Sintered and sealed electric connector resistant to high pressure

A technology of sintering sealing and electrical connectors, which is applied in the direction of connection and connection device components, circuits, etc., can solve the problems of poor compression resistance of electrical connectors, and achieve the effects of quality assurance, easy quality, and sintering quality solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

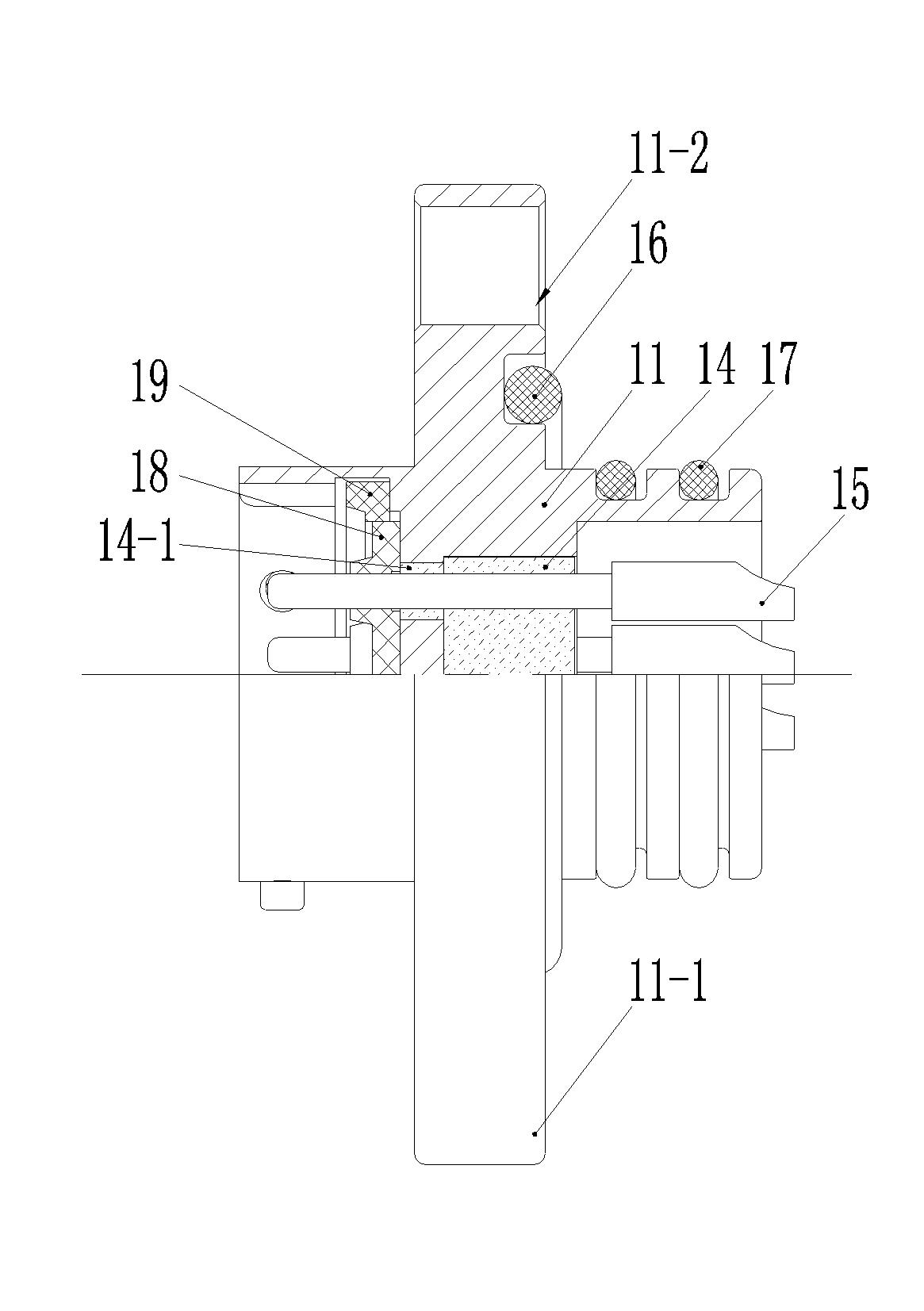

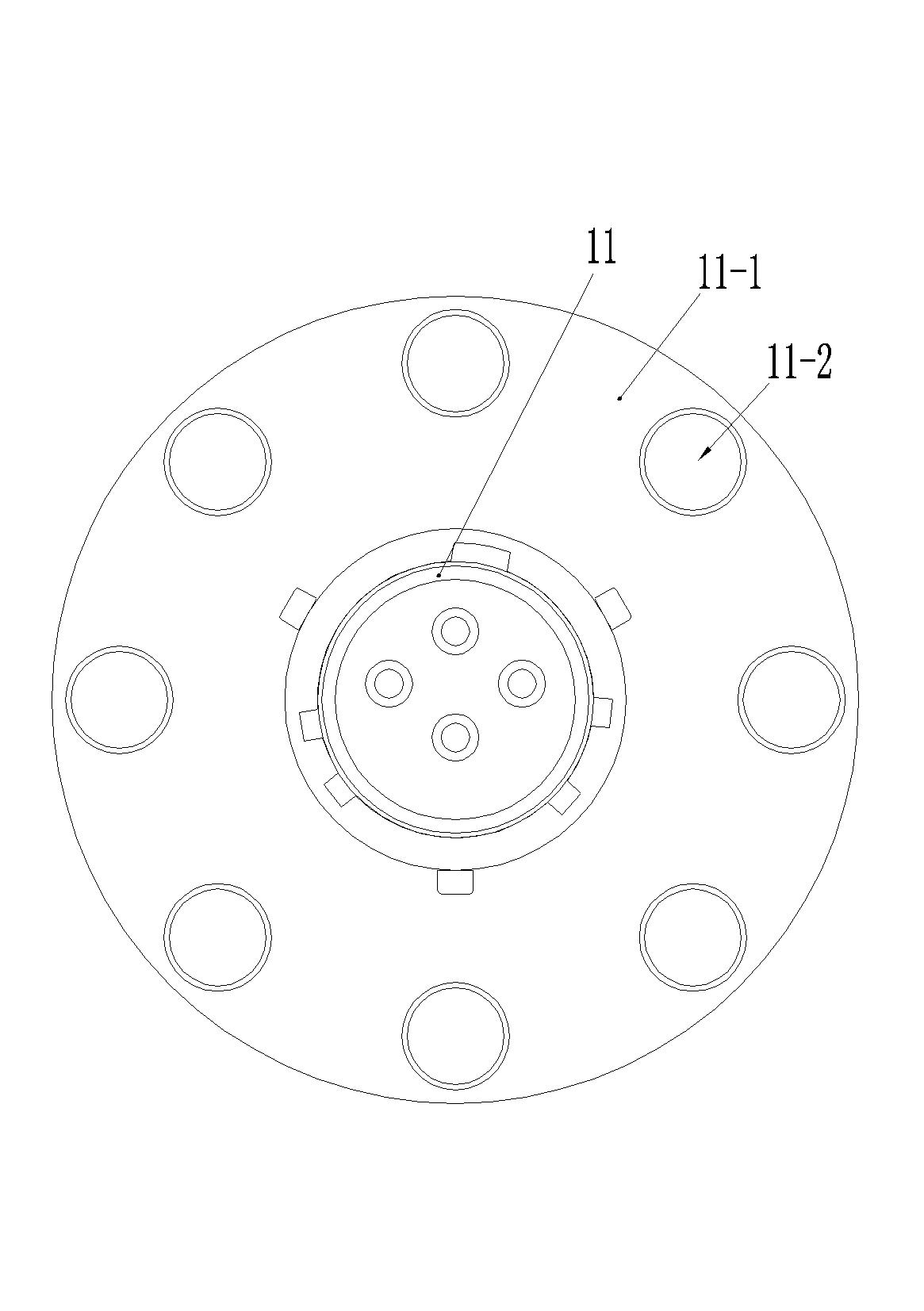

