Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Good dispersion system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium titanate composite material and preparation method thereof

InactiveCN101759227AThe first discharge specific capacity is highImprove rate discharge performanceMaterial nanotechnologyAlkali titanatesElectrochemistryImpurity

Owner:BYD CO LTD

Method for preparing dispersible ultra-fine silicon dioxide

InactiveCN101838479AAvoid reunionEvenly dispersedPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsSilica particlePhysical chemistry

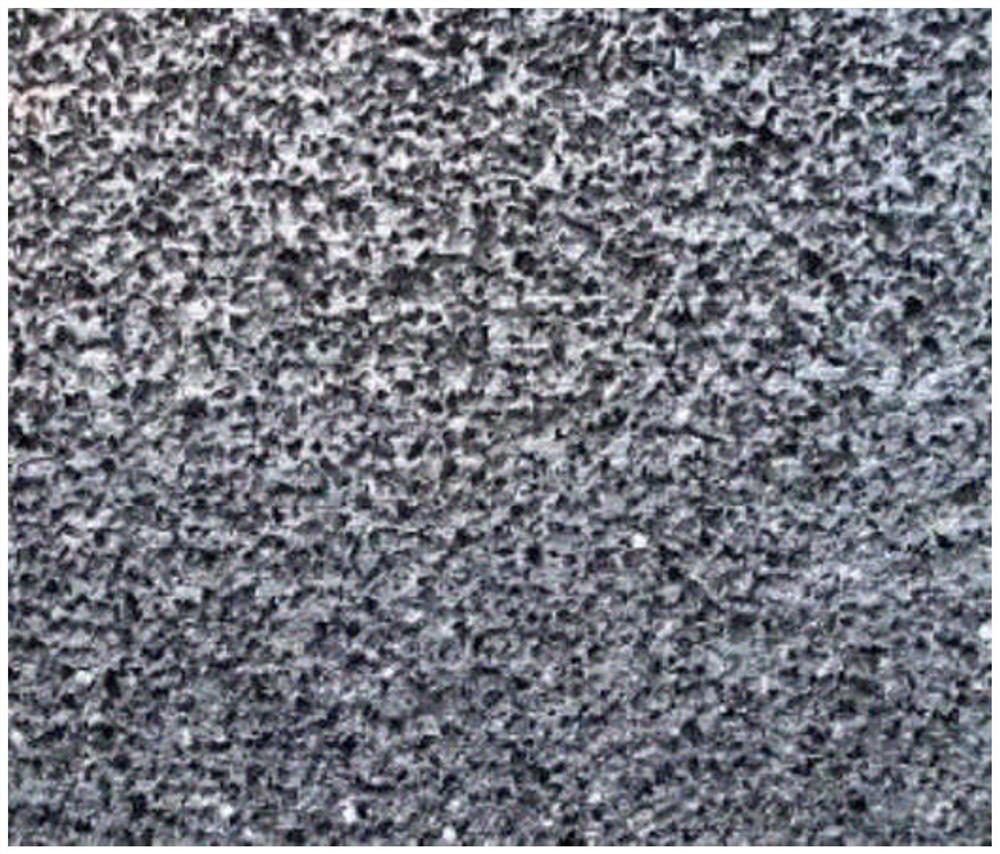

The invention discloses a method for preparing dispersible ultra-fine silicon dioxide. The method is characterized by comprising the following steps of: adding a liquid surface modifier into a precipitated silicon dioxide filter cake raw material; coating the surfaces of silicon dioxide particles in the precipitated silicon dioxide filter cake to form coating liquid by using the liquid surface modifier with strong stirring; and drying and activating the coating liquid to prepare a dispersible ultra-fine silicon dioxide powder product, wherein the surface modifier accounts for 1 to 50 percent of the mass of the silicon dioxide of the precipitated silicon dioxide filter cake. Experiment results show that: according to an SEM image of the dispersible ultra-fine silicon dioxide dispersed in an organic medium, the particle sizes of silicon dioxide particles are between 100 nm and 10 mu m; and the particle sizes of the silicon particles are between 100 and 400 nm and are distributed uniformly when a boric acid ester coupling agent is adopted.

Owner:FUJIAN NORMAL UNIV

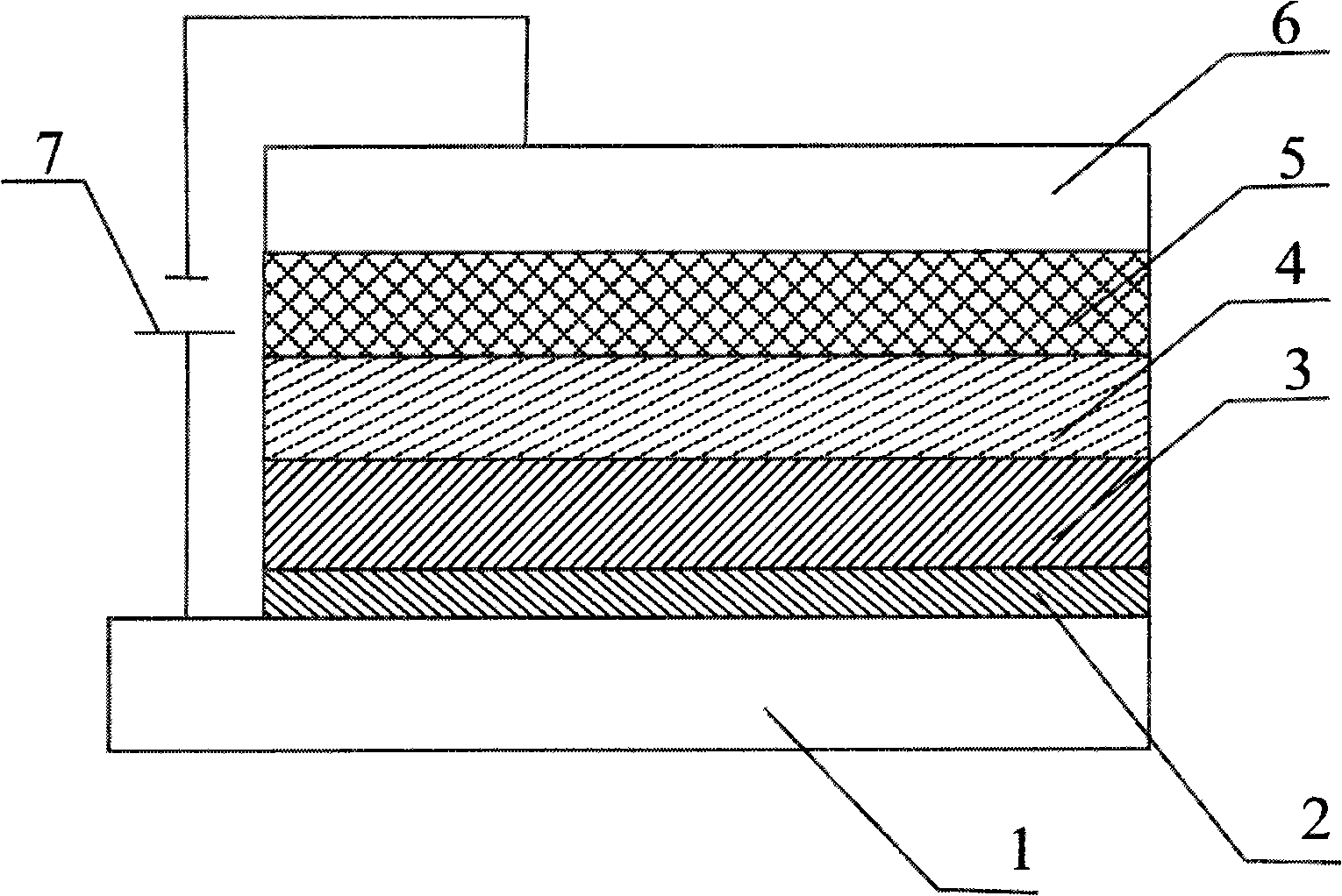

Method for producing organic electroluminescence device

InactiveCN101540379AGood film-forming propertiesGood dispersion systemSolid-state devicesSemiconductor/solid-state device manufacturingHole injection layerLED display

