Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Good thickness controllability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

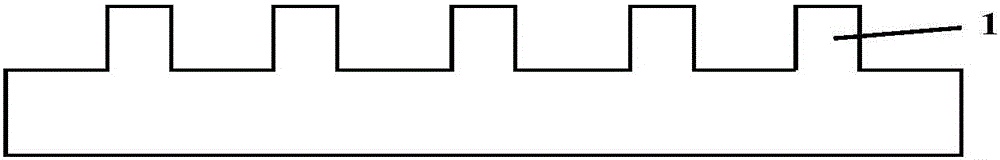

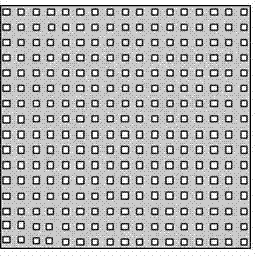

Forming method of multigraph

InactiveCN104022022AGood thickness controllabilityGood film shape retentionSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

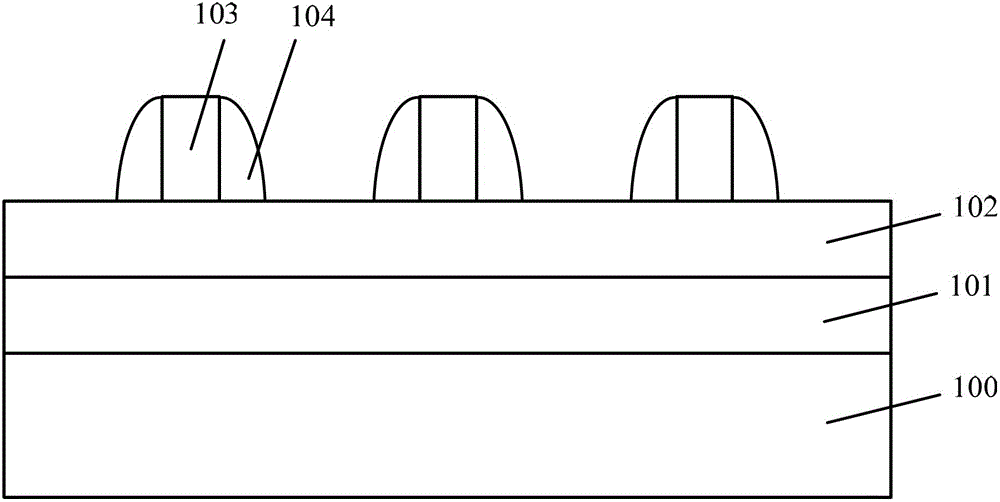

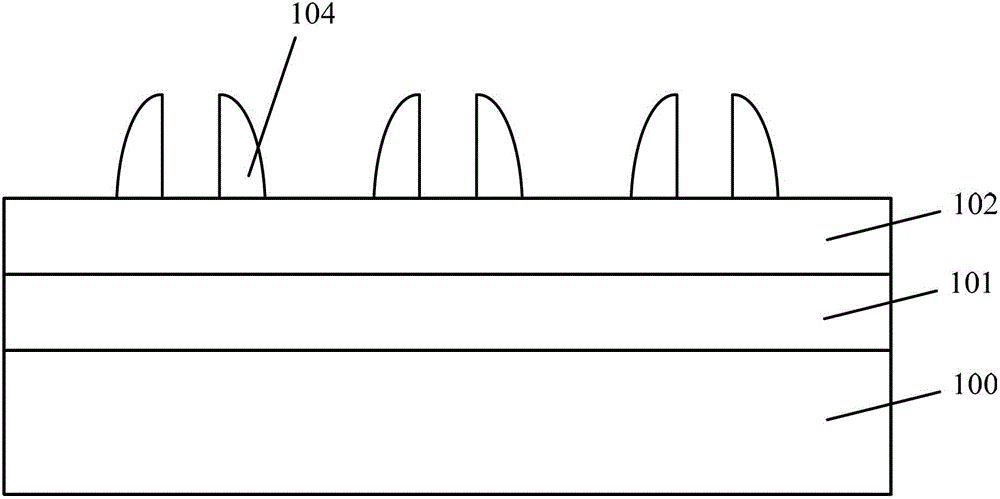

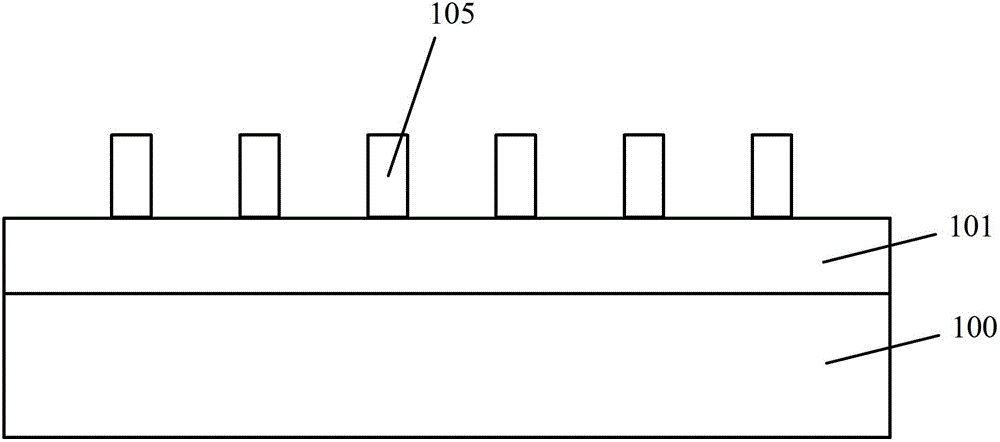

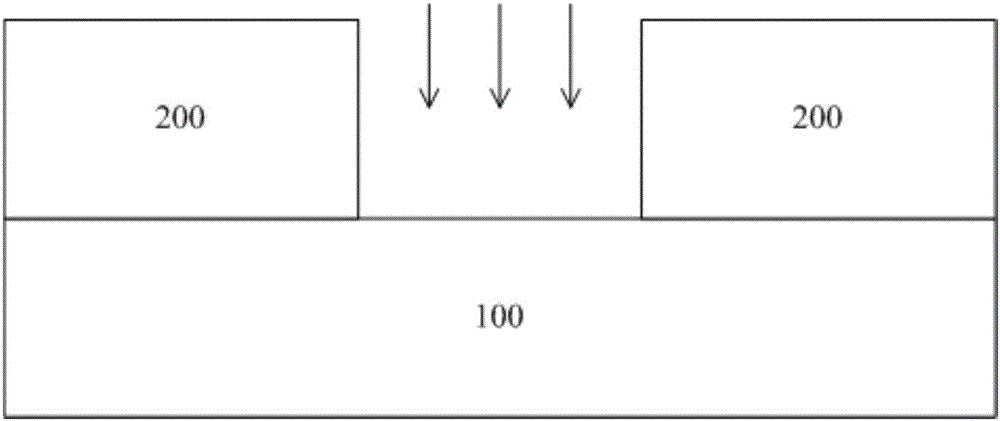

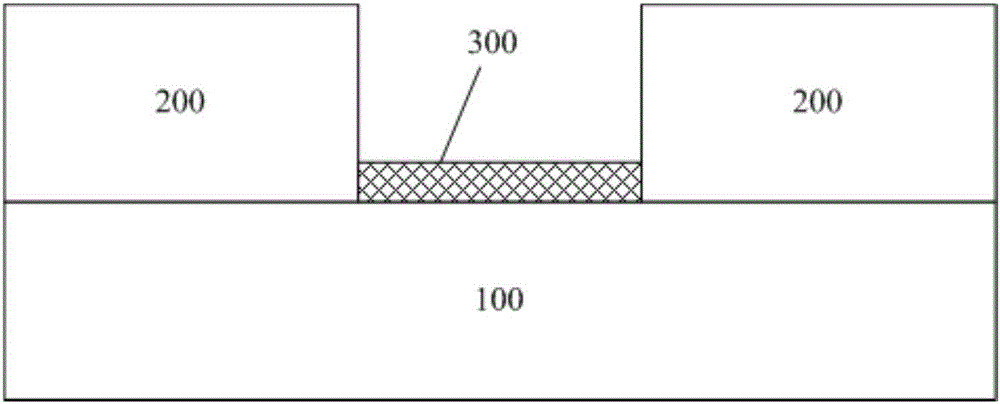

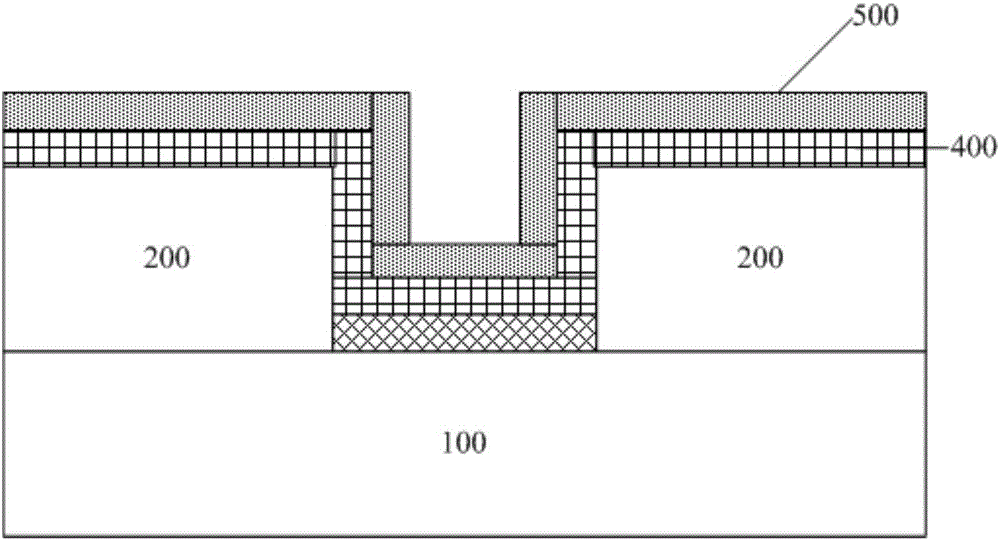

A forming method of a multigraph comprises the following steps: providing an etched material layer; forming a plurality of discrete first hard mask layers on the etched material layer; forming a first side wall positioned around the first hard mask layer; forming a second side wall positioned around the first side wall, and the first side wall and the second side wall are made of different materials; repeating the technology forming the first side wall and the second side wall for a plurality of times, and forming multi-layer side wall structures around the first hard mask layer spaced by the first side wall and the second side wall; removing the first hard mask layer and the second side wall; using the first side wall to serve as a mask so as to etch the etched material layer, thereby forming the target graph. In the forming method of the multigraph, the target graph is small in linewidth, the target graph with controllable number can be realized without carrying out hard mask transfer for many times, so technology is simple.

Owner:SEMICON MFG INT (SHANGHAI) CORP

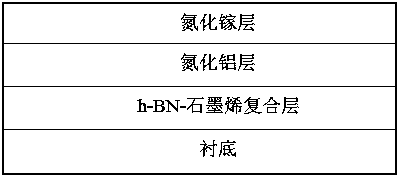

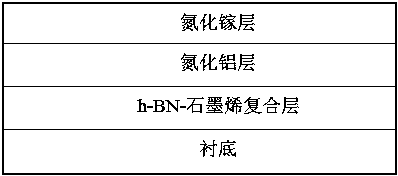

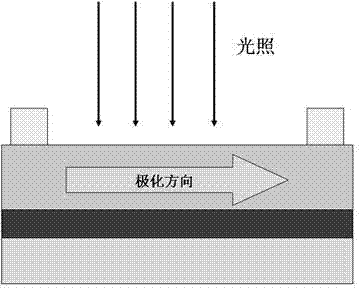

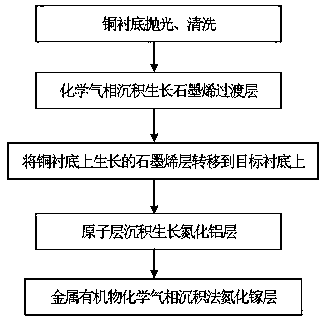

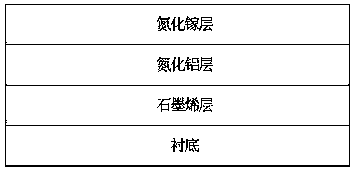

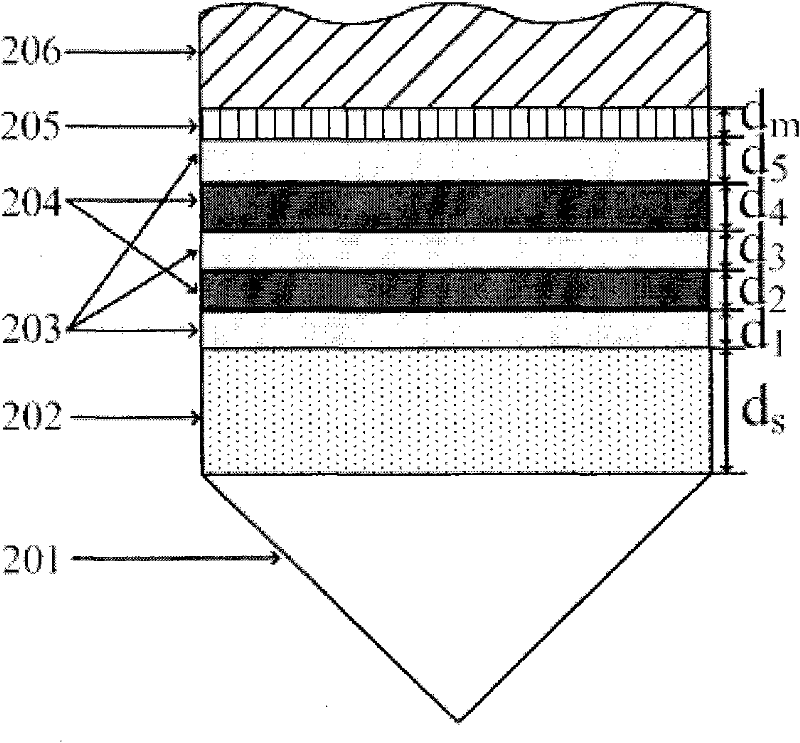

Preparation method of GaN epitaxial structure taking hexagonal BN-graphene composite layer as buffer layer

ActiveCN107706274AQuality improvementSolve defects, dislocations, cracks, etc.Semiconductor devicesHexagonal boron nitrideGallium nitride