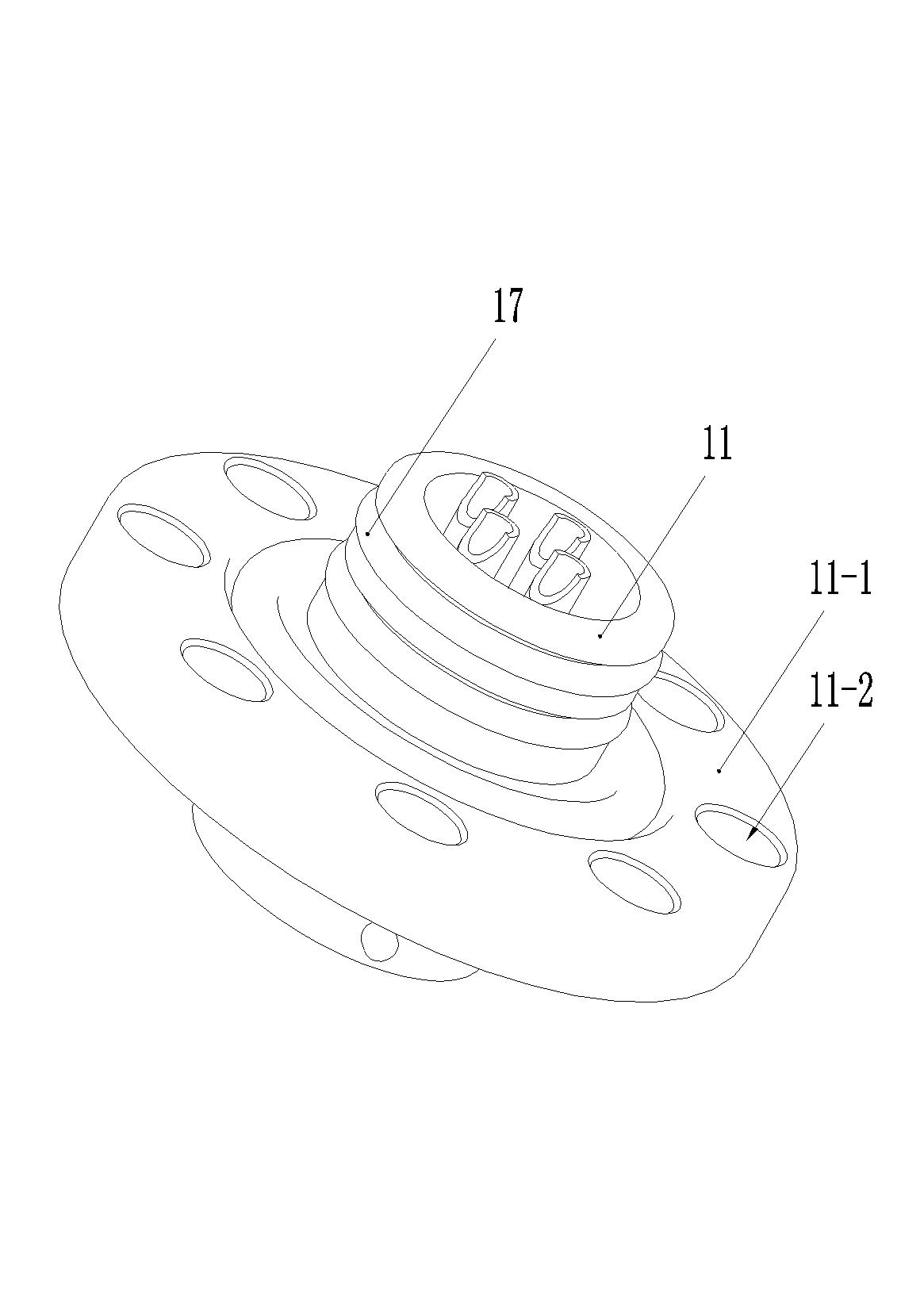

[0016] Embodiment 1 of the high pressure resistant sintered sealed electrical connector of the present invention, as Figure 1-4 As shown, it includes a metal shell 11. In this embodiment, the metal shell 11 is cylindrical, and its outer peripheral surface is provided with an eversion edge 11-1, and an eversion edge 11-1 is provided with a bolt connection hole. At this time, the metal shell 11 can be fixed on the corresponding installation panel 13 by penetrating the screw 12 in the bolt connection hole. The contact piece 15 is fixed in the metal shell 11 by sintering the glass cake 14. In addition, the metal shell 11 A pressure-receiving wall 11-2 is arranged between its two ends. The pressure-receiving wall 11-2 is integrated with the metal shell 11 and is located between the two ends of the contact. The pressure-receiving wall has a passage for the contact to pass through. The outer peripheral surface of the glass cake 14 is sintered and fixed with the inner wall of the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com