The invention discloses a method for producing an organic electroluminescence device. The method comprises the followings steps: frirstly, conducting polymer or conducting polymer nano-particle composite materials are formed on the anode of a device, and are used as the hole injection layers of the device; and secondly, other functional layers and membrane electrodes of the device are produced. The conducting polymers in the hole injection layers include conducting polymers and nano-particles thereof, and the device has the characteristics of high electrical conductivity and good membrane planeness. The method can not only be used for producing the organic electroluminescence device with the advantages of high luminous efficiency and long service life, but also can be applied to the fields of backlights, luminance light panels, and the like for color LED display.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

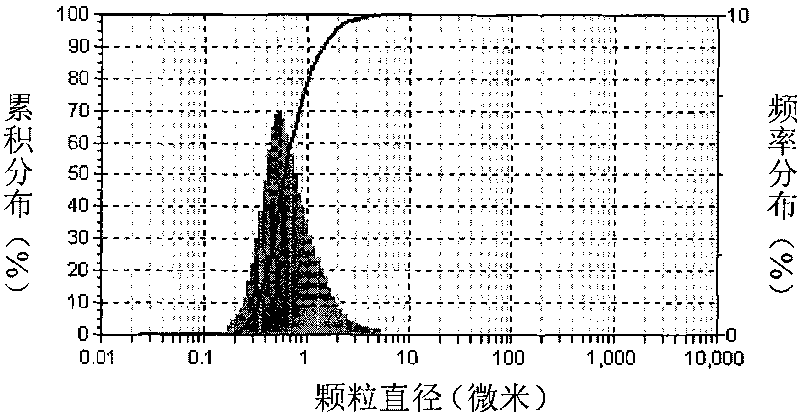

Preparation method of nanometer titanium dioxide

InactiveCN108483490AAvoid reunionGood dispersion systemPhysical/chemical process catalystsTitanium dioxideDissolutionHydrolysis

The invention belongs to the technical field of environment-friendly materials, and particularly relates to a preparation method of nanometer titanium dioxide. The preparation method comprises the following steps: 1, adding n-butyl titanate into absolute ethanol, then adding a dispersing agent, ultrasonically dispersing till complete dissolution to obtain n-butyl titanate alcohol dispersion; 2, adding a polymer surfactant into distilled water, uniformly stirring till complete dissolution to obtain a dropping solution; 3, slowly dropwise adding the dropping solution into the n-butyl titanate alcohol solution, sealing, slightly heating while stirring for 1-3 hours to obtain a suspension; 4, placing the suspension in a reaction kettle, performing a vacuum distillation reaction for 1-3h, cooling, then filtering at low temperature to obtain a wrapped titanium dioxide precipitate; 5, adding the wrapped titanium dioxide precipitate into an aqueous ethanol solution, performing an ultrasonic reaction for 10-20min, then taking and drying at a high temperature to obtain the nanometer titanium dioxide. Through hydrolysis of the n-butyl titanate, and by virtue of the dual action of polyvinylpyrrolidone and sodium lauryl sulfate, a good dispersion system can be formed, so that agglomeration of titanium dioxide is prevented.

Owner:蒋建华

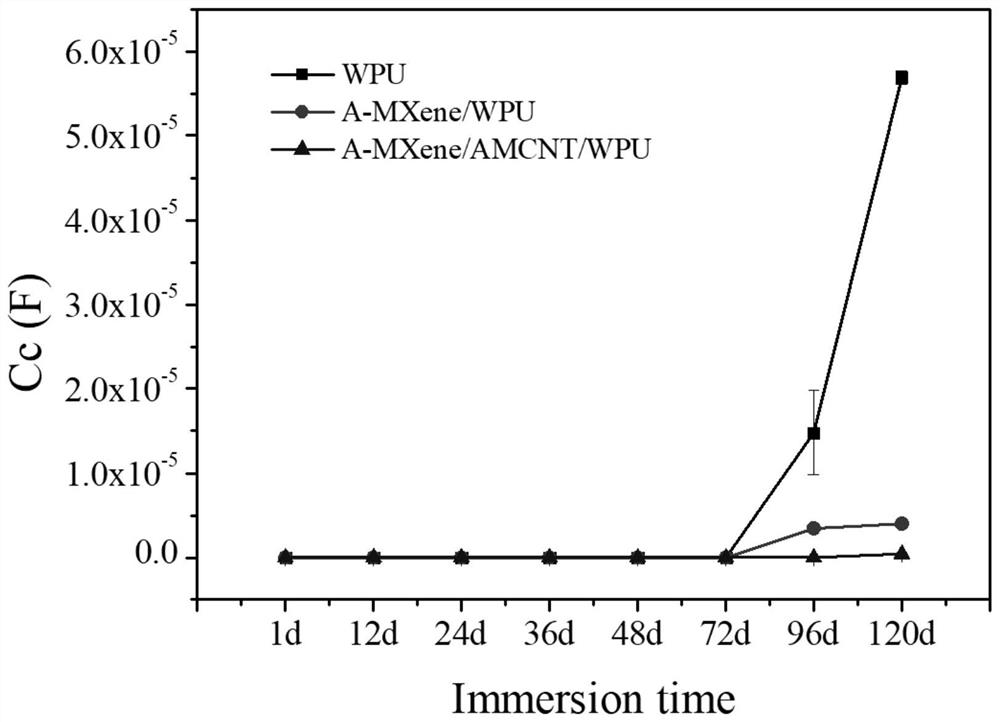

MXene and carbon nano tube synergistically modified polyurethane anticorrosive paint as well as preparation method and construction process thereof

ActiveCN114276743APrevent diffusion and penetrationGood mechanical properties and anti-corrosion propertiesPretreated surfacesAnti-corrosive paintsSilane couplingCarbon nanotube

The invention discloses an MXene and carbon nanotube synergistically modified polyurethane anti-corrosion coating as well as a preparation method and a construction process thereof, and relates to the field of anti-corrosion coatings. Comprising the following steps: S1, taking MXene nanosheets, and adding a silane coupling agent for modification to obtain functionalized MXene nanosheets; s2, dispersing the functionalized MXene nanosheets and the aminated carbon nanotubes in deionized water, and carrying out ultrasonic treatment until the functionalized MXene nanosheets and the aminated carbon nanotubes are uniformly dispersed, so as to obtain A-MXene / AMCNT dispersion liquid; and S3, adding the A-MXene / AMCNT dispersion liquid into waterborne polyurethane, and uniformly stirring, so as to obtain the MXene and carbon nanotube synergistically modified polyurethane anticorrosive coating. According to the preparation method disclosed by the invention, the MXene nanosheet can have good compatibility and relatively strong interface interaction with the WPU substrate, so that the MXene and the carbon nanotubes of the coating are uniformly dispersed in the WPU substrate, and the coating has excellent corrosion resistance and mechanical properties.

