Inspection well trenchless reparation device and reparation method thereof

A repair method and inspection well technology, which are applied in water supply installations, waterway systems, water conservancy projects, etc., can solve the problems of narrow inspection well space, uneven inner lining, and no skeleton structure formed in the sprayed inner lining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

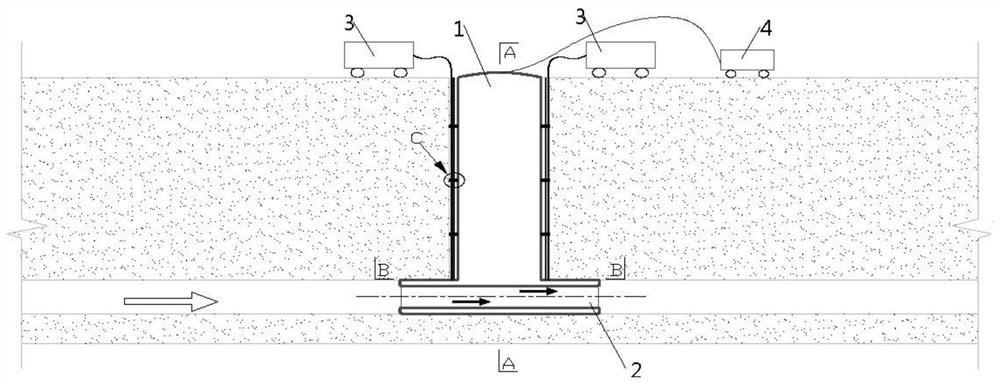

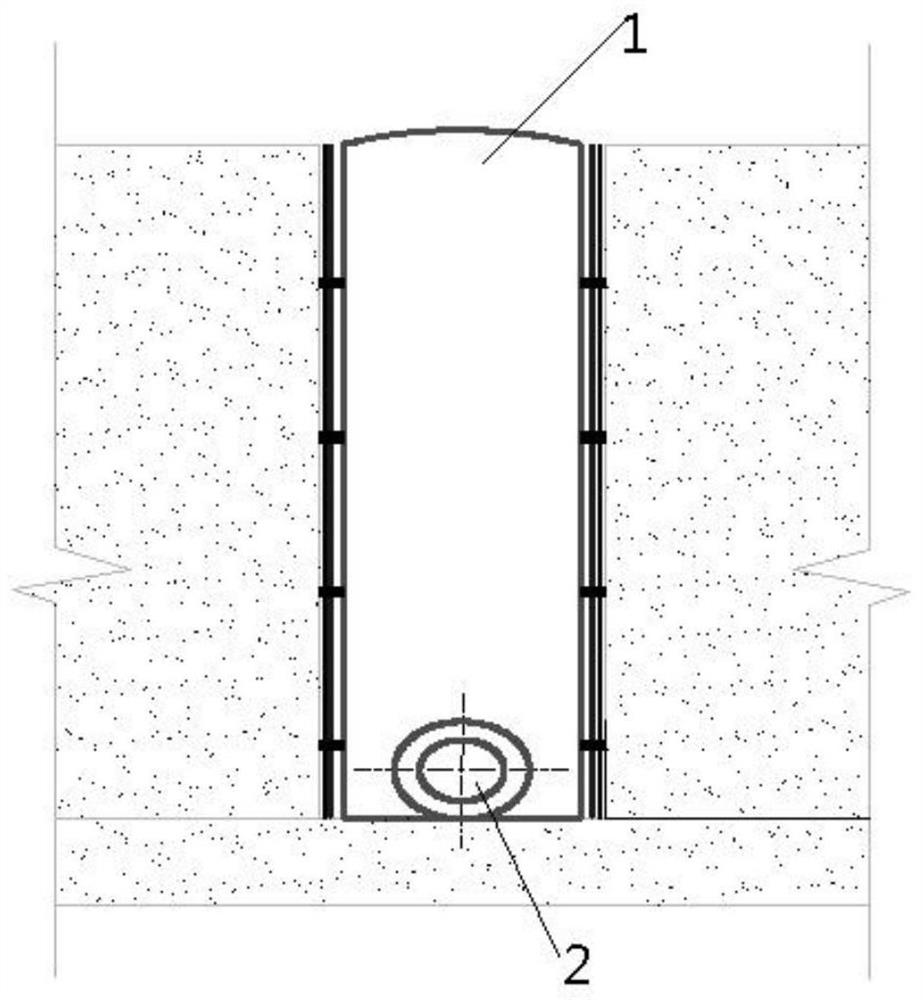

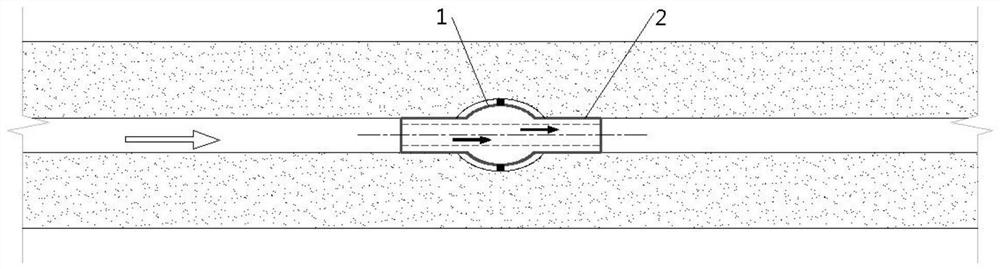

[0044] Example 1: Refer to the attached Figure 1-5 , A device for non-excavation repair of inspection wells, comprising an airbag. The airbag includes a main airbag 1 arranged vertically and a guide airbag 2 vertically connected to the bottom of the main airbag 1. A number of sets of spacer block groups are uniformly arranged along the longitudinal and circumferential ranges, and each of the spacer block groups includes a spacer block I6 and a spacer block II7 connected together by glue connection, and a grouting pipe fixing hole is arranged on the spacer block II7, A grouting pipe 5 is glued in the fixing hole of the grouting pipe, and a plurality of grouting holes are provided on the grouting pipe 5, and grouting is grouted in the grouting pipe 5.

[0045] In this embodiment, a steel mesh 9 is clamped at the position where the adjacent spacer block I6 and the spacer block II7 are connected by glue connection.

[0046] In this embodiment, the type of the main airbag 1 is round.

...

Embodiment 2

