MXene and carbon nano tube synergistically modified polyurethane anticorrosive paint as well as preparation method and construction process thereof

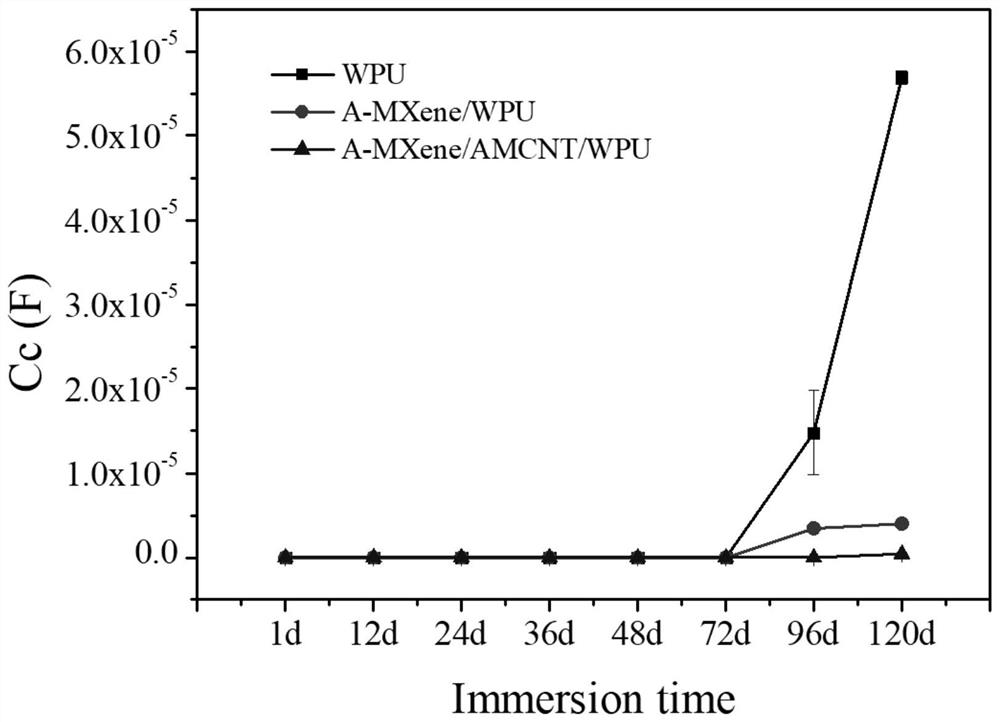

A technology of synergistic modification and carbon nanotubes, applied in the direction of polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve the problem of ineffective prevention of nano-filler agglomeration and stacking, reduced anti-corrosion performance of coatings, weak interaction, etc. problems, to achieve excellent corrosion resistance and mechanical properties, good mechanical properties and anti-corrosion properties, and the effect of protecting metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of preparation method of MXene and carbon nanotube synergistically modified polyurethane anticorrosion coating, comprises the following steps:

[0037] 1) Preparation of MXene nanosheets: Weigh 3 g of titanium aluminum carbide (Ti 3 AlC 2 ), then measure 60ml of hydrofluoric acid (HF) in a polyethylene beaker with a graduated cylinder, place the beaker on a magnetic stirrer, and slowly add Ti 3 AlC 2 , and completed within half an hour; continued magnetic stirring for 12 hours, washed the obtained MXene suspension with distilled water and absolute ethanol until the solution was neutral, and finally dried in vacuum at 45°C for 12 hours to obtain MXene nanosheets.

[0038] 2) Preparation of functionalized MXene nanosheets (A-MXene): under nitrogen protection, the silane coupling agent 3-(2-aminoethylamino)propyltrimethoxysilane (AEAPTMS) was first dispersed in ethanol solution, Stir to dissolve it fully, then add it into the MXene aqueous solution, ultrasonicate...

Embodiment 2

[0048] A kind of preparation method of MXene and carbon nanotube synergistically modified polyurethane anticorrosion coating, comprises the following steps:

[0049] 1) Preparation of MXene nanosheets: Weigh 5 g of titanium aluminum carbide (Ti 3 AlC 2 ), then measure 100ml hydrofluoric acid (HF) in a polyethylene beaker with a graduated cylinder, place the beaker on a magnetic stirrer, and slowly add Ti 3 AlC 2 , and completed within half an hour; continued magnetic stirring for 12 hours, washed the obtained MXene suspension with distilled water and absolute ethanol until the solution was neutral, and finally dried in vacuum at 45°C for 12 hours to obtain MXene nanosheets.

[0050] 2) Preparation of functionalized MXene nanosheets (A-MXene): under nitrogen protection, the silane coupling agent 3-(2-aminoethylamino)propyltrimethoxysilane (AEAPTMS) was first dispersed in ethanol solution, Stir to fully dissolve it, then add it into the MXene aqueous solution, sonicate for 60...

Embodiment 3

[0058] A kind of preparation method of MXene and carbon nanotube synergistically modified polyurethane anticorrosion coating, comprises the following steps:

[0059] 1) Preparation of MXene nanosheets: Weigh 4 g of titanium aluminum carbide (Ti 3 AlC 2 ), then measure 100ml hydrofluoric acid (HF) in a polyethylene beaker with a graduated cylinder, place the beaker on a magnetic stirrer, and slowly add Ti 3 AlC 2 , and completed within half an hour; continued magnetic stirring for 24 hours, washed the obtained MXene suspension with distilled water and absolute ethanol until the solution was neutral, and finally dried in vacuum at 45°C for 24 hours to obtain MXene nanosheets.

[0060] 2) Preparation of functionalized MXene nanosheets (A-MXene): under nitrogen protection, the silane coupling agent 3-(2-aminoethylamino)propyltrimethoxysilane (AEAPTMS) was first dispersed in ethanol solution, Stir to fully dissolve it, add it to the MXene aqueous solution, ultrasonicate for 60 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com