Owner:HENAN INST OF ENG

Insulating coating for high-voltage electrical equipment and preparation method thereof

InactiveCN108841325AGood insulation performanceStrong hydrophobicityCarboxyl rubber coatingsAnti-corrosive paintsSolventChemistry

The invention provides an insulating coating for high-voltage electrical equipment and a preparation method thereof. The insulating coating comprises the following components: a fluorosiloxane polymer, nano-silica, composite modified resin, an aniline monomer, organic acid, polyvinyl alcohol, an oxidant, filler, a curing agent, a solvent and water. The coating provided by the invention has excellent insulation performance, strong hydrophobicity, large wetting angle and low adhesion to dust and oil pollution, realizes low adhesion and non-penetration to pollutants such as water, steam and ash,and avoids the adverse effects of such substances on corona suppression, insulation, corrosion and so on.

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

Foamed aluminum supercritical preparation method with controllable hole diameters

ActiveCN109434111AStable pore structureImprove porosity controllabilityRecycling and recovery technologiesDecompositionNitrogen gas

The invention belongs to the technical field of aluminum materials, and particularly relates to a foamed aluminum supercritical preparation method with controllable hole diameters. The method includesthe steps that 1, ethyecellulose is added into absolute ethyl alcohol for ultrasonic treatment for 5-10 min, and dispersive alcohol liquid is obtained; 2, broken aluminum skimmings are added into thedispersive alcohol liquid to be stirred for 20-50 min, and suspended alcohol liquid is obtained; 3, supercritical carbon dioxide fluid is flushed into the suspended alcohol liquid for a constant-pressure microwave reaction for 1-3 h, and mixed liquid is obtained after settling is completed; 4, the mixed liquid is put in a metal mold for a heating constant-pressure reaction for 1-3 h and a slow constant-temperature pressure relief reaction for 2-4 h, cooling is carried out after nitrogen purging, and a foamed aluminum precursor is obtained; and 5, the foamed aluminum precursor is subjected toan illumination decomposition reaction for 2-4 h, and a foamed aluminum material is obtained. The problems that structural parameters cannot be controlled or adjusted at will are completely solved; the preparation method is simple, batched production is facilitated, and the production cost is low; and the prepared foamed aluminum has a stable and uniform pore structure, and the pore controllability is improved.

Owner:SHAOXING UNIVERSITY

Compound propelling system for Dermlin skin dressing

The invention relates to a compound propelling system for a Dermlin skin dressing, belonging to the technical field of aerosols. The compound propelling system substantially consists of a propellant and / or a cosolvent, a dispersant or a compatibilizer as well as a disinfectant and is characterized in that the propellant is liquid nitrogen or liquid carbon dioxide; the cosolvent, the dispersant or the compatibilizer is isopentane or cyclopentane; the disinfectant is bromogeramine, 2% glutaraldehyde disinfectant or 0.5% o-phthalaldehyde disinfectant; and the emulsifier is tween-80. The compound propelling system is wide in application range, good in safety and high in volatile speed, does not contain Freon, and can realize disinfection.

Owner:JIANGSU YENSSEN BIOTECH CO LTD

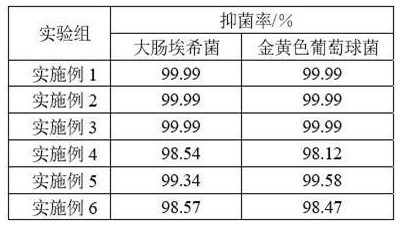

High-temperature-resistant composite antibacterial agent and preparation method thereof

InactiveCN109303050AHigh antibacterial efficiencyEasy to prepareBiocideFungicidesHydrolysateEthyl acetate

The invention provides a high-temperature-resistant composite antibacterial agent and a preparation method thereof. The composite antibacterial agent is prepared from the following components: chitin,a chitosan solution, a zinc lactate solution, a starch solution, a sodium hydroxide solution, a hydrochloric acid solution, an enzymatic hydrolysate, ethyl acetate, a dopamine solution, calcium oxide, a silver nitrate solution and deionized water. The prepared antibacterial agent is high in antibacterial efficiency and resistant to high temperature, the preparation method is simple and low in cost, the particle size of the antibacterial agent is uniform, no agglomeration phenomenon occurs, and the antibacterial agent has excellent antibacterial property.

Owner:HEFEI HUAGAI BIOTECH CO LTD

High-efficiency solar heat absorbing material and preparation method thereof

InactiveCN109021639AExcellent solar absorption performancePromote absorptionRadiation-absorbing paintsFiberCarbon fibers

The invention provides a high-efficiency solar heat absorbing material and a preparation method thereof. The high-efficiency solar heat absorbing material is prepared from organosilicone resin, graphene, carbon fibers, butyl acrylate, hydroxylated linseed oil, sodium lauryl sulfate, nano-powder, metal nitrate, a curing agent, a light absorbing agent, a film former, polyethylene glycol, an organicsolvent and a polyether modified silicone oil defoamer. The heat absorbing material has excellent solar energy absorption performances, utilizes a heat conductive material having photocatalytic migration properties, increases a solar energy absorption range and the heat conduction performance and has a long service life. The preparation method has mild reaction process conditions, realizes a low production cost and is suitable for industrial large-scale production.

Owner:来安县森浩茂环保工程有限公司

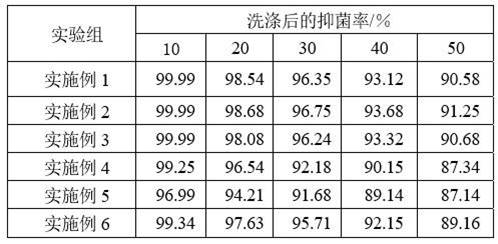

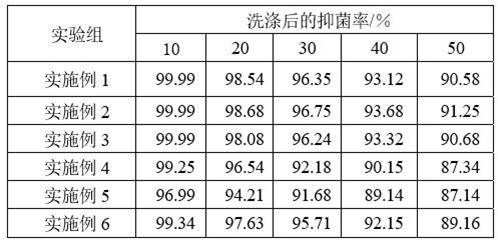

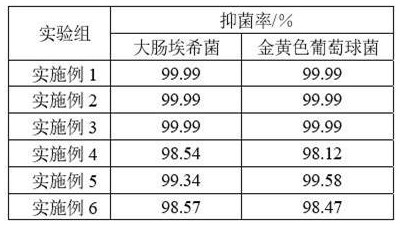

Antibacterial fabric for sofa cushion and production process of antibacterial fabric

ActiveCN112853755AImproved antibacterial durabilityEvenly dopedWeft knittingBiochemical fibre treatmentAnti bacterialCushion

The invention relates to the field of textile materials, and particularly discloses an antibacterial fabric for a sofa cushion and a production process of the antibacterial fabric. An antibacterial coating layer comprises the following substances in parts by weight of 45-50 parts of deionized water, 3-5 parts of chitosan and 6-8 parts of modified antibacterial particles; and the modified antibacterial particles are titanium dioxide particles of 200 to 300 meshes. The titanium dioxide particles are adopted as the main component of an antibacterial agent, on one hand, the active centers of the titanium dioxide particles can absorb energy of the environment and inhibit or kill bacteria, so that the antibacterial performance is achieved, and on the other hand, titanium dioxide serves as an opacifying agent, ultraviolet light can be effectively absorbed, the aging reaction of the ultraviolet light on the surface of a material is reduced, and therefore, the antibacterial durability of the fabric is effectively improved.

