Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

104results about How to "Eliminate environmental pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A rotatory series-pole magnetic refrigerating system

ActiveUS20160282021A1Heat dissipationAbsorption of heatMachines using electric/magnetic effectsSustainable buildingsHeat flowEngineering

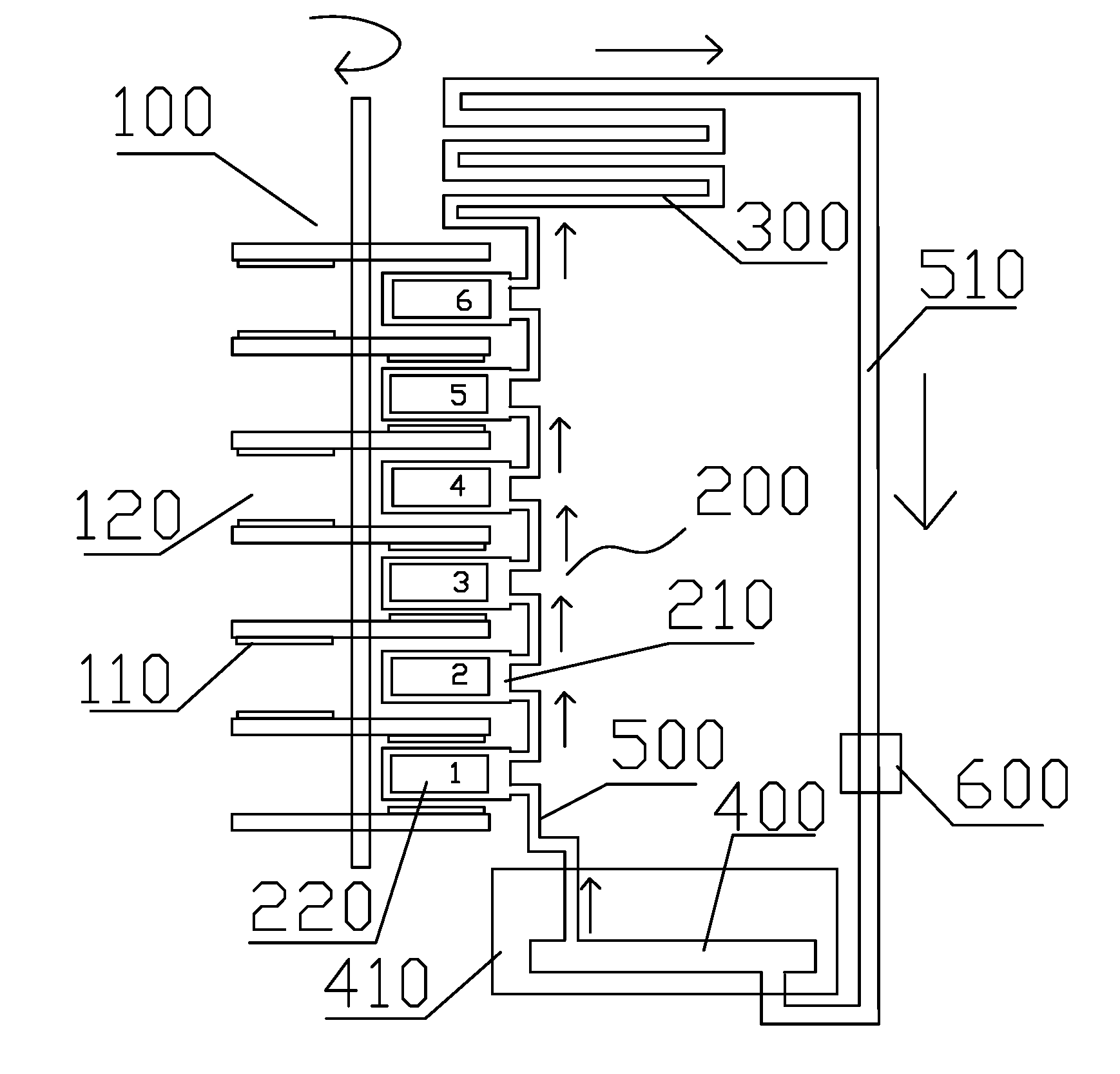

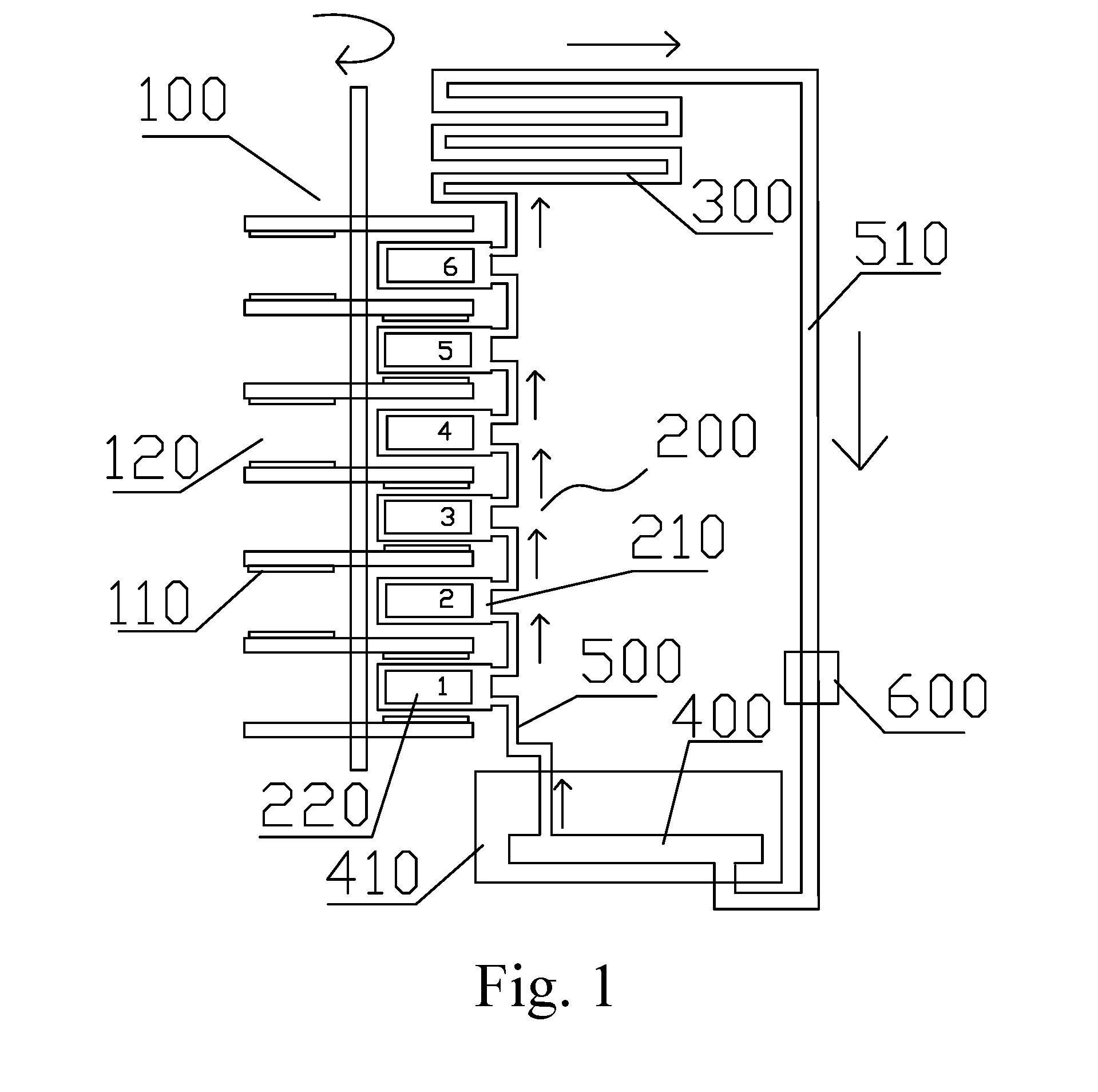

The present invention relates to a rotatory series-pole magnetic refrigerating system, comprising a moving magnetic body and at least one vertically-disposed magnetic series, wherein the magnetic series further comprising a plurality of heat insulated cavities, wherein the heat insulated cavities are interconnected in series successively, wherein the interior of the heat insulated cavities are provided with magnetic working mediums, and wherein the moving magnetic body is capable of magnetizes and demagnetizes the magnetic working mediums in a crossing pattern, wherein the upper and lower magnetic working mediums which are adjacent to any magnetic working medium in demagnetizing state in the same magnetic series must be in a magnetizing state, wherein the system further comprising a heat-flow structure, which assists the internal heat energy in the magnetic series to flow in one direction.

Owner:FOSHAN CHUANDONG MAGNETOELECTRICITY

Cleaning production technique of 16-dehydro pregnenetrolone and its same kind compound

InactiveCN1475494AImprove utilizationEliminate environmental pollutionSteroidsCompound aOrganic solvent

