A kind of high-strength rapid aluminized film adhesive and preparation method thereof

A technology of aluminized film and adhesive, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesive types, etc. And other problems, to achieve good environmental protection and mildew resistance, improve the bonding speed, improve the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

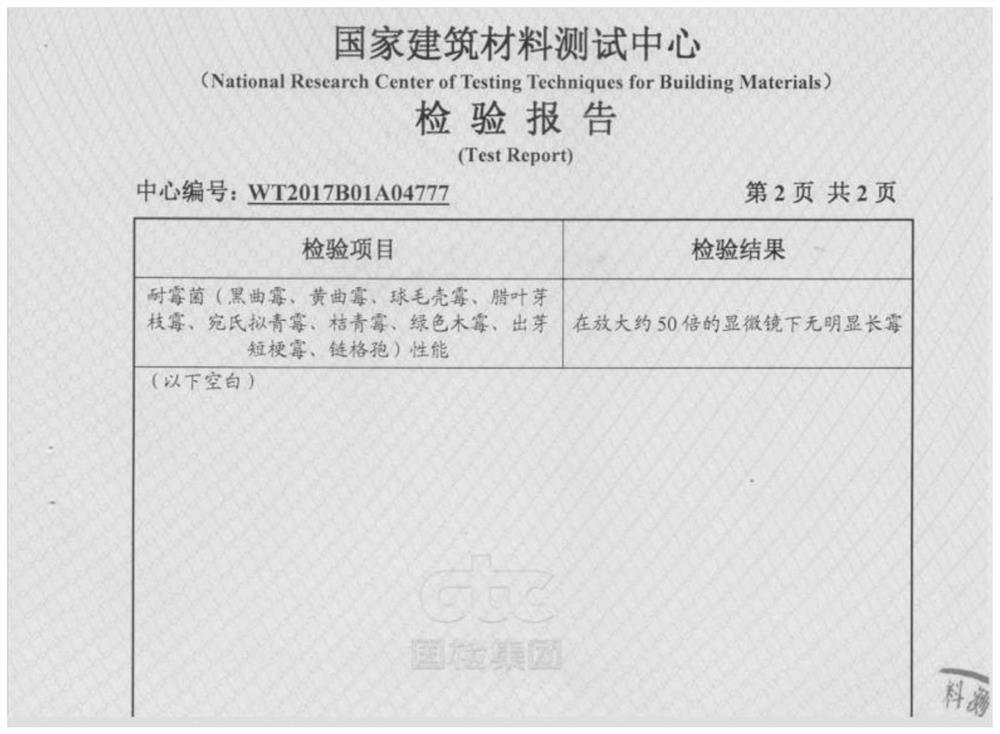

Image

Examples

preparation example Construction

[0058] The present invention also provides a preparation method of the high-strength rapid aluminized film adhesive described in the above technical scheme, comprising the following steps:

[0059] A) heat up for the first time after mixing the polymerized monomer and part of the solvent, add an initiator to heat up the second time to generate a polymerization reaction, and then cool down to obtain mixed solution A;

[0060] b) after the thickening agent is mixed with a part of the solvent, heat up for the first time, then cool down for the first time, add the thickener and mix and heat up for the second time, and then cool down for the second time to obtain mixed solution B;

[0061] c) mixing tackifying resin, residual solvent and quick-drying agent to obtain mixed solution C;

[0062] d) after mixing filler, antifungal agent, antioxidant, emulsifier and dispersant with described mixed solution B, then mixed with described mixed solution A and mixed solution C to obtain an a...