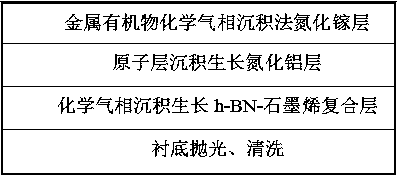

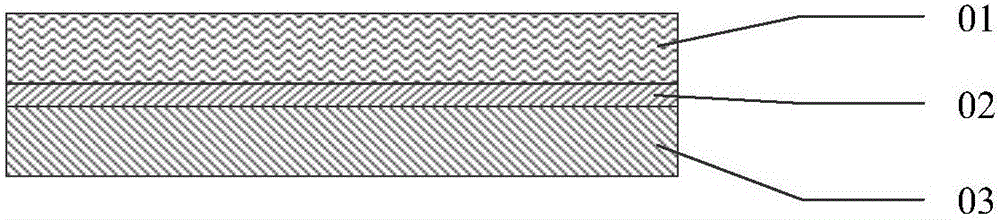

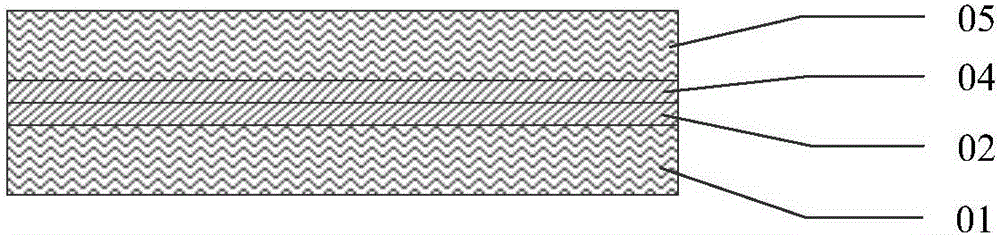

The invention relates to a preparation method of a GaN epitaxial structure taking a hexagonal BN-graphene composite layer as a buffer layer, and belongs to the technical field of photoelectron. The method comprises the steps of polishing and cleaning a copper substrate; growing an h-BN-graphene composite layer on the copper substrate; growing an AlN layer on the h-BN-graphene composite layer by anatomic layer deposition method; and growing a GaN layer on the AIN thin layer by a metal organic matter chemical vapor deposition method. The h-BN-graphene composite layer is used as the buffer layerbetween the copper substrate and the GaN epitaxial layer, thus, the problems of defect dislocation, crack and the like caused by lattice mismatching and thermal mismatching between the substrate andthe epitaxial layer can be solved, the stress between the substrate and an epitaxial material is effectively reduced, and the quality of the GaN epitaxial layer is improved.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

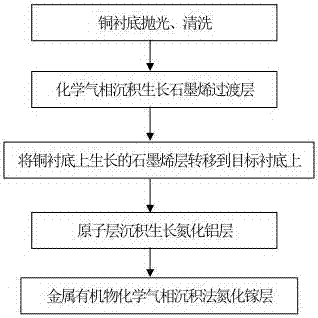

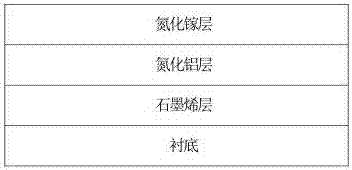

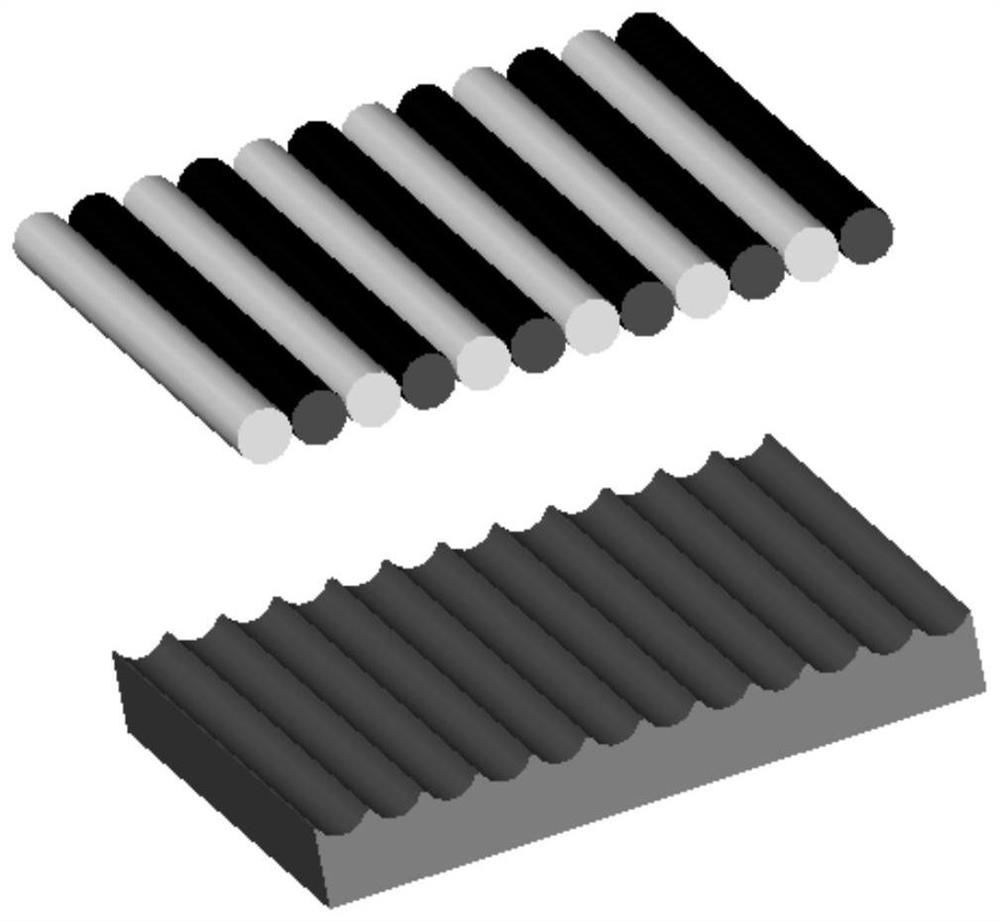

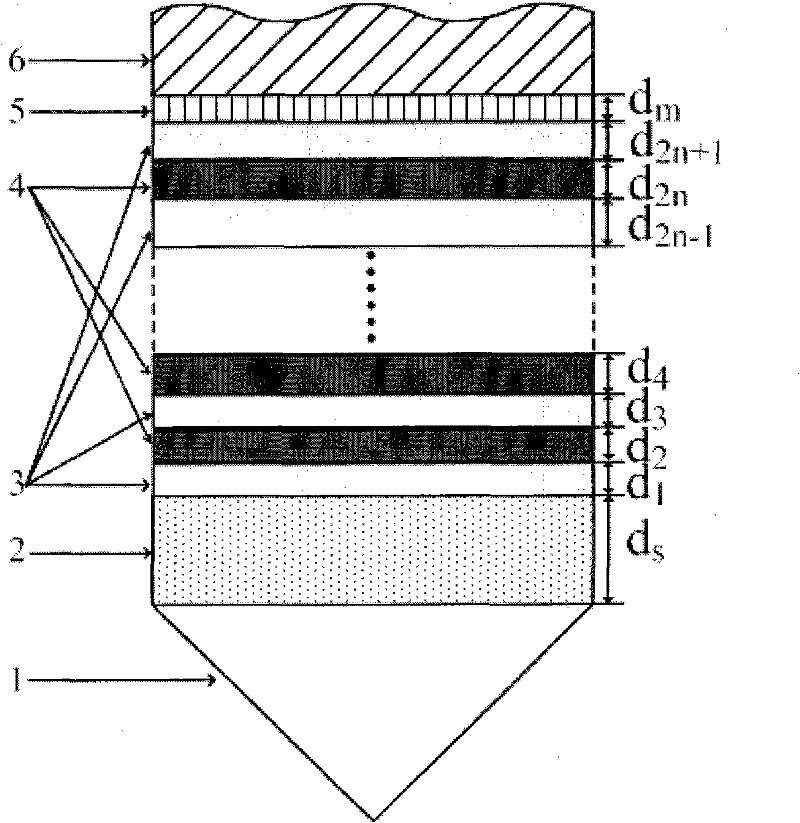

Production method of nitride epitaxial wafers and gallium nitride laser device

ActiveCN106868472AQuality improvementSolve defects, dislocations, cracks, etc.Laser detailsChemical vapor deposition coatingLattice mismatchGallium nitride

The invention relates to a production method of nitride epitaxial wafers and a gallium nitride laser device. The method comprises the following steps that 1, a copper substrate is polished and cleaned; 2, a graphene layer grows on the copper substrate; 3, the graphene layer growing on the copper substrate is transferred to target substrates; 4, an aluminum nitride thin layer grows on the graphene layer through an atomic layer deposition method; and 5, a GaN layer grows on the aluminum nitride thin layer through a metal organic matter chemical vapor deposition method. By means of the method, the nitride epitaxial wafers can grow on the different target substrates, the epitaxial wafers are transferred through the copper substrate, and therefore graphene is transferred to the different target substrates. The graphene layer is used as a buffer layer between the substrate and the GaN epitaxial layer, and the aluminum nitride layer is prepared through the atomic layer deposition method. Layer-by-layer growth of material atomic layers, good thickness controllability and high-precision film growth quality can be achieved, the large lattice mismatch problem between the substrate and the epitaxial layer is solved, the epitaxial layer quality is improved, and high-quality gallium nitride laser device can be obtained.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

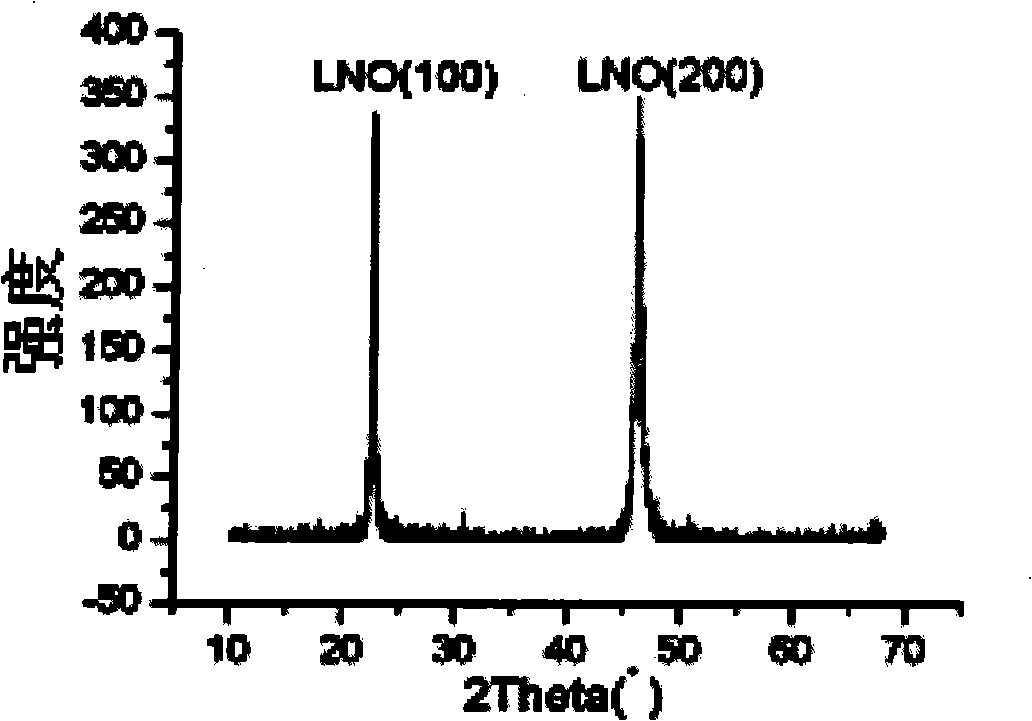

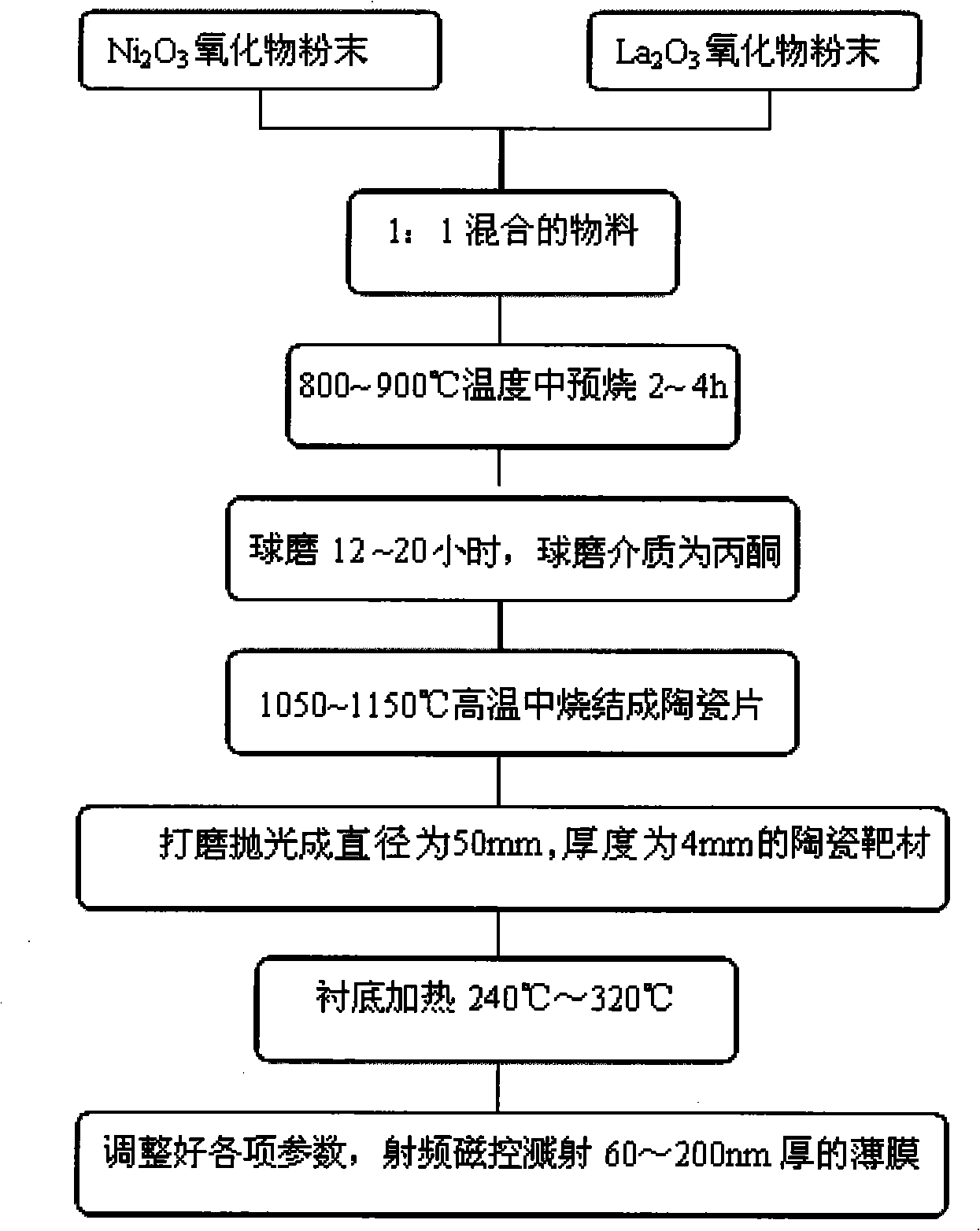

Method for preparing lanthanum nickelate conductive metallic oxide nano-film

InactiveCN101343729AUniform and dense film formationGood thickness controllabilityVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringLanthanum

Disclosed is a preparation method of a lanthanum nickelate conductive metal oxide nanometer film. The LaNiO3 nanometer film preparation method comprises: firstly, the preparation of a target material, namely oxide powders of Ni2O3 and La2O3 of an analytical reagent are mixed in a ratio of 1:1 for implementing the preheating and then ball grinding, then the powders are pressed into a round sheet with the diameter of 50 mm and thickness of 4 mm, and finally the round sheet is sintered into a ceramic target at a high temperature of 1050 to 1150 DEG C; and secondly, the preparation of a film material, namely a radio frequency magnetic control sputtering method is adopted, all the parameters of a sputtering machine are adjusted, and the film with the required thickness is obtained through sputtering and deposition after a substrate reaches a certain temperature by in situ heating. The film manufactured in the method has high preferred orientation and good electric conductivity, the surface is compact and smooth, and the resistance rate under room temperature is about 1m Omega cm. The film can be used as a buffer layer for the preparation of high quality perovskite structure ferroelectric film material, or used as a bottom electrode of a ferroelectric film device.