Owner:南通雅文纺织品有限公司

Environment-friendly guiding material

The invention disclose an environment-friendly guiding material. The environment-friendly guiding material comprises, by weight, 28 to 30 parts of kaolin pulp fine material, 13 to 15 parts of polyethylene resin, 13 to 15 parts of phenolic resin, 10 to 13 parts of magnesium oxide, 16 to 18 parts of fly ash, 10 to 14 parts of ceramic powder, 10 to 14 parts of gypsum powder, 12 to 17 parts of wood chip, 16 to 21 parts of vegetable fiber, 8 to 10 parts of polyethylene glycol, 12 to 15 parts of a toughening filling material, 9 to 11 parts of an anti-oxidant, 3 to 6 parts of an expanding aid, and 13to 15 parts of water. A preparation method comprises following steps: a, fly ash, gypsum powder, wood chip, and water are mixed, an obtained mixture is introduced into a material mixing machine for uniform stirring, kaolin pulp fine material and the expanding aid are added, an obtained mixed material is heated to 72 to 74 DEG C, is stirred for 16 to 18min at a rotating speed of 200 to 220r / min, and is cooled to normal temperature so as to obtain a mixture 1. The preparation method is simple; deformation is not easily caused under pressing; a plurality of domestic waste and industrial waste are adopted; low carbon green environment protection is achieved; the environment-friendly guiding material can be widely used in the field of building material; the using rate is increased; the obtained environment-friendly guiding material is light in mass, high in compression resistance, and excellent in sound insulation thermal insulation effect.

Owner:王旭

Environmental-friendly material for decoration and preparation method thereof

InactiveCN108864900AImprove adhesionGood weather resistanceAnti-corrosive paintsPolyether coatingsEnvironmental resistanceEpoxy

The invention provides an environmental-friendly material for decoration and a preparation method thereof. The environmental-friendly material is prepared from the following ingredients of diatom ooze, epoxy resin, modified chabazite powder, modified acrylic microemulsion, solid filling materials, seaweed gel, cellulose hydroxypropyl methyl ether, polyethylene glycol, ester solvents initiators, additives and deionized water. The prepared paint is green, and realizes the environment protection and environmental-friendly effects; meanwhile, excellent weather resistance, chemical resistance and wear resistance are realized; the adhesion power of coating substrates is good; the preparation process is simple; the operation is easy; the cost is low; the environmental-friendly material can be widely applied to industries of decoration, communication lines, fan blades, high-voltage cables and the like.

Owner:HEFEI DAHU ELECTRIC WIRE & CABLE TECH CO LTD

Microwave synthesis method of bismuth vanadate/bismuth phosphate compound visible-light-induced photocatalyst

InactiveCN110614103ALower reaction barrierQuick responseWater/sewage treatment by irradiationWater treatment compoundsSynthesis methodsBismuth vanadate

The invention discloses a microwave synthesis method of a bismuth vanadate / bismuth phosphate compound visible-light-induced photocatalyst, which comprises the following steps: (1) adding a surfactantinto dilute nitric acid, carrying out ultrasonic dispersion dissolution, adding bismuth nitrate, and carrying out ultrasonic dispersion dissolution to obtain a solution A; (2) adding ammonium metavanadate and disodium hydrogen phosphate into water, and ultrasonically dispersing and dissolving to obtain a solution B; (3) slowly adding the solution B into the solution A, and uniformly mixing the solutions to obtain a solution C; (4) transferring the solution C into a round-bottom flask, carrying out microwave irradiation, and carrying out heating reflux to obtain reflux liquid; and (5) removingthe supernatant of the reflux, carrying out centrifugal separation, washing the precipitate with pure water, and dehydrating and drying the photocatalyst. The method provided by the invention is simple, efficient, energy-saving and environment-friendly, the preparation time is greatly shortened, and the prepared product has good photocatalytic performance and high catalytic performance.

Owner:HUANGGANG NORMAL UNIV

Moisture-proof coating material for power supply equipment, and preparation method thereof

InactiveCN109266135AGood chemical resistanceWater resistantFireproof paintsAcrylic resinThermal insulation

The invention provides a moisture-proof coating material for power supply equipment, and a preparation method thereof, wherein the moisture-proof coating material is prepared from a modified acrylic resin, zinc oxide, calcium oxide, nanometer titanium dioxide, a moisture absorbing filler, a polysiloxane resin, an organosilicon resin, an amino resin, aminopropyl triethoxysilane, a polyurethane emulsion, diatomaceous earth powder, polyethylene glycol, sucrose acetate isobutyrate, a thickener, a curing agent, a wetting agent and an auxiliary agent. According to the present invention, the preparedcoating material has characteristics of strong chemical resistance, good water resistance, good moisture resistance, high gloss, long service life of coating film and the like, can effectively hinderthe condensation of water vapor, can prevent the surface of power supply equipment from being oxidized, can maintain good thermal insulation performance in a humid environment for a long time, and further has good performances of high temperature resistance, weather resistance, ultraviolet ray aging resistance and the like.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

