Environmental-friendly material for decoration and preparation method thereof

A technology for environmental protection materials and raw materials, applied in the field of decorative environmental protection materials and their preparation, can solve the problems of complex preparation methods and high preparation costs, and achieve the effects of simple preparation process, low cost and excellent weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

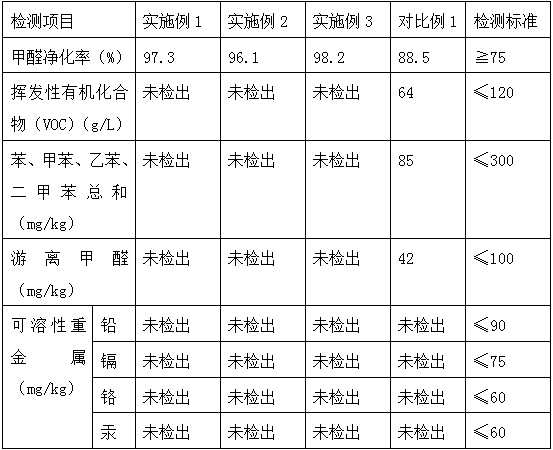

Examples

Embodiment 1

[0028] An environmentally friendly material for decoration, comprising the following raw materials in parts by weight: 25 parts of diatom mud, 12 parts of epoxy resin, 14 parts of modified chabazite powder, 7 parts of modified acrylic microemulsion, 10 parts of solid filler, seaweed 11 parts of glue, 12 parts of hydroxypropyl methylcellulose ether, 9 parts of polyethylene glycol, 9 parts of ester solvent, 4 parts of initiator, 5 parts of additive and 15 parts of deionized water.

[0029] A preparation method for an environmentally friendly material for decoration, comprising the following preparation steps:

[0030] a. Import the diatom ooze into the calciner, calcinate at 480°C for 1.4h, cool to room temperature, and pulverize it through a pulverizer to pass through a 500-mesh sieve to obtain a powder;

[0031] b. Import powder, modified chabazite powder and solid filler into polyethylene glycol, mix evenly, import into a mixer, heat up to 90°C, stir and react at a speed of 2...

Embodiment 2

[0041] An environmentally friendly material for decoration, comprising the following raw materials in parts by weight: 23 parts of diatom mud, 17 parts of epoxy resin, 11 parts of modified chabazite powder, 7 parts of modified acrylic microemulsion, 12 parts of solid filler, seaweed 9 parts of glue, 12 parts of hydroxypropyl methylcellulose ether, 9 parts of polyethylene glycol, 9 parts of ester solvent, 8 parts of initiator, 7 parts of additive and 14 parts of deionized water.

[0042] A preparation method for an environmentally friendly material for decoration, comprising the following preparation steps:

[0043] a. Import diatom ooze into a calciner, calcinate at 450°C for 1.4h, cool to room temperature, and pulverize through a pulverizer to pass through a 300-mesh sieve to obtain a powder;

[0044] b. Import the powder, modified chabazite powder, and solid filler into polyethylene glycol, mix evenly, import it into a mixer, heat up to 80°C, stir and react at a speed of 200...

Embodiment 3

[0054] An environmentally friendly material for decoration, comprising the following raw materials in parts by weight: 24 parts of diatom mud, 15 parts of epoxy resin, 13 parts of modified chabazite powder, 8 parts of modified acrylic microemulsion, 13 parts of solid filler, seaweed 10 parts of glue, 13 parts of hydroxypropyl methylcellulose ether, 7 parts of polyethylene glycol, 8 parts of ester solvent, 6 parts of initiator, 6 parts of additive and 13 parts of deionized water.

[0055] A preparation method for an environmentally friendly material for decoration, comprising the following preparation steps:

[0056] a. Import diatom ooze into a calciner, calcinate at 450°C for 1.4h, cool to room temperature, and pulverize through a pulverizer to pass through a 300-mesh sieve to obtain a powder;

[0057] b. Import the powder, modified chabazite powder, and solid filler into polyethylene glycol, mix evenly, import it into a mixer, heat up to 90°C, stir and react at a speed of 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com