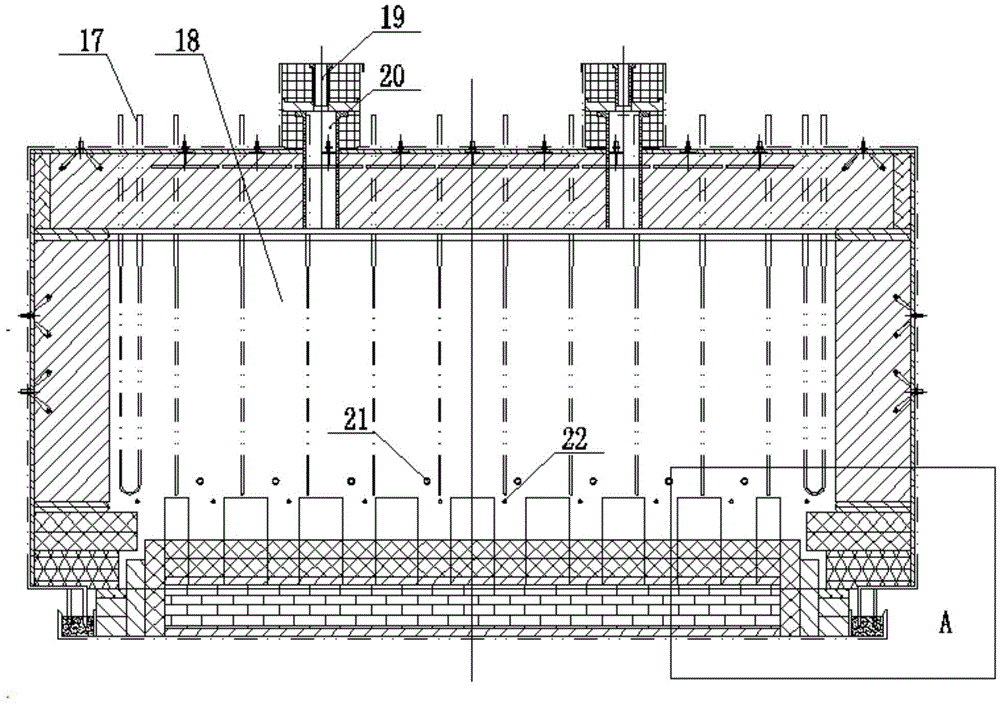

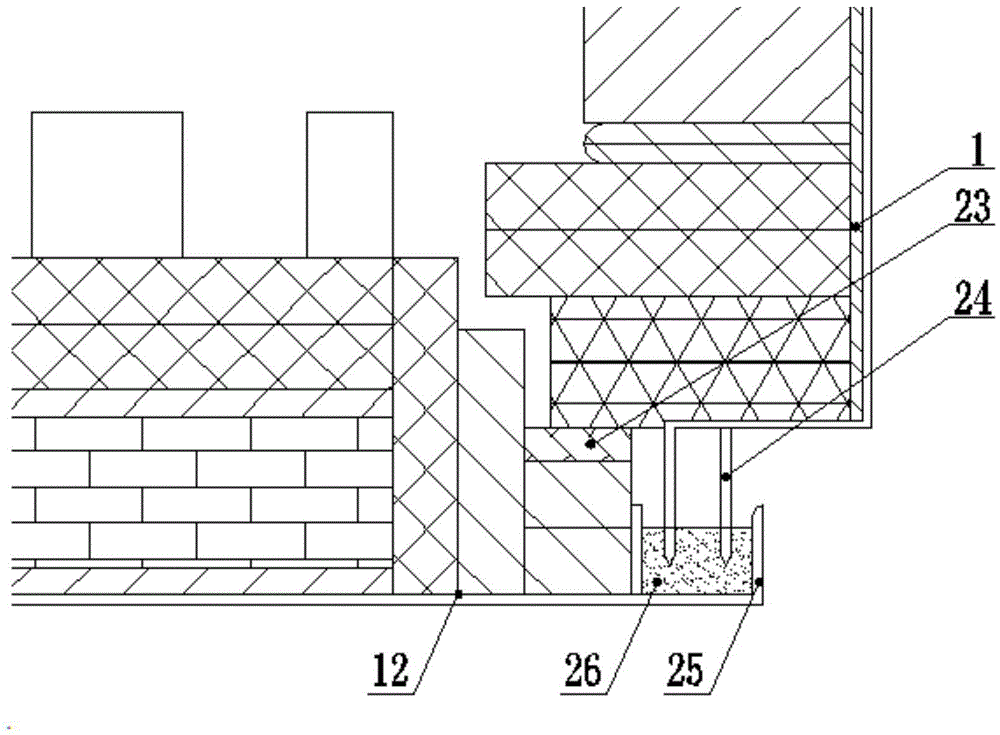

High-temperature tunnel type electrothermal dynamic sintering furnace

PendingCN111059895ASimple structureReduce loadCharge treatment typeFurnace typesAir preheaterEngineering