Owner:SHANGHAI JIAO TONG UNIV

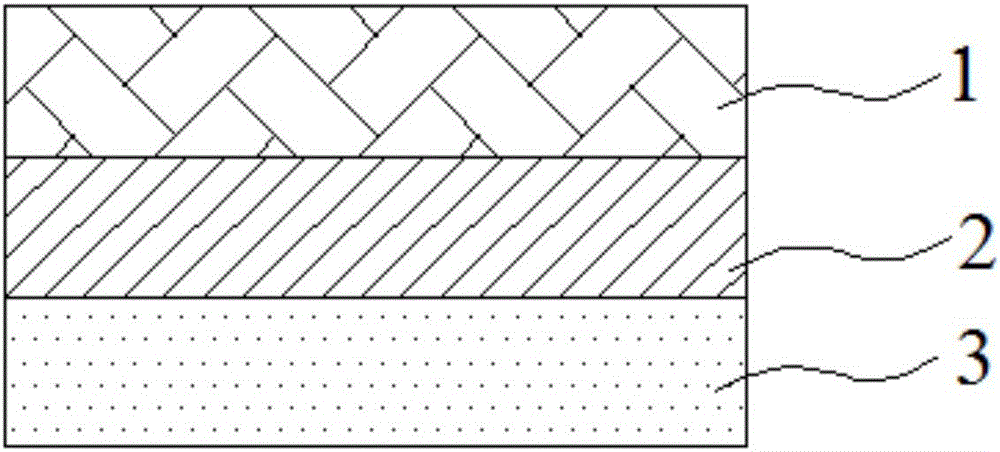

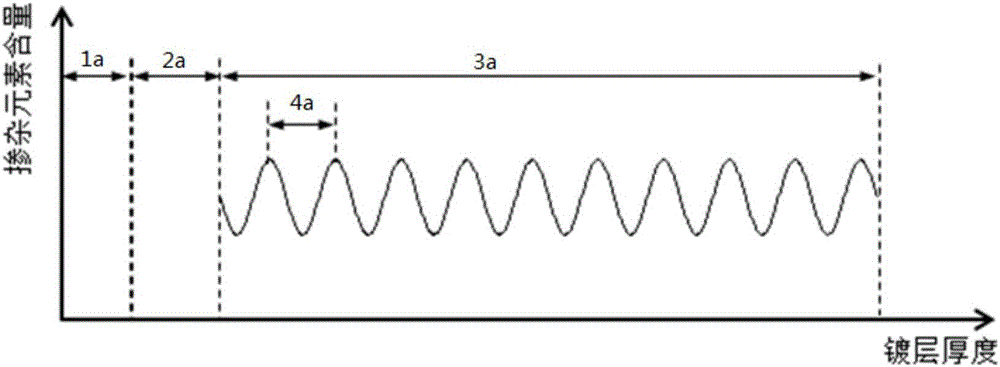

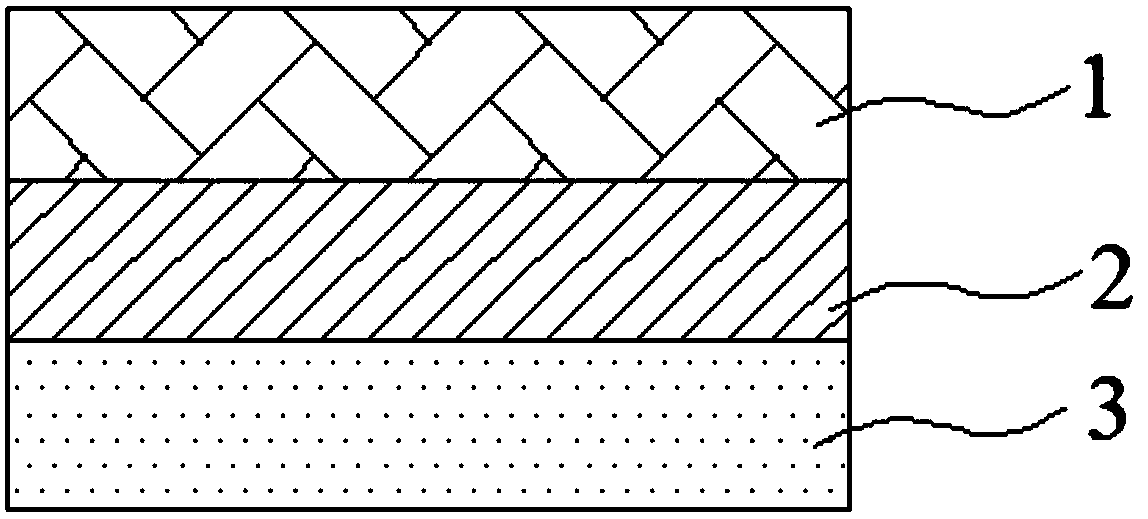

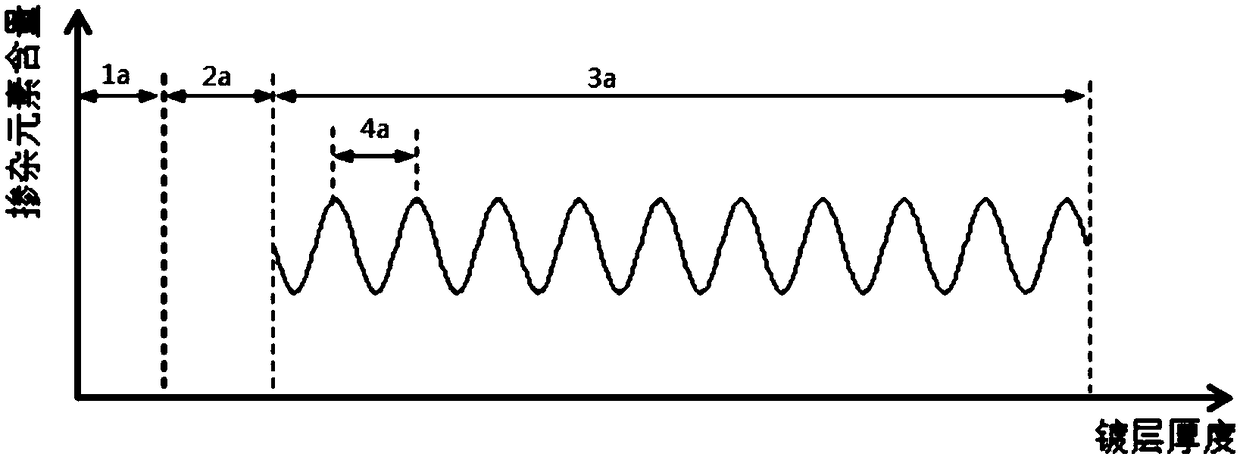

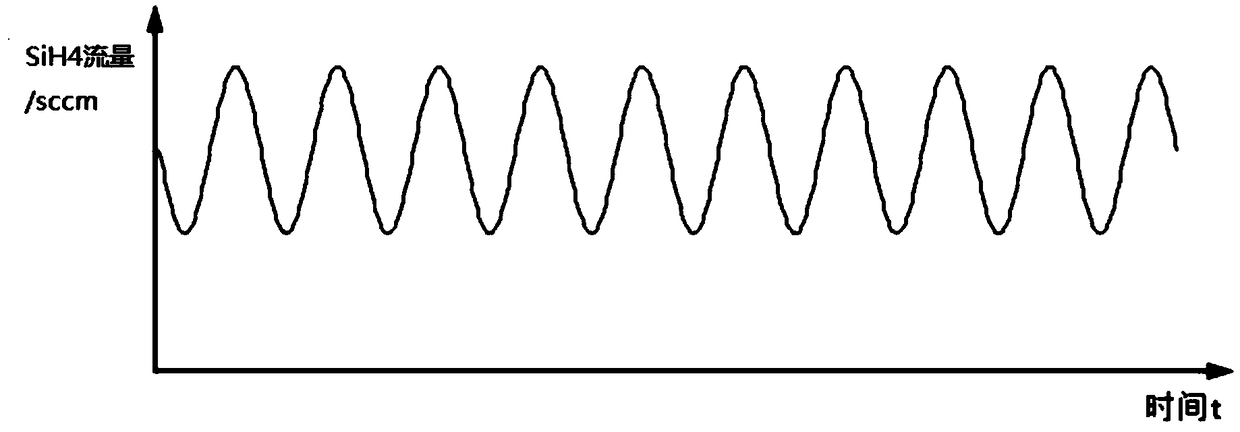

Diamond-like carbon coating applied to surface of piston ring, piston ring and manufacturing technology

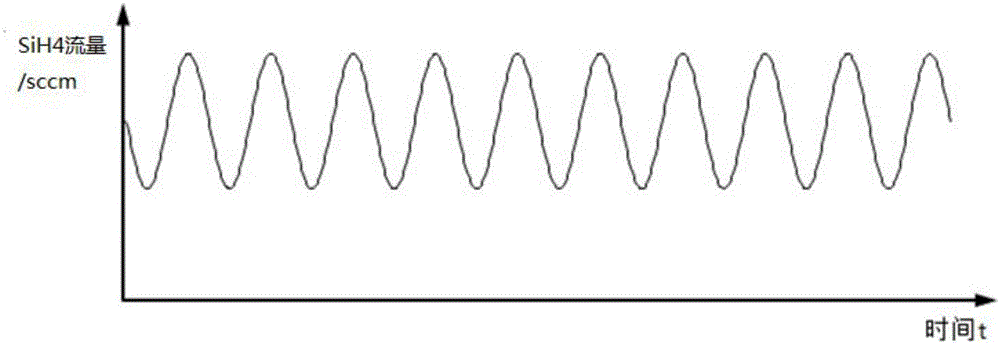

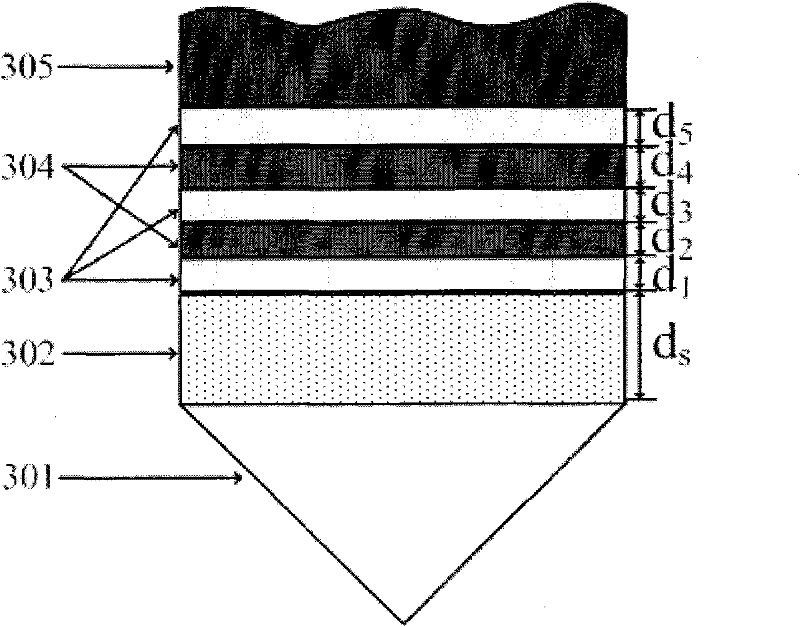

ActiveCN105734527AIncreasing the thicknessReduce stressPiston ringsVacuum evaporation coatingCarbon coatingSine wave

The invention relates to a diamond-like carbon coating applied to the surface of a piston ring. The diamond-like carbon coating includes a base layer, a gradient layer and an amplitude modulation layer sequentially from bottom to top, wherein the amplitude modulation layer is a diamond-like carbon coating body doped with doping elements, the doping elements include one or more than two of Cr, Si and Ti, and the doping element content of the amplitude modulation layer changes periodically in a sine wave fluctuation mode along with the thickness of the amplitude modulation layer. Compared with a traditional single-layer structure or gradient-layer structure, as the doping element content of the amplitude modulation layer changes periodically in the sine wave fluctuation mode along with the thickness of the amplitude modulation layer, the amplitude modulation layer of the diamond-like carbon coating is of a multi-layer cycle modulation structure; and on the basis of the high abrasion resistance and low friction coefficient, stress in the coating can be lowered advantageously, the toughness of the coating can be improved, it is ensured that the thickness of the diamond-like carbon coating is increased, and the durability of the piston ring of the diamond-like carbon coating is also improved.

Owner:ASIMCO SHUANGHUAN PISTON RING YIZHENG

Graphite sheet and metal layer composed thermally conductive sheet and its composing method

PendingCN106328614AGood thickness controllabilityIncrease heating capacitySemiconductor/solid-state device detailsSolid-state devicesDiffusion methodsGraphite

The invention provides a graphite sheet and metal layer composed thermally conductive sheet and its composing method. According to one embodiment of the invention, through a PVD aluminum deposition layer, the composition of a graphite sheet and other metal layers becomes possible so as to solve the difficulty with increasing the thickness of graphite sheet and thermally-conductive sheet and the problem of low thermal conductivity in the thickness direction. Based on these ideas, the invention aims to improve the overall heat capacity of the thermally conductive sheet and the comprehensive thermal conductivity in the thickness direction. The thermally conductive sheet of the invention can replace the product structure characterized by the adhesion of adhesive layers among multiple graphite sheet layers or between a graphite sheet and metal. Based on the prior art, the present invention combines the PVD aluminum plating technique and the metal hot-press diffusion method. Compared with the pure use of CVD or liquid plating method, the method of the invention is more efficient to obtain a composite metal layer with the same thickness. In addition, the once hard-to-obtain composite thickness and composite structure in the prior art can be more likely to be achieved. The composing method resolves the problem of how to accumulate composite metal layers with designated thicknesses and avoids the inherent defects of CVD and the liquid plating method.