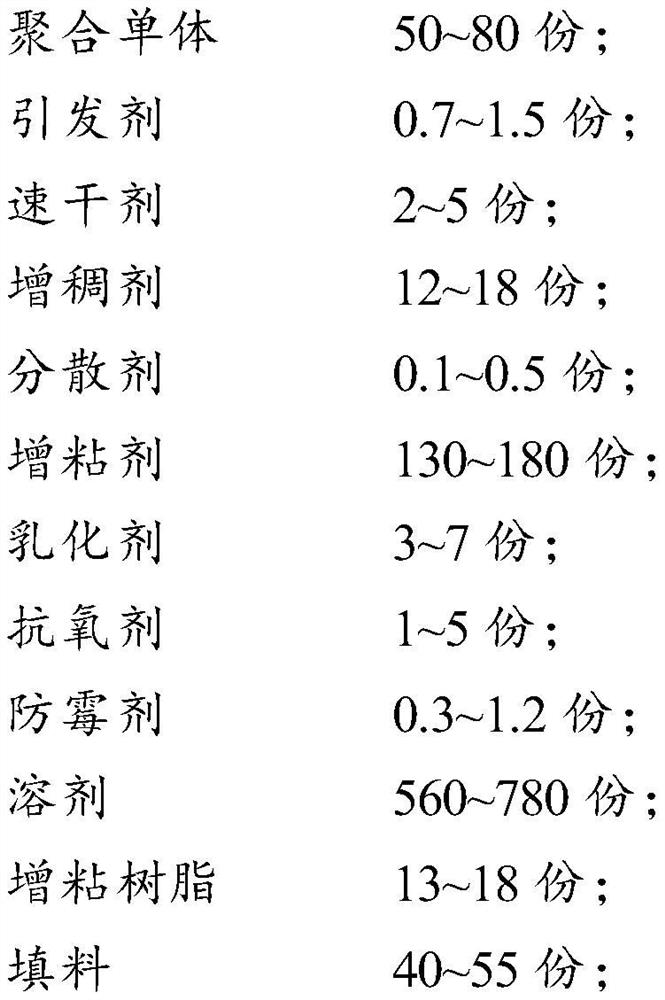

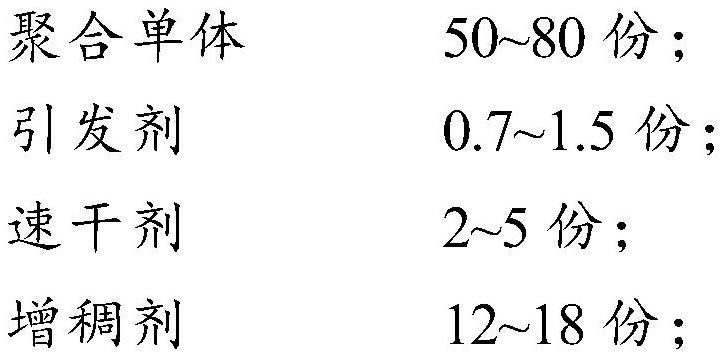

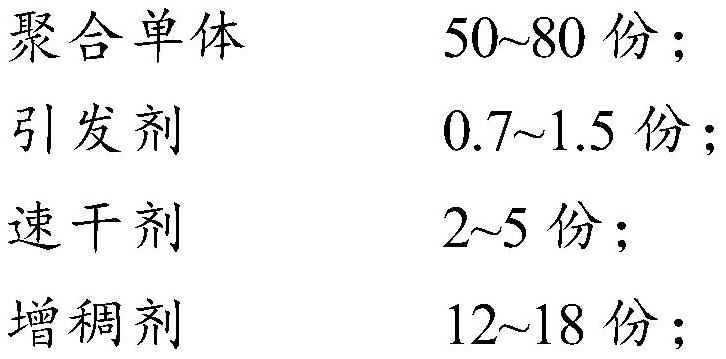

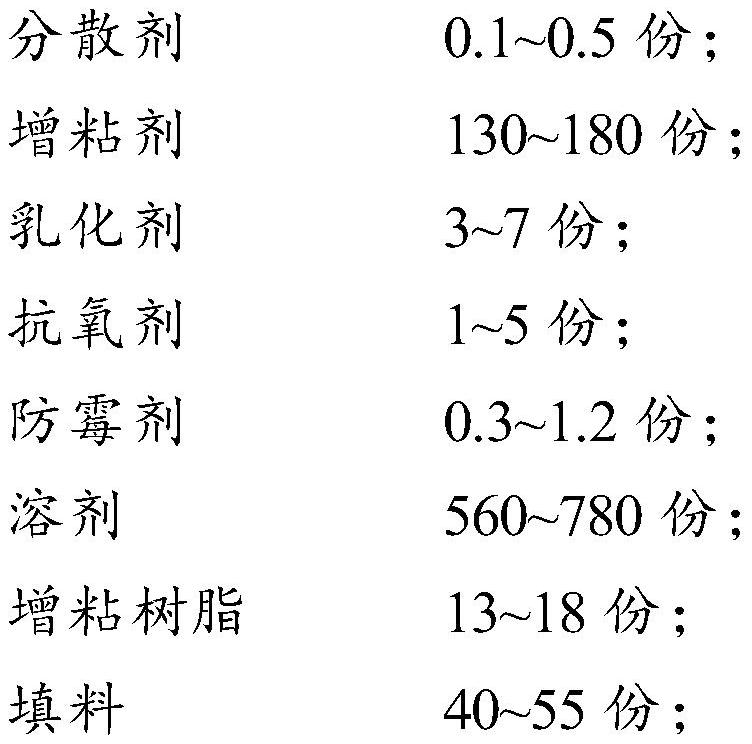

High-strength quick aluminized film adhesive and preparation method thereof

ActiveCN112063342AHigh speedImprove adhesionNon-macromolecular adhesive additivesBio-packagingWeather resistanceAdhesive

The invention provides a high-strength quick aluminized film adhesive and a preparation method thereof. The aluminized film adhesive provided by the invention is prepared from the components accordingto a certain proportion, the polymeric monomer, the specific tackifying resin, the tackifier and the certain quick-drying agent have a synergistic effect, and the thickening agent, the dispersing agent, the filler and the emulsifying agent are matched, so that the adhesive meets the roller coating construction requirement of a pasting roller, and the bonding speed and the bonding strength of theadhesive can be effectively improved; in addition, the antioxidant and the mildew preventive are matched, so that the aging resistance, the heat resistance, the chemical corrosion resistance, the weather resistance and the mildew-proof and antibacterial properties of the adhesive can be improved; in addition, the adhesive is relatively safe and environment-friendly.

Owner:TAISHAN GYPSUM CO LTD

Antibacterial fabric for sofa cushion and production process thereof

ActiveCN112853755BDisrupt proliferationReduce aging responseWeft knittingBiochemical fibre treatmentUltraviolet lightsEngineering

Owner:南通雅文纺织品有限公司

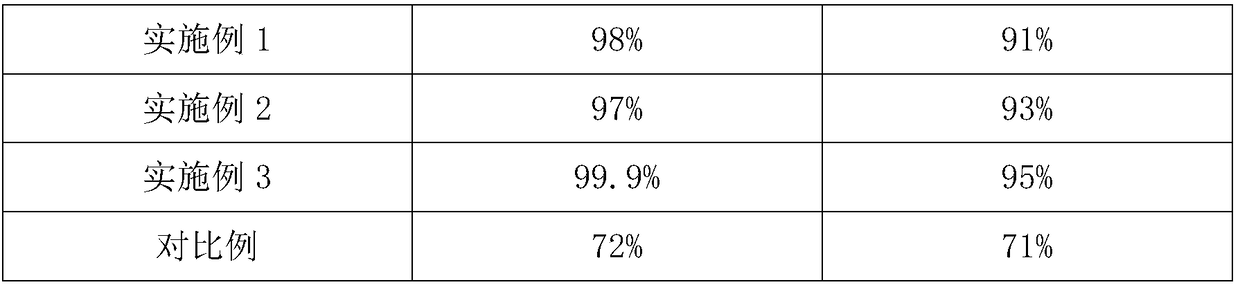

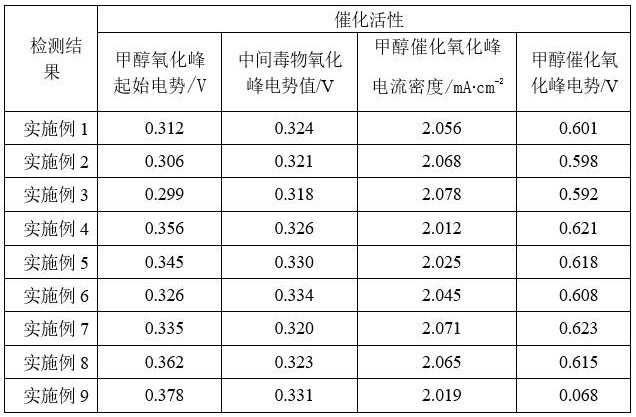

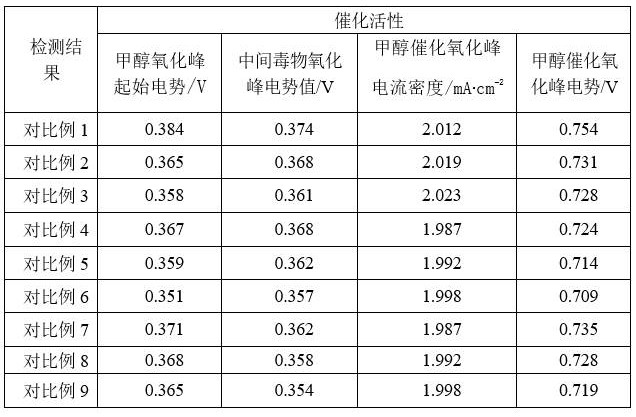

A kind of preparation method of methanol fuel decomposition catalyst with high stability

Owner:江苏优尚环境工程有限公司

A supercritical preparation method of aluminum foam with controllable pore size

ActiveCN109434111BStable pore structureImprove porosity controllabilityRecycling and recovery technologiesAlcoholPhysical chemistry

Owner:SHAOXING UNIVERSITY

Ultraviolet-proof dye used for curtain and preparation method thereof

InactiveCN108867099AGood UV shielding functionDoes not affect ventilationDyeing processPotassiumUltraviolet

The invention provides ultraviolet-proof dye used for a curtain and a preparation method thereof. The ultraviolet-proof dye used for the curtain is prepared from the following components: a mineral dyeing raw material, phenolic resin, sorbitol, oleic acid, potassium diphosphate, a modification auxiliary, organic filler, mixed sodium alkyl sulfate, an alpha-cyanoacrylate adhesive, a coloring agent,a defoaming agent and water. The prepared dye has a very good ultraviolet shielding function, does not affect the air permeability and the moisture permeability of the curtain, and is suitable for various fabrics and wide in application, the cost of the raw materials of the dye is low, the preparation method is simple, and a preparation process is safe, environmentally friendly and pollution-free, so that the ultraviolet-proof dye used for the curtain is suitable for large-scale production and popularization.

