A high-temperature heat-insulating protective coating structure and preparation method thereof

A technology of protective coating and heat insulation layer, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problems of short working life, cracks, peeling, etc., to prevent performance degradation and prevent ablation loss , Improve the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

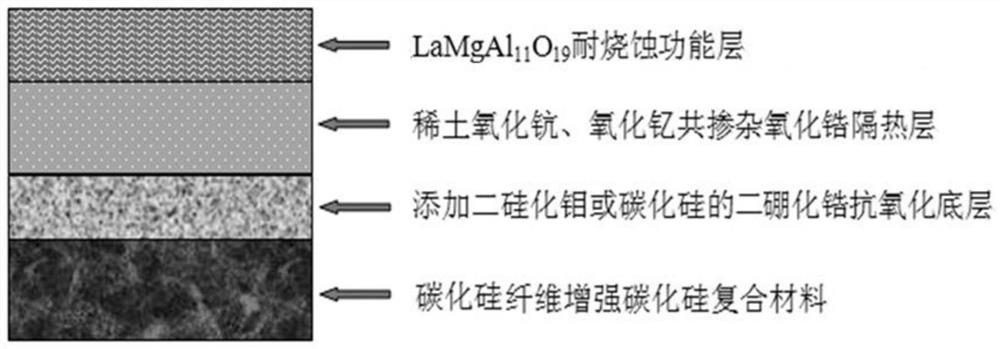

[0025] The embodiment of the present invention is aimed at the working temperature of barium strontium aluminum silicon (BSAS) and rare earth silicate thermal protection coating containing silicon oxide on the surface of SiC / SiC composite material in the prior art, and the working temperature is not higher than 1500°C. Zirconium carbide and zirconium diboride coatings have good ablation resistance at 1700°C, but the coating itself has no heat insulation function, and it is easy to crack or even peel off during heating when used alone, and the working life is too short. A high-temperature heat-insulating protective coating structure and a preparation method thereof are provided, especially for use in the technical field of high-temperature coating preparation, especially a coating structure of a high-temperature heat-insulating protective coating and a preparation method thereof. The structure of the high temperature thermal insulation protective coating includes:

[0026] Adde...

Embodiment 1

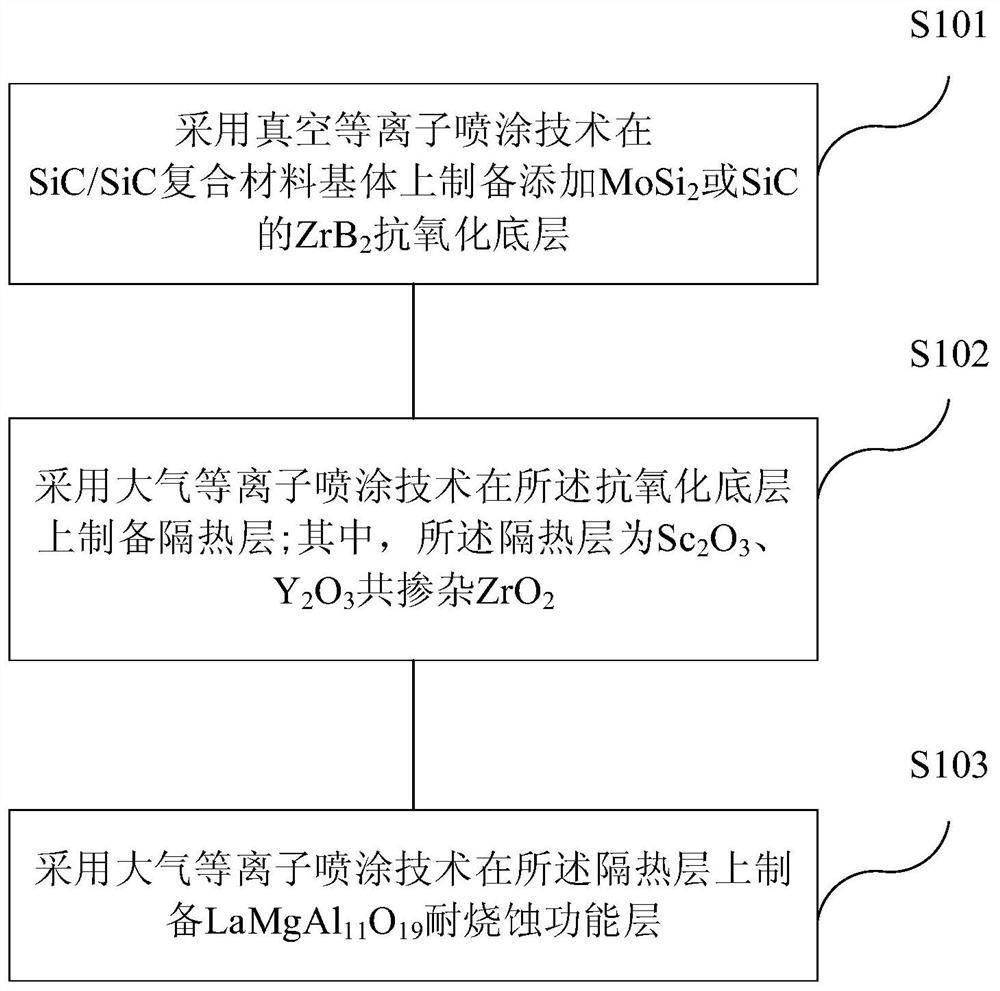

[0040] Clean the SiC / SiC composite surface with dry and clean compressed air. Spraying and adding MoSi on the surface of SiC / SiC composite materials by vacuum plasma spraying process 2 ZrB 2 Anti-oxidation bottom layer, MoSi in powder material 2 The volume fraction is 30%, the particle size of the powder material is in the range of 5-40 microns, the vacuum plasma spraying power is 45KW, the powder feeding rate is 20g / min, the spraying distance is 240mm, and the thickness of the bottom layer is 0.15mm.

[0041] On the above-mentioned vacuum plasma spraying anti-oxidation bottom layer, the heat insulation layer is prepared by atmospheric plasma spraying process, and the powder material of the heat insulation layer is rare earth Sc 2 o 3 , Y 2 o 3 Co-doped ZrO 2 , where Sc 2 o 3 The mole fraction is 5.5%, Y 2 o 3 The mole fraction is 0.9%, the rest is ZrO 2 , The particle size of the powder material is in the range of 10-50 microns, the atmospheric plasma spraying powe...

Embodiment 2

[0044] Clean the SiC / SiC composite surface with dry and clean compressed air. Spraying SiC-added ZrB on the surface of SiC / SiC composites by vacuum plasma spraying process 2 Anti-oxidation bottom layer, the volume fraction of SiC in the powder material is 25%, the particle size of the powder material is in the range of 5-40 microns, the vacuum plasma spraying power is 45KW, the powder feeding rate is 20g / min, the spraying distance is 200mm, and the bottom layer thickness is 0.15mm.

[0045] On the above-mentioned vacuum plasma spraying anti-oxidation bottom layer, the heat insulation layer is prepared by atmospheric plasma spraying process, and the powder material of the heat insulation layer is rare earth Sc 2 o 3 , Y 2 o 3 Co-doped ZrO 2 , where Sc 2 o 3 The mole fraction is 5.5%, Y 2 o 3 The mole fraction is 0.9%, the rest is ZrO 2 , The particle size of the powder material is in the range of 10-50 microns, the atmospheric plasma spraying power is 42KW, the powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com