Owner:SHENZHEN XINHENGKUN TECH

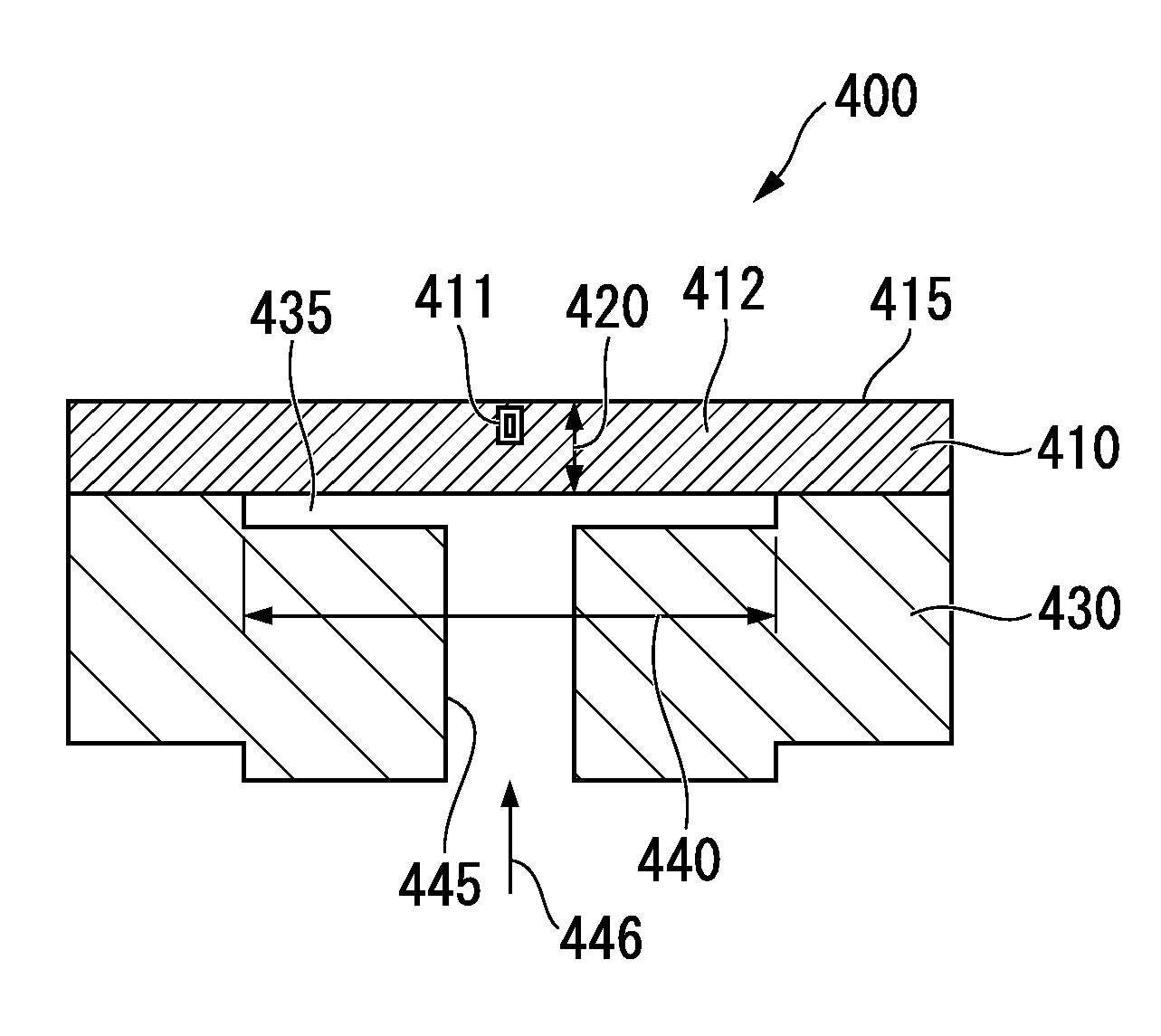

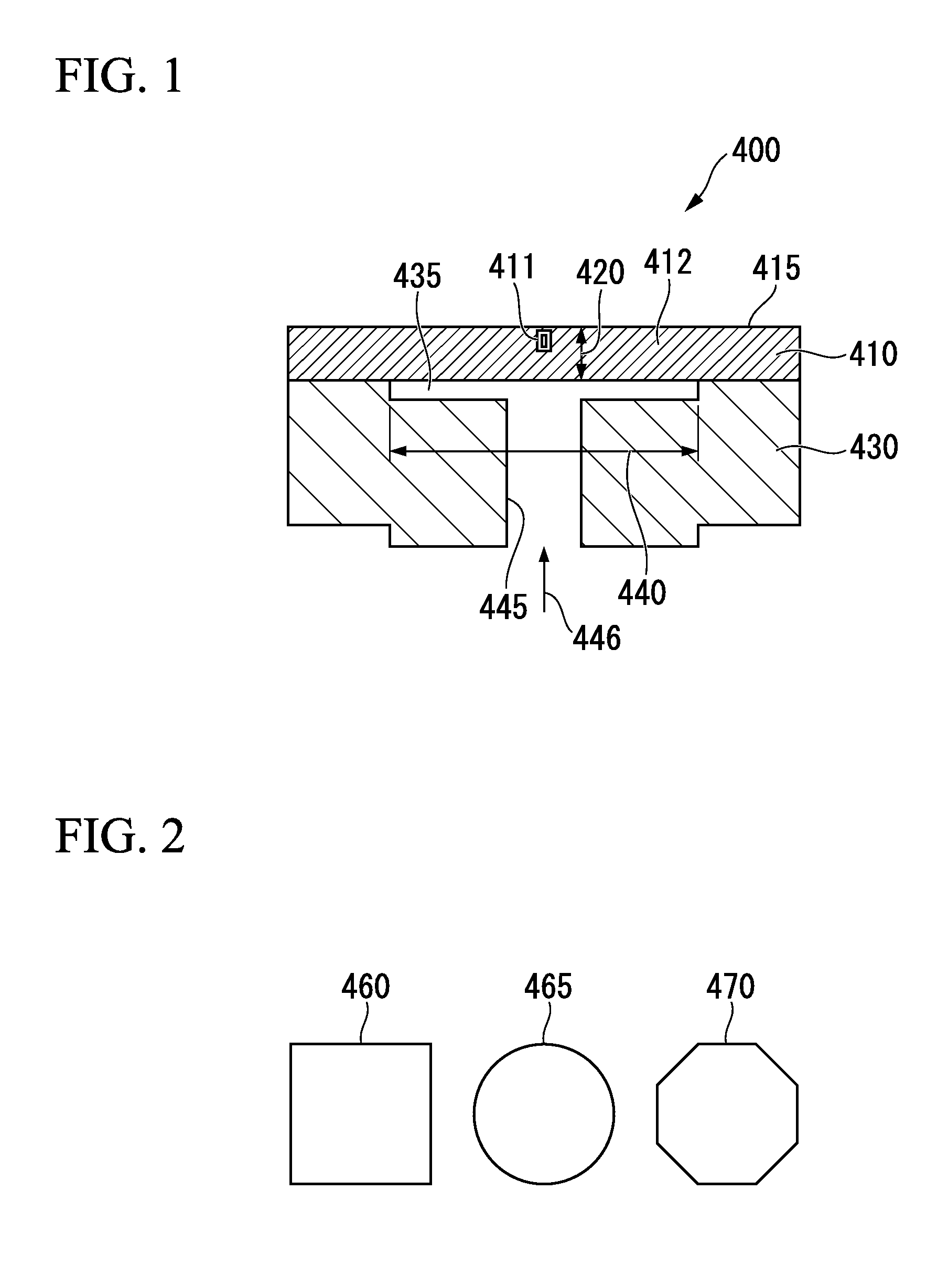

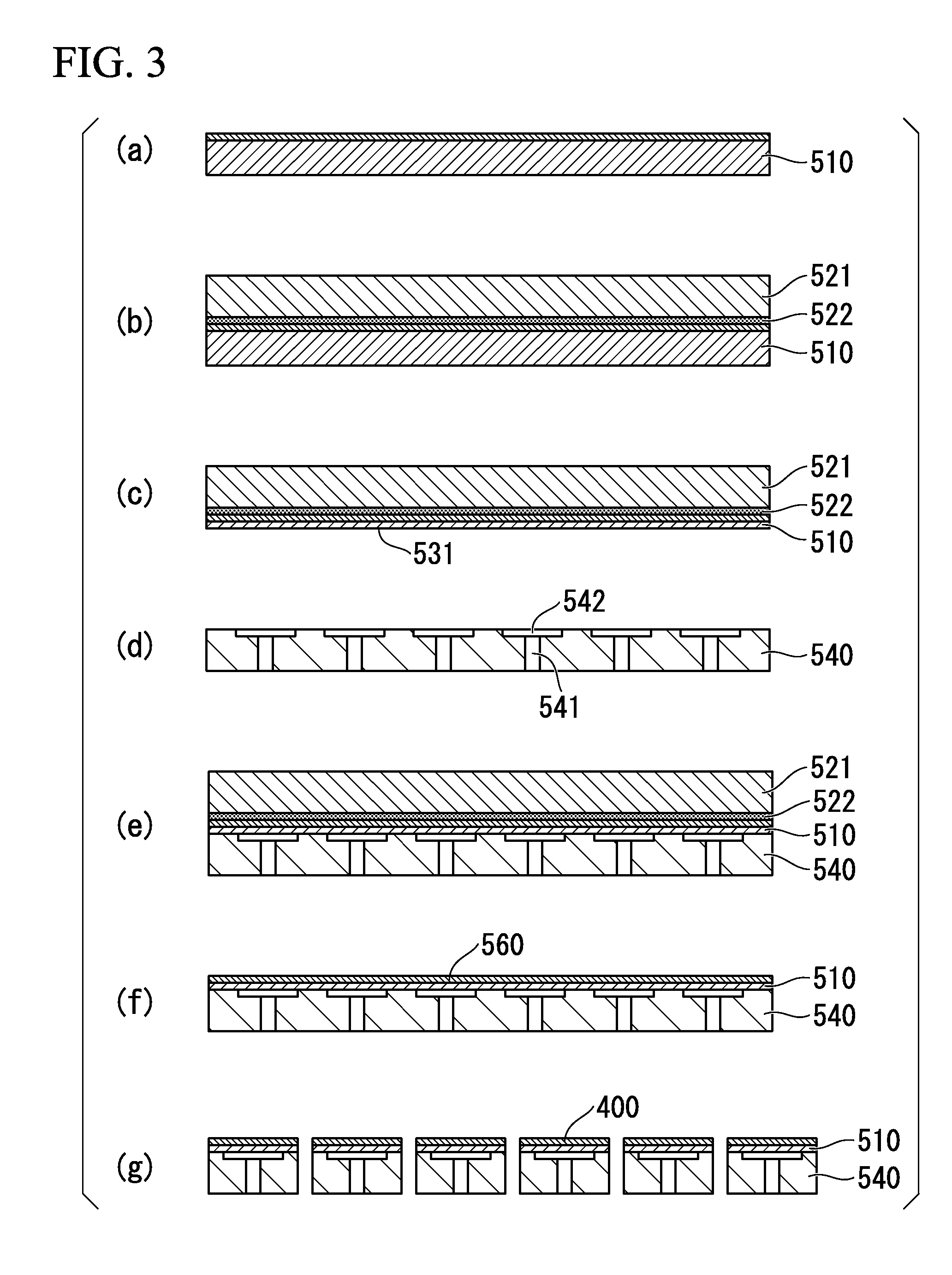

Resonant pressure sensor and method of manufacturing the same

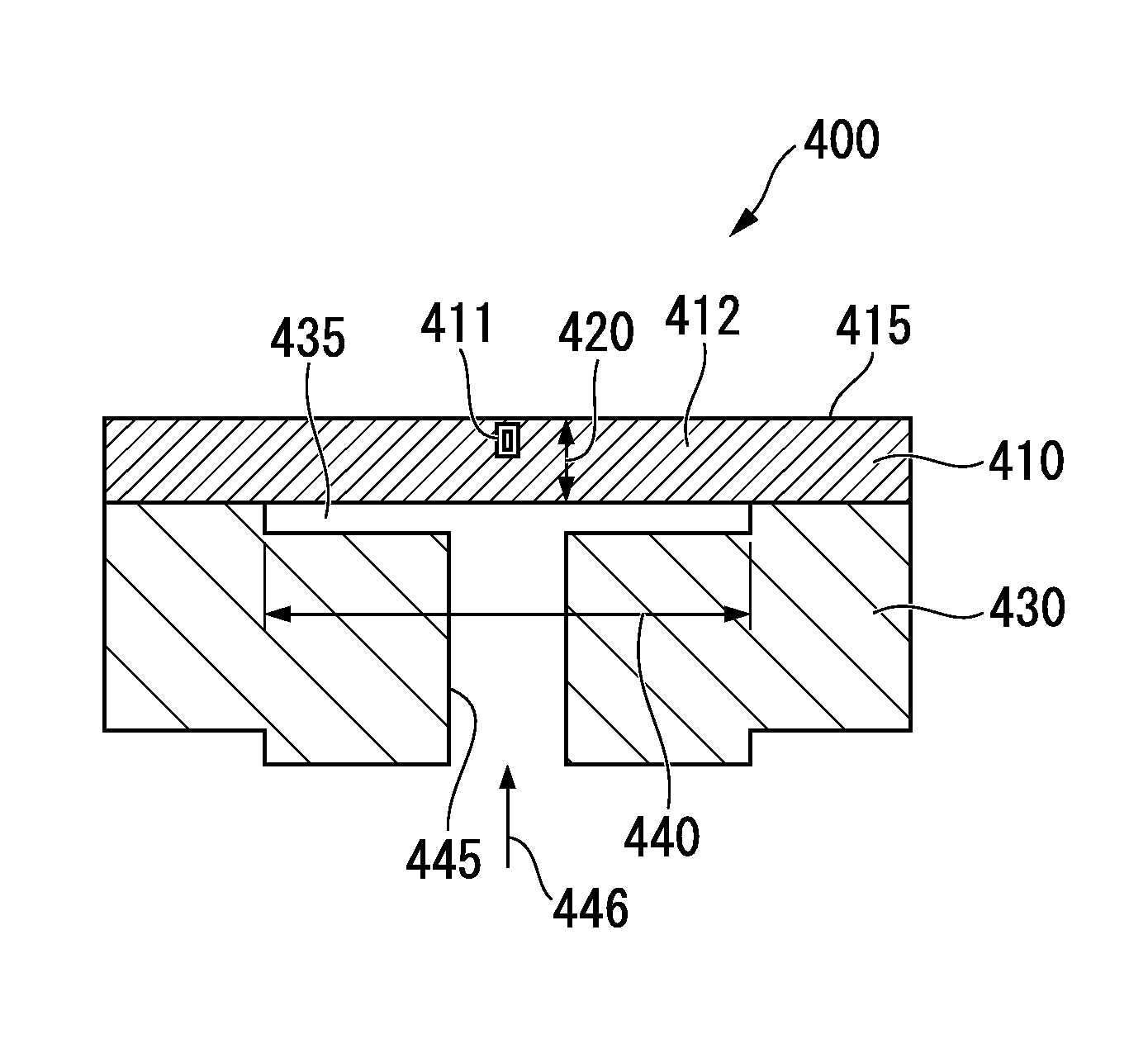

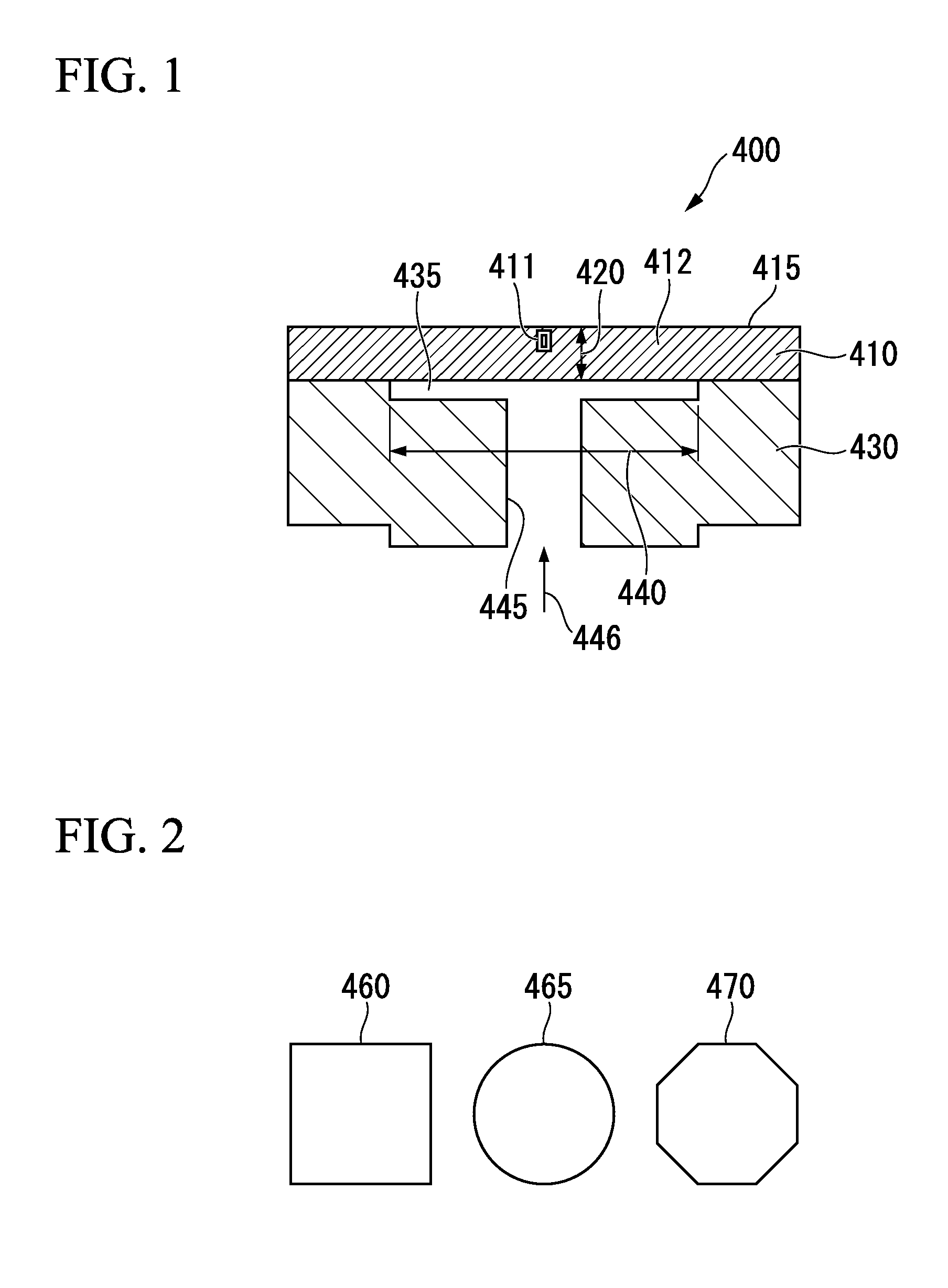

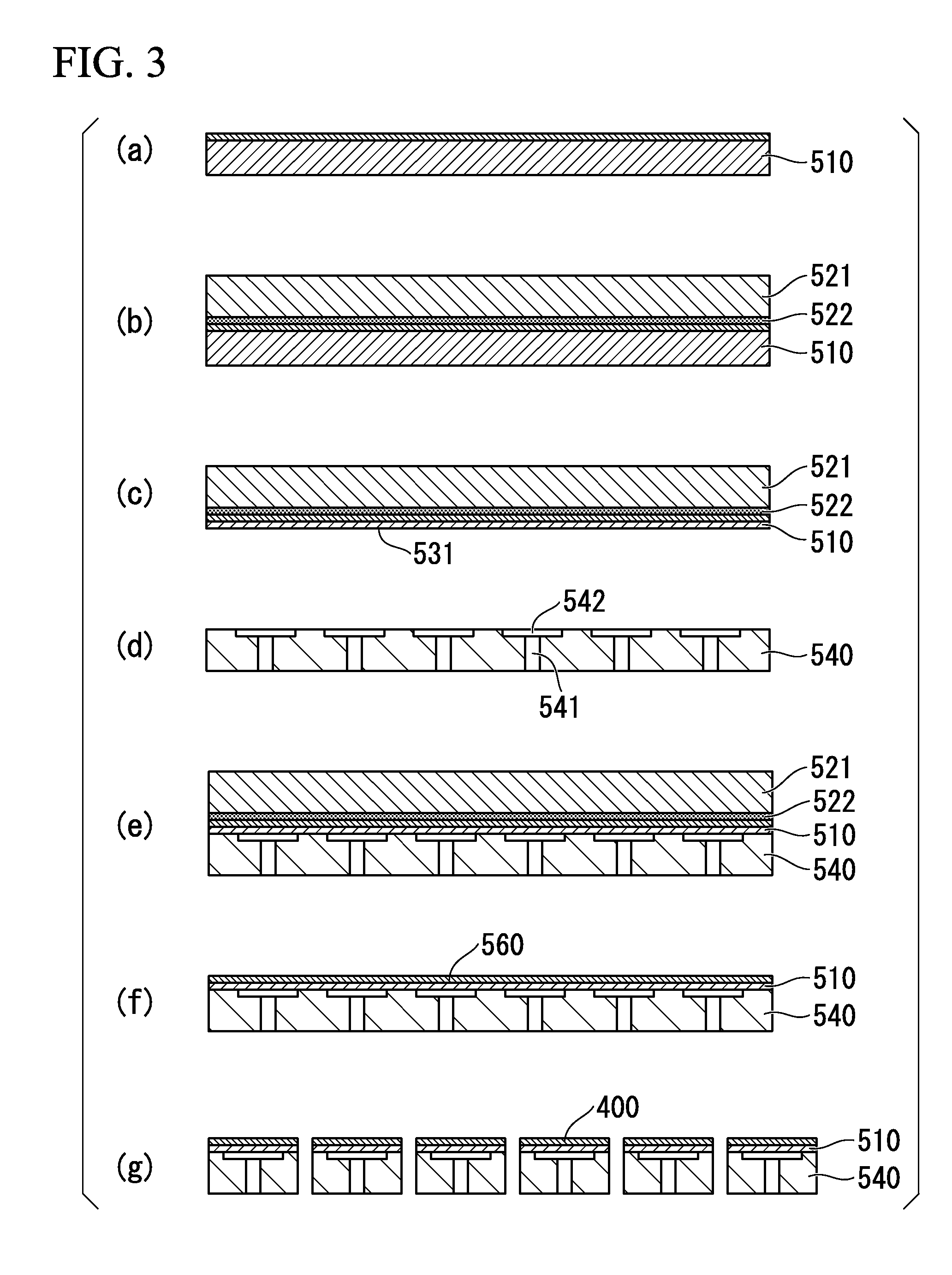

ActiveUS20130047734A1Variation can be suppressedGood thickness controllabilityLamination ancillary operationsDecorative surface effectsForeign matterEngineering

A resonant pressure sensor including one or more resonant-type strain gauges arranged on a diaphragm may include a sensor substrate made of silicon and including one surface on which one or more resonant-type strain gauge elements are arranged and the other surface which is polished to have a thickness corresponding to the diaphragm, a base substrate made of silicon and including one surface directly bonded with the other surface of the sensor substrate, a concave portion formed in a portion of the base substrate bonding with the sensor substrate, substantially forming the diaphragm in the sensor substrate, and including a predetermined gap that does not restrict a movable range of the diaphragm due to foreign substances and suppresses vibration of the diaphragm excited by vibration of the resonant-type strain gauge elements, one or more conducting holes, and a fluid.

