A kind of preparation method of surface-modified graphite microflake waterborne epoxy resin anticorrosion coating

A technology of water-based epoxy resin and graphite microchips, which is applied in the direction of epoxy resin coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems of poor anti-corrosion effect, and achieve the characteristics of not easy to pulverize, increase adhesion, and good weather resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

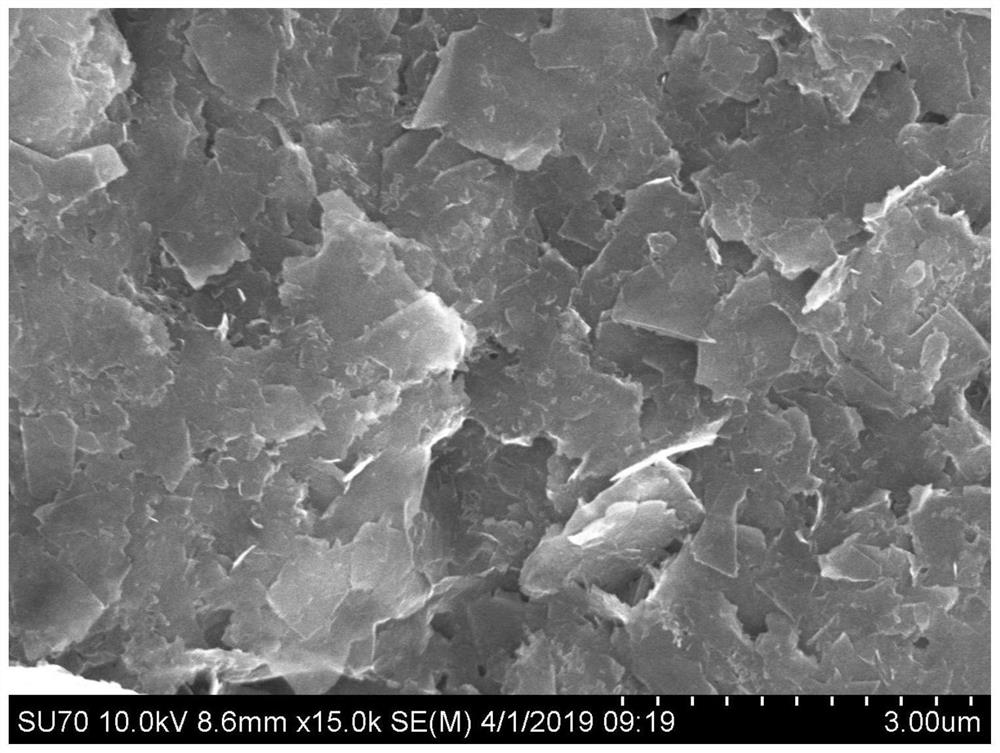

Image

Examples

Embodiment 1

[0022] A preparation method for surface-modified graphite microflake waterborne epoxy resin anticorrosion coating, comprising the following steps:

[0023] 1) Preparation of graphite oxide powder: immerse 10g of ground graphite powder in 200ml of concentrated nitric acid, soak for 1h at 0°C, cool down to -15°C, add 1ml of concentrated phosphoric acid and 40g of potassium ferrate, react at 60°C for 0.5h and then centrifuge , washing the filter cake with deionized water until the pH of the washing solution is 6-7, placing it in a vacuum drying oven, and drying at 60°C for 6 hours to obtain graphite oxide powder;

[0024] 2) prepare the graphite oxide powder of hydroxyl group and carboxyl group: the graphite oxide powder containing NaBH 4 and CaCl 2 Soak in the solution for 10 hours and then filter, wash the filter cake with deionized water and dry it in a drying oven at 60°C for 6 hours to obtain multilayer graphite powder containing hydroxyl and carboxyl groups;

[0025] 3) P...

Embodiment 2

[0030] A preparation method for surface-modified graphite microflake waterborne epoxy resin anticorrosion coating, comprising the following steps:

[0031] 1) Preparation of graphite oxide powder: immerse 10g of ground graphite powder in 200ml of concentrated nitric acid, soak for 1.5h at 0°C, cool down to -15°C, add 1ml of concentrated phosphoric acid and 40g of potassium ferrate, react at 25°C for 12h and then centrifuge , washing the filter cake with deionized water until the pH of the washing solution is 6-7, placing it in a vacuum drying oven, and drying at 65°C for 5 hours to obtain graphite oxide powder;

[0032]2) prepare the graphite oxide powder of hydroxyl group and carboxyl group: the graphite oxide powder containing NaBH 4 and CaCl 2 Soak in the solution for 9 hours and then filter, wash the filter cake with deionized water and dry it in a drying oven at 60°C for 6 hours to obtain a multilayer graphite powder containing hydroxyl and carboxyl groups;

[0033] 3) ...

Embodiment 3

[0038] A preparation method for surface-modified graphite microflake waterborne epoxy resin anticorrosion coating, comprising the following steps:

[0039] 1) Preparation of graphite oxide powder: immerse 10g of ground graphite powder in 200ml of concentrated nitric acid, soak at 0°C for 2h, cool down to -15°C, add 1ml of concentrated phosphoric acid and 40g of potassium ferrate, react at -10°C for 24h and then centrifuge , washing the filter cake with deionized water until the pH of the washing solution is 6-7, placing it in a vacuum drying oven, and drying at 70°C for 4 hours to obtain graphite oxide powder;

[0040] 2) prepare the graphite oxide powder of hydroxyl group and carboxyl group: the graphite oxide powder containing NaBH 4 and CaCl 2 Soak in the solution for 10 hours and then filter, wash the filter cake with deionized water and dry it in a drying oven at 60°C for 6 hours to obtain multilayer graphite powder containing hydroxyl and carboxyl groups;

[0041] 3) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com