Support frame for sintering soft magnetic ferrite cores based on chain wheel transmission

A technology of soft ferrite and sprocket drive, which is applied in charging support, furnaces, lighting and heating equipment, etc. It can solve the problems of high product failure rate, low heating efficiency of blanks, deformation of magnetic core blanks, etc. , to achieve the effect of ensuring sintering quality, ensuring positioning and improving sintering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

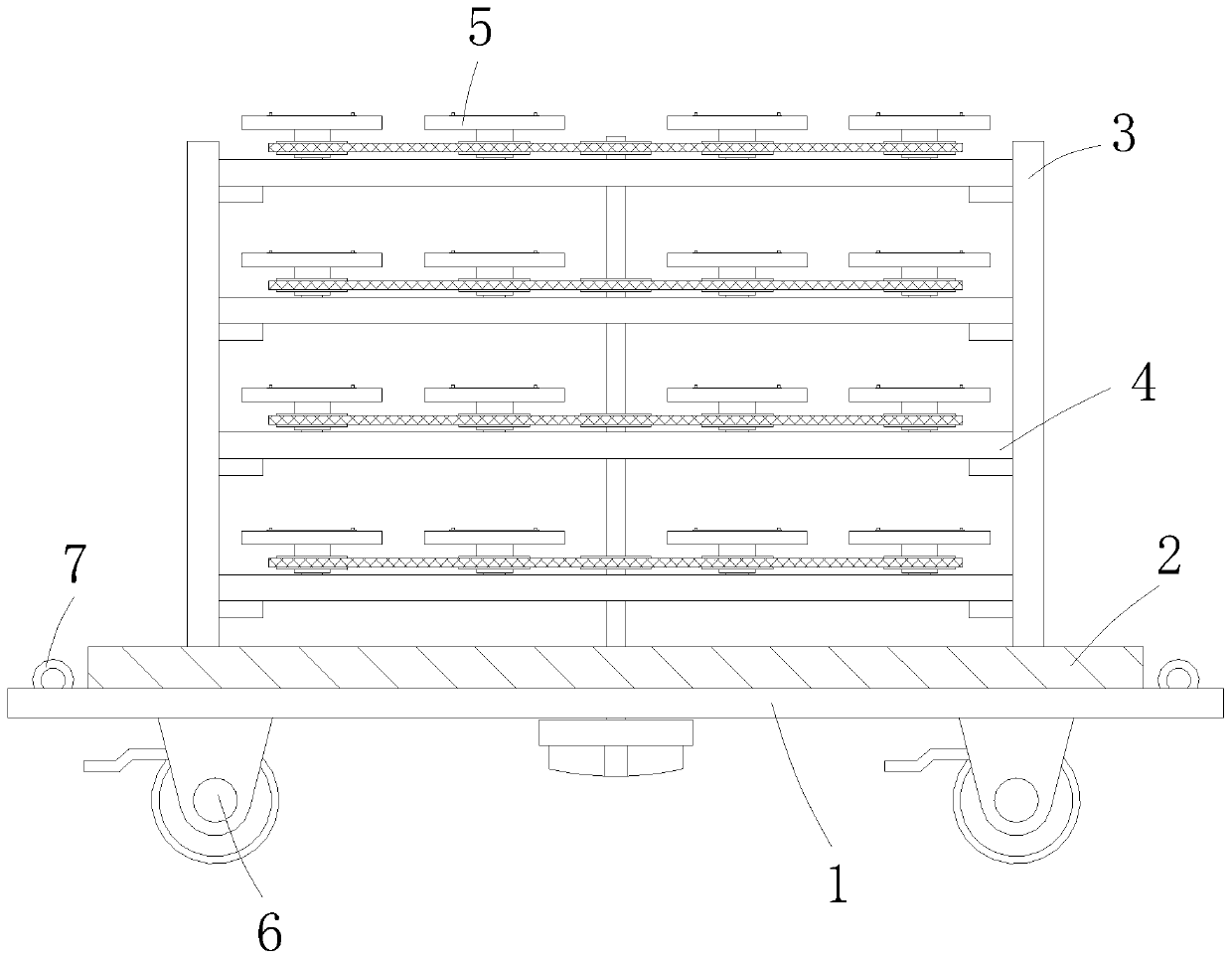

[0035] A support frame for soft ferrite core sintering based on sprocket transmission, comprising a support bottom plate 1 and a clamping base 2 installed on the upper end of the support bottom plate 1, the upper end of the clamping base 2 is fixedly installed with four A plurality of support blocks are equidistantly installed on the opposite side walls of the four columns 3, and a mounting plate 4 is set up on the four support blocks at the same level, and a sintering discrete mechanism 5 is provided on the mounting plate 4. It is used for the placement of soft ferrite cores. At the same time, it can be diffused during sintering to improve the quality of sintering. It can also be aggregated after sintering for easy collection;