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

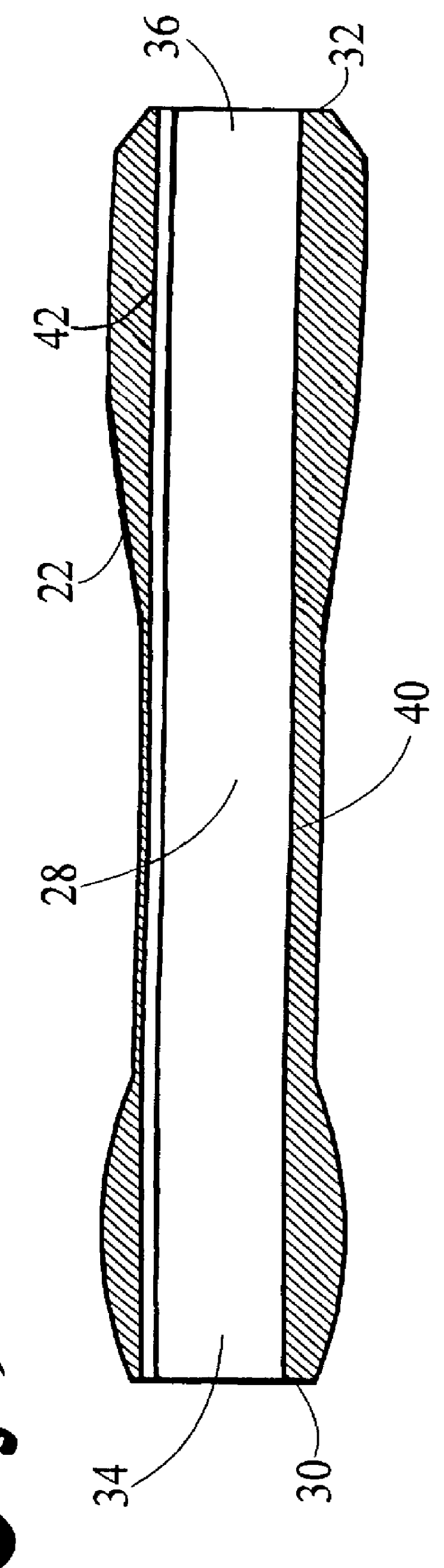

Floating bait caster and bait protector with depth control

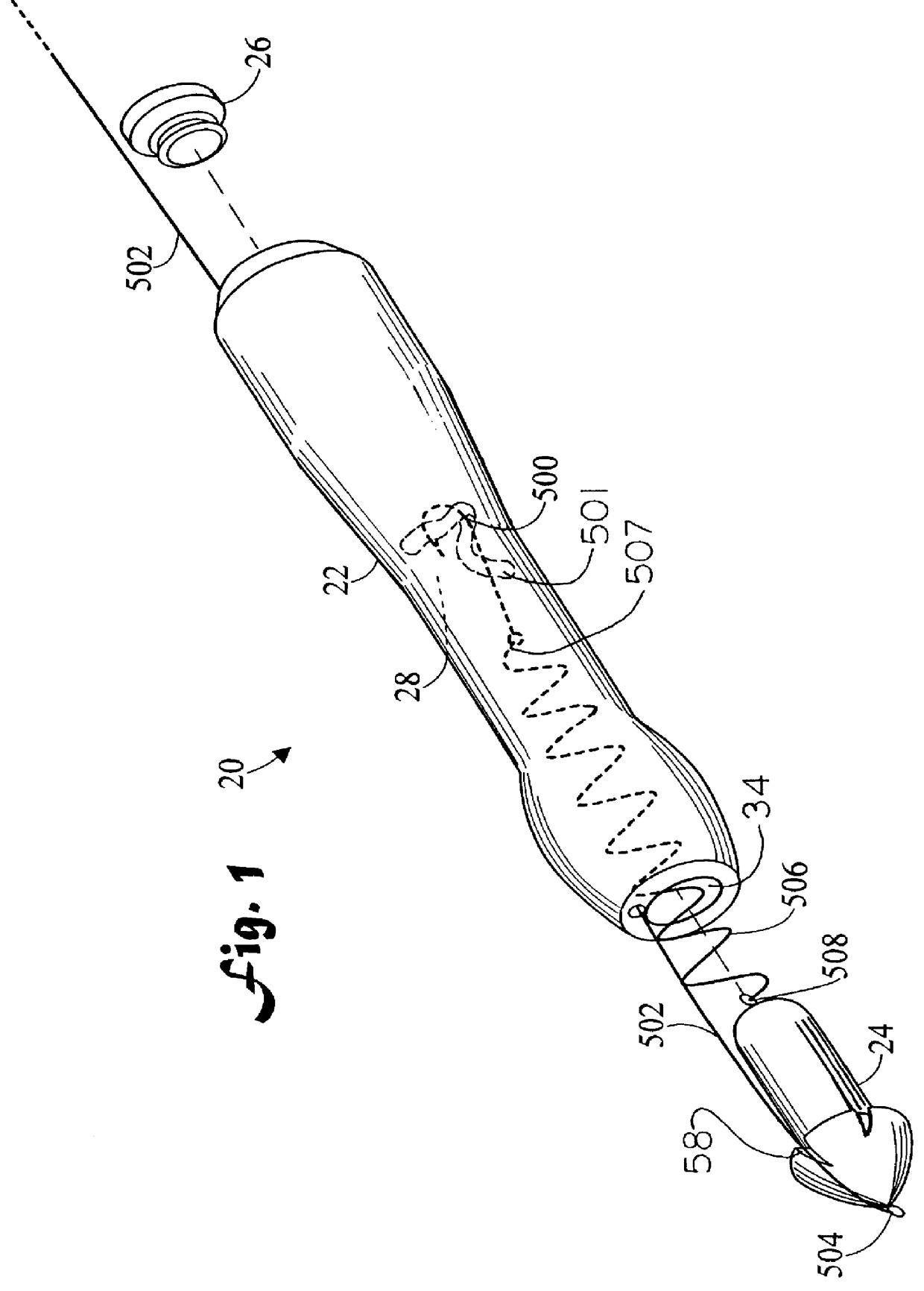

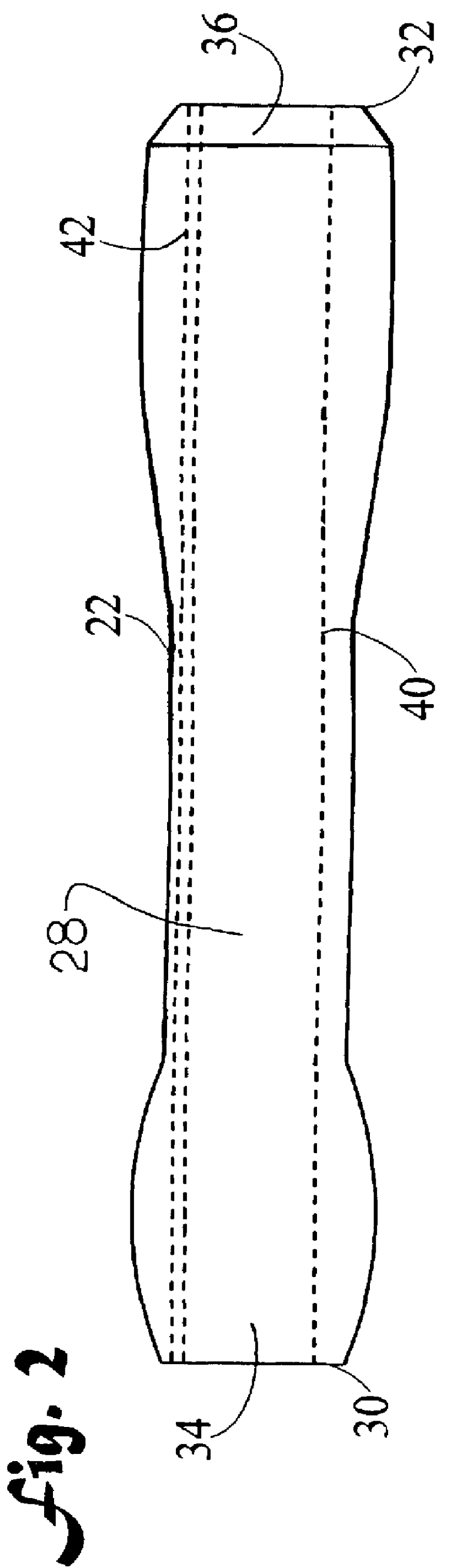

Apparatus (20) for safely casting a fishing hook (500) and fishing line includes a float (22) having a cavity (28) for receiving the bait (501), fishing hook (500), leader (506), and sinker (24). The sinker is slidably received in the mouth (34) of the cavity (28) which is at the front end (30) of the float. The main fishing line (502) is tied to the front of the sinker and passes through a secondary tube (42) inside the float exiting the rear end (32) to the fisherman. Float (22) and installed sinker (24) have a streamlined configuration. The fisherman casts the apparatus over the water (510) using a fishing rod. Upon impact of the apparatus with the water, the sinker continues due to inertia pulling the leader, fishing hook, and bait out of the cavity allowing them to sink into the water.

Owner:LIM JESUS P

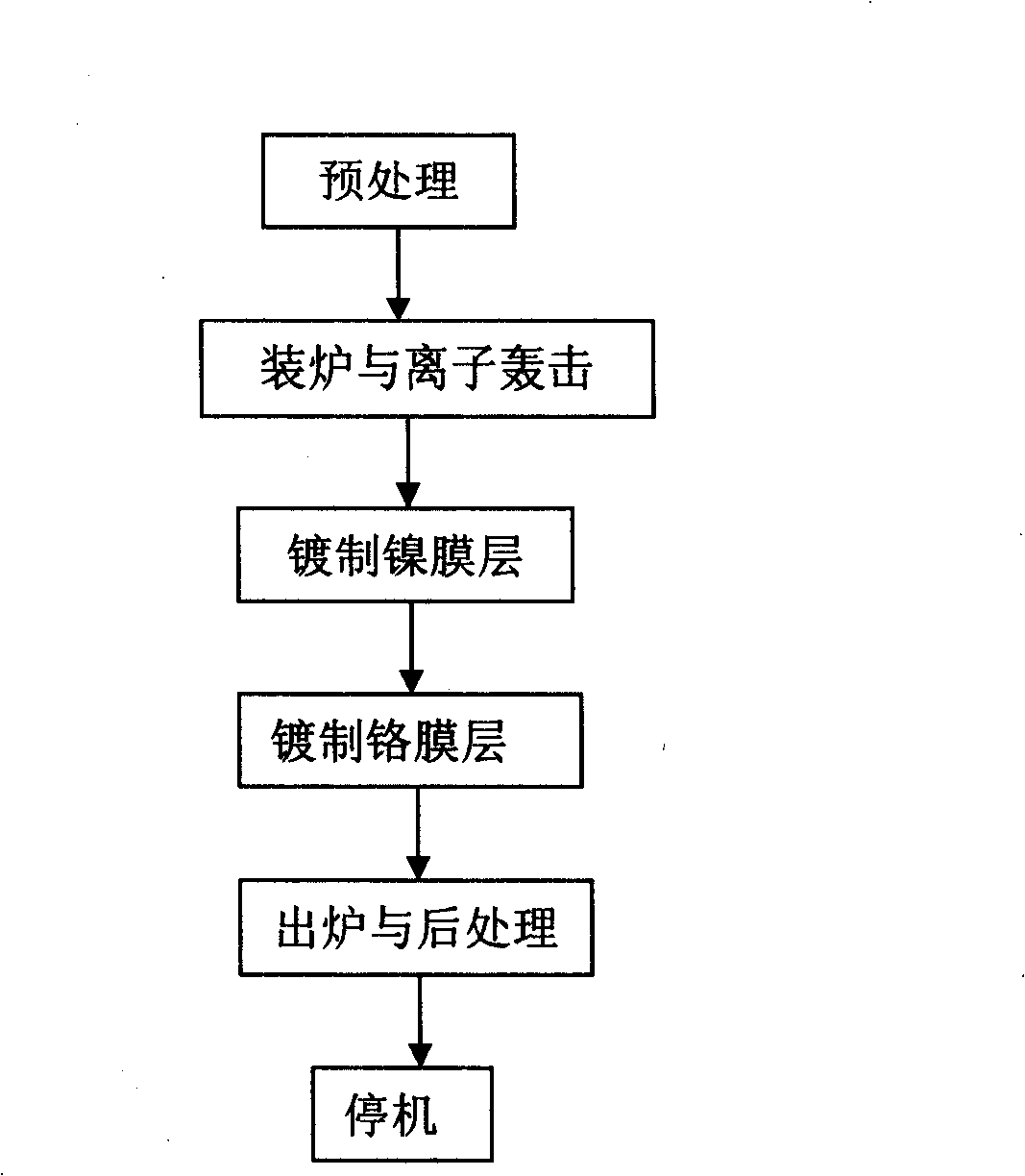

Combined vacuum coating process of magnetron sputtering and multisphere ion plating

InactiveCN101307428AEliminate environmental pollutionSimple processVacuum evaporation coatingSputtering coatingIonPre treatment

The invention relates to a magnetron sputtering and multi-arc ion plating composite vacuum coating method, which is characterized in that: the method utilizes a magnetron sputtering and multi-arc ion plating composite vacuum coating machine and adopts the composite vacuum coating method of nickel plating through magnetron sputtering and chrome plating through multi-arc ion plating; the method comprises the following six steps of pretreatment, charging and ion bombardment, plating of a nickel film, plating of a chrome film, discharging and aftertreatment, and stopping; and a nickel / chrome composite film is plated on a copper substrate, which can realize charging of a workpiece to be coated at a time to finish plating of the nickel film and the chrome film. The product plated by the method meets the requirements of a corrosion and abrasion resistant coating of a copper water heater; and the method can replace the prior water galvanizing and solve the problem of environmental pollution caused by the prior water galvanizing. The method can realize high-efficiency mass production without environmental pollution.

Owner:玉环金源比特科技发展有限公司

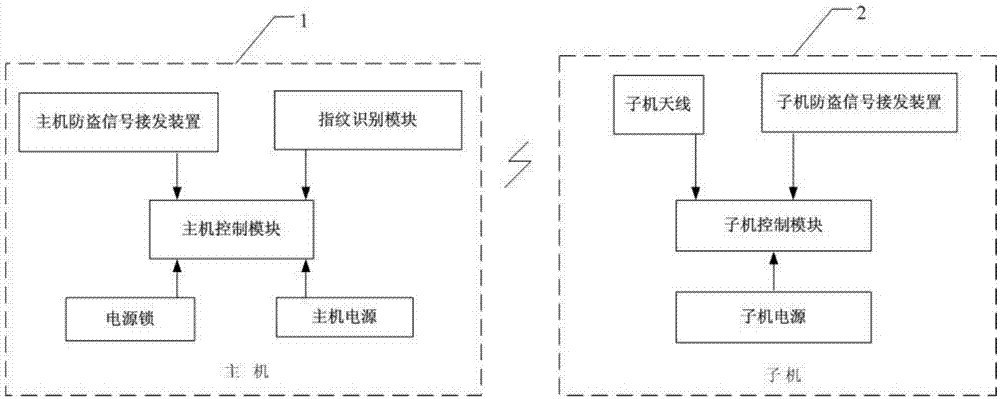

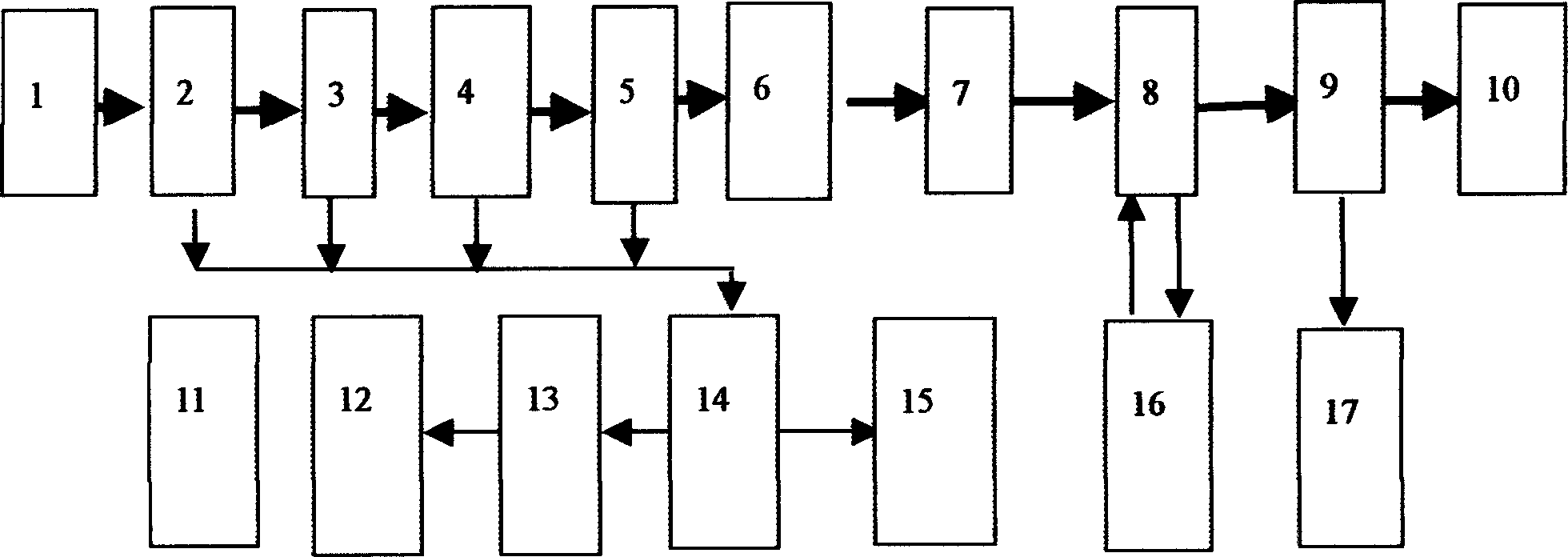

Anti-theft system of mobile phone

InactiveCN103595863AWith anti-lost functionFunction increaseTelephone set constructionsBurglar alarm electric actuationElectricityEngineering

The invention discloses an anti-theft system of a mobile phone, and belongs to the technical field of telecommunication. The anti-theft system of the mobile phone comprises a primary machine and a secondary machine. The primary machine is communicated with the secondary machine through wireless electric signals. The anti-theft system of the mobile phone has the advantages that after an anti-theft device is turned on, if the mobile phone is stolen, the mobile phone can give an alarm in 1s-2s, rings all the time and is free of influences when turned on or turned off; the large alarm sound can help a user determine the position of the mobile phone; the anti-theft device has the anti-lost function, and when the user places the mobile phone at a certain place and forgets to take the mobile phone, the mobile phone can give an alarm to remind the user when the mobile phone is more than 8m away from the user; a battery lock can automatically lock the mobile phone when the mobile phone is turned on, and the battery lock can not unlock the mobile phone under the situation that fingerprints of the user do not exist, so that a thief is prevented from disassembling a battery to forcefully break off the alarm after stealing the mobile phone; due to the use of a fingerprint identification board, the anti-theft device of the mobile phone is safer and more convenient to use; in addition, the fingerprint identification board of the anti-theft device of the mobile phone can be shared with other functions of the mobile phone, and the functions of the mobile phone are added; the price of the anti-theft device of the mobile phone is only 170 RMB, and the anti-theft device of the mobile phone is excellent in quality and reasonable in price from the point of view of the cost performance.