Owner:YOKOGAWA ELECTRIC CORP

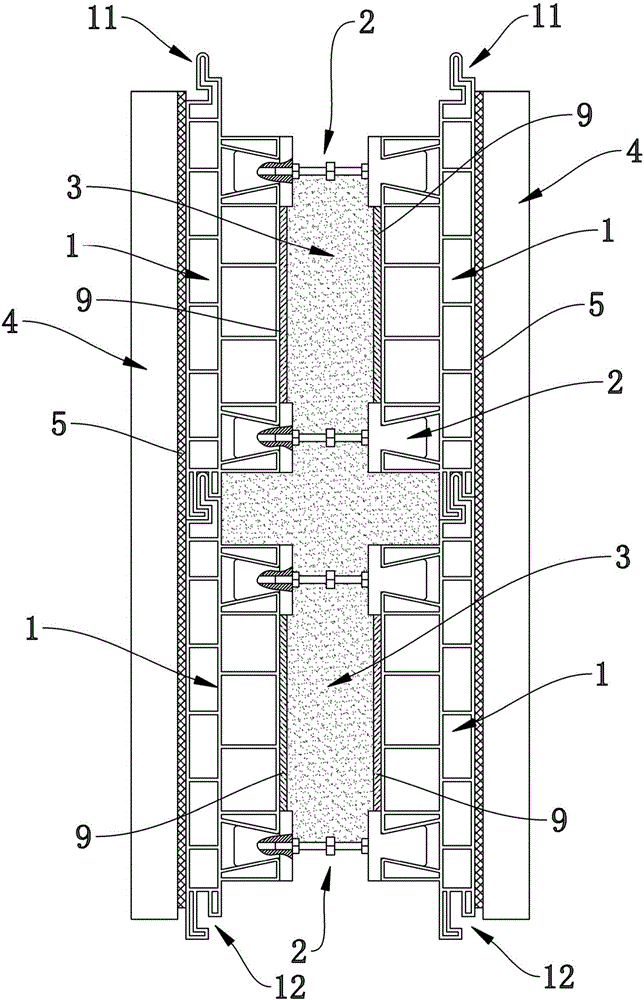

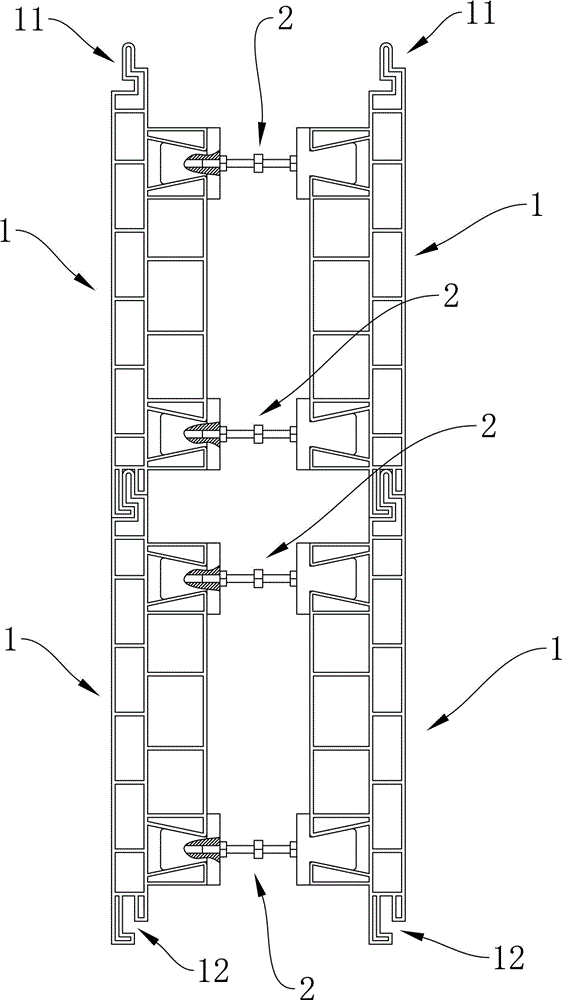

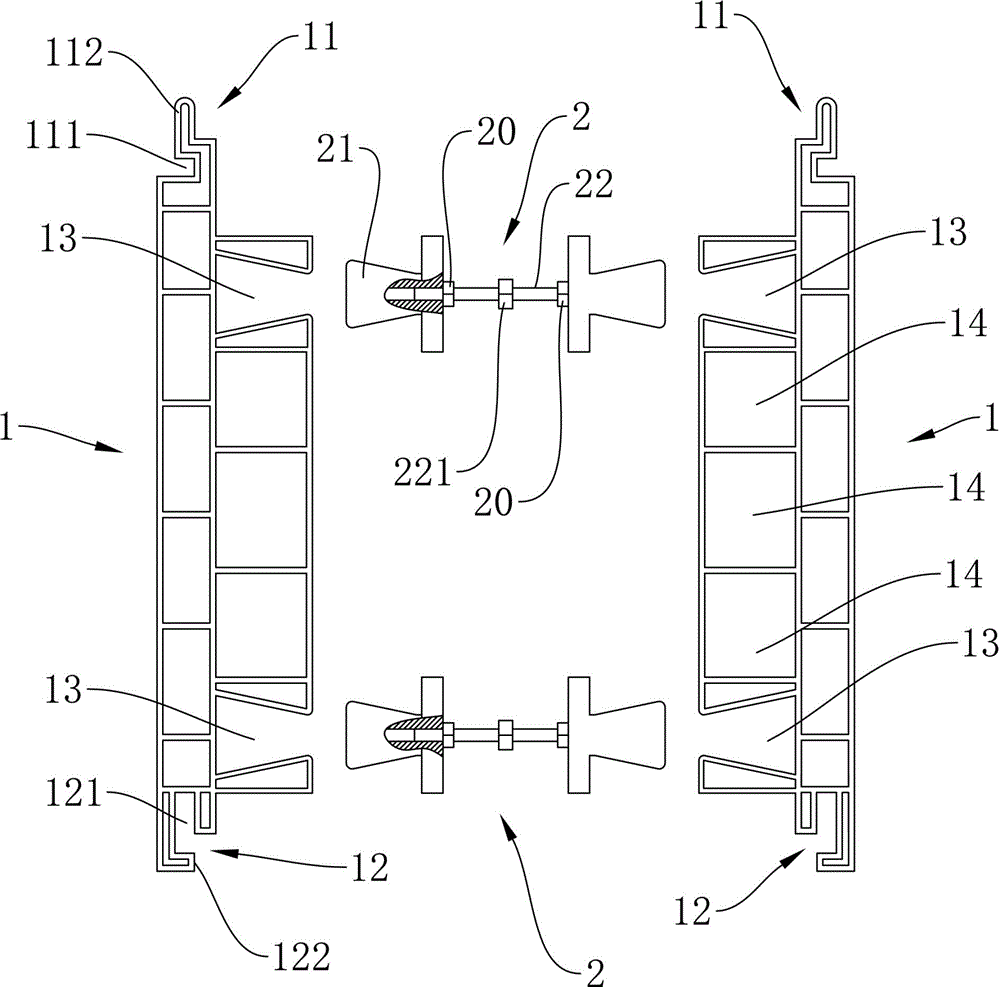

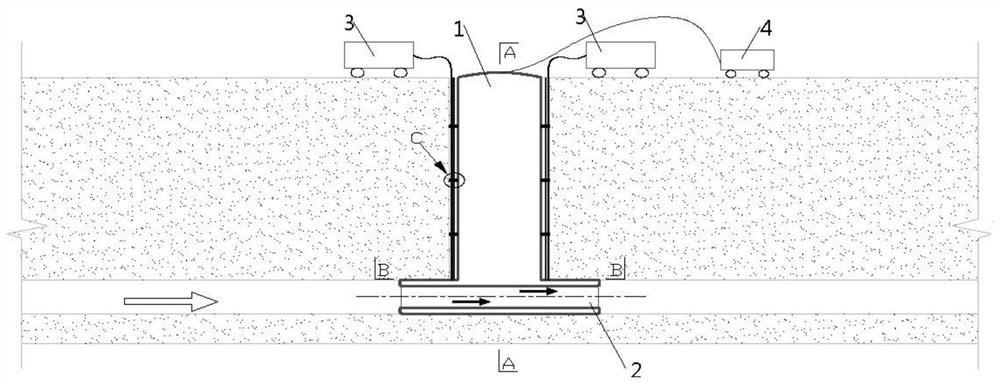

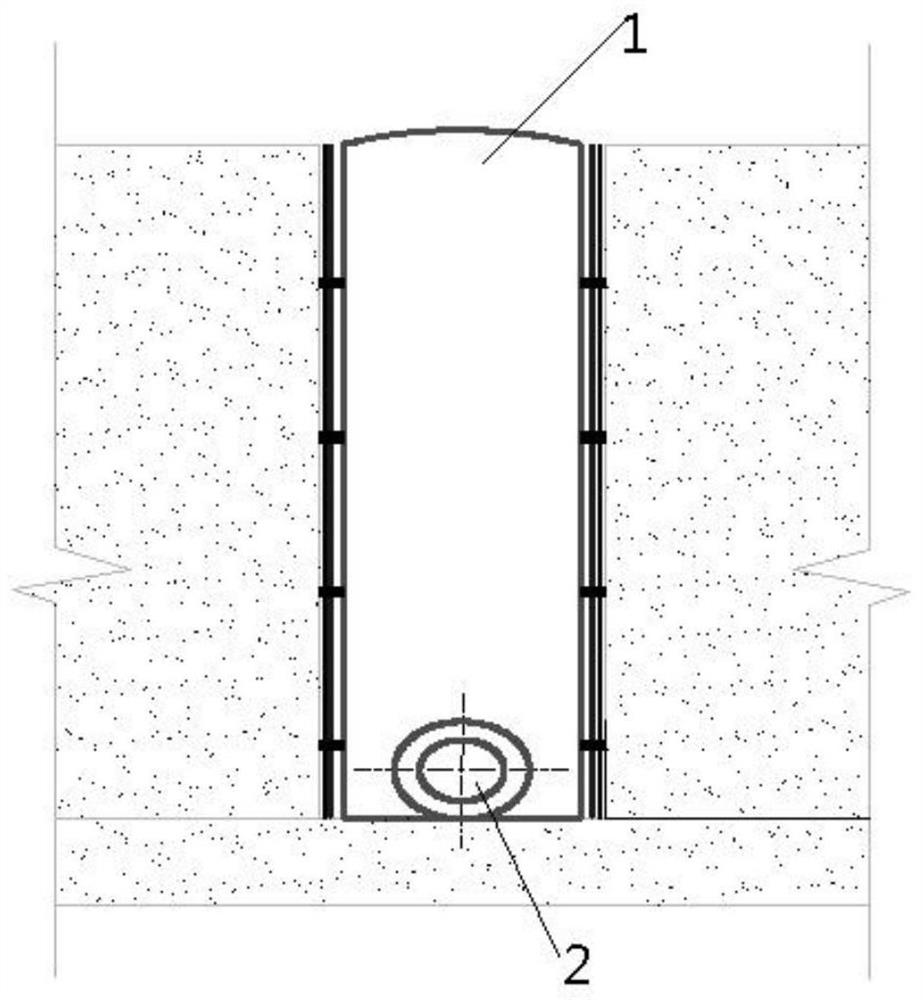

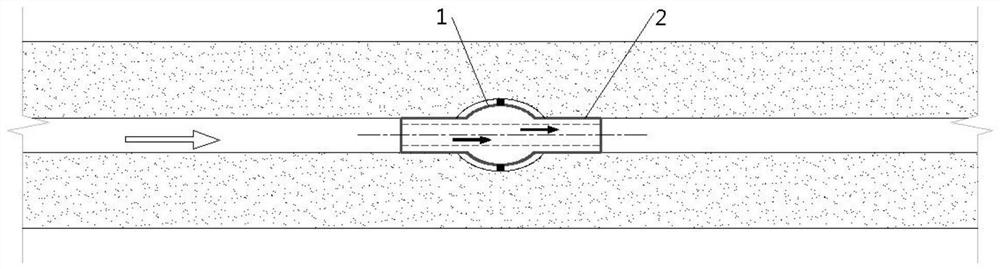

Light-weighted high-intensity assembled wall

PendingCN107178166ASignificantly progressiveGood thickness controllabilityHeating fuelCovering/liningsEarthquake resistancePlastic materials

The invention relates to a light-weighted high-intensity assembled wall. The light-weighted high-intensity assembled wall is characterized by comprising two parallel hollow boards made of metal materials or plastic materials, an adjustable connection assembly and a foaming rubber filler; the adjustable connection assembly is connected between the two hollow boards so as to connect the two hollow boards and adjust the distance between the two hollow boards; and the foaming rubber filler is arranged in an interval gap between the two hollow boards. By means of the scheme of the wall, standard, modular and factory-like production and manufacturing can be achieved, no building garbage is generated during assembly and application, even pieces of broken materials generated in the assembling and cutting process can be recycled, later decoration is not needed, decoration pollution is avoided, flying dust is not generated, the construction noise is low, and the light-weighted high-intensity assembled wall is environmentally friendly, safe and free of cracking and peeling off of paint; and the wall is good in leakage resistance, fire resistance, earthquake resistance and heat insulation performance, the building construction period is shortened quite advantageously, the construction efficiency is improved, and the construction environment is improved.

Owner:彭志军

Inspection well trenchless reparation device and reparation method thereof

PendingCN111809712AGood thickness controllabilityHigh strengthArtificial islandsSewerage structuresSlurryAirbag

The invention provides an inspection well trenchless reparation device and a reparation method thereof, and belongs to the field of municipal construction. The device includes an airbag, and the airbag includes a main airbag arranged vertically, and a flow guide airbag vertically connected with the bottom of the main airbag. A plurality groups of cushion block groups are evenly arranged on the outer wall of the main airbag along the longitudinal and circumferential ranges, each group of cushion block groups includes at least one cushion block connected together in a bonding mode, a slurry injecting pipe fixing hole is formed in the cushion block, a slurry injecting pipe is connected in the slurry injection pipe fixing hole in a bonding mode, a plurality of slurry injecting holes are formedin the slurry injecting pipe, and slurry injecting is carried out in the slurry injecting pipe. The invention further provides an inspection well trenchless reparation method of the reparation device, and the method can solve the defects that 1 the compactness of a lining layer after spraying reparation is insufficient; 2 the space of an inspection well is narrow, and the inspection well cannot be troweled after the spraying reparation so that the lining layer is not level; 3 a skeleton structure is not formed in a spraying lining layer, and the inspection well structure cannot be reinforced;and 4 a connecting pipeline of the inspection well is subjected to blocking and water transferring before the spraying reparation.

Owner:HUNAN DALU TECH CO LTD

Compound-based semiconductor ultrathin substrate manufacturing method

InactiveCN106409671AGuaranteed thickness toleranceSmall thickness errorSemiconductor/solid-state device manufacturingLithographic artistOrganic solvent

The invention discloses a compound-based semiconductor ultrathin substrate manufacturing method. The method includes 1) manufacturing a device in a compound-based epitaxial material layer; 2) and then forming an isolated table top of a device to be packaged on the right side of a compound semiconductor substrate sheet by means of lithography and etching methods, and etching to the depth of 3-10 micrometers; 3) coating a photoresist on the right side of the compound semiconductor substrate sheet; 4) growing 20 nm of protective medium silica on a temporary substrate sheet; 5) bonding the compound semiconductor substrate to the temporary substrate sheet; 6) performing rapid thinning, slow thinning, polishing on the compound-based semiconductor substrate sheet until the thickness of the compound-based substrate is thinned to 20-30 micrometers; 7) etching the back side of the substrate by means of plasma etching until the epitaxial layer outside the table top are fully etched; and 8) removing the adhesive and photoresist by organic solvent immersion to obtain a compound-based semiconductor device having a substrate thickness of 3 to 10 micrometers.