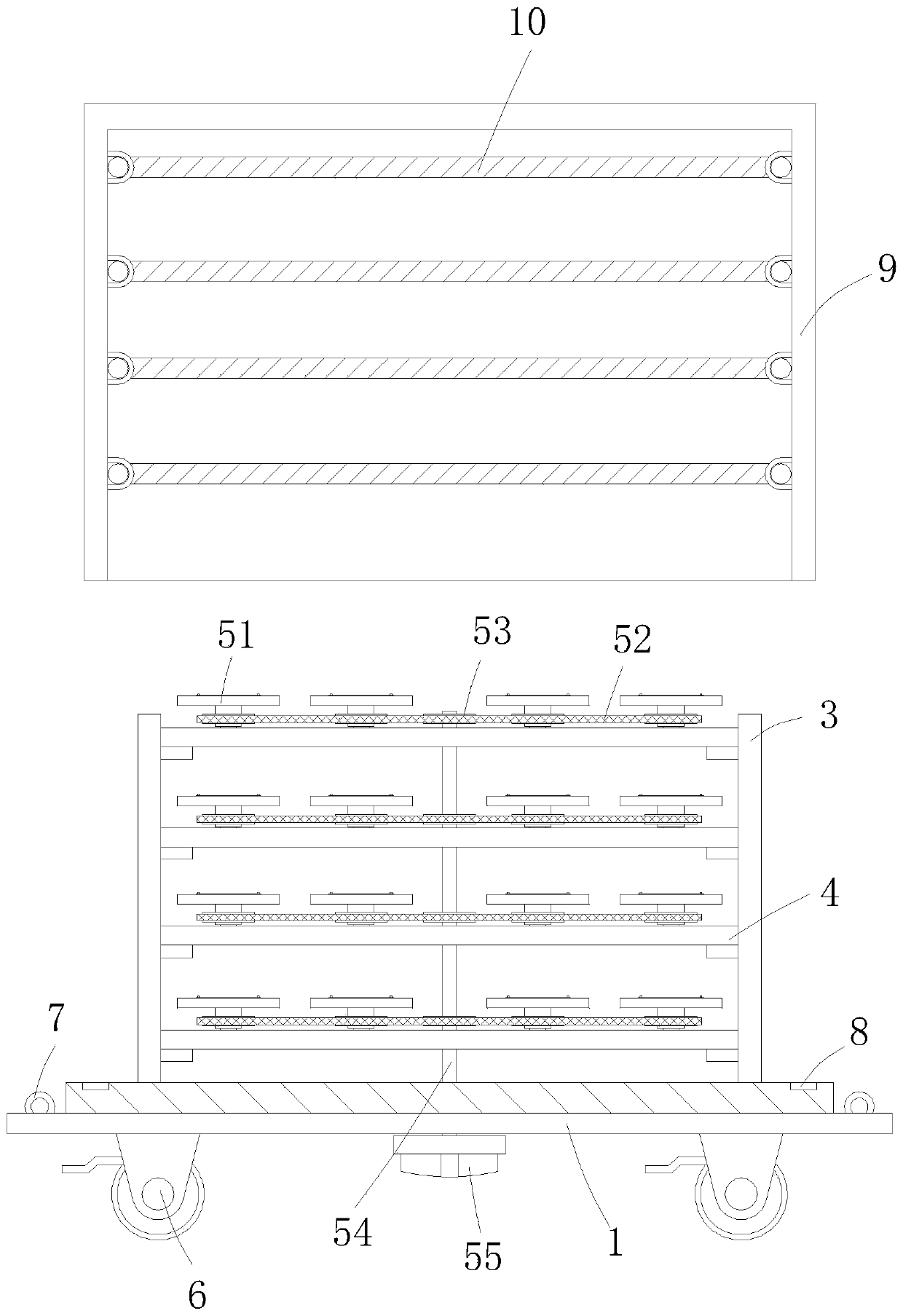

[0036] In this example, if Figure 2-5 As shown, the sintering discrete mechanism 5 includes a plurality of supporting columns 57 arranged in parallel on the upper end surface of the mounting plate 4, and the upper end of the supporting columns 57 is ...

Embodiment 2

[0044] The difference between this embodiment and embodiment 1 is that, as Figure 2-3 As shown, the upper edge of the mold clamping base 2 is provided with an upper die groove 8 that matches the upper die 9 of the sintering furnace. The upper die 9 of the sintering furnace is an open structure with an open lower end, and the upper die 9 of the sintering furnace The heating pipe network 10 is evenly attached. In this embodiment, the heating pipe network 10 can be a common resistance heating structure on the market, which can be understood by those skilled in the art, and will not be repeated here.

[0045] In this example, if Figure 1-3 As shown, four locking universal wheels 6 distributed in a matrix are installed on the lower end of the support bottom plate 1, which is convenient for moving and transporting.

[0046] In this example, if Figure 1-3 As shown, the upper edge of the support bottom plate 1 is equipped with a plurality of lifting rings 7 distributed in a matri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com