Owner:SHENYANG JIANZHU UNIVERSITY

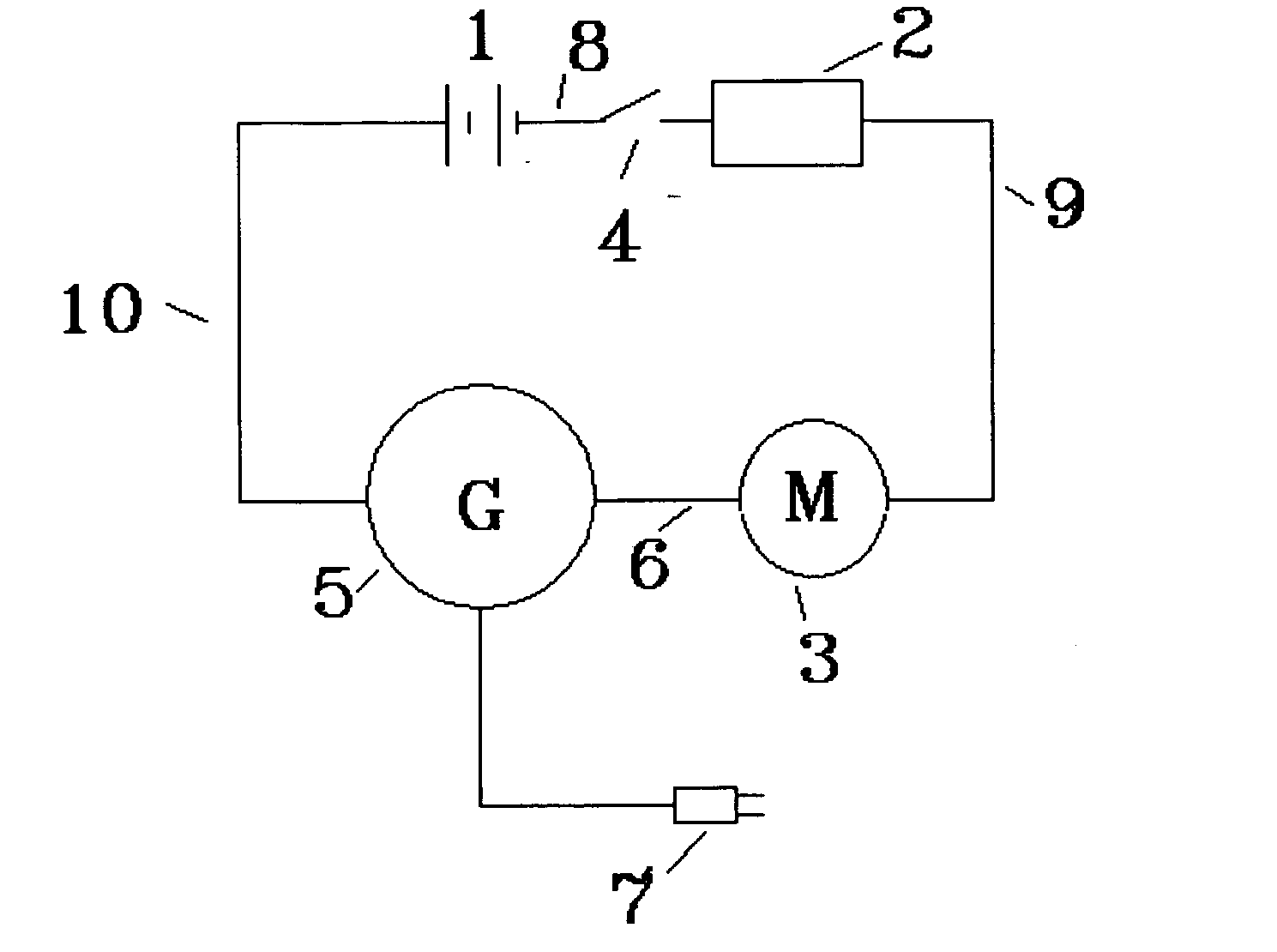

Generator system

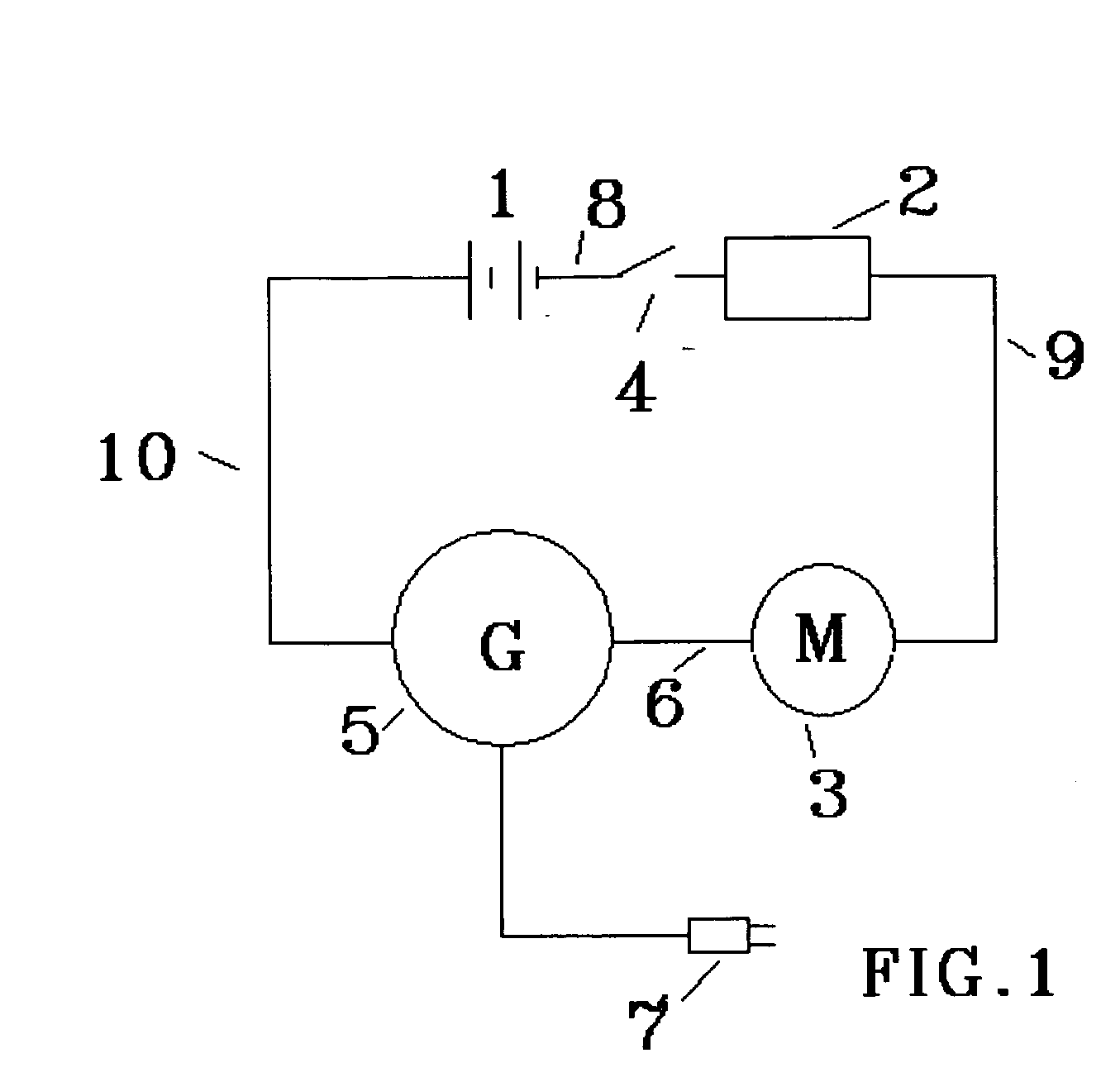

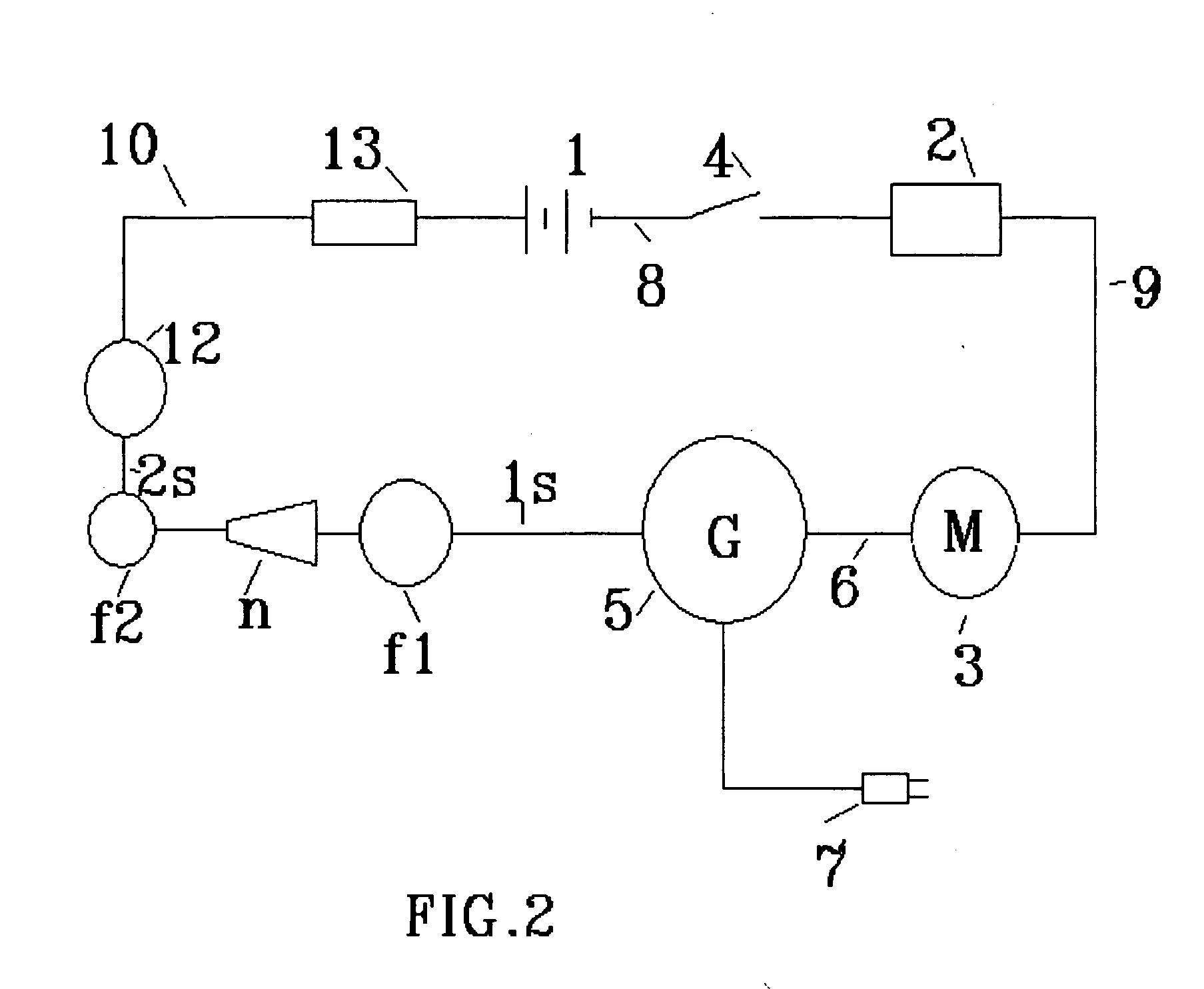

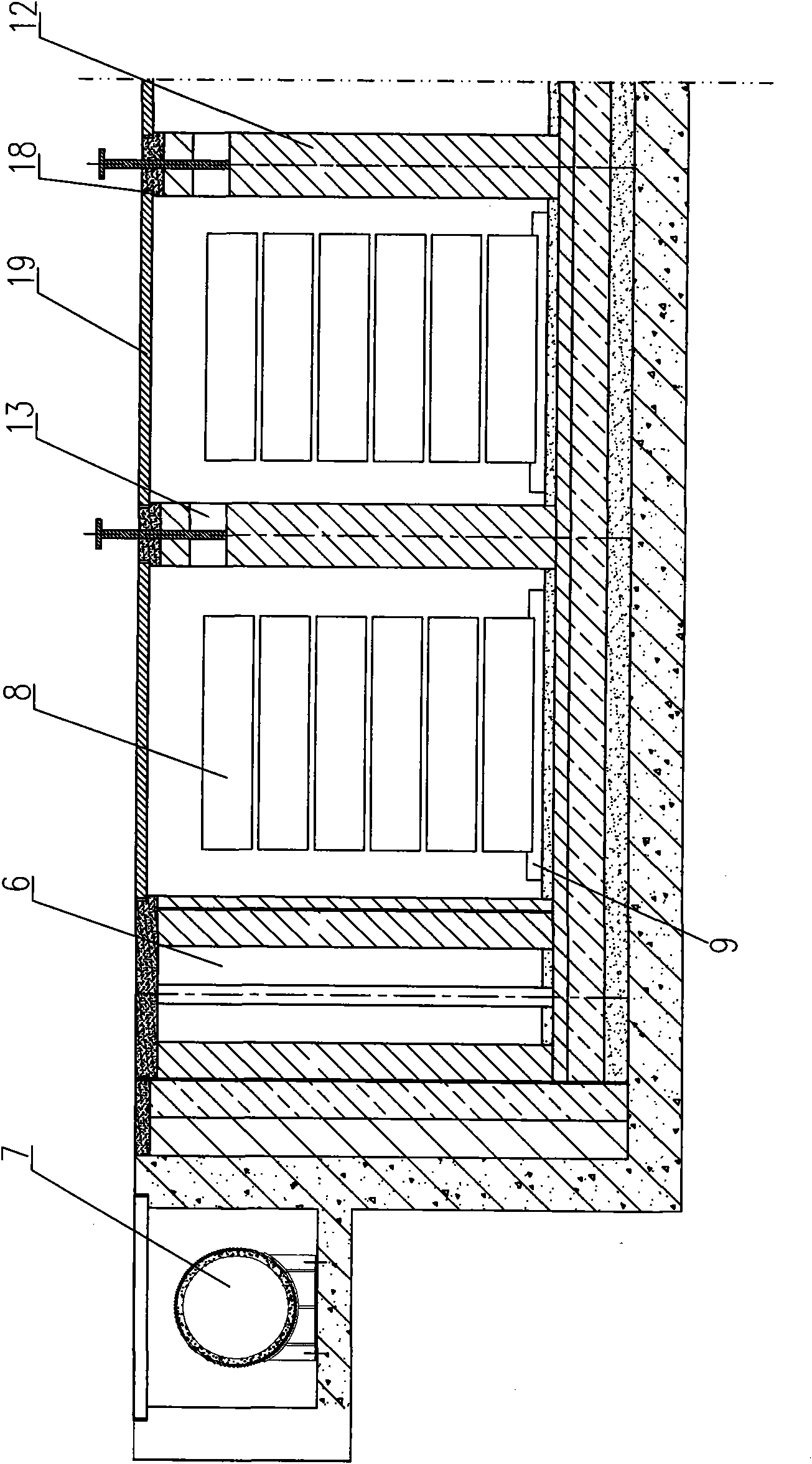

InactiveUS20060152007A1Reduce noiseRemove pollutantsMachines/enginesMechanical energy handlingElectric power transmissionTransmitted power

A generator system includes a DC battery, an inverter, AC motor and a generator. The generator is use to transmit power to an alternating current source, such as an entire house, a refrigerator, a TV, etc. In order to run the generator, a DC battery is connected to an AC motor to supply energy so that the motor can run the generator. An inverter is introduced between the DC battery and the AC motor to change direct current to alternate current. The DC battery is charged in different ways, such as using part of the power generated by the generator or a battery charger or a 12VDC generator.

Owner:ORTIZ JORGE L

Method for recovering and utilizing three wastes during titanium white production through sulfuric acid process

ActiveCN102431975AEliminate environmental pollutionReduced decomposition temperatureCalcium/strontium/barium sulfatesFerrous oxidesSlagGypsum

The invention discloses a method for recovering and utilizing three wastes during titanium white production through a sulfuric acid process, which is characterized in that crystal water is removed from titanium white waste slag copperas, anhydrous titanium white waste slag is reduced and decomposed into ferrous oxide residue and sulfur dioxide gas by reducing agents in weak oxidization mixing atmosphere at high temperature, sulfuric acid prepared by sulfur dioxide gas returns the acidolysis work procedure in the titanium white production process, the decomposed ferrous oxide residue is directly used for neutralizing the 10 to 25 weight percent waste sulfuric acid generated in the titanium white production process, excessive ferrous oxide residues can be used as raw materials for producingferric oxide series pigments and for steel plants, crystal water is removed from titanium white waste slag red gypsum, semihydrated gypsum is obtained, the semihydrated gypsum is reduced and decomposed into calcium oxide residue and sulfur dioxide gas by reducing agents in weak oxidization mixing atmosphere at high temperature, the sulfur dioxide gas can be used for preparing sulfuric acid, ferrous waste water and 0.1 to 10 percent waste sulfuric acid are neutralized by calcium oxide residues or quick lime, ferrous red gypsum is obtained through filtering, and the filter liquid can be reused.

Owner:SICHUAN UNIV

Secondary roasting furnace for carbon products and roasting method of secondary roasting furnace

InactiveCN102381696AEliminate environmental pollutionLower fuel consumptionChemical industryFlueAsphalt

The invention discloses a roasting furnace, and particularly relates to a secondary roasting furnace for carbon products. The secondary roasting furnace is structurally characterized in that two rows of furnace chambers are symmetrically arranged on two sides of a furnace central line in a furnace body, each row of furnace chambers consists of a plurality of single chamber bodies, each single furnace chamber body is divided into n-1 material tanks by n flame paths, each material tank comprises flame path walls on two sides, transverse walls at two ends and a material tank bottom, a light heat-insulation furnace cover for sealing is arranged on the top of each material tank, volatile matter balancing channels are arranged on upper portions of the flame path walls, volatile matter flowing channels are arranged on upper portions of the transverse walls, ends of the two rows of furnace chambers are connected by communicating flame paths, volatile