Owner:DONGGUAN GUANGXIN INTPROP SERVICES CO LTD

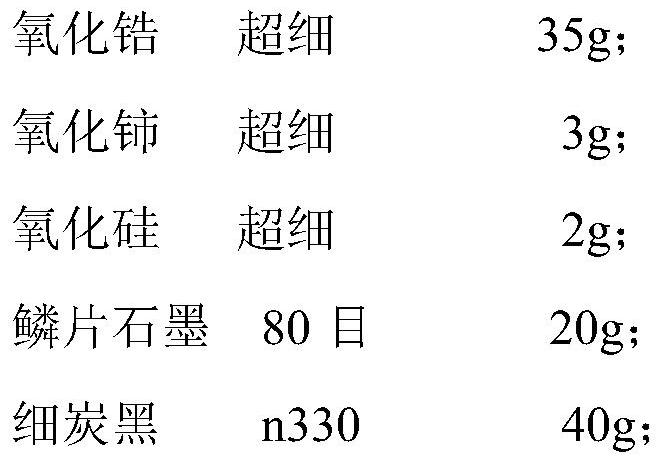

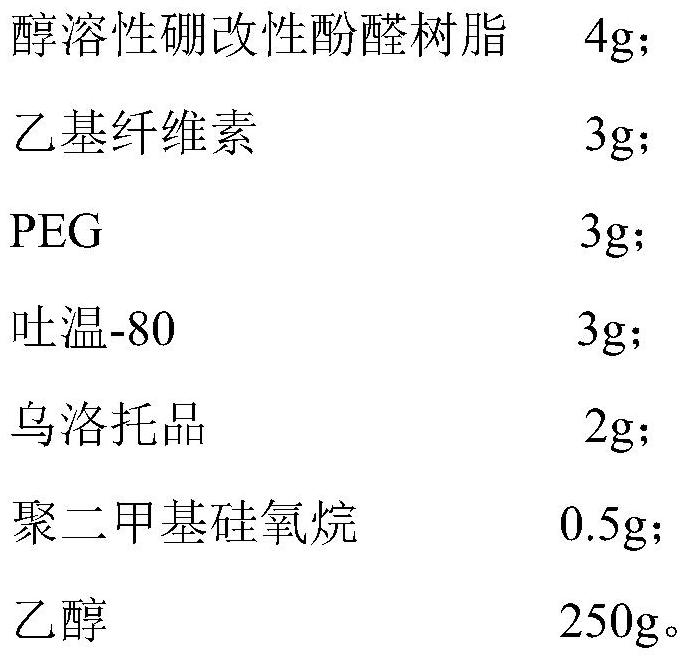

Hard alloy sintered anti-sticking coating adopting alcohol-soluble boron modified phenolic resin as well as preparation method and application of hard alloy sintered anti-sticking coating

InactiveCN112457738AImprove heat resistanceHigh bonding strengthCharge supportsCoatingsAdhesiveActive agent

The invention discloses a hard alloy sintered anti-sticking coating adopting alcohol-soluble boron modified phenolic resin as well as a preparation method and application of the hard alloy sintered anti-sticking coating; the anti-sticking coating is formed by mixing solid isolation powder and a liquid adhesive; the solid isolation powder comprises the components in parts by weight: 18-53 parts ofzirconium oxide, 1-6 parts of cerium oxide, 1-5 parts of silicon oxide, 10-30 parts of crystalline flake graphite and 5-45 parts of fine carbon black; and the liquid adhesive comprises the componentsin parts by weight: 3-10 parts of alcohol-soluble boron modified phenolic resin, 1-5 parts of a thickening agent, 2-5 parts of a dispersing agent, 3-5 parts of an active agent, 2-5 parts of a curing agent, 0.1-1.5 parts of a defoaming agent and 250-300 parts of a diluent. The anti-sticking coating has enough bonding strength and hardness after being brushed, and a coating layer is not prone to falling off and chipping in the hard alloy product placing, transporting and charging processes; after sintering, the coating layer can still keep high hardness and bonding strength, and the influence ofwater on the stability of an alloy product during sintering is avoided.

Owner:株洲润昌新材料股份有限公司

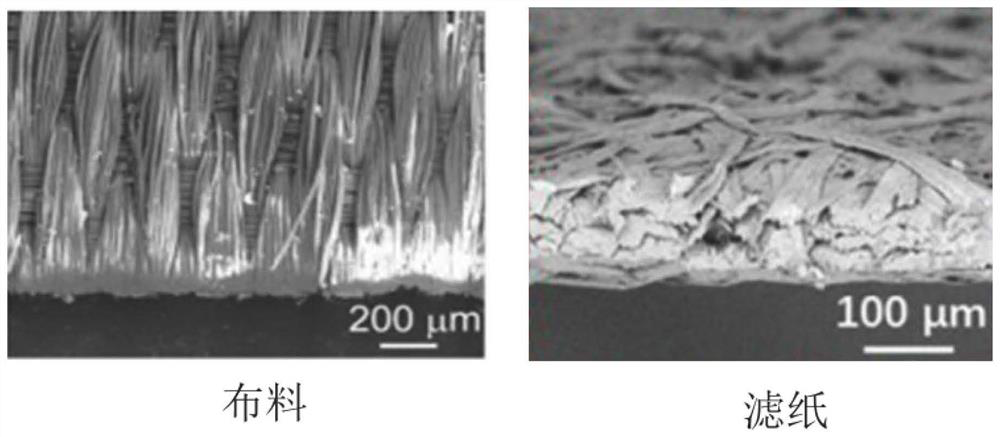

A kind of carbon fiber mat reinforced inorganic polymer matrix composite material and preparation method thereof

The invention provides a carbon fiber felt reinforcement inorganic polymer matrix composite and a preparation method of the carbon fiber felt reinforcement inorganic polymer matrix composite, and relates to an inorganic polymer matrix composite and a preparation method of the inorganic polymer matrix composite, in particular to the carbon fiber felt reinforcement inorganic polymer matrix composite and a preparation method of the carbon fiber felt reinforcement inorganic polymer matrix composite. The problems that an existing inorganic polymer material is poor in mechanical performance and low in toughness and the operation for adding short carbon fiber is complex are solved. The product is prepared through inorganic polymer material pulp and carbon fiber felt. The inorganic polymer material pulp is prepared through potassium hydroxide, silica sol and aluminosilicate powder. The method includes the steps of firstly, preparing the inorganic polymer material pulp; secondly, washing the carbon fiber felt; thirdly, preparing a prefabricated material blank; fourthly, preparing the carbon fiber felt reinforcement inorganic polymer matrix composite. The method is simple in process, low in cost, environmentally friendly and capable of being use for large-area preparation, and the prepared composite is good in mechanical property and wider in application range.

Owner:HARBIN INST OF TECH

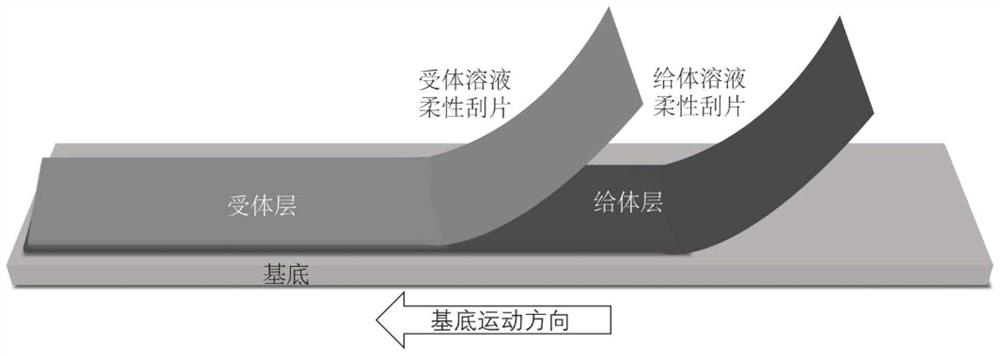

Preparation method and application of active layer of organic photovoltaic device

ActiveCN113241412ASimple and efficient operationLower requirementFinal product manufactureSolid-state devicesOrganic solar cellEngineering

The invention discloses a preparation method and application of an organic photovoltaic device active layer. The prepared organic photovoltaic device active layer comprises a donor layer, a donor-acceptor blending layer and an acceptor layer which are sequentially stacked from bottom to top, wherein the donor layer and the acceptor layer are prepared layer by layer through a flexible microstructure blade coating method, and the donor-acceptor blending layer is formed by mutual diffusion of donor molecules and acceptor molecules near an interface in the low-temperature annealing process. The method has the advantages that the acceptor material and the donor material use the same solvent to prepare the active layer layer by layer, the material utilization rate is close to 100%, material waste and environmental pollution are reduced, controllability and repeatability are high, the method can be applied to preparation of organic solar cell devices, the prepared organic solar cell devices are stable in property, and the method is suitable for large-scale production. and the method is suitable for large-area production.