The invention relates to the technical field of electronic component production, specifically to a high-temperature tunnel type electrothermal dynamic sintering furnace. The high-temperature tunnel type electrothermal dynamic sintering furnace comprises a heat insulation wall body, a tunnel type muffle tank installed in the heat insulation wall body and a conveying mechanism, wherein a connectingrod is fixedly connected to the side wall of a heat insulation plate; the end part of the connecting rod slidably penetrates through the side wall of a heating furnace to reach out of the heating furnace, and is fixedly connected to a first electric telescopic rod; the first electric telescopic rod works under the control of a controller; an air inlet capable of being blocked is formed in the sidewall of the heating furnace; and a temperature sensor is arranged in the heating furnace. During heating by gas, a sealing plug is dragged by a second electric telescopic rod to move rightwards, anddue to the fact that air pressure at a chimney is lower than air pressure at the air inlet, air enters from the air inlet at the moment and heat on the first cooling fin is taken away, so on one hand,heat dissipation effect is achieved, and on the other hand, air entering the heating furnace can be preheated and an original air preheater is replaced.

Owner:SHENZHEN XINTAO KILN EQUIP CO LTD

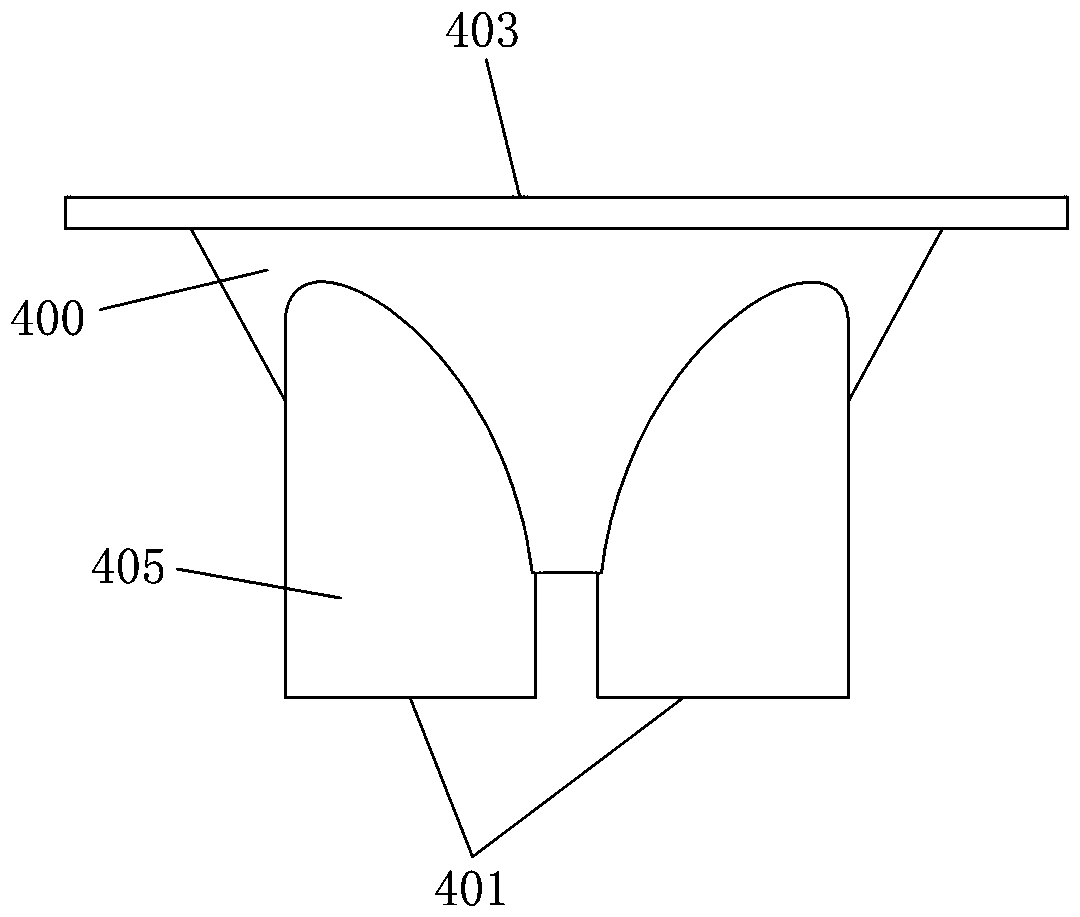

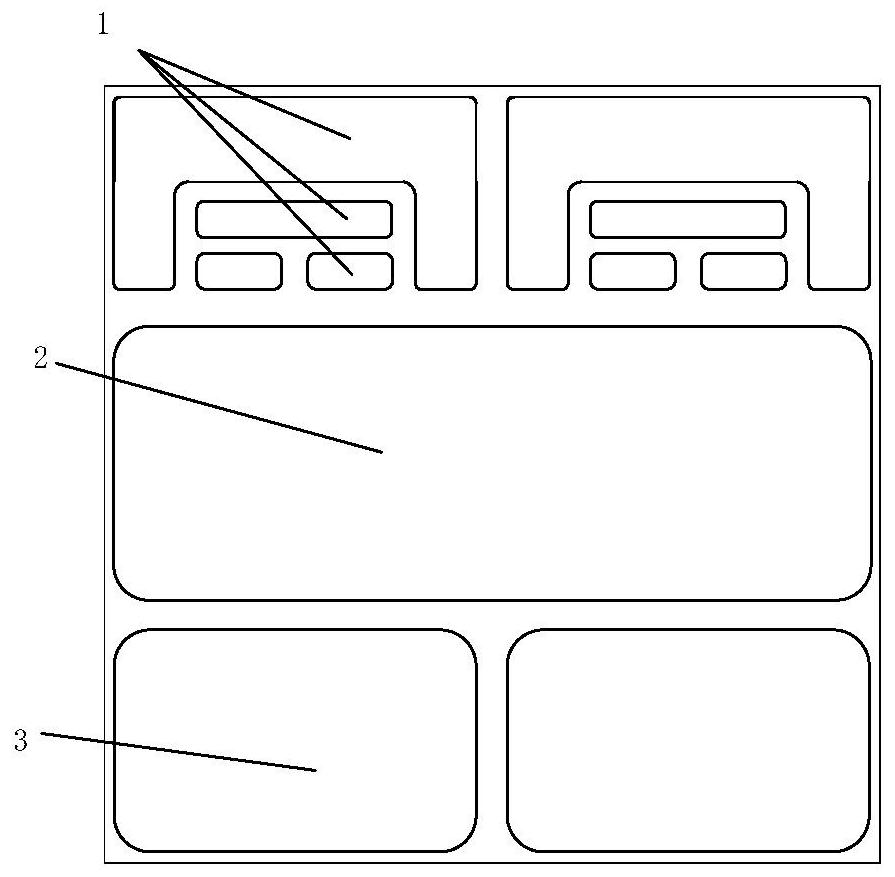

Unloading head, automatic bowl loading machine with unloading head and bowl loading method

ActiveCN107757983ADoes not affect bulk densityReduce accumulationPackagingEngineeringStructural engineering

The invention discloses an unloading head, an automatic bowl loading machine with the unloading head and a bowl loading method. The unloading head comprises an unloading head body; the unloading headbody is provided with a guide cavity and a feed port communicating with the guide cavity; multiple discharge ports communicating with the guide cavity are formed in one end of the unloading head body;all the discharge ports are positioned on the same fixed plane on the unloading head body; the multiple discharge ports are uniformly arranged at intervals around a fixed axis perpendicular to the fixed plane; a guide cone for guiding materials into each discharge port is arranged in the guide cavity; and the axis of the guide cone is overlapped with the fixed axis. The automatic bowl loading machine comprises an unloading device, a fixing device, and a loading conveying line driven by a three-dimensional space displacement driving device; and the unloading device adopts the unloading head. The bowl loading method is to use the automatic bowl loading machine for enabling the unloading head to extend into a sagger for unloading and leveling at the same time. The unloading head, the automatic bowl loading machine with the unloading head and the bowl loading method have such advantages as uniform discharge and facilitation of improving the bowl loading efficiency and the bowl loading quality.