matter flowing control gate discs are inserted into the volatile matter flowing channels from tops of the transverse walls, smoke vents are disposed on upper surfaces of the transverse walls and communicated with smoke discharge devices, the smoke discharge devices are communicated with a main smoke flue, and flame path gate discs are arranged among the flame path walls of the adjacent single furnace chamber bodies. Asphalt volatile matters generated during roasting are guided to the high-temperature flame paths to be completed burned, and environmental pollution due to the fact that asphalt smoke is discharged into the atmosphere is thoroughly eliminated.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Composite emulsion breaking scavenging agnet and preparation method thereof

InactiveCN101139115ALow costEliminate environmental pollutionWater/sewage treatment by flocculation/precipitationChemical industryChemistry

The present invention relates to a compound emulsion clarifier consisting of two clarifiers of A and B applied to waste water purification treatment of ABS chemical industry production line. Calculated by weight percentage, the clarifier of A consists of 16 to 18 percent of octadecyl methacrylate, 2 to 4 percent of APAM, 22 to 25 percent of AEO and water. The clarifier of B consists of 2 to 4 percent of CPAM, 36 to 38 percent of PFS, 20 to 22 percent of polyaluminium chloride and water. The clarifiers of A and B are respectively deposited and matchedly utilized to carry through emulsion separation on the white emulsion waste water discharged by the ABS chemical industry production line to lead the ABS material to be separated out as white floccule to realize recycling of waste materials; the water discharged is colorless transparent rinsing and can be recycled or discharged with meeting the requirements of national standards. The application of the present invention can save the cost of chemical plants and eliminate the environment pollution of the water discharged by chemical plants, thereby acquiring good economic effect, social effect and environment protection effect. The present invention is suitable for popularization and application.

Owner:马冬兰

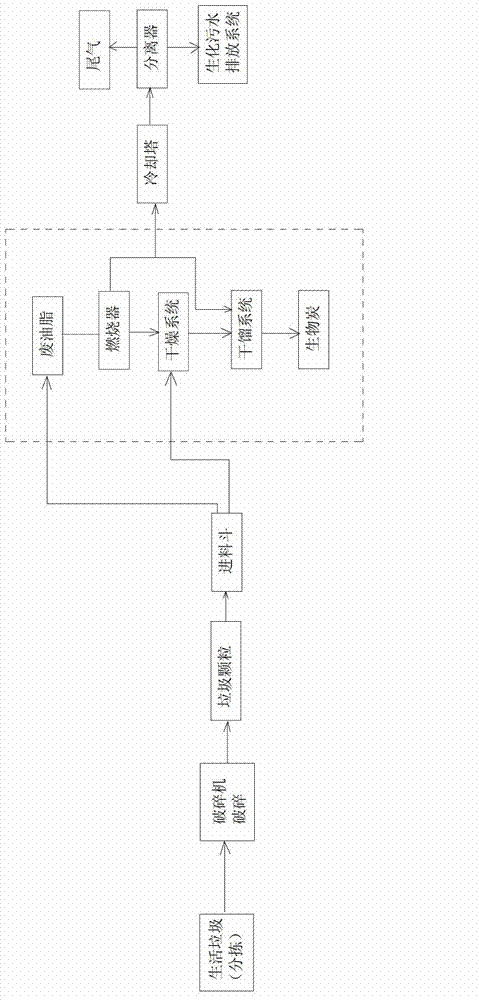

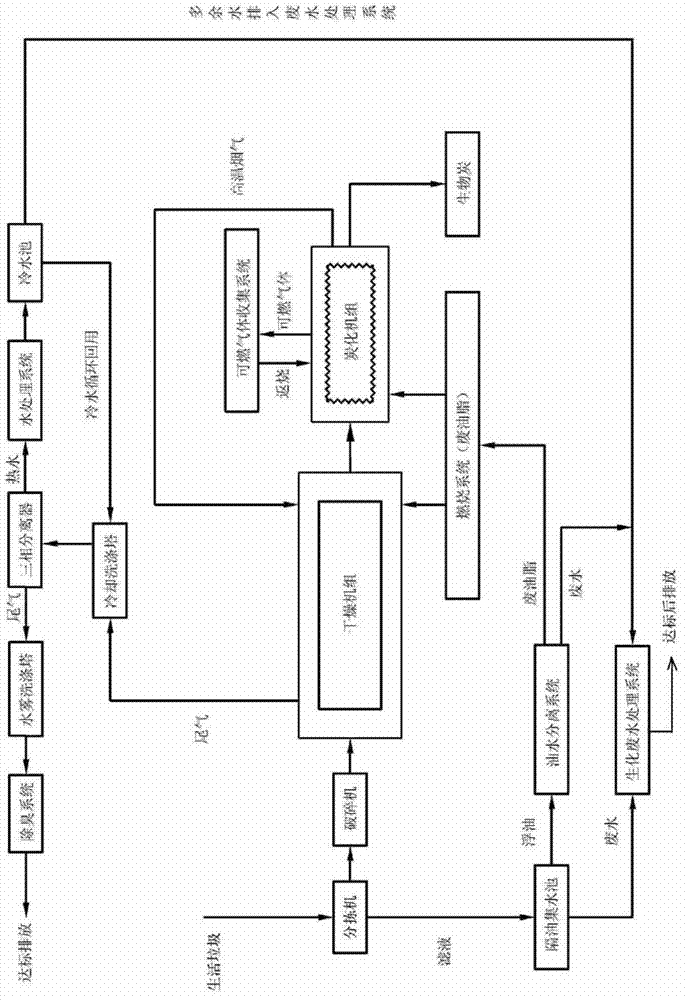

Environment-friendly comprehensive treatment method for household garbage and waste oil and fat

ActiveCN103111455AIncrease valueEliminate environmental pollutionSolid waste disposalDirect heating destructive distillationHot blastScrew conveyor

The invention discloses an environment-friendly comprehensive treatment method for household garbage and waste oil and fat. The method comprises the following steps of: (1) sorting the household garbage, breaking the household garbage into garbage particles through a breaking machine, and conveying the garbage particles to a feeding hopper through a spiral transmitting machine; (2) carrying out the procedures of pre-heating, drying and dry distillation on the garbage particles to obtain charcoal through a sealed spiral conveying machine; (3) separating part of waste oil and fat into two parts through an oil and water separating system, and burning one part of waste oil and fat as fuel through a hot blast stove so as to perform drying and dry distillation on the garbage and convert the garbage into charcoal; and (4) treating the other part of wastewater through a biochemical wastewater treatment system, and discharging the processed wastewater reaching the standard. The comprehensive treatment method disclosed by the invention is a hazard-free, reducing and recycling technology for the household garbage, is free from pollution in processing, low in cost, good in practicability and high in operability, and has remarkable social and economic benefits.