Owner:NANJING UNIV OF POSTS & TELECOMM

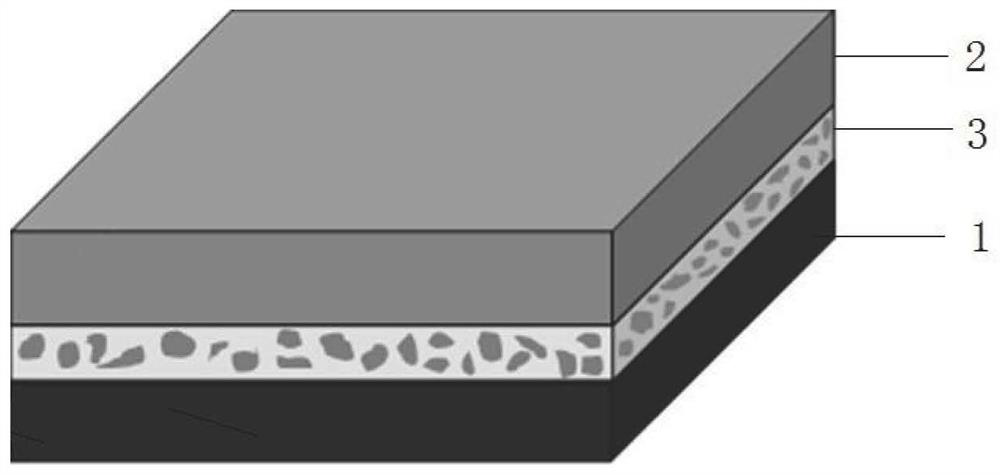

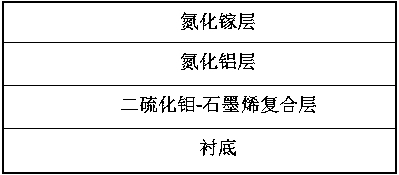

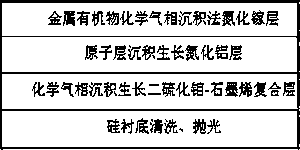

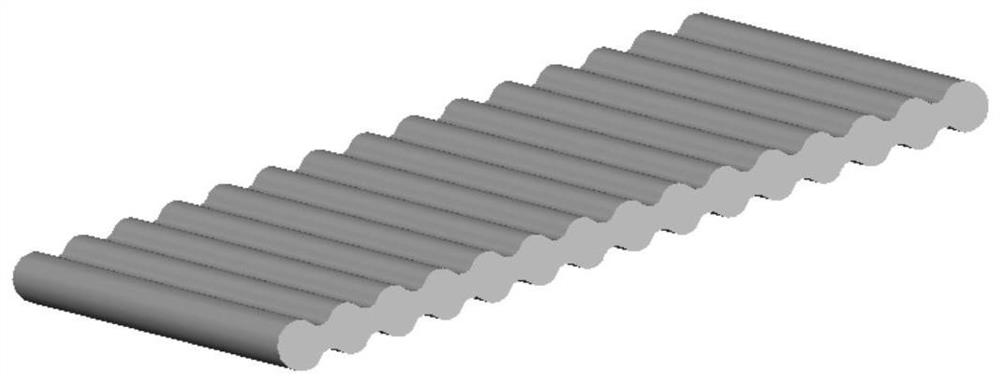

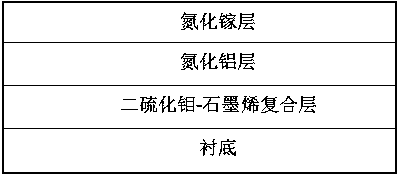

Preparation method of gallium nitride epitaxial structure based on molybdenum disulfide-graphene composite buffer layer

ActiveCN107768235AQuality improvementReduce stressSemiconductor/solid-state device manufacturingLattice mismatchEpitaxial material

The invention relates to a preparation method of a gallium nitride epitaxial structure based on a molybdenum disulfide-graphene composite buffer layer, and belongs to the technical field of photoelectronics. The preparation method comprises the steps of performing cleaning on a silicon substrate; enabling a molybdenum disulfide-graphene composite layer to be grown on the silicon substrate; enabling an aluminum nitride layer to be grown on the molybdenum disulfide-graphene composite layer by adopting an atomic layer deposition method; and enabling a gallium nitride layer to be grown on the aluminum nitride layer by adopting a metal organic chemical vapor deposition method, and the like. By adopting the molybdenum disulfide-graphene composite layer as the buffer layer between the silicon substrate and the GaN epitaxial layer, the problems of defect malposition, cracks and the like caused by high lattice mismatch and thermal mismatch between the substrate and the epitaxial layer can be solved, the stress between the substrate and the epitaxial material can be lowered effectively, and the GaN epitaxial layer quality is improved.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

Anti-sticking coating for sintering of hard alloy as well as preparation method and application thereof

The invention provides an anti-sticking coating for sintering of hard alloy as well as a preparation method and application thereof. The anti-sticking coating is formed by mixing solid isolation powder and a liquid adhesive. The solid isolation powder is prepared from, by weight, 22-40 parts of zirconium oxide, 5-8 parts of cerium oxide, 3-6 parts of magnesium oxide, 13-26 parts of crystalline flake graphite and 14-27 parts of fine carbon black. The liquid adhesive comprises the following components in parts by weight: 80-120 parts of water-soluble modified phenolic resin, 1.0-3.0 parts of a thickening agent, 3-6 parts of a dispersing agent, 4-8 parts of an active agent, 1-5 parts of a curing agent, 0.5-1.0 part of a defoaming agent and 80-120 parts of a diluent. A mass ratio of the solidisolation powder to the liquid adhesive is 1: (2.0-3.0). After the coating is brushed, bonding strength and hardness are high, and the coating is not prone to falling off and chipping in alloy productplacing, transporting and charging processes; and after sintering, the coating still maintains high hardness and bonding strength, and alloy carburization is avoided.

Owner:株洲润昌新材料股份有限公司

Method for preparing anti-radiation coating film

InactiveCN102675671AImprove adhesionGood thickness controllabilityFilm/foil adhesivesCoatingsAdhesiveQuality performance

The invention discloses a method for preparing an anti-radiation coating film. The method comprises the following steps of: performing surface treatment on a transparent film substrate, and coating a compound adhesive layer on the treated surface; adding a dispersing agent into mixed nano powder of which the average particle diameter is 15-300 nanometers, and grinding and dispersing into a suspension by using a grinder; and coating the suspension onto a compound adhesive layer surface of the transparent film substrate, and curing into a film to obtain an anti-radiation coating film. Compared with the prior art, the method has the advantages: the anti-radiation coating film produced by adopting the method has the characteristics of uniformity and high thickness controllability of a coating formed by a coating compound, higher adhesion among film layers, and excellent product quality performance; and the method has the advantages of simple process, high efficiency, low cost and capability of realizing industrial mass production.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

Resonant pressure sensor and method of manufacturing the same

ActiveUS9003889B2Variation can be suppressedGood thickness controllabilityLamination ancillary operationsDecorative surface effectsEngineeringStrain gauge

A resonant pressure sensor including one or more resonant-type strain gauges arranged on a diaphragm may include a sensor substrate made of silicon and including one surface on which one or more resonant-type strain gauge elements are arranged and the other surface which is polished to have a thickness corresponding to the diaphragm, a base substrate made of silicon and including one surface directly bonded with the other surface of the sensor substrate, a concave portion formed in a portion of the base substrate bonding with the sensor substrate, substantially forming the diaphragm in the sensor substrate, and including a predetermined gap that does not restrict a movable range of the diaphragm due to foreign substances and suppresses vibration of the diaphragm excited by vibration of the resonant-type strain gauge elements, one or more conducting holes, and a fluid.

Owner:YOKOGAWA ELECTRIC CORP

Preparation method of scale material

ActiveCN108395091AImprove flatnessIncreasing the thicknessGlass making apparatusGlass fiberMetallurgy

The invention relates to a preparation method of a scale material. The method comprises the following steps of continuously arranging glass fiber or basalt fiber into one row; performing heat treatment at 850 to 1150 DEG C for 5 to 20 min; then, performing annealing for 1 to 5 h at 500 to 800 DEG C to obtain the scale material. The method has the advantages that the process is simple; the preparedscale has high flatness degree and can be filled into a coating at the maximum layers; in addition, a plurality of grooves are formed in fiber connecting parts of each scale, so that the surface friction between the scales and the resin is greatly improved; the performance of anti-corrosion coating can be effectively improved.

Owner:DONGHUA UNIV +1

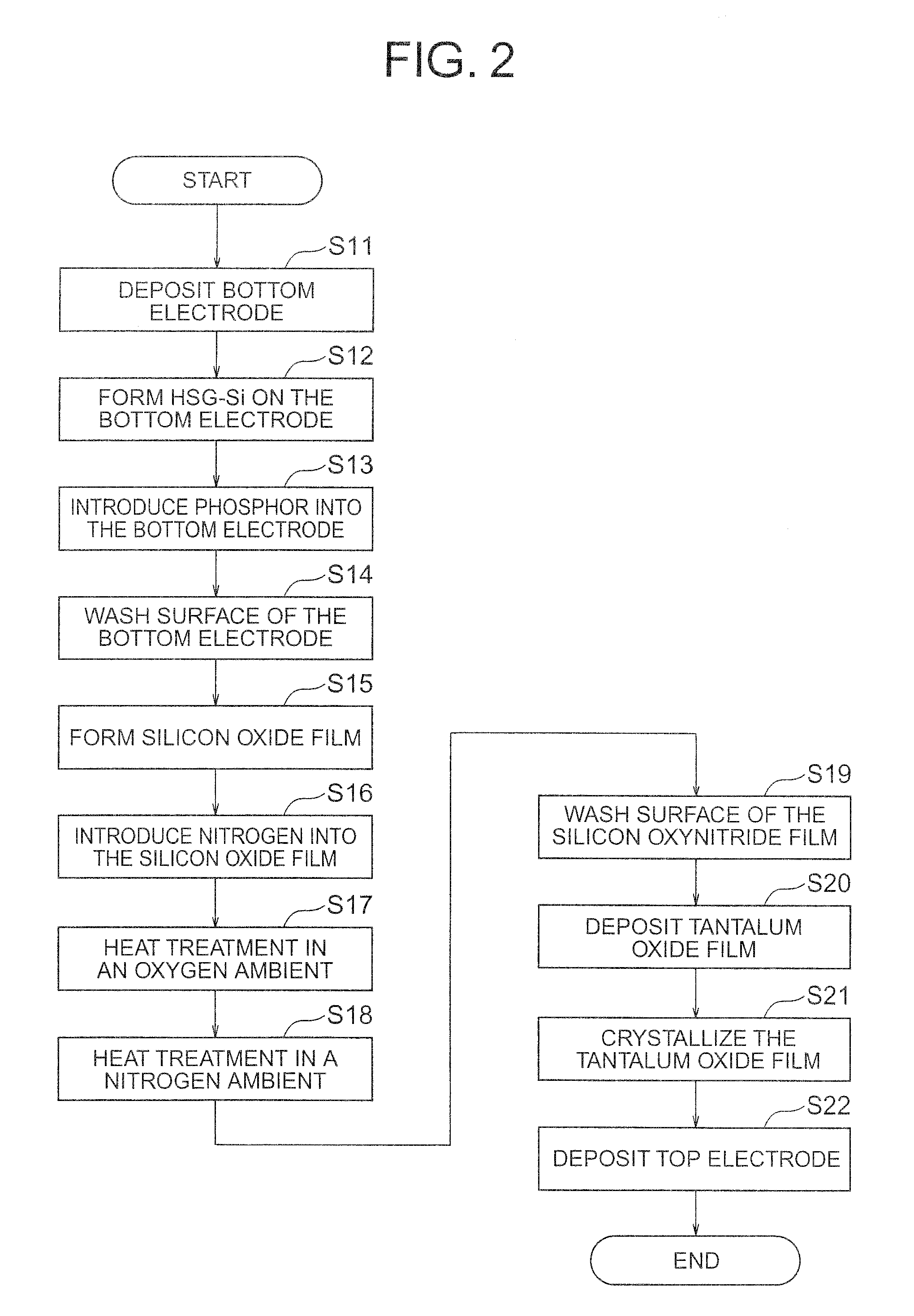

Method for manufacturing a semiconductor device including a stacked capacitor

InactiveUS20080090375A1Good thickness controllabilityIncrease capacitance per unit areaSemiconductor/solid-state device manufacturingCapacitorsCapacitanceDevice material

A process for forming a capacitor in a semiconductor device includes the step of forming a two-layer capacitor insulation film including a silicon oxynitride film and a tantalum oxide film. The step for forming the silicon oxynitride film is performed at a first substrate temperature, and the step of forming the tantalum oxide film uses a heat treatment performed at a second substrate temperature. The second substrate temperature is lower than the maximum of the first substrate temperature, to provide a higher capacitance per unit area and a lower leakage current in the capacitor.

Owner:ELPIDA MEMORY INC

Method for preparing the carbide coat on surface of metal alloy basal body containing carbon

InactiveCN1431340AGood controllability of coating thicknessImprove wear resistanceSuperimposed coating processMetalMetallic alloy

A process for preparing a coated carbide layer on the surface of C-contained metallic alloy substrate incldues precoating a metallic alloy layer on the surface of said substrate, and heating to thermally diffuse the C element from substrate into the coated layer. Its advantages are high metallurgical adhesion, controllable thickness and high antiwear and anticorrosion performance.