[0057] Example two, refer to the attached Figure 1-3 , 6, and 7, a trenchless repair device for inspection wells, comprising an airbag. The airbag includes a vertical main airbag 1 and a guide airbag 2 vertically connected to the bottom of the main airbag 1. The outer wall of the airbag 1 is uniformly provided with multiple sets of cushion blocks along the longitudinal and circumferential ranges, and each group of the cushion blocks includes a cushion block I6 and a cushion block II7 connected together by glue connection, on the cushion block I6 and the cushion block II7. A grouting pipe fixing hole is respectively provided, and a grouting pipe 5 is glued in the grouting pipe fixing hole, and a plurality of grouting holes are provided on the grouting pipe 5, and the grouting pipe 5 is Grouting.

[0058] In this embodiment, a reinforced mesh 9 is clamped at the position where the adjacent spacer block I6 and the spacer block II7 are connected by glue connection.

[0059] In this ...

Embodiment 3

[0070] Example three, refer to the attached Figure 1-3 8. A device for non-excavation repair of inspection wells, comprising an airbag, the airbag includes a main airbag 1 vertically arranged and a guide airbag 2 vertically connected to the bottom of the main airbag 1. The main airbag 1 A plurality of spacer blocks I6 are uniformly arranged along the longitudinal and circumferential range of the outer wall, and a grouting pipe fixing hole is arranged on the spacer block I6, and a grouting pipe 5 is glued in the fixing hole of the grouting pipe. The grouting pipe 5 is provided with a plurality of grouting holes, and grouting is injected into the grouting pipe 5.

[0071] In this embodiment, a steel mesh is provided on the outside of the cushion block I6.

[0072] In this embodiment, the type of the main airbag 1 is selected to be irregular.

[0073] In this embodiment, the type of the spacer I6 is a square spacer.

[0074] In this embodiment, the material of the main airbag 1, the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com