Metal powder pre-pressing device and method for polycrystalline diamond wire-drawing die bushing

A polycrystalline diamond and metal powder technology, applied in the field of metal powder pre-pressing devices, can solve the problems of expensive hydraulic devices, frequent changes in pressure values, and affecting processing efficiency, etc., and achieve strong adaptability of processing technology, easy operation, and improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

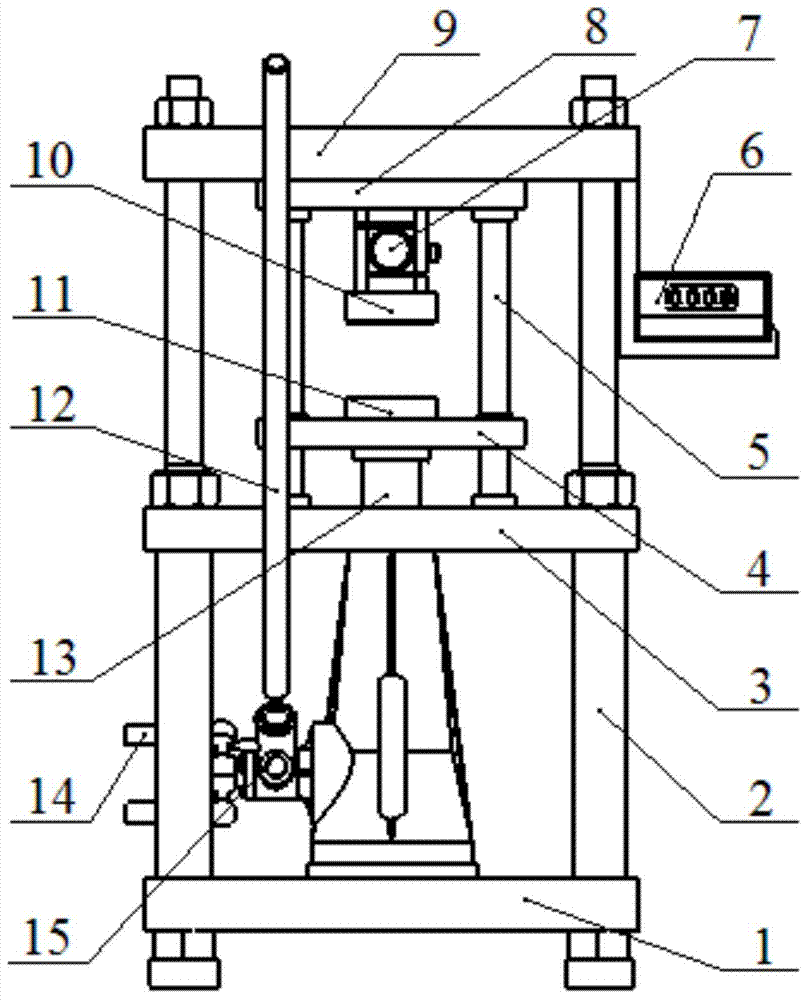

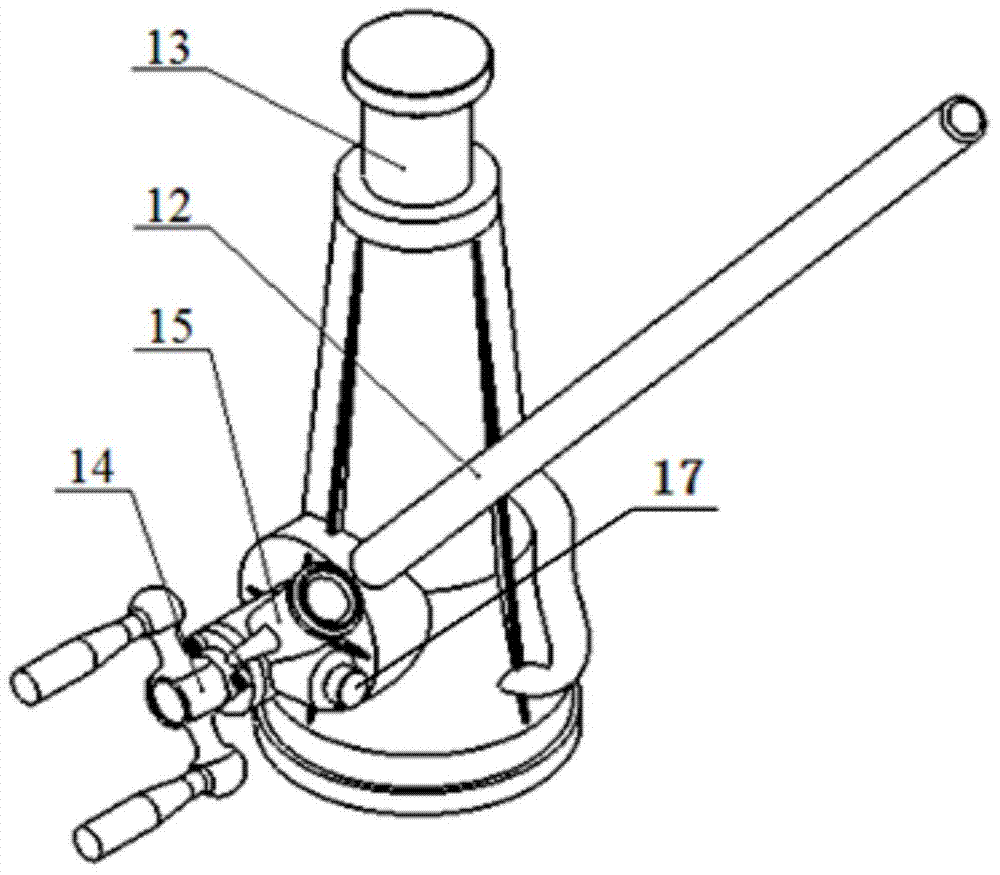

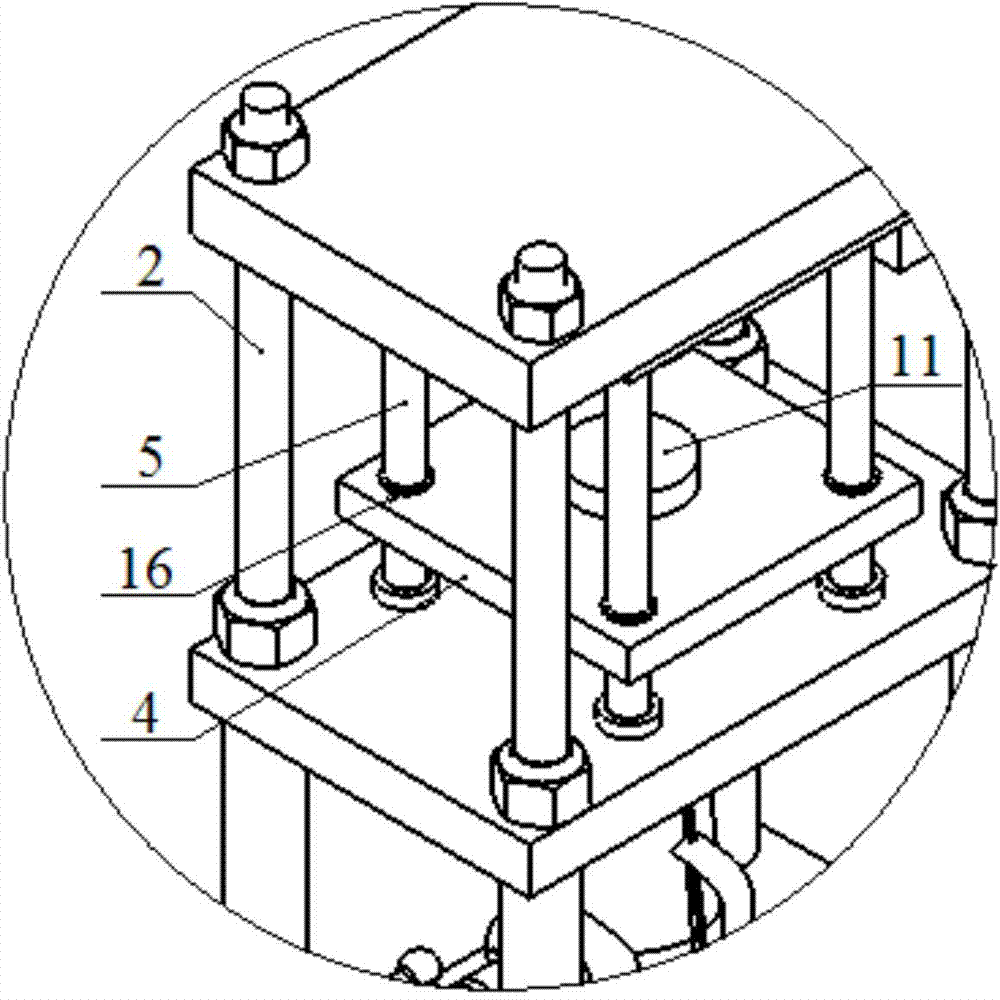

[0046] In order to effectively solve the problem in the prior art that the sintering inserts of medium and large-sized polycrystalline diamond wire drawing dies are prone to quality problems, and the use of large billets to make small-sized molds causes great waste, the present invention provides such figure 1 The metal powder pre-pressing device for the polycrystalline diamond wire drawing die insert is shown. The metal powder pre-pressing device is suitable for the metal powder pre-pressing process with variable pressure values. The metal powder pre-pressing process is realized by means of the pressure source operating mechanism, the lower pressure head operating mechanism and the pressure value display mechanism using a mechanical jack as the pressure source. The entire metal powder pre-pressing process is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com