Owner:XI AN JIAOTONG UNIV

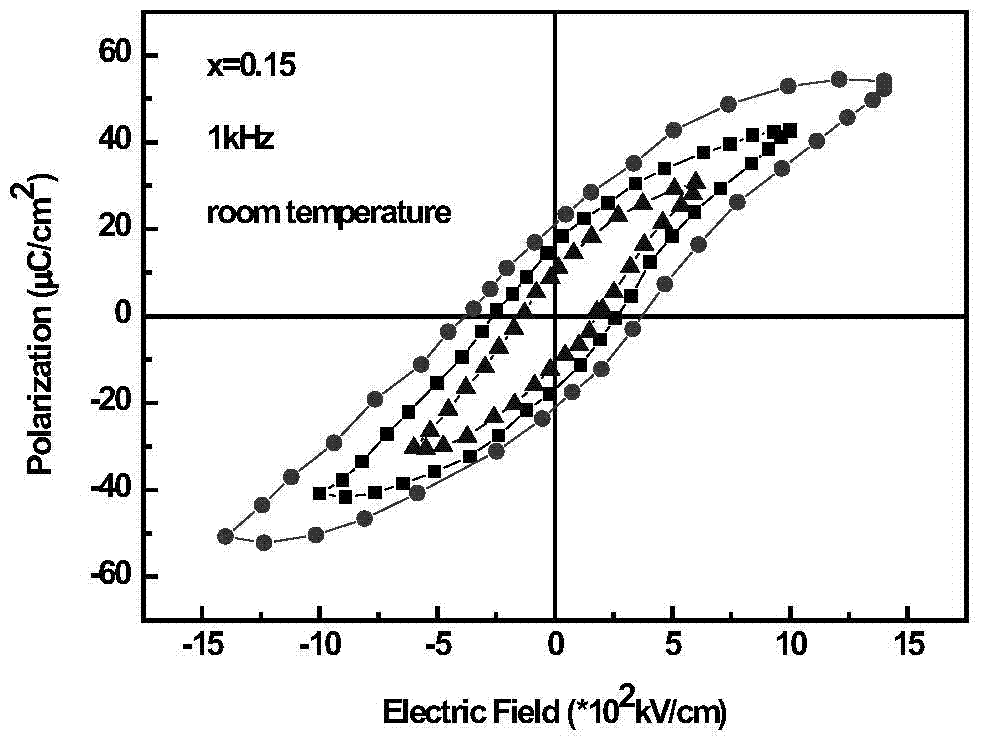

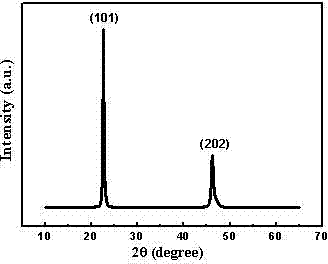

Highly doped batio3:fe multiferroic thin film material and preparation method thereof

InactiveCN105568265BImprove one-wayUniform and dense surfaceChemical vapor deposition applicationLiquid applicationSpinsRoom temperature

The invention relates to a high-Fe-content doped BaTiO3 multiferroic thin-film material and a preparation method thereof. The molecular formula of the high-Fe-content doped BaTiO3 multiferroic thin-film material is BaTi<1-x>FexO3, wherein x is the atomic ratio of doped components and ranges from 0.01 to 0.4. The preparation method sequentially includes the steps that (1) a precursor is prepared; (2) a substrate is cleaned and pretreated; (3) a highly doped BaTiO3:Fe multiferroic thin film is prepared, specifically, the substrate obtained in the step (2) is spin-coated with the highly doped BaTiO3:Fe sol precursor prepared in the step (1), and then stepped annealing is conducted on the precursor; and (4) the sol coating and annealing processes of the step (3) are repeated, and a thin film sample of a needed thickness is obtained. A precursor solution is clear and transparent and can be stored for a long time; the grown thin film is uniform and compact in surface, good in crystallization property and free of impurity phases, and the grown thin film is good in thickness controllability and high in unipolarity; and the thin-film material has good ferroelectricity and ferromagnetism at the room temperature.

Owner:HENAN UNIVERSITY

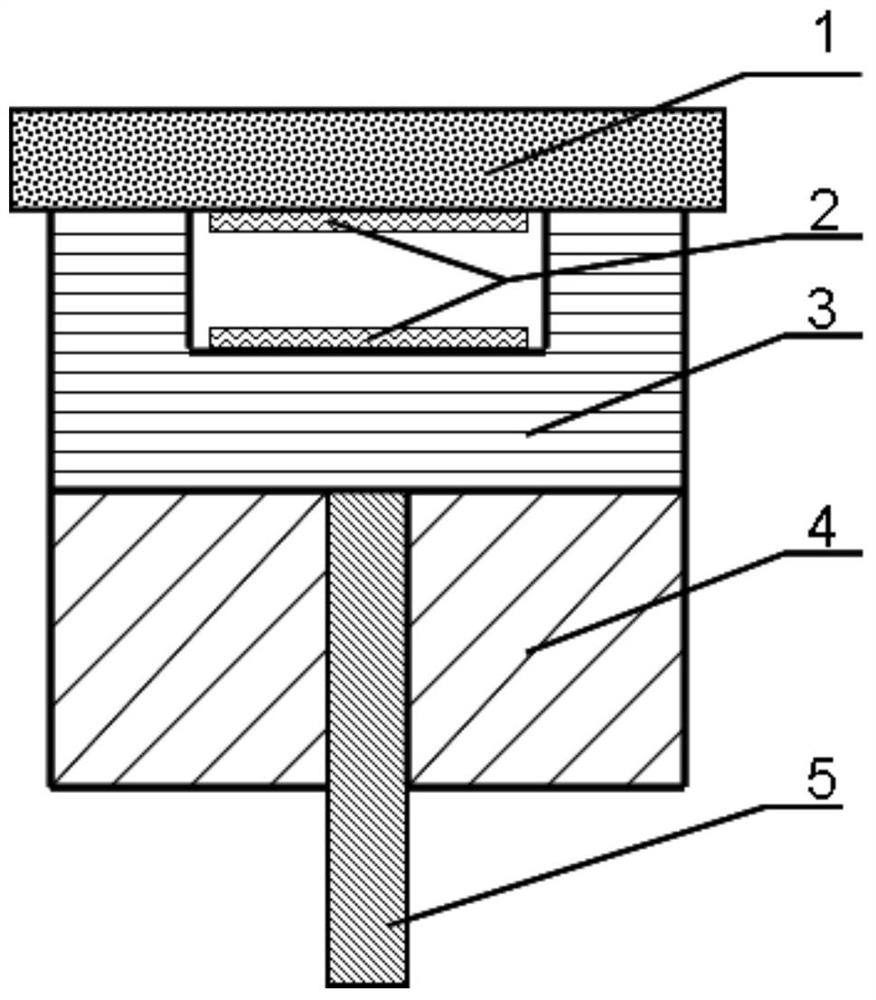

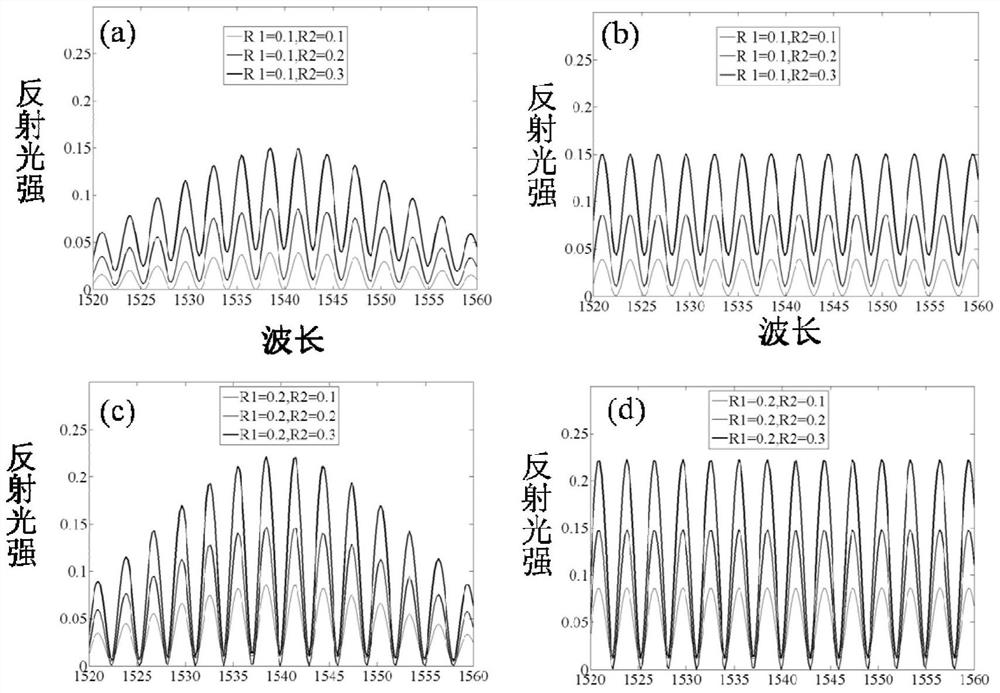

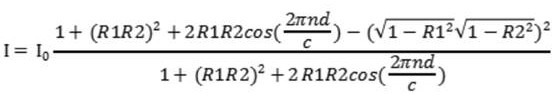

f-p pressure sensor with composite dielectric film

ActiveCN106323516BHigh hardnessImprove thermal stabilityForce measurement by measuring optical property variationFluid pressure measurement by optical meansFiberResonant cavity

Owner:CHENGDU KAITIAN ELECTRONICS

A kind of preparation method of gallium nitride epitaxial structure based on hexagonal boron nitride-graphene composite layer as buffer layer

ActiveCN107706274BQuality improvementReduce stressSemiconductor devicesHexagonal boron nitrideLattice mismatch

The invention relates to a preparation method of a GaN epitaxial structure taking a hexagonal BN-graphene composite layer as a buffer layer, and belongs to the technical field of photoelectron. The method comprises the steps of polishing and cleaning a copper substrate; growing an h-BN-graphene composite layer on the copper substrate; growing an AlN layer on the h-BN-graphene composite layer by anatomic layer deposition method; and growing a GaN layer on the AIN thin layer by a metal organic matter chemical vapor deposition method. The h-BN-graphene composite layer is used as the buffer layerbetween the copper substrate and the GaN epitaxial layer, thus, the problems of defect dislocation, crack and the like caused by lattice mismatching and thermal mismatching between the substrate andthe epitaxial layer can be solved, the stress between the substrate and an epitaxial material is effectively reduced, and the quality of the GaN epitaxial layer is improved.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

Bulk effect solar cell material and preparation method thereof

InactiveCN102176472BUniform and dense surfaceHigh crystallinityFinal product manufacturePhotovoltaic energy generationSolar cellMetal electrodes

Owner:EAST CHINA NORMAL UNIV

A growth method of nitride epitaxial wafer and gallium nitride laser

ActiveCN106868472BQuality improvementReduce stressLaser detailsChemical vapor deposition coatingLattice mismatchGallium nitride

The invention relates to a production method of nitride epitaxial wafers and a gallium nitride laser device. The method comprises the following steps that 1, a copper substrate is polished and cleaned; 2, a graphene layer grows on the copper substrate; 3, the graphene layer growing on the copper substrate is transferred to target substrates; 4, an aluminum nitride thin layer grows on the graphene layer through an atomic layer deposition method; and 5, a GaN layer grows on the aluminum nitride thin layer through a metal organic matter chemical vapor deposition method. By means of the method, the nitride epitaxial wafers can grow on the different target substrates, the epitaxial wafers are transferred through the copper substrate, and therefore graphene is transferred to the different target substrates. The graphene layer is used as a buffer layer between the substrate and the GaN epitaxial layer, and the aluminum nitride layer is prepared through the atomic layer deposition method. Layer-by-layer growth of material atomic layers, good thickness controllability and high-precision film growth quality can be achieved, the large lattice mismatch problem between the substrate and the epitaxial layer is solved, the epitaxial layer quality is improved, and high-quality gallium nitride laser device can be obtained.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

A kind of preparation method of scale material

ActiveCN108395091BImprove flatnessIncreasing the thicknessGlass making apparatusGlass fiberBasalt fiber

The invention relates to a preparation method of a scale material, comprising: arranging glass fibers or basalt fibers in a row continuously, heat-treating at 850-1150°C for 5-20 minutes, and then annealing at 500-800°C for 1-5 hours to obtain the scale material . The process of the invention is simple, the prepared scales have high flatness, and the maximum number of layers can be filled in the coating, and each scale has many grooves at the fiber joints, which greatly increases the surface friction between the scales and the resin, and can effectively Improve the performance of anti-corrosion coatings.

Owner:DONGHUA UNIV +1

A preparation method of gallium nitride epitaxial structure based on molybdenum disulfide-graphene composite buffer layer

ActiveCN107768235BQuality improvementReduce stressSemiconductor/solid-state device manufacturingLattice mismatchEpitaxial material

The invention relates to a preparation method of a gallium nitride epitaxial structure based on a molybdenum disulfide-graphene composite buffer layer, and belongs to the technical field of photoelectronics. The preparation method comprises the steps of performing cleaning on a silicon substrate; enabling a molybdenum disulfide-graphene composite layer to be grown on the silicon substrate; enabling an aluminum nitride layer to be grown on the molybdenum disulfide-graphene composite layer by adopting an atomic layer deposition method; and enabling a gallium nitride layer to be grown on the aluminum nitride layer by adopting a metal organic chemical vapor deposition method, and the like. By adopting the molybdenum disulfide-graphene composite layer as the buffer layer between the silicon substrate and the GaN epitaxial layer, the problems of defect malposition, cracks and the like caused by high lattice mismatch and thermal mismatch between the substrate and the epitaxial layer can be solved, the stress between the substrate and the epitaxial material can be lowered effectively, and the GaN epitaxial layer quality is improved.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

High-sensitivity surface plasma resonance sensor

InactiveCN101865841BImprove performanceHigh sensitivityPhase-affecting property measurementsScattering properties measurementsThin layerRefractive index

The invention discloses a high-sensitivity surface plasma resonance sensor, which consists of a multi-layer medium layer, a transparent dielectric medium substrate (2) and a metal film layer (5), wherein the multi-layer medium layer is alternatively formed by a low-refractive-index medium thin layer (3) and a high-refractive-index medium thin layer (4), one side of the transparent dielectric medium substrate of the sensor is adjacent to a coupling prism (1), one side of the metal film layer is adjacent to a sample (6) to be tested, the total quantity of the low-refractive-index medium thin layer and the high-refractive-index medium thin layer in the multi-layer medium layer is of an odd number, the thickness of each layer is different from each other, and the low-refractive-index medium thin layer in the multi-layer medium layer is always adjacent to both the transparent dielectric medium substrate and the metal film layer. Compared with the traditional surface plasma resonance sensorbased on the single metal film layer, the sensitivity of the sensor is remarkably improved, at the same time the structure of the multi-layer medium layer is relatively simple, total thickness is smaller, the processing is easy, the cost is reduced, and stronger practical value can be realized.

Owner:BEIHANG UNIV

Method for forming MIS structure

ActiveCN106328509AControl thicknessPrecise thickness controlSemiconductor/solid-state device manufacturingSemiconductor devicesTungstenMetal

The invention provides a method for forming an MIS structure. The method includes: step1, performing ion implantation and thermal annealing on a silicon substrate to form an N-type well or a P-type well; step 2, growing a SiO2 layer on the surface of the exposed silicon substrate; step 3, growing a metal Ti layer and a TiN layer on the SiO2 layer in sequence; and step 4, filling tungsten plugs in grooves of the exposed SiO2 layer, and performing planarization processing on the tungsten plugs, the metal Ti layer, and the TiN layer.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

A kind of diamond-like coating for piston ring surface, piston ring and preparation process

ActiveCN105734527BIncreasing the thicknessReduce stressPiston ringsVacuum evaporation coatingPiston ringToughness

The invention relates to a diamond-like coating used on the surface of a piston ring. The diamond-like coating consists of a primer layer, a gradient layer and an amplitude modulation layer from bottom to top. The amplitude modulation layer is a diamond-like coating doped with doping elements. The doping element is one or more of Cr, Si and Ti, and the content of the doping element in the amplitude modulation layer changes periodically in the form of sinusoidal fluctuations with the thickness of the amplitude modulation layer. Compared with the traditional single-layer structure or gradient layer structure, because the content of doping elements in the amplitude modulation layer of the diamond-like coating changes periodically with the thickness of the amplitude modulation layer in the form of sinusoidal fluctuations, the amplitude modulation of the diamond-like coating The layer has a multi-layer cyclic modulation structure; on the basis of high wear resistance and low friction coefficient, it is beneficial to reduce the internal stress of the coating, improve the toughness of the coating, and ensure the increase of the thickness of the diamond-like coating, while improving the piston of the diamond-like coating. ring durability.

Owner:ASIMCO SHUANGHUAN PISTON RING YIZHENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com