Owner:陈丰

Magnetron sputtering rose gold target material and preparation method thereof

ActiveCN101358331ABright colorUniform colorVacuum evaporation coatingSputtering coatingSputteringIndium

The invention relates to a magnetic control spattering rose gold target and a preparation method thereof, which is characterized in that the components of the rose gold target by weight percent are as follows: 65 weight percent to 78 weight percent of gold, 16 weight percent to 33 weight percent of copper, 0.01 weight percent to 4 weight percent of yttrium, 1 weight percent to 7 weight percent of zinc, 0.001 weight percent to 1.2 weight percent of cobalt, 0.001 weight percent to 0.2 weight percent of stibium and 0.02 weight percent to 5 weight percent of indium. The preparation method comprises the following steps: the copper and the cobalt are heated and melted, the yttrium, the zinc, the stibium and the indium are added into the melted cooper and cobalt, to be refined for 3min under 1400 DEG C to 1450 DEG C, and the intermediate alloy material is obtained after conventional surface milling, rolling and shearing; the gold is heated and melted, and the prepared intermediate alloy material is added into the melted gold to be refined for 5min under 1200 DEG C to 1300 DEG C; the magnetic control spattering rose gold target prepared by the invention can eliminate the environment pollutin and product oxidability caused by a galvanic plating process, has stable performance and extremely good decoration effect.

Owner:沈阳东创贵金属材料有限公司

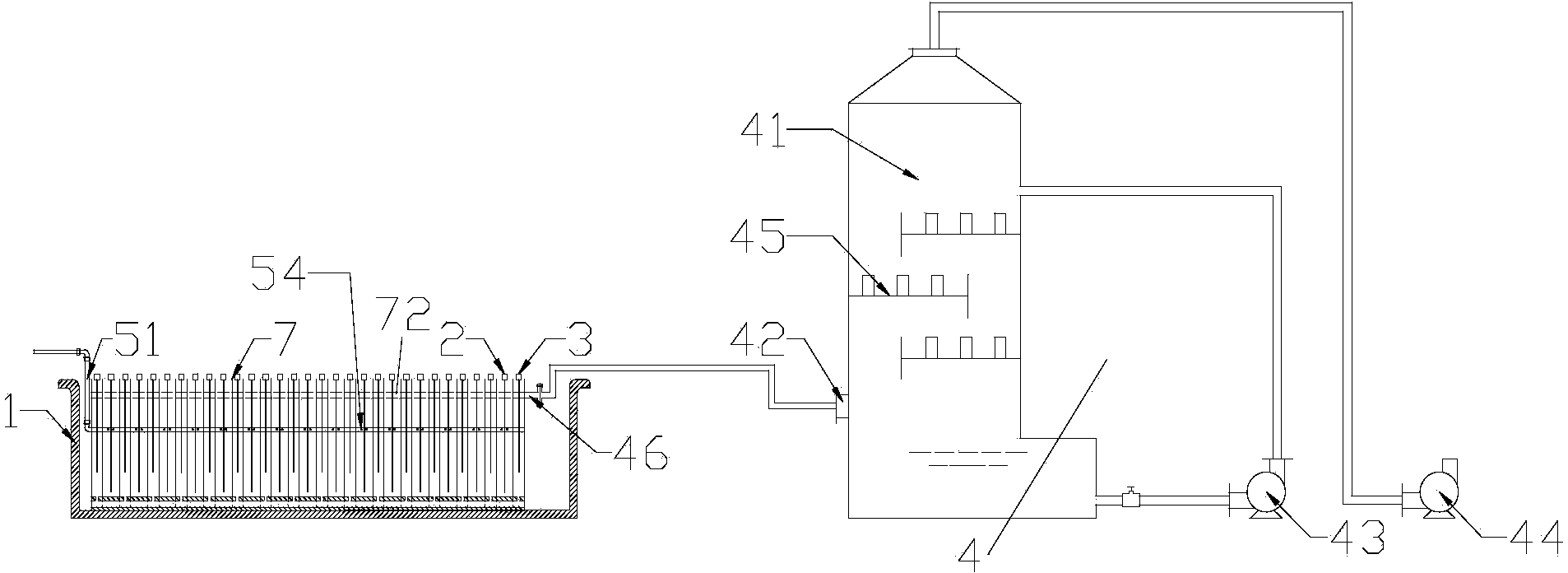

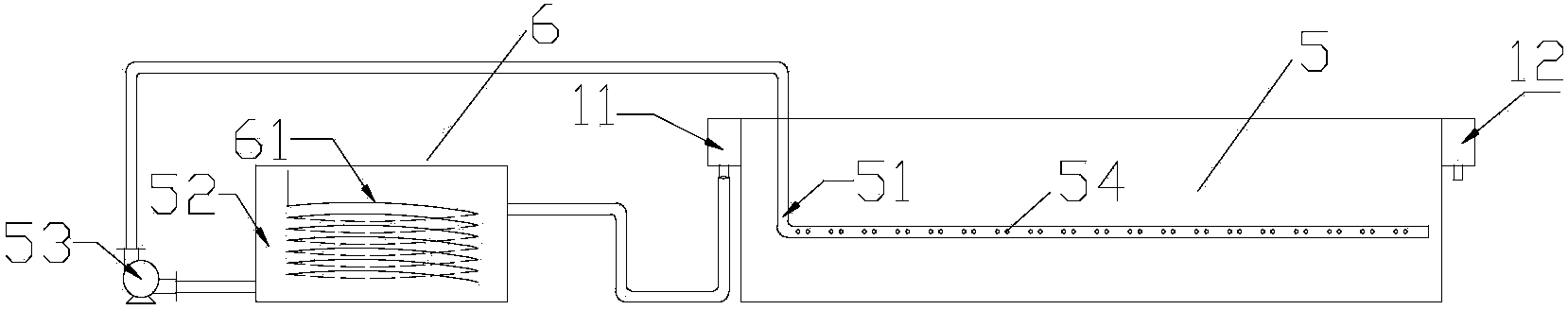

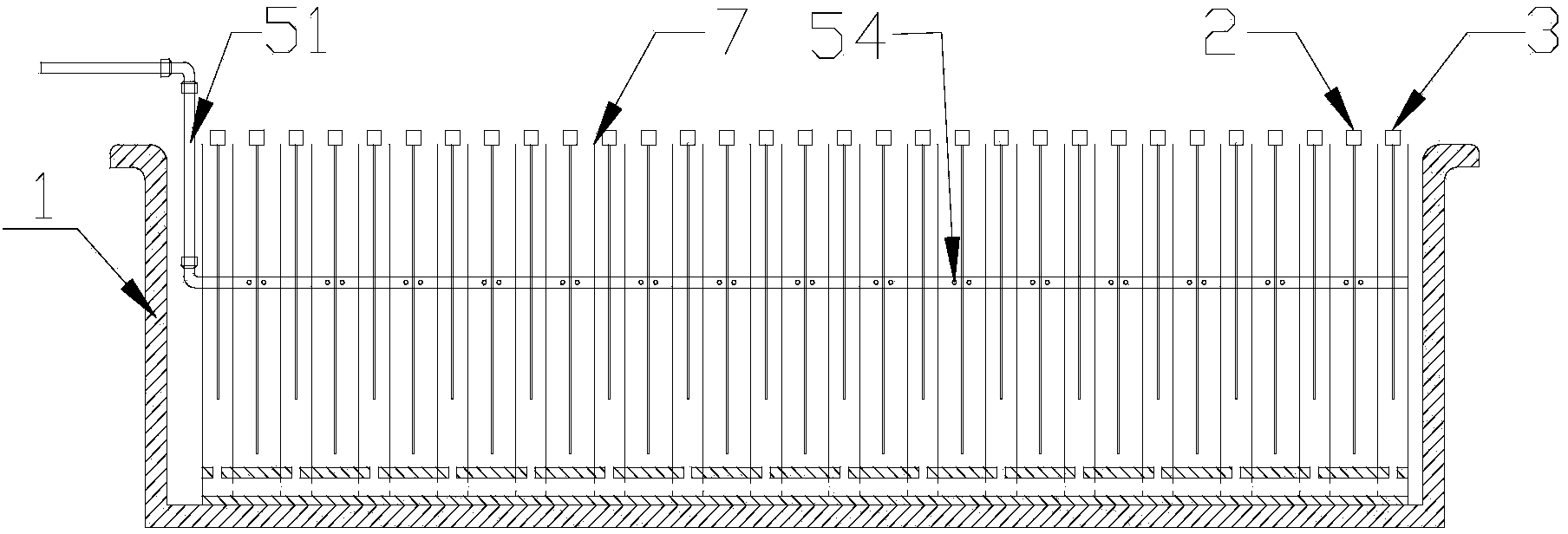

Environmental-protection and energy-conversion type diaphragm electrolysis device

ActiveCN104032328AEliminate environmental pollutionImprove current efficiencyPhotography auxillary processesDiaphragmsWater circulationEnvironmental resistance

The invention relates to an environmental-protection and energy-conversion type diaphragm electrolysis device. The device comprises an electrolytic bath, cathode plates and anode plates, wherein the cathode plates and the anode plates are accommodated in the electrolytic bath; the device further comprises an acid mist catching device; the acid mist catching device comprises an acid mist absorption tower, a water pump and an exhaust fan; diaphragm frame sets are arranged between the cathode plates and the anode plates; acid mist collecting holes are formed in the two sides of the upper parts of the diaphragm frame sets, and form acid mist catching channels; acid mist generated on anode is caught through the exhaust fan; tower plates are arranged in the acid mist absorption tower; and the middle between the bottom end and the upper end of one side of the acid mist absorption tower is connected with the water pump to form water circulation. The environmental protection and energy conversion type diaphragm electrolysis device has the following benefits: the diaphragm frame sets are arranged to realize overall sealing of an anode room; the acid mist on the anode is effectively collected to eliminate the pollution; meanwhile, a forced catholyte circulating device realizes forced catholyte circulation to realize the purposes of eliminating the concentration polarization and improving the cathode current efficiency so as to reduce the electric consumption; and the device realizes the outer circulating cooling of the electrolytic bath, improves the cooling efficiency, and achieves the purposes of reducing the energy consumption and decreasing the cost.

