A growth method of nitride epitaxial wafer and gallium nitride laser

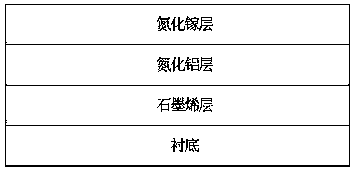

A growth method and epitaxial wafer technology, applied in the field of optoelectronics, can solve problems such as poor quality of nitride materials, inability to grow AlN layers, poor film quality, etc., achieve stress reduction, good thickness controllability, and solve lattice mismatch Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

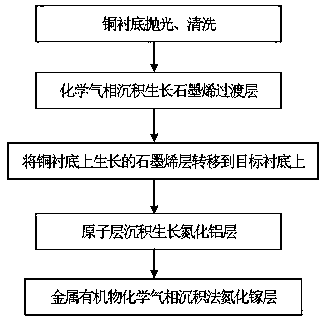

Method used

Image

Examples

Embodiment 1

[0049] In step S1, the copper substrate is cleaned to remove the oil stain and oxide layer on the surface, and after double polishing of mechanical polishing and electrochemical polishing, it is washed with ethanol and deionized water three times in sequence, washed with dilute hydrochloric acid for 5-10 minutes, and washed with deionized water. several times, N 2 Blow dry to get copper substrate.

[0050] Step S2 grows a graphene layer on the copper substrate:

[0051] S2a Put the copper substrate treated in step S1 into the quartz tube of tube furnace, and vacuumize for 5 minutes;

[0052] S2b injects hydrogen, heats the tube furnace to 800°C and anneals for 1 hour;

[0053] In S2c, the carbon source gas methane and the mixed gas of argon and hydrogen with a volume ratio of 10:1 are introduced to grow, the carbon source gas methane and hydrogen are turned off, and the quartz tube of the tube furnace is cooled to room temperature with the furnace in an argon atmosphere to obt...

Embodiment 2

[0067] In step S1, the copper substrate is cleaned to remove the oil stain and oxide layer on the surface, and after double polishing of mechanical polishing and electrochemical polishing, it is washed with ethanol and deionized water three times in sequence, washed with dilute hydrochloric acid for 5-10 minutes, and washed with deionized water. several times, N 2 Blow dry to get copper substrate.

[0068] Step S2 grows a graphene layer on the copper substrate:

[0069] S2a Put the copper substrate treated in step S1 into the quartz tube of tube furnace, and vacuumize for 5 minutes;

[0070] S2b is fed with hydrogen, the flow rate is 100 sccm, and the tube furnace is heated to 1000°C and then annealed for 2 hours;

[0071] In S2c, the carbon source gas methane and the mixed gas of argon and hydrogen with a volume ratio of 20:1 are introduced to grow, the carbon source gas methane and hydrogen are closed, and the quartz tube of the tube furnace is cooled to room temperature u...

Embodiment 3

[0084] In step S1, the copper substrate is cleaned to remove the oil stain and oxide layer on the surface, and after double polishing of mechanical polishing and electrochemical polishing, it is washed with ethanol and deionized water three times in sequence, washed with dilute hydrochloric acid for 5-10 minutes, and washed with deionized water. several times, N 2 Blow dry to get copper substrate.

[0085] Step S2 grows a graphene layer on the copper substrate:

[0086] S2a Put the copper substrate treated in step S1 into the quartz tube of tube furnace, and vacuumize for 7 minutes;

[0087] S2b is fed with hydrogen, the flow rate is 100 sccm, and the tube furnace is heated to 1050°C and then annealed for 3 hours;

[0088] In S2c, the carbon source gas methane and the mixed gas of argon and hydrogen with a volume ratio of 20:1 are introduced to grow, the carbon source gas methane and hydrogen are closed, and the quartz tube of the tube furnace is cooled to room temperature u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com