Owner:HUNAN JINLU TECH CO LTD

Full-washing coal gangue self-thermal insulation building block and manufacturing method thereof

The invention discloses a full-washing coal gangue self-thermal insulation building block and a manufacturing method thereof.The full-washing coal gangue self-thermal insulation building block is characterized by being prepared from, by mass, 10-15% of water, 80-88% of washing coal gangue and 2-5% of a pore-forming agent.The manufacturing method comprises the steps of smashing, water adding to achieving uniform stirring, normal-temperature aging, extrusion, slitting, low-temperature drying, high-temperature sintering and the like.The adopted raw materials are convenient to obtain, the burning consumption of the self-thermal insulation building block can be effectively lowered, the production cost is lowered, the mineral waste utilization rate is enlarged, and environmental protection is achieved.The building block is high in strength level and low in density level, water absorption rate and heat transfer coefficient, the requirement for that a public building in a hot summer and cold winter area saves energy by 65%, and the wall heat transfer coefficient is smaller than 1 W(m<2>.k) according to the national building energy-saving design standard can be met, the technology is simple, the production cost is low, popularization and application are easy.

Owner:HUAIBEI XINYU IND & TRADE

Heater structure of electronic powder firing furnace

ActiveCN102384650AWork lessGuarantee the quality of sinteringFurnace typesElectric heating for furnacesMetallurgyMaterials science

A heater structure of an electronic powder firing furnace belongs to the technical field of the electronic product firing furnace. The heater structure comprises a heater body and a protection tube, wherein the middle part of the heater body in the length direction is located within the cavity of the protection tube, while the two ends thereof extend out of the cavity of the protection tube; a first temperature resistant spacer bush and a second temperature resistant spacer bush are arranged at the two ends of the cavity, respectively; the end faces of the first temperature resistant spacer bush and the second temperature resistant spacer bush are in contact with each other, and both of the first temperature resistant spacer bush and the second temperature resistant spacer bush are arranged on the heater body, and wherein the first temperature resistant spacer bush extends to the cavity opening part of the cavity and is sealed by a sealing packing course. The heater structure has the following advantage that: the severe atmosphere in the hearth can be effectively prevented from affecting the heater body so that the heater body can work normally and enduringly, which is advantageous not only to ensure the sintering quality of an electronic powder material and but also to save the use cost and ensure the normal operation of the electronic powder firing furnace.

Owner:SUZHOU HUIKE EQUIP CO LTD

First furnace smelting method for new electric arc furnace

InactiveCN102021269BShorten smelting timeSufficient temperatureProcess efficiency improvementElectric furnaceSteelmakingElectric arc furnace

The invention belongs to the technical field of metallurgy, relates to a first furnace smelting method of a new furnace for electric arc furnace steelmaking, and aims to provide a smelting method which can guarantee the sintering quality of a refractory material and the metallurgical quality of first furnace steel. The method comprises the following steps of: A, preparing materials, namely adding pig iron into a waste steel material, wherein the amount of the added pig iron is 25 to 30 percent of the total weight of the furnace charge, and the amount of added carbon is 1.2 to 1.4 percent of the total weight of the furnace charge; B, loading 60 to 70 percent of the total weight of the furnace charge at the first time, supplying 577 to 592V power after the first loading, supplying 637 to 671V power and 671 to 691V power in turn after arcing is stabilized, and starting an oxygen burner to contribute to smelting when the supplied power reaches 2 to 4MW.h; C, powering off for 15 to 25 minutes before second loading, wherein the second charge is the remaining furnace charge, supplying 577 to 592V power, supplying 637 to 671V power and 671 to 691V power in turn after the arcing is stabilized, and starting the oxygen burner to contribute to smelting after charging; D, after the furnace charge is smelted, powering off for 15 to 25 minutes after the temperature of a weld pool reaches 1,540 to 1,560 DEG C; and E, smelting according to the conventional process.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

Bidirectional switch power module and preparation method thereof

PendingCN113097154AGood symmetryReduce uneven distributionEfficient power electronics conversionSemiconductor/solid-state device detailsMOSFETElectronic switch

The invention discloses a bidirectional switch power module and a preparation method thereof, one side surface of a copper-clad substrate DBC is sequentially provided with a driving terminal, silicon carbide MOSFET chips and a power terminal, a plurality of silicon carbide MOSFET chips are arranged at intervals, the plurality of silicon carbide MOSFET chips are connected in parallel in pairs to form two power electronic switches in different directions, the grid electrode and the source electrode of each silicon carbide MOSFET chip are respectively connected with the driving terminal through a driving resistor, the plurality of silicon carbide MOSFET chips are arranged on the same copper substrate, and the source electrodes are respectively connected with the power terminal to form common drain electrode connection. According to the invention, the working frequency is higher, the reliability is better, the thermal resistance is lower, and the electrical performance is good.