Owner:HANGZHOU SANAL ENVIRONMENTAL TECH

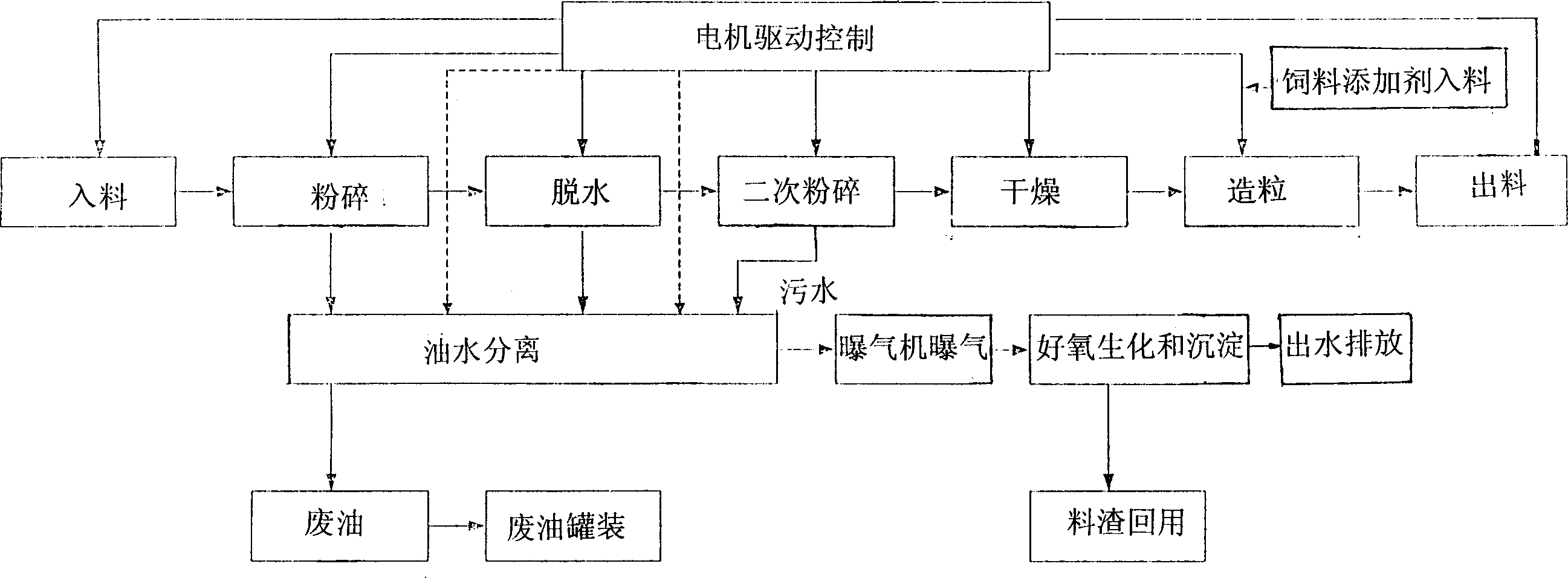

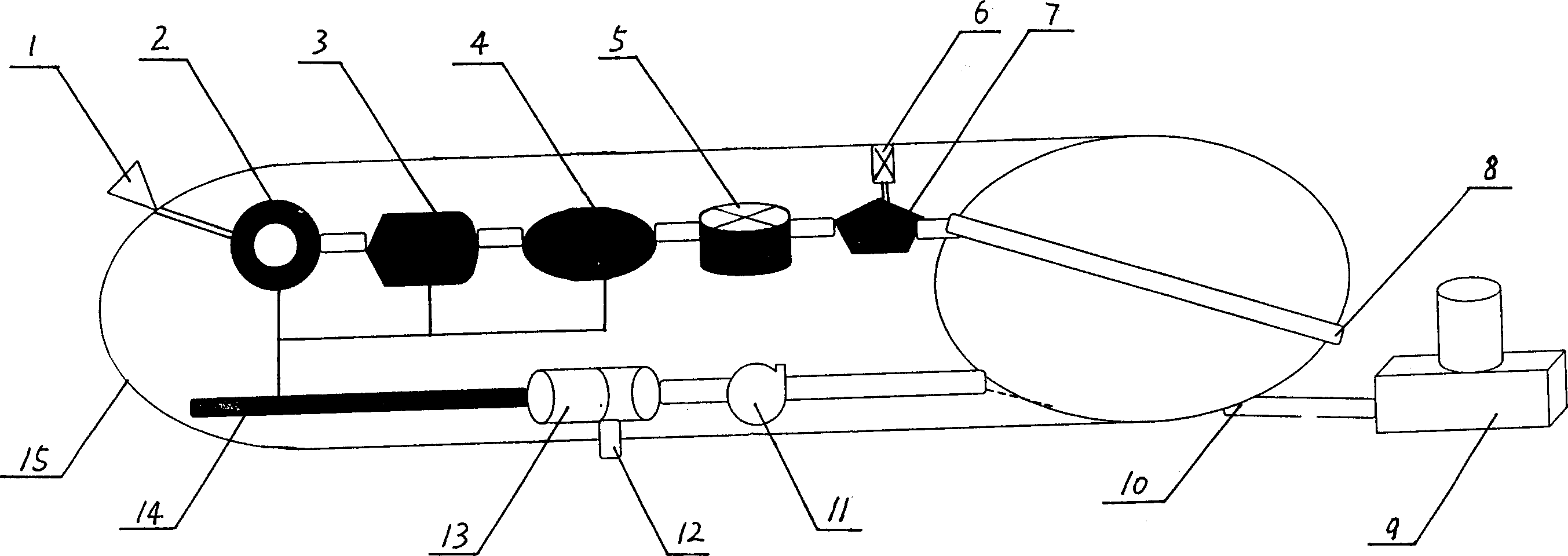

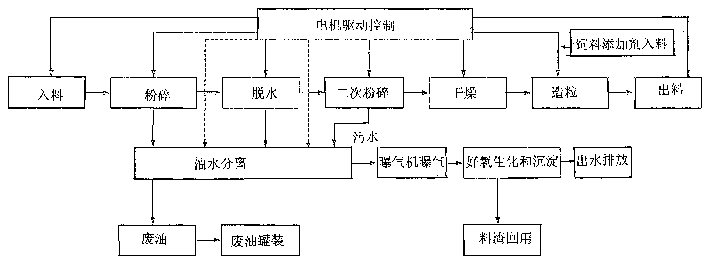

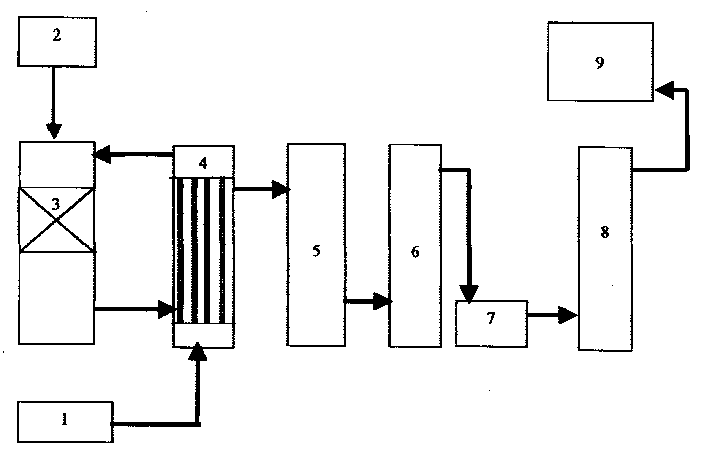

Method for treating food and beverage refuse into fodder and complete equipment

InactiveCN1391824AReduce drying energy consumptionSimple processFeeding-stuffFood processingEngineeringOil water

The present invention relates to the method and system for treating restaurant and catering refuse into fodder. The treating process includes crushing, dewatering, secondary crushing, drying, sterilizing, mixing with additive, palletizing, oil-water separation of effluent, aerating waste water and other steps. The system includes various apparatus to complete the said steps and all the apparatus are inside one sealed cylinder for automatic closed running. By means of the method and system of the present invention, restaurent and catering refuse may be produced into granulated fodder reaching relevant sanitary and nutritive standards.

Owner:吴桐

Low-zincium organophosphor scale inhibitor for recirculated cooling water process

ActiveCN101244872AEliminate environmental pollutionReduced zinc contentScale removal and water softeningPhosphoric acidCorrosion

The invention relates to an environment-friendly low-zinc organic phosphorus corrosion and scale inhibitor, which comprises the following components in percentages by weight: organic phosphono-carboxylic acid (PBTC) 20 to 25%, organic phosphoric acid (HEDP) 10 to 12%, organic phosphoric acid ester 5 to 8%, zinc salt 3 to 4%, macromolecular dispersing agent with sulfonic group, mildew inhibitor 0.5%, and pure water accounting for the rest percentage. The corrosion and scale inhibitor in the invention has the advantages that: the zinc content in circulating water and sewer water is less than 1.5mg / L, and desirable corrosion and scale resistant effects can be achieved at the same time of reducing the pollution to the environment.

Owner:BAOSHAN IRON & STEEL CO LTD

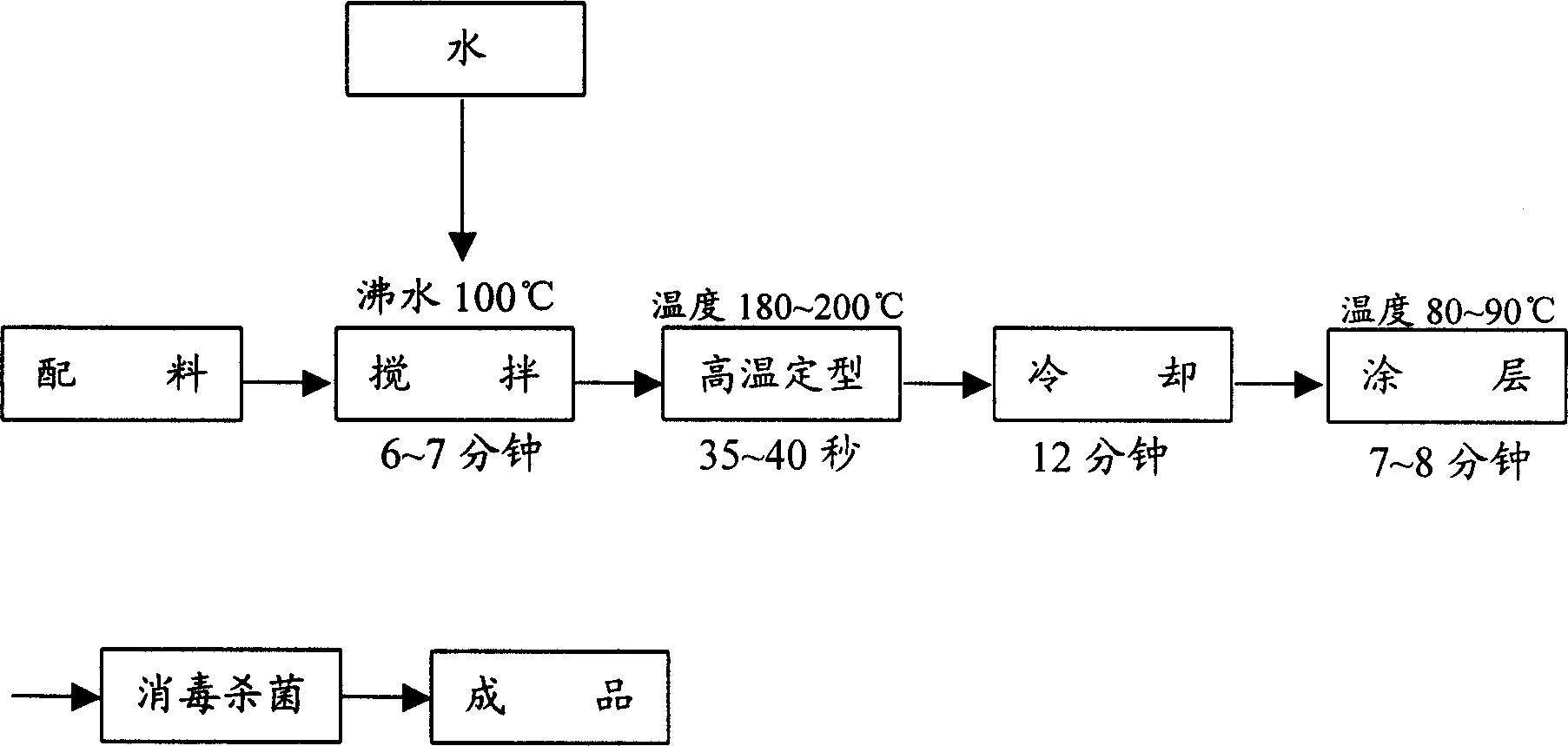

Process for preparing disposable full degradation product

The present invention relates to the field of tableware, and is especially the production process of degradable tableware, artistic article and packing material. The present invention features that starch in 30-70 wt%, edible talcum powder in 10-60 wt%, plant fiber in 6-12 wt% and husk powder in 40-50 wt% are produced into the product through mixing and high temperature setting. The technological process is simple and the product is degradable and low in cost.