Owner:HEFEI YIZHI DOORS & WINDOWS CO LTD

A kind of preparation method of hollow aluminum oxide microsphere

ActiveCN108217703BSolve preparation difficultiesSimple manufacturing methodElectrolysis componentsAluminium oxides/hydroxidesPolyvinyl alcoholMicrosphere

Owner:陕西瑞科新材料股份有限公司

Method for preparing dispersible ultra-fine silicon dioxide

InactiveCN101838479BAvoid reunionEvenly dispersedPigment treatment with macromolecular organic compoundsPigment treatment with organosilicon compoundsSilica particlePhysical chemistry

The invention discloses a method for preparing dispersible ultra-fine silicon dioxide. The method is characterized by comprising the following steps of: adding a liquid surface modifier into a precipitated silicon dioxide filter cake raw material; coating the surfaces of silicon dioxide particles in the precipitated silicon dioxide filter cake to form coating liquid by using the liquid surface modifier with strong stirring; and drying and activating the coating liquid to prepare a dispersible ultra-fine silicon dioxide powder product, wherein the surface modifier accounts for 1 to 50 percent of the mass of the silicon dioxide of the precipitated silicon dioxide filter cake. Experiment results show that: according to an SEM image of the dispersible ultra-fine silicon dioxide dispersed in an organic medium, the particle sizes of silicon dioxide particles are between 100 nm and 10 mu m; and the particle sizes of the silicon particles are between 100 and 400 nm and are distributed uniformly when a boric acid ester coupling agent is adopted.

Owner:FUJIAN NORMAL UNIV

Novel environment-friendly acoustic insulating building material and preparation method thereof

The invention provides a novel environment-friendly acoustic insulating building material and a preparation method thereof. The novel environment-friendly acoustic insulating building material is prepared from the following components: kaolin ore slurry concentrate, polyethylene resin, phenolic resin, magnesium oxide, fly ash, ceramic powder, gypsum powder, sawdust, plant fibers, polyethylene glycol, toughening filler, an antioxidant, a puffing aid and water. The preparation method of the novel environment-friendly acoustic insulating building material disclosed by the invention has the advantages of simple production process and low possibility of deformation when being pressed; low carbon, and environment friendliness are realized by adopting a variety of domestic and industrial wastes;the novel environment-friendly acoustic insulating building material can be widely applied to the field of building materials, and the utilization rate is improved; in addition, the building materialprepared by the invention has the characteristics of light weight, high pressure resistance and good sound insulation and thermal insulation effects.

Owner:肥西县碧涛建材有限公司

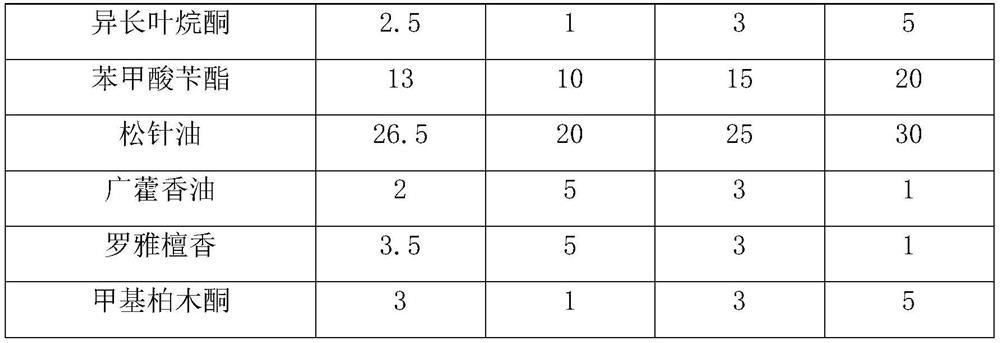

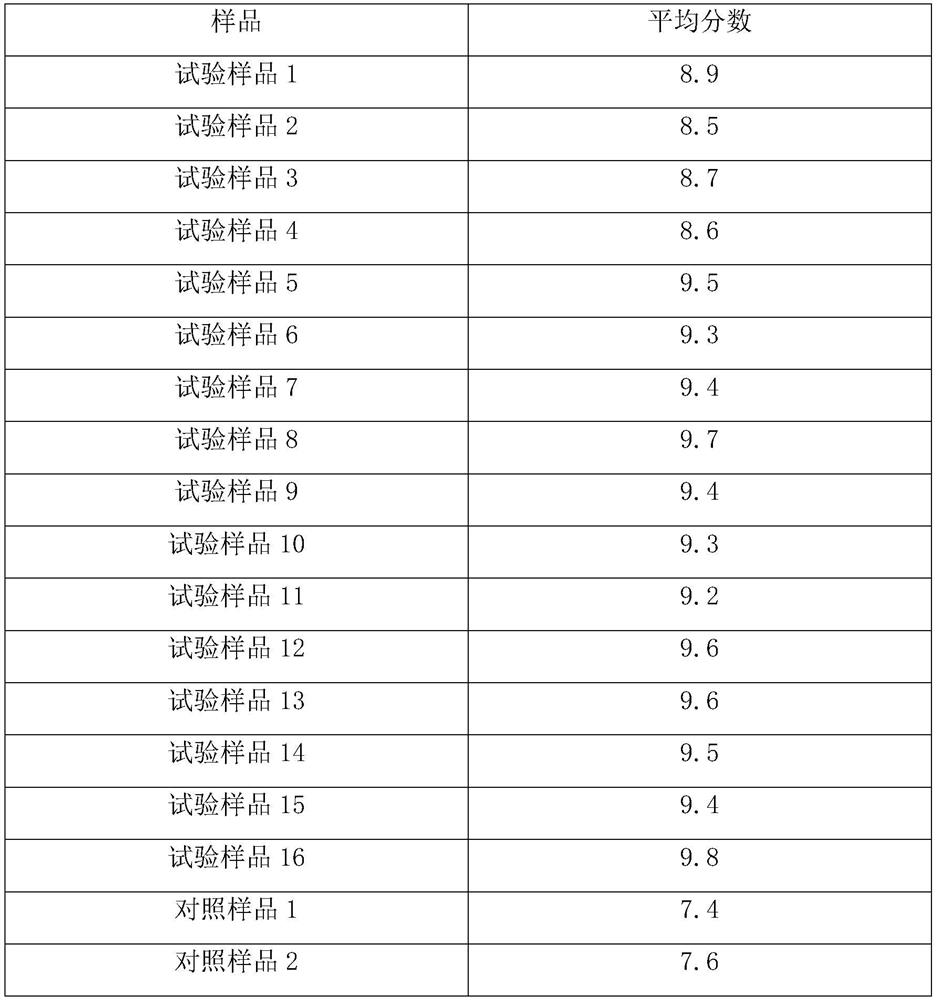

Hot-fragrance explosive candle essence and preparation method thereof

ActiveCN113462472AExplosiveHigh aroma intensityEssential-oils/perfumesCandle ingredientsBenzyl benzoatKetone