Owner:XI AN JIAOTONG UNIV

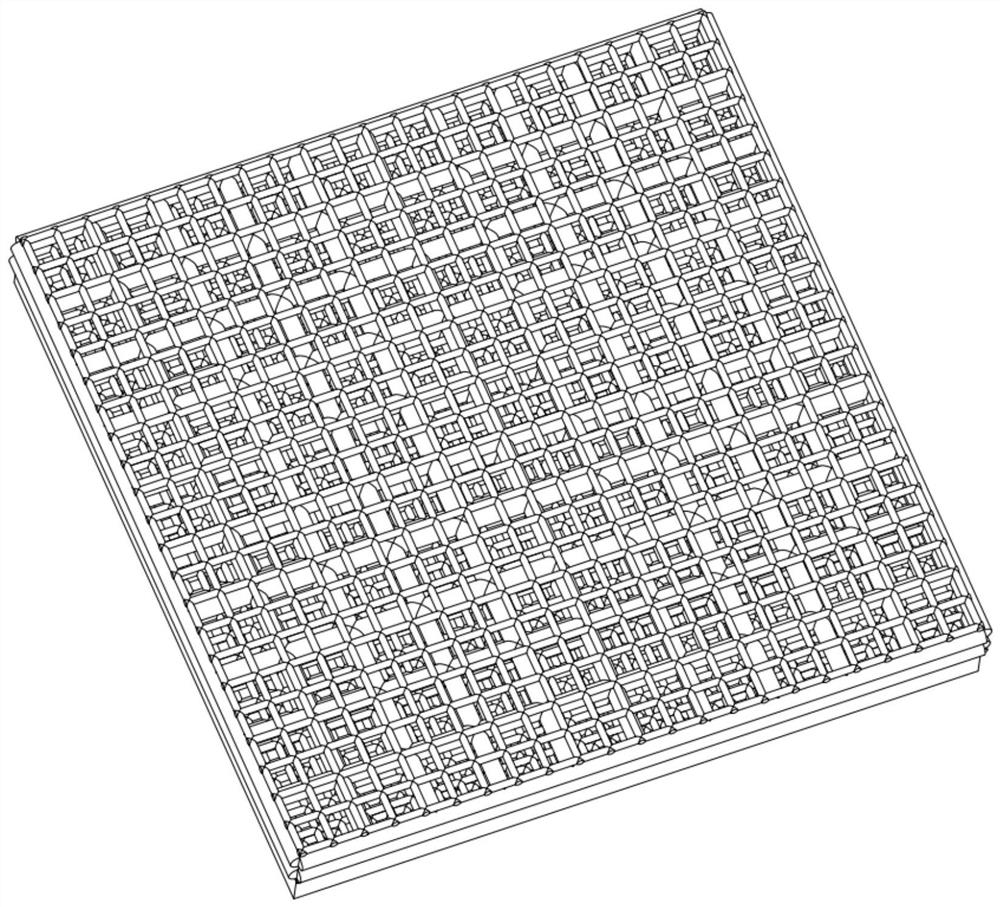

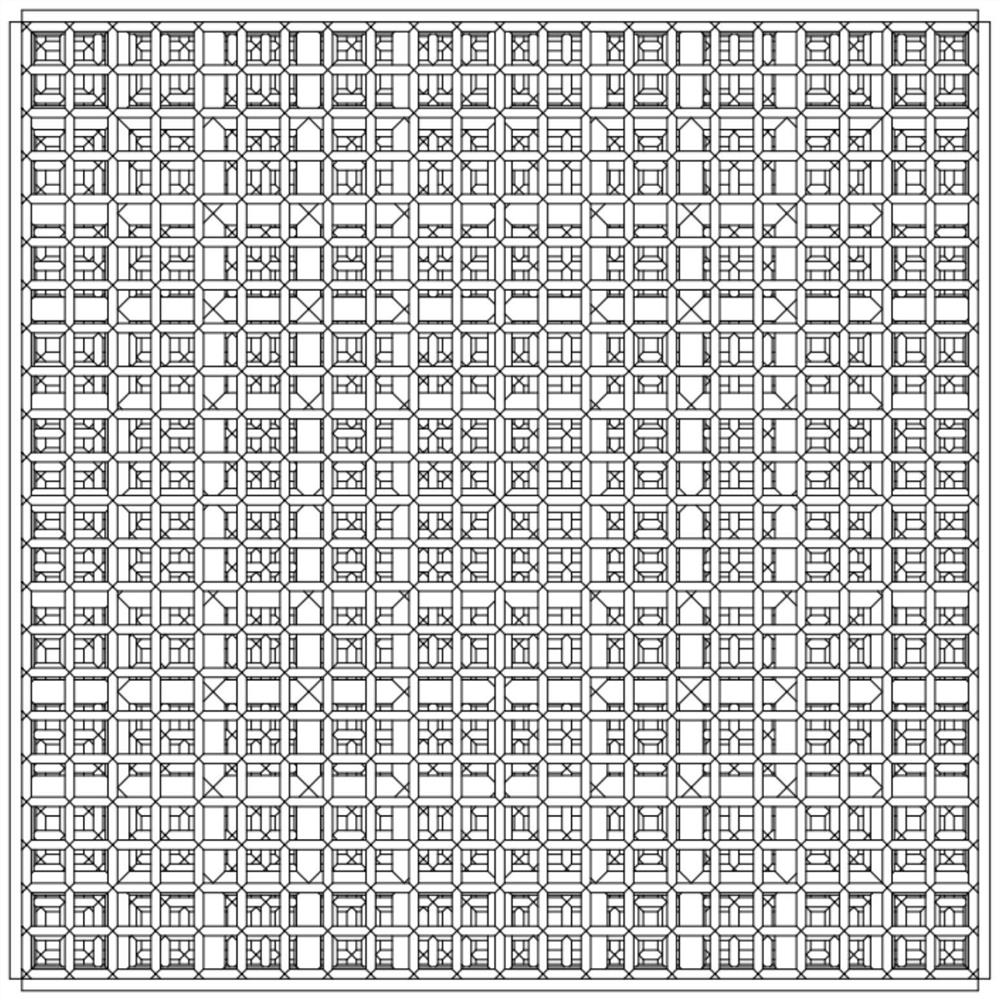

Electronic device heat dissipation structure with three-dimensional net-shaped structure and manufacturing method

ActiveCN111933592AHigh densityReduce mutual blockageSemiconductor/solid-state device detailsSolid-state devicesMicron scaleMechanical engineering

The invention discloses an electronic device heat dissipation structure with a three-dimensional net-shaped structure and a manufacturing method. The electronic device heat dissipation structure comprises a heat dissipation plate, a multi-layer micron-sized net-shaped structure and a multi-layer framework. A plurality of layers of micron-sized net structures are arranged on the heat dissipation plate, a framework layer is arranged between every two adjacent layers of micron-sized net structures, the micron-sized net structures are modified with nano-sized microstructures, and the heat dissipation plate, the micron-sized net structures and the framework layers are all made of copper. On the microcosmic level, the supplementing capacity of liquid can be improved, and bubble disengagement isfacilitated, and on the macroscopic level, the heat exchange area can be increased, and the heat exchange capacity is enhanced.