Owner:沈阳祥溢植物纤维工艺制品厂

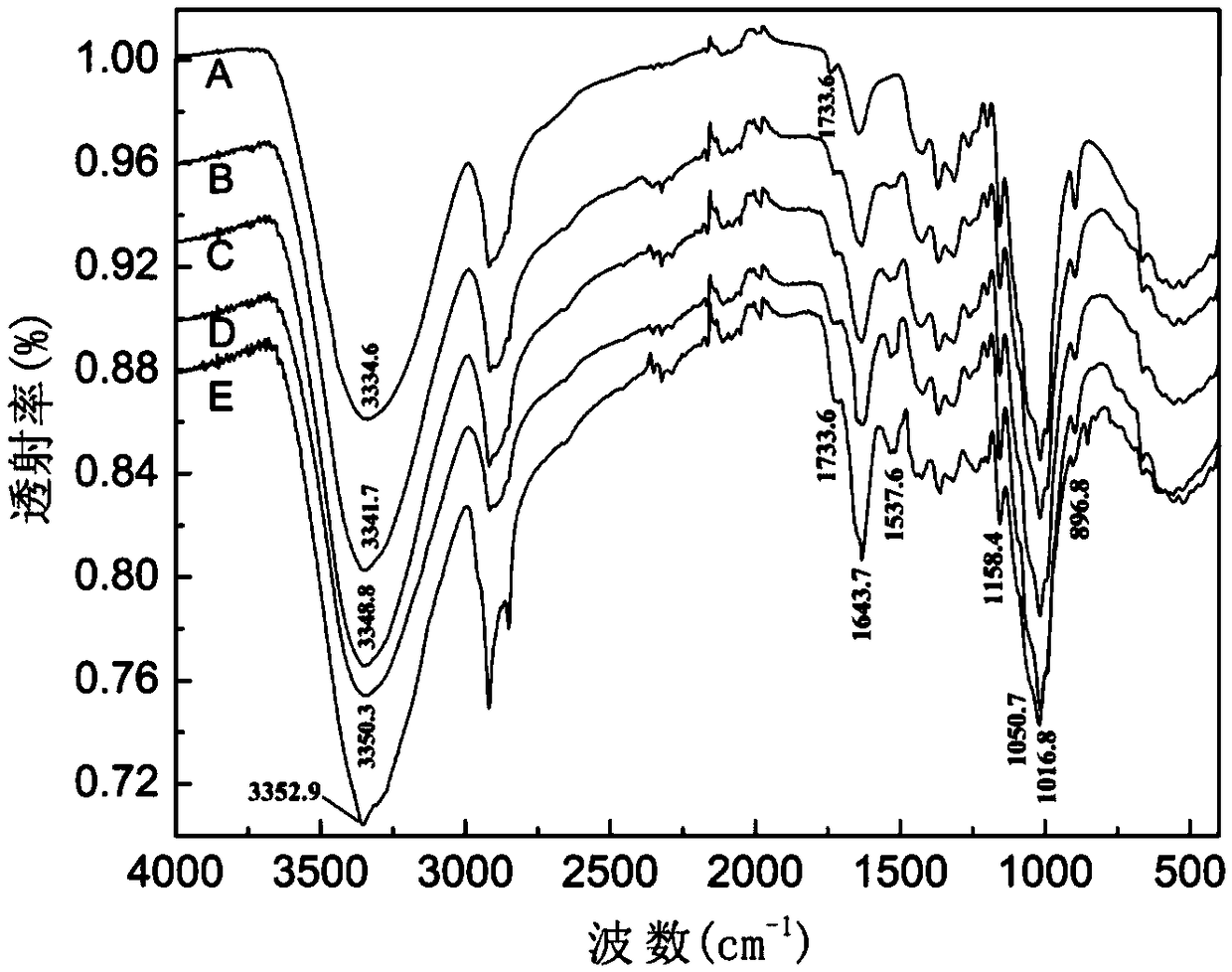

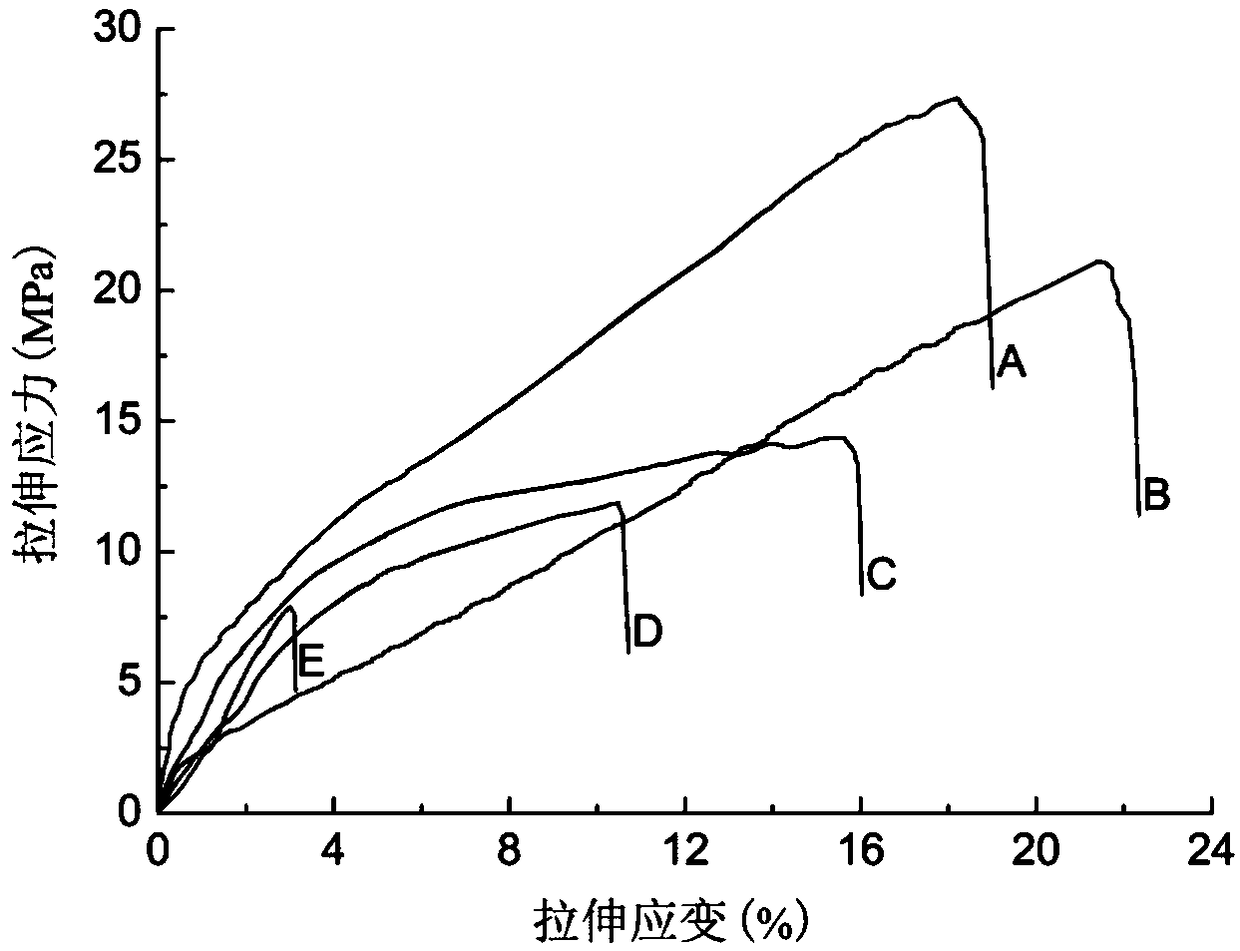

Cellulose based water-absorbing and oil-absorbing film and preparation method thereof

The invention discloses a preparation method of a cellulose based water-absorbing and oil-absorbing film. According to the invention, water-absorbing substances and oil-absorbing substances are grafted on lignocellulose, the prepared film is smart and convenient to use and is wide in application fields. The homogeneous grafting copolymerization is adopted, and the problems of the microphase separation of heterogeneous copolymerization, unsatisfactory grafting effect and uneven component distribution are avoided effectively. As the substrate material (namely, cellulose) has good degradability and can eliminate the pollution of the waste synthesized material to the environment and maintains the ecological balance, the problem that the common water-absorbing and oil-absorbing materials can not meet the water absorbing and oil absorbing properties and biodegradation simultaneously can be solved.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Method of preparing particulate phase toner using fractional dissolution and particulate phase toner prepared using the same

A method is provided for preparing a particulate phase toner for use in an electrophotographic image forming apparatus. The method uses fractional dissolution rather than pulverization and chemical preparation. Accordingly, it is easy to control the size and the shape of toner particles. The fluidity of the toner particles according to the invention is improved. The method of the invention also reduces or eliminate the environmental pollution. A particulate phase toner prepared by the method is also provided.

Owner:S PRINTING SOLUTION CO LTD

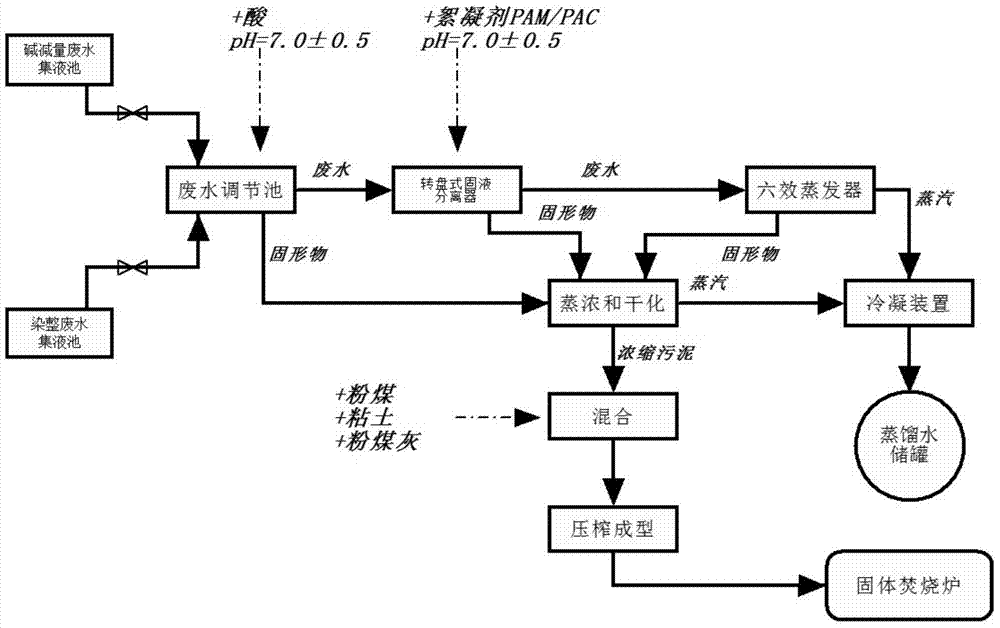

Wastewater zero discharge method in manufacturing process of island superfine fiber synthetic leather

InactiveCN103693792ASolve the technical bottleneck of zero emissionQuality improvementSludge treatment by de-watering/drying/thickeningBiofuelsFiberAluminium chlorohydrate

The invention discloses a wastewater zero discharge method in a manufacturing process of island superfine fiber synthetic leather. The method comprises the following steps: merging an alkali-minimization wastewater and a dyeing wastewater into a wastewater regulating reservoir, or merging the alkali-minimization wastewater into the wastewater regulating reservoir; adding acid to the wastewater regulating reservoir to form a solid matter; transferring the wastewater after the solid matter is cleaned into a turntable solid-liquid separator; adding a polyacrylamide flocculant and a polyaluminium chloride flocculant; evaporating the solid matter and the sludge obtained by solid-liquid separation in an evaporation tank, and simultaneously collecting distilled water in a condensation manner; transferring the wastewater from solid-liquid separation into a multi-effect evaporator to evaporate, and collecting distilled water by condensation; merging the residual residue in the evaporator into a sludge concentrating tank to continue to process. The production of the island superfine fiber synthetic leather is taken as a basic system, and is combined with collection, treatment and comprehensive utilization technologies of the production wastewater and the solid matter, the technical bottlenecks of wastewater zero discharge in the production process is solved, and the island superfine fiber synthetic leather which is friendly to environment and high in quality can be produced.

Owner:FUJIAN KELISHENG SUPERFINE FIBER

Method for producing two-layer transfer coating leather by aqueous polyurethane dry-method transfer coating process

InactiveCN102501442AImprove hygieneEliminate pollutionLamination ancillary operationsPolyureas/polyurethane adhesivesProduction lineSolvent based

The invention discloses a method for producing two-layer transfer coating leather by aqueous polyurethane dry-method transfer coating process. The method comprises the following steps of: firstly coating a bottom-closing foamed coating material on the surface of the split leather by use of a roll coating machine in leather production, and drying and then ironing by use of a drum-type ironing machine to form a bottom-closing foamed coating; then blade coating a top coating material and an adhesive coating material on release paper by use of a dry-method production line in synthetic leather production process; and finally, bonding the split leather with the bottom-closing foamed coating and the release paper with the adhesive coating, drying in a drying channel, cooling, separating, and transferring the coatings on the release paper onto the bottom-closing foamed coating, to obtain the two-layer transfer coating leather. The method produces the two-layer transfer coating leather by aqueous polyurethane dry-method transfer coating process and replaces the solvent-type polyurethane production system by the aqueous polyurethane production system, so as to eliminate pollution caused by solvents and solve the problem of MDF residues in the two-layer transfer coating leather. Besides, the method can enhance water permeability and vapor permeability of the coatings and improve health performance of the two-layer transfer coating leather final product.

Owner:SHAANXI UNIV OF SCI & TECH

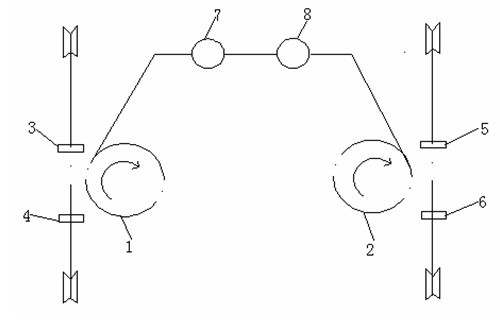

Method for applying diamond wire to mortar square cutting device

InactiveCN102490280ALarge output advantageEliminate environmental pollutionWorking accessoriesFine working devicesEngineeringCrystalline silicon

The invention relates to a method for crystalline silicon square cutting, in particular to a method for applying a diamond wire to a mortar square cutting device, which adopts a photoelectric sensor to monitor the diameter of a diamond wire wheel in real time and feed back to a computer control system. During square cutting, the correction time is regarded as a control point of the shutdown detection time, namely, at every interval of the correction time, a machine is shut down and the diameter of the wire wheel recorded by the photoelectric sensor is manually input to a system display value, then a program is recovered, cutting continues, and the operation is repeated until the cutting process is finished. The control system of the device makes corresponding adjustments on rotation speed of the wire wheel and enables the wire speed to approach to regulated speed so that real-time deviation rectification during the diamond wire square cutting process is achieved. Due to the fact that the operational steps of monitoring the diameter of the wire wheel in real time, shutting down the machine to input the monitored actual diameter to the system of the device and the like are added, breakage of steel wires during the diamond wire square cutting process is effectively avoided, processing quality of single crystal and polycrystal square rods is improved, and meanwhile the problem of environmental pollution caused by mortar cutting is resolved.

Owner:INNER MONGOLIA ZHONGHUAN SOLAR MATERIAL

Industrial preparing process of organic humic acid fertilizer

InactiveCN1397526AWide variety of sourcesEliminate environmental pollutionBio-organic fraction processingOrganic fertiliser preparationHumic acidEnvironmental chemistry

An organic humic acid fertilizer is industrially prepared from peat, fresh cow dung and filtered mud through proportioning, mixing, fermenting, supplementing oxygen and dewatering. It contains organic mass (20-50%), N+P2O5+K2O (15-30%), humi acid (6-10%) and water (0-10%). Its advantages are broad spectrum and high fertility.