Embodiment 1

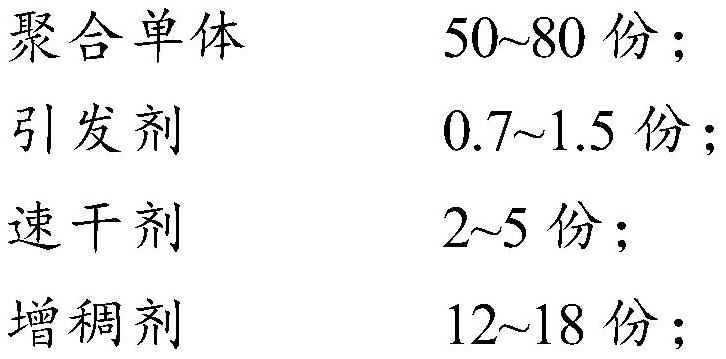

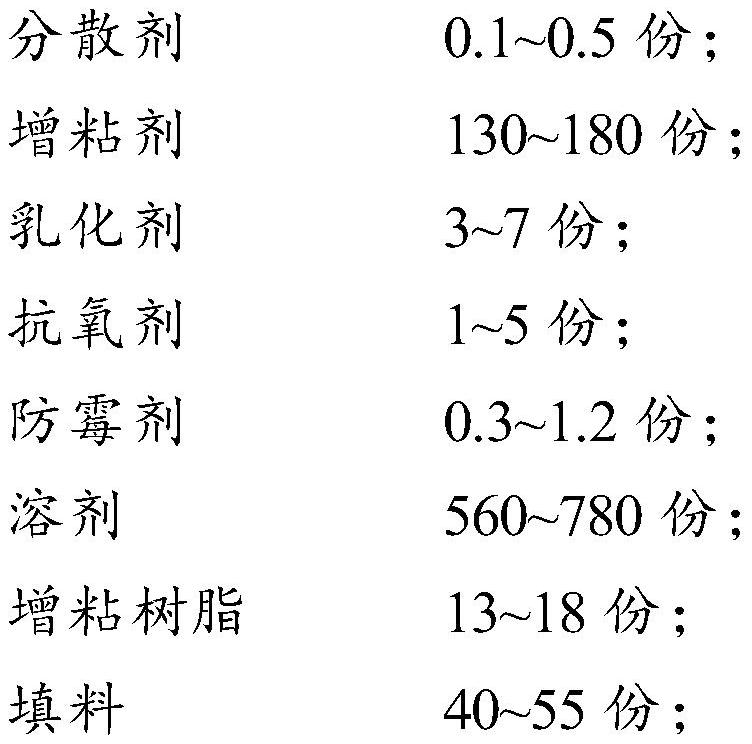

[0081] 1.1 Recipe

[0082]

[0083]

[0084] 1.2 Preparation

[0085] S1. The polymerized monomer and solvent (220 parts) were mixed and stirred for 15 minutes, heated to 60° C., added an initiator, heated to 95° C., polymerized for 60 minutes, and cooled to 60° C. to obtain mixed solution A.

[0086] S2. Add the thickener to the solvent (520 parts), soak at room temperature for 1 hour, then stir while heating until the water temperature reaches 95°C, and then continue to stir for 1 hour. Then, the solution was cooled to 60°C, a thickening agent was added, stirred for 30 minutes, heated to 75°C, stirred for 1 hour, and then cooled to 60°C to obtain mixed solution B.

[0087] S3, the tackifying resin, solvent (17 parts) and quick-drying agent are mixed and stirred for 30min to obtain mixed solution C.

[0088] S4. Add filler, antifungal agent, antioxidant and emulsifier into mixed solution B, stir at 1000r / min for 30min, then add mixed solution A and mixed solution C, s...

Embodiment 2

[0090] 1.1 Recipe

[0091]

[0092]

[0093] 1.2 Preparation

[0094] S1. The polymerized monomer and solvent (200 parts) were mixed and stirred for 15 minutes, heated to 60° C., added an initiator, heated to 90° C., polymerized for 60 minutes, and cooled to 50° C. to obtain mixed solution A.

[0095] S2. Add the thickener to the solvent (465 parts), soak for 1 hour at room temperature, then stir while heating until the water temperature reaches 90°C, and then continue to stir for 1 hour. Then, the solution was cooled to 60°C, a thickening agent was added, stirred for 30 minutes, heated to 70°C, stirred for 1 hour, and then cooled to 50°C to obtain mixed solution B.

[0096] S3, the tackifying resin, the solvent (18 parts) and the quick-drying agent are mixed and stirred for 15 min to obtain a mixed solution C.

[0097] S4. Add filler, antifungal agent, antioxidant and emulsifier into mixed solution B, stir at 1000r / min for 30min, then add mixed solution A and mixed so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com