Owner:西安交通大学深圳研究院

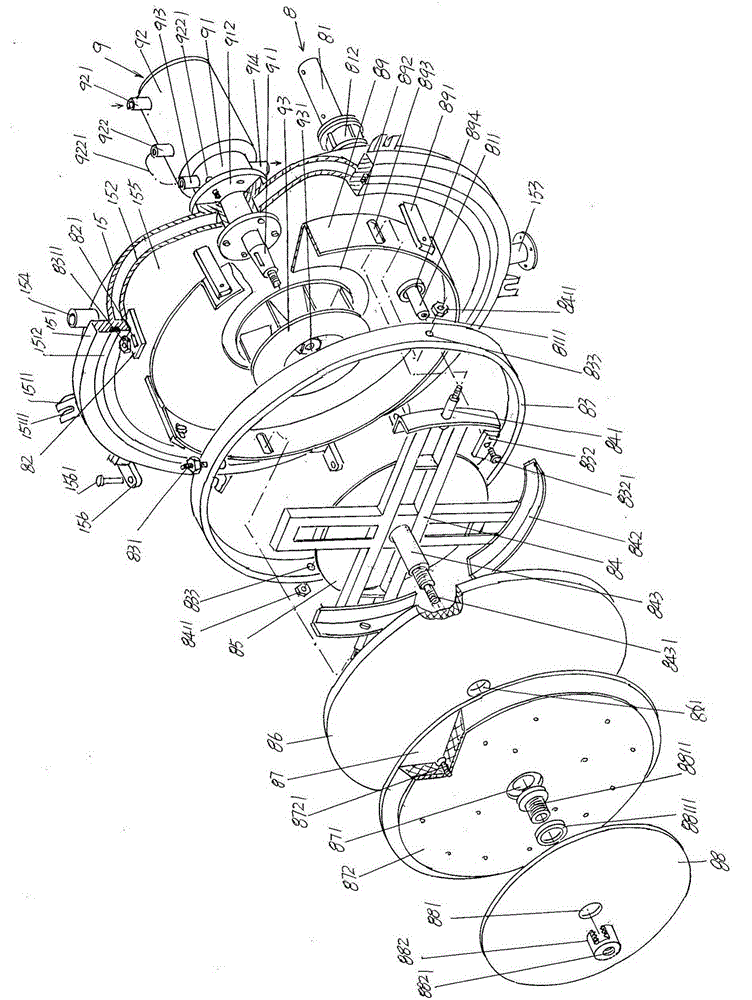

Atmosphere bell furnace for ito target sintering

ActiveCN104296529BGuarantee the quality of sinteringReduce external temperatureFurnace typesTemperature controlControl system

The invention discloses a bell-type atmosphere furnace applicable to sintering of ITO targets. The bell-type atmosphere furnace comprises a furnace body, a furnace frame, a cooling system, an atmosphere control and adjustment system and a temperature control system. The furnace body is of a hollow structure mounted on the furnace frame. A cavity in the furnace body is arranged to be a furnace chamber. The bottom of the furnace body is provided with a kiln car serving as a movable furnace door. The kiln car can be connected with the furnace body in a sealed mode when closed as the movable furnace door. The top and the inner walls of the four sides of the furnace chamber are provided with high-temperature refractory layers. The top of the furnace body is provided with heating elements extending downwards into the furnace chamber. A cooling air pipeline of the cooling system penetrates through the sidewall of the bottom of the furnace body and is led into the furnace chamber. A ventilating pipeline of the atmosphere control and adjustment system penetrates through the sidewall of the bottom of the furnace body and is led into the furnace chamber. The temperature control system comprises a plurality of temperature measurement thermocouples mounted on the furnace body. The bell-type atmosphere furnace has the advantages of being simple in structure, low in cost, convenient to maintain, good in sintering effect and particularly applicable to sintering of the ITO targets.