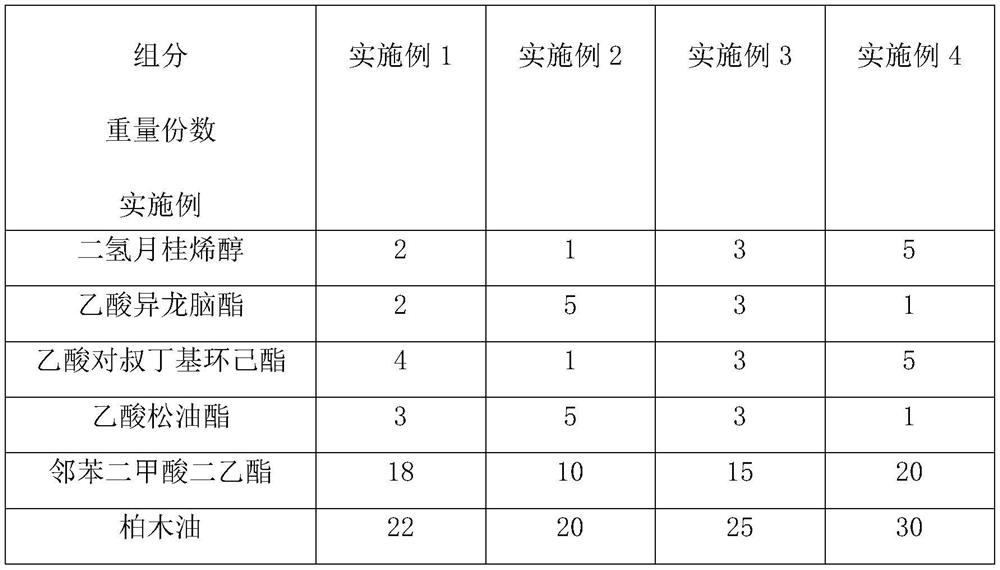

The invention relates to the field of flavors and fragrances, and particularly discloses a hot-fragrance explosive candle essence and a preparation method thereof. The invention relates to a hot fragrance explosive candle essence, which comprises the following components by weight: 1-5 parts of dihydromyrcenol; 1 to 5 parts of isobornyl acetate; 1 to 5 parts of p-tert-butyl cyclohexyl acetate; 1 to 5 parts of terpinyl acetate; 10 to 20 parts of diethyl phthalate; 20 to 30 parts of cedar wood oil; 1 to 5 parts of isolongifolanone; 10 to 20 parts of benzyl benzoate; 20-30 parts of pine needle oil; 1 to 5 parts of patchouli oil; 1 to 5 parts of Roya sandalwood; and 1 to 5 parts of methyl cedryl ketone. The preparation method comprises the following steps: uniformly stirring and mixing the raw materials in a stirring container, and homogenizing the obtained mixed liquid at high pressure to obtain the hot-fragrance explosive candle essence. When the hot-fragrance explosive candle essence is applied to a candle for combustion, the hot-fragrance explosive candle essence has stronger explosive power after being heated, can continuously maintain higher fragrance intensity for a longer time, and is good in overall applicability.

Owner:上海意安实业有限公司 +1

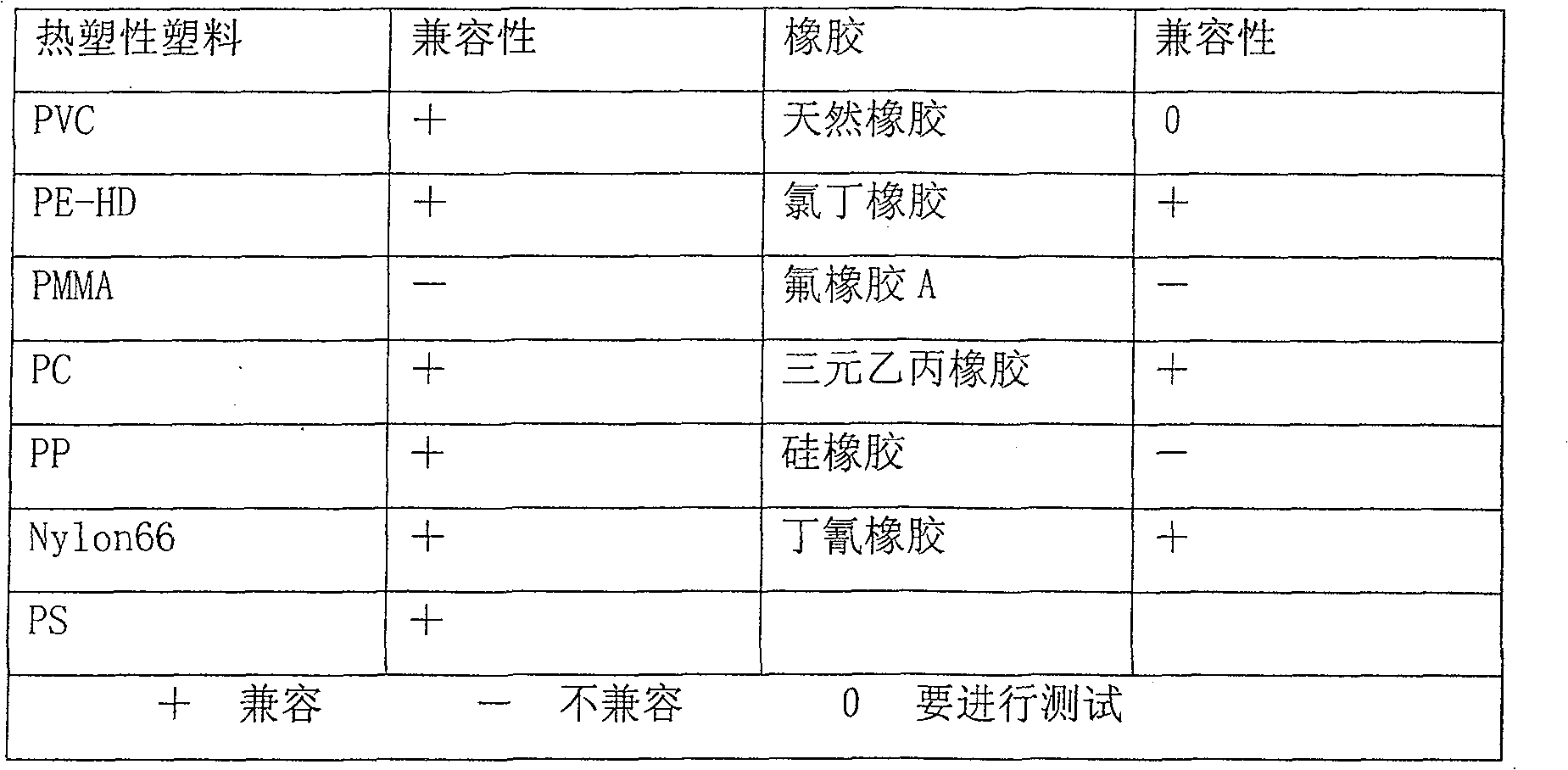

Safe, high performance composite casting system of aerosol not containing Freon

This invention relates to a freon-free safe and efficient composite propelling system for aerosol. The composite propelling system is composed of propellent and latent solvent, dispersant or compatibilizer. The propellent is 1,1,1,2-tetrafluoroethane or 1,1,1,2,3,3,3-heptafluoropropane. The latent solvent, dispersant or compatibilizer is 1,1,1,3,3-pentafluorobutane, 1,1,2,3,3-pentafluoropropane, cyclopentane or isopentane. The composite propelling system has such advantages as wide applications, no freon, high safety and high volatilization speed.

