Application of a graphene oxide composite polymer material in anti-corrosion coatings

A graphene composite, polymer material technology, used in anti-corrosion coatings, epoxy resin coatings, conductive coatings, etc., can solve problems such as poor anti-corrosion effect, and achieve the effects of increasing adhesion, stable performance, and solving poor solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

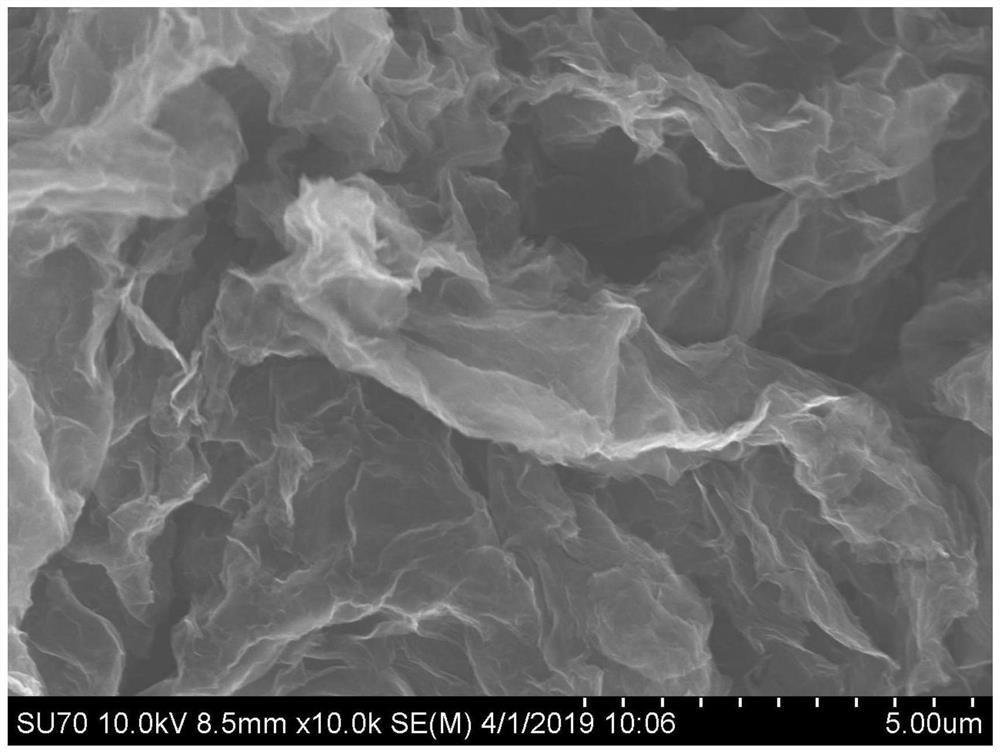

Image

Examples

Embodiment 1

[0028] A kind of application of graphene oxide composite macromolecule material in anticorrosion coating, comprises the following steps:

[0029] 1) Preparation of graphene oxide powder: immerse 10g of ground graphite powder in 200ml of concentrated nitric acid, soak at 0°C for 1-2h, cool down to -15°C, add 1ml of concentrated phosphoric acid and 40g of potassium ferrate, react at -10°C for 24h After centrifugation, the filter cake is washed with deionized water until the pH of the washing solution is 6-7, placed in a vacuum drying oven, and dried at 60°C-70°C for 4-6h to obtain graphene oxide powder;

[0030] 2) Preparation of surface-modified graphene oxide: soak the graphene oxide powder obtained in step 1) in a coupling agent at 30°C for 12-15 hours, vacuum filter after soaking, wash the filter cake with ethanol or acetone, and then Drying in a vacuum drying oven at 80°C for 6-10 hours to obtain a modified graphene oxide powder containing amino groups or isocyanate groups ...

Embodiment 2

[0037] A kind of application of graphene oxide composite macromolecule material in anticorrosion coating, comprises the following steps:

[0038] 1) Preparation of graphene oxide powder: immerse 10g of ground graphite powder in 200ml of concentrated nitric acid, soak at 0°C for 1-2h, cool down to -15°C, add 1ml of concentrated phosphoric acid and 40g of potassium ferrate, and react at 20°C for 12h Centrifuge, wash the filter cake with deionized water until the pH of the washing solution is 6-7, place it in a vacuum drying oven, and dry it at 60°C-70°C for 4-6h to obtain graphene oxide powder;

[0039] 2) Preparation of surface-modified graphene oxide: soak the graphene oxide powder obtained in step 1) in a coupling agent at 30°C for 12-15 hours, vacuum filter after soaking, wash the filter cake with ethanol or acetone, and then Drying in a vacuum drying oven at 80°C for 6-10 hours to obtain a modified graphene oxide powder containing amino groups or isocyanate groups on the surf...

Embodiment 3

[0046] A kind of application of graphene oxide composite macromolecule material in anticorrosion coating, comprises the following steps:

[0047] 1) Preparation of graphene oxide powder: immerse 10g of ground graphite powder in 200ml of concentrated nitric acid, soak at 0°C for 1-2h, cool down to -15°C, add 1ml of concentrated phosphoric acid and 40g of potassium ferrate, and react at 60°C for 0.5h After centrifugation, the filter cake is washed with deionized water until the pH of the washing solution is 6-7, placed in a vacuum drying oven, and dried at 60°C-70°C for 4-6h to obtain graphene oxide powder;

[0048] 2) Preparation of surface-modified graphene oxide: soak the graphene oxide powder obtained in step 1) in a coupling agent at 30°C for 12-15 hours, vacuum filter after soaking, wash the filter cake with ethanol or acetone, and then Drying in a vacuum drying oven at 80°C for 6-10 hours to obtain a modified graphene oxide powder containing amino groups or isocyanate gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com