Owner:福建省尤溪县绿地生物制品有限公司

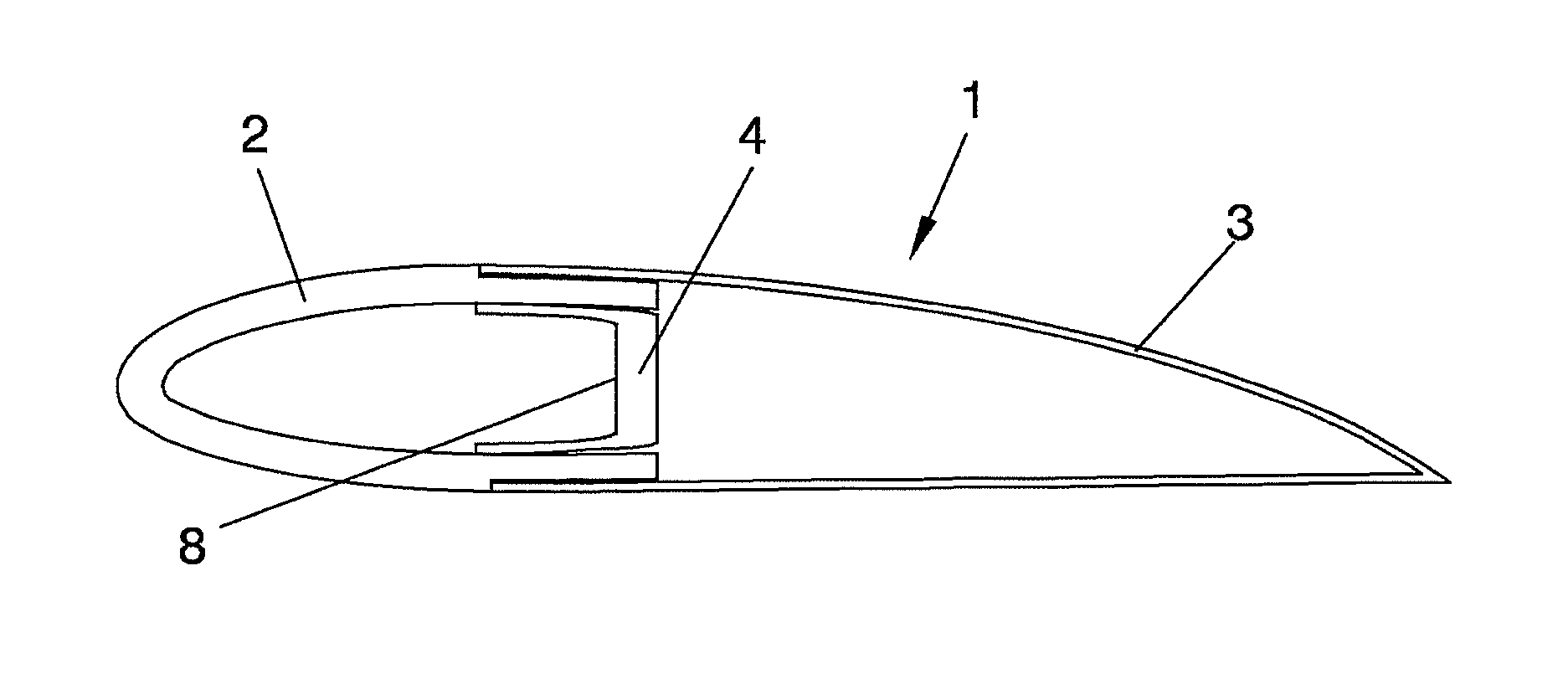

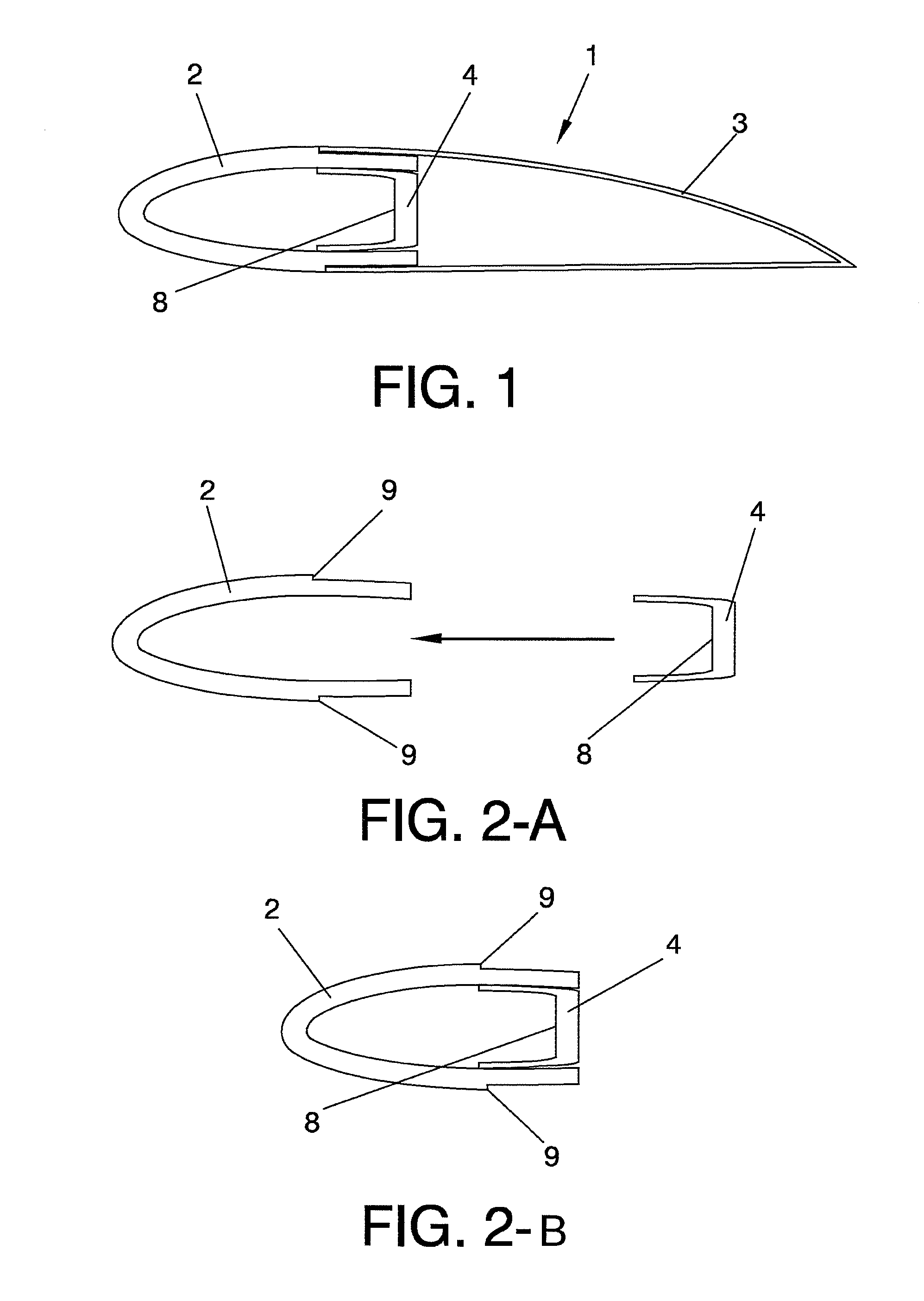

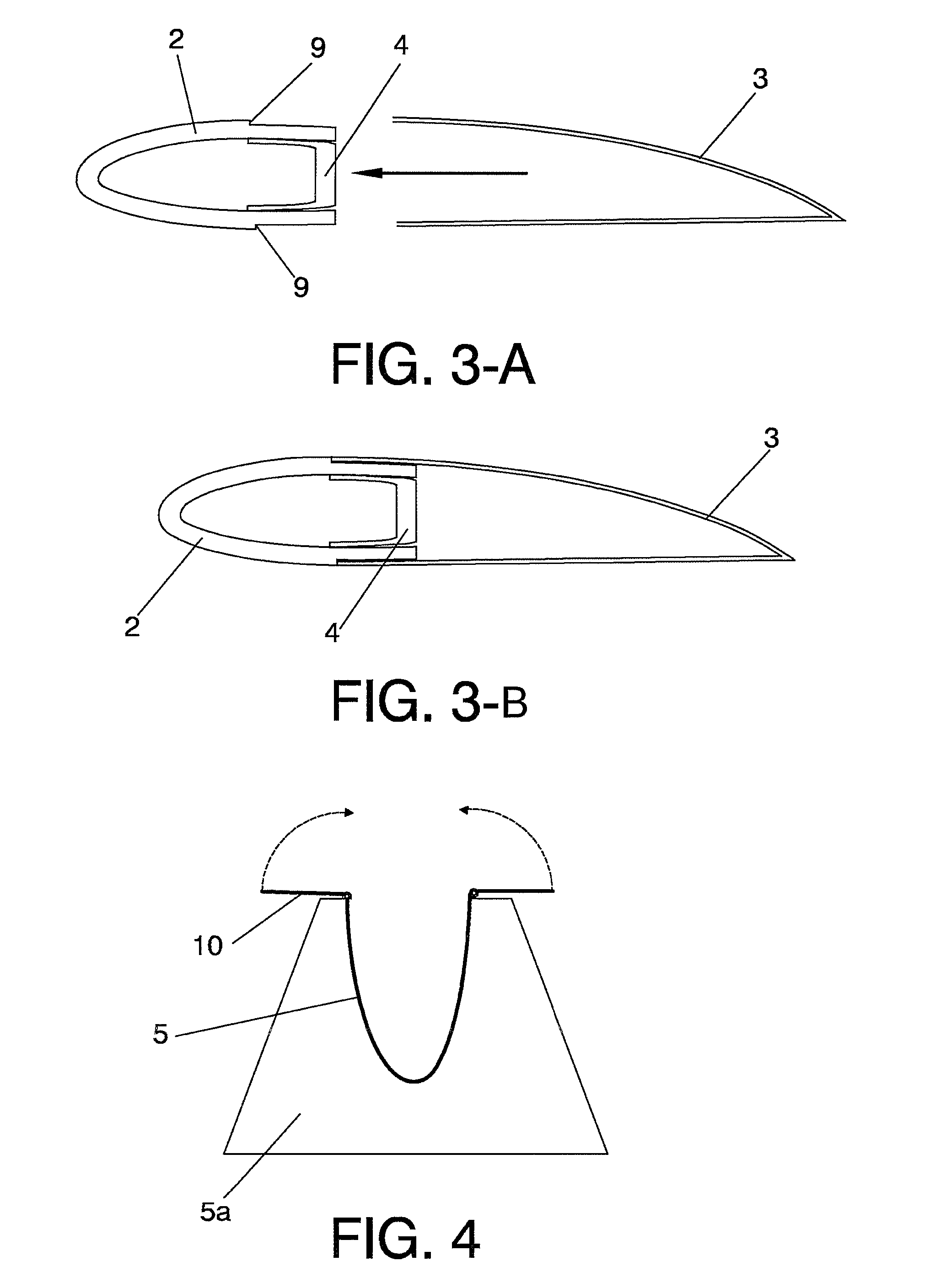

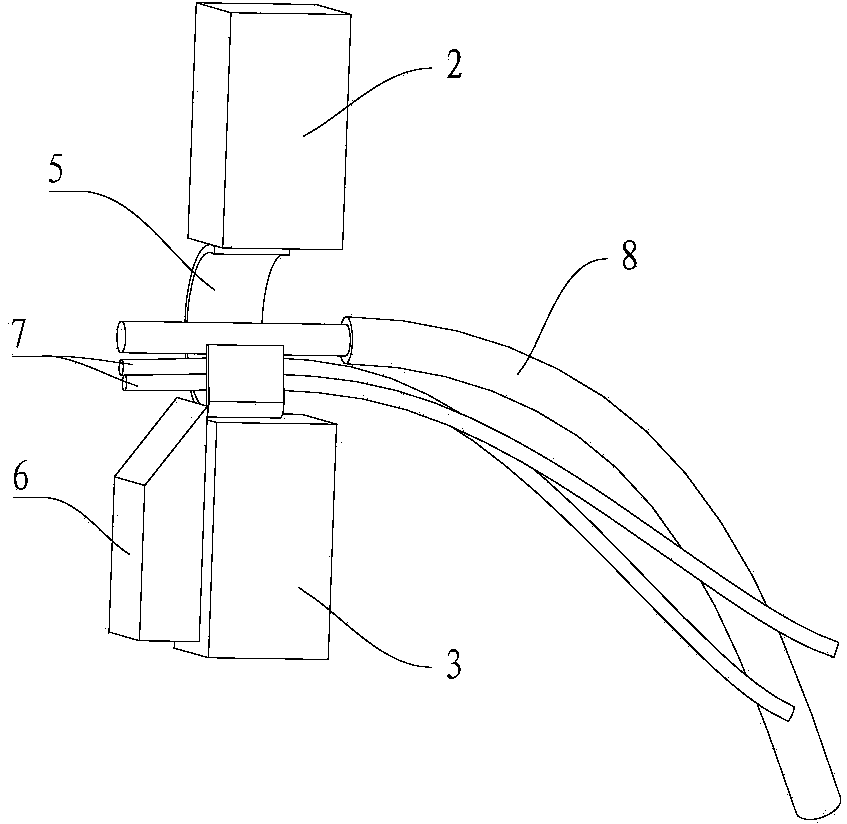

Method for manufacturing wind turbine blades, blades for propellors, wings, or similar structures, and structure in the form of a blade obtained by means of this procedure

InactiveUS20130340252A1Swift regulationSwift thermal controlFinal product manufactureMetal-working apparatusLeading edgeSingle stage

The invention relates to a method for manufacturing wind turbine blades, blades for propellers, wings or similar structures, and to a structure in the shape of a blade produced by means of said method, including: use a female mold of the leading edge (5), a female mold of the trailing edge (6), and a third mold (7) for a composite male tool (8) as a lost mold for manufacturing at least an inner crossbeam (4); wherein a demolding agent and an outer protective varnish is applied on the inner sides by robot or a digitally-controlled device; applying prepreg in superimposed layers; coating the prepreg with a vaccum film, and connecting to a pump for extracting air from between the prepreg layers; fitting together the molds and positioning the pieces with the prepreg laminates; and applying pressure and thermal curve for the method of curing or polymerizing the set of pieces in a single stage or all at once.

Owner:GARCIA CASTRO FRANCISCO JAVIER +1