Owner:JIANGSU YENSSEN BIOTECH CO LTD

Heat-resistant coating for electronic equipment as well as preparation method thereof

InactiveCN108841280AImprove heat resistanceImprove waterproof performanceFireproof paintsAnti-corrosive paintsFiberPolymer science

The invention provides heat-resistant coating for electronic equipment as well as a preparation method thereof. The heat-resistant coating for the electronic equipment is prepared from the following components: modified acrylic acid resin, amino resin, a dispersing agent, toughening fiber, diatomite, talcum powder, carbon black, barium sulfate, an organic solvent, a film-forming agent, paraffin, an antioxidant, an adhesive and a leveling agent. The coating prepared by the method has high heat resistance and waterproofness and also has high glossiness, high anti-static capability, high mechanical property, ageing resistance and wear resistance; furthermore, the coating has the advantages of simple preparation process, short curing time, high coating leveling property, strong adhesive force,good coating appearance and long service life.

Owner:HEFEI DONGHENGRUI ELECTRONICS TECH CO LTD

Gluronic acid ecological fertilizer aid and application thereof

InactiveCN114292142AGood dispersionIncrease profitSolid/semi-solid fertilisersLayered/coated fertilisersEnvironmental resource managementUronic acid

The invention discloses a glyuronic acid ecological fertilizer aid and application, and belongs to the technical field of fertilizer aids, and the glyuronic acid ecological fertilizer aid is prepared by proportionally preparing and processing glyuronic acid, modified sodium lignin sulfonate, a compounded sulfonate composite material, humic acid and boric acid. According to the invention, glyuronic acid and modified sodium lignin sulfonate can be adsorbed on the surface of a common fertilizer after being mixed with the common fertilizer, so that fertilizer particles form a good dispersion system under the action of electrostatic mutual exclusion, and trace metal ions can be chelated; furthermore, particles in a common fertilizer can form a stable solution body fluid after being dissolved in water, phosphorus fixation is reduced, precipitation is avoided, and the utilization rate of fertilizer nutrients is increased; the fertilizer added with the glyuronic acid ecological fertilizer aid has the effects of stress resistance, disease resistance, root promotion and growth promotion.

Owner:安徽朴茂农业科技有限公司

A preparation method of high-performance carbon-silicon composite material for lithium batteries

ActiveCN108987693BSolve the chalking problemWell mixedMaterial nanotechnologyCell electrodesViscous liquidNano silicon

The invention belongs to the technical field of lithium batteries, in particular to a method for preparing a high-performance carbon-silicon composite material for lithium batteries, comprising the following steps: step 1, putting nano-carbon materials and nano-silicon materials into absolute ethanol and stirring evenly , and then put it into a ball mill for constant temperature ball milling for 1-3h to obtain a mixed alcohol solution; step 2, add hydroxypropyl cellulose to the mixed alcohol solution and stir evenly, and ultrasonically react for 30-60min to obtain a dispersed suspension; step 3, Put the dispersed suspension in a vacuum distillation kettle for 30-70 minutes to obtain a viscous liquid; step 4, add the viscous liquid to distilled water and stir evenly, put it into a grinding tool for gradient solidification distillation reaction 3- 6h, to obtain the carbon-silicon composite preform; Step 5, adding the carbon-silicon composite preform to the reactor for gradient anaerobic carbonization reaction for 5‑7h, to obtain the carbon-silicon composite nanomaterial. The invention solves the problems of friability and pulverization of carbon-silicon composite particles in the prior art.

Owner:东莞市睿丰能源科技有限公司

A kind of high-strength rapid aluminized film adhesive and preparation method thereof

ActiveCN112063342BFast bondingMeet the needs of online pastingNon-macromolecular adhesive additivesBio-packagingPolymer scienceWeather resistance

Owner:TAISHAN GYPSUM CO LTD

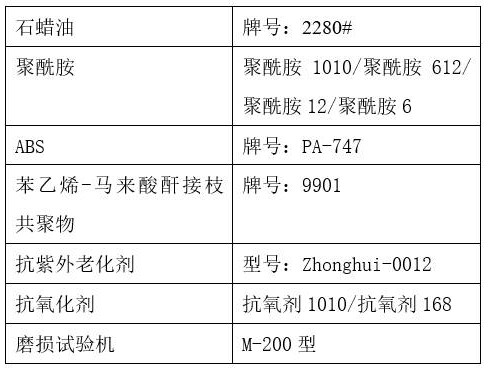

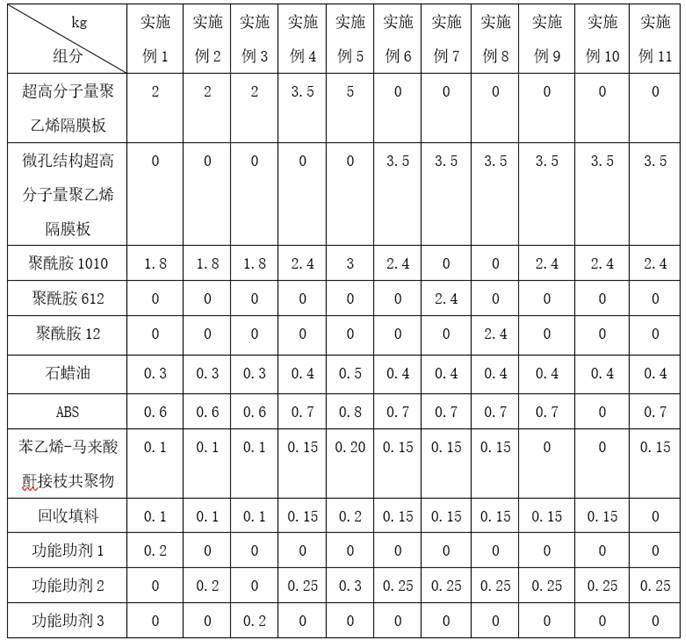

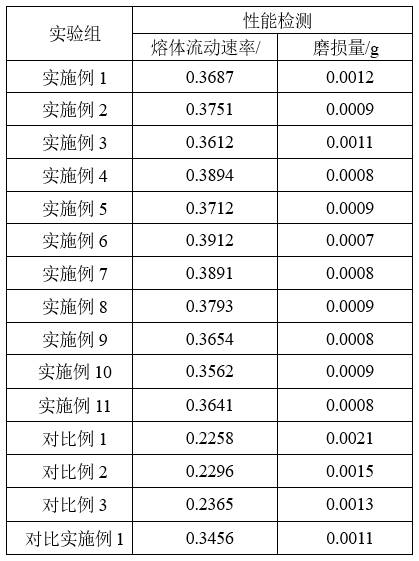

High-fluidity ultra-high molecular weight polyethylene wear-resistant plate and preparation method thereof

The invention relates to the field of high polymer materials, and particularly discloses a high-fluidity ultra-high molecular weight polyethylene wear-resistant plate and a preparation method thereof. The high-fluidity ultra-high molecular weight polyethylene wear-resistant plate comprises the following substances in parts by weight: 20-50 parts of an ultra-high molecular weight polyethylene diaphragm plate, 18-30 parts of polyamide, 3-5 parts of paraffin oil and 2-3 parts of a functional additive. After the ultra-high molecular weight polyethylene diaphragm plate is recycled, polyamide is adopted to replace an oily material adopted in a traditional diaphragm plate, so that on one hand, the flowing property of the ultra-high molecular weight polyethylene material is effectively improved, and the ultra-high molecular weight polyethylene material is convenient to process and extrude; on the other hand, due to the good crystallization property and wear resistance of polyethylene, polyethylene is added into the ultra-high molecular weight polyethylene material, so that the wear resistance of the composite material can be improved, and the defects of poor processability and wear resistance of the recycled ultra-high molecular weight polyethylene diaphragm plate after no oily substance is added are effectively overcome.

Owner:常州利尔德通新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com