Owner:HUNAN JINLU TECH CO LTD

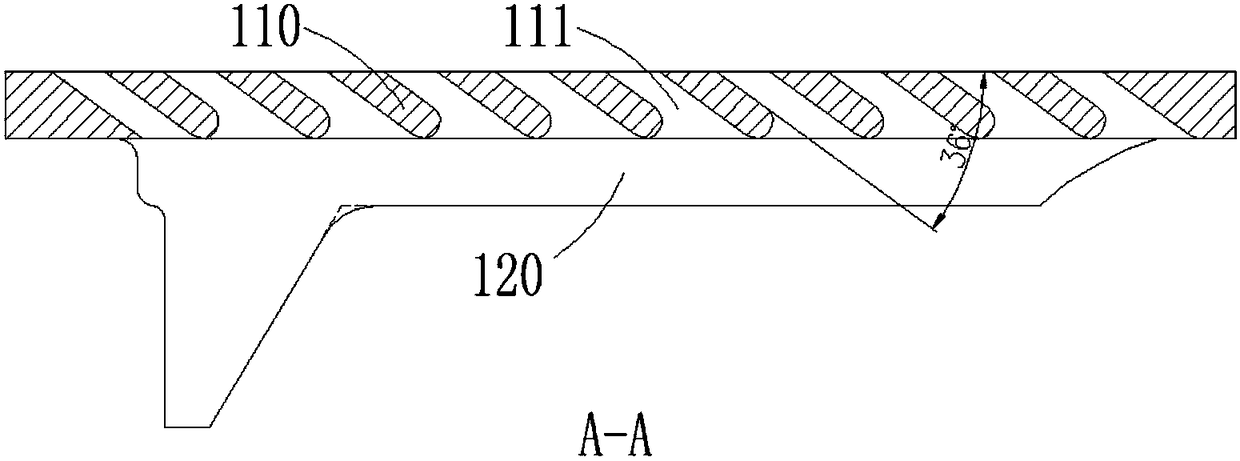

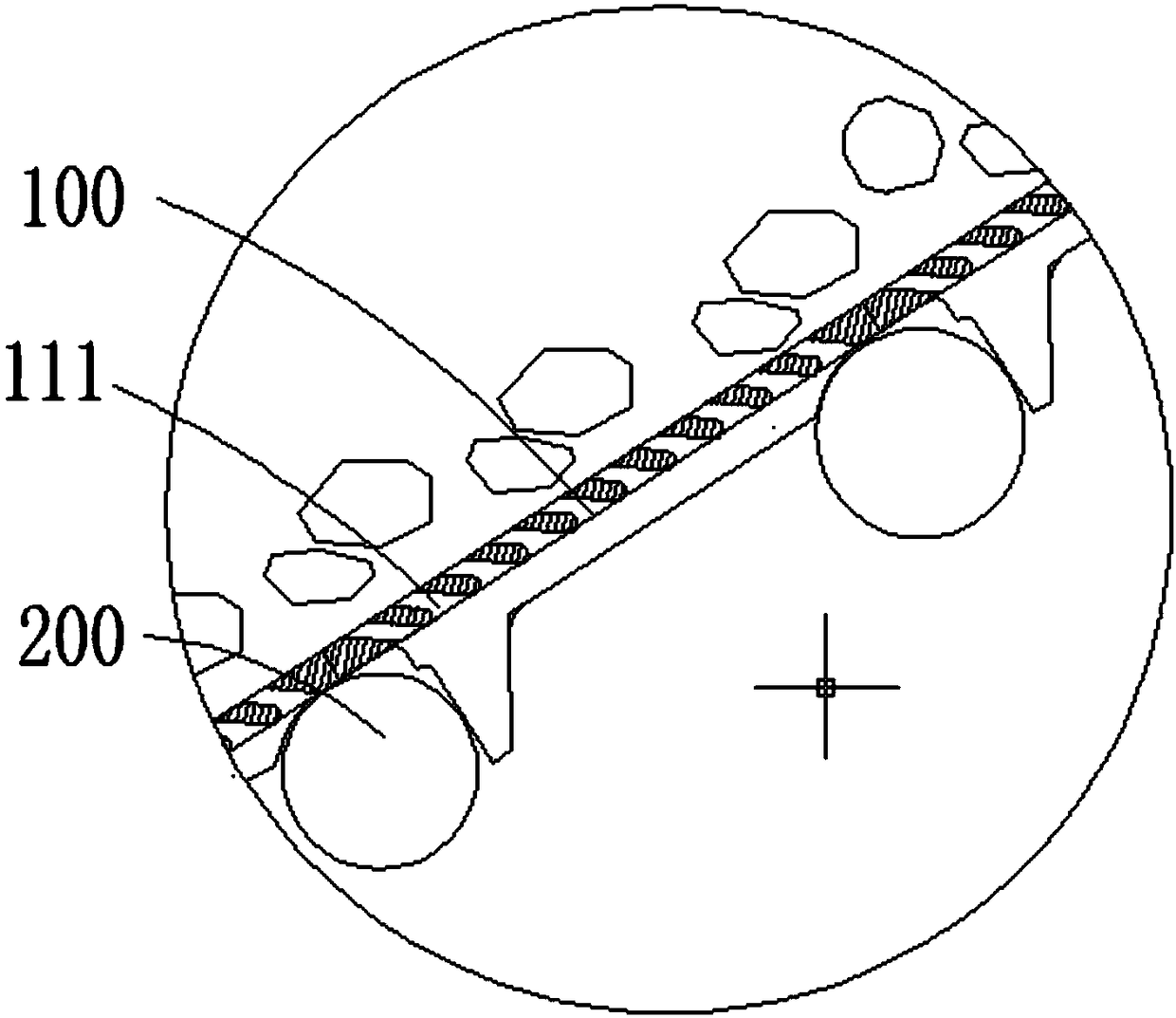

Blind window drying bed fire grate bar and smelting production method thereof

PendingCN108302930AReduce the probability of cloggingIncrease ventilation rateCharge treatment typeVertical furnacesWindow shutterEngineering

The invention discloses a blind window drying bed fire grate bar and a smelting production method thereof, and belongs to the technical field of pellet production equipment. The fire grate bar comprises a fire grate bar body; web plates are symmetrically arranged on the two sides of the fire grate bar body; a strip hole is formed in the fire grate bar body; the aperture D of the strip hole is 21-25 mm; the strip hole is inclined; an air inlet is flared; the strip hole is located in a horizontal state in use; and the two ends of the web plates are machined as shapes cooperating with the outer surface of a water beam. The fire grate bar solves the large-area blockage difficulty of grate bar gaps, improves the drying effect of a drying bed, and increases the shaft furnace pellet yield; the smelting production method of the fire grate bar is low in manufacturing cost and excellent in use performance, can reach 1-2 years of service life, and achieves excellent popularization and applicationvalue; and the fire grate bar has the advantages of simple structure, reasonable design and easy manufacturing.

Owner:马鞍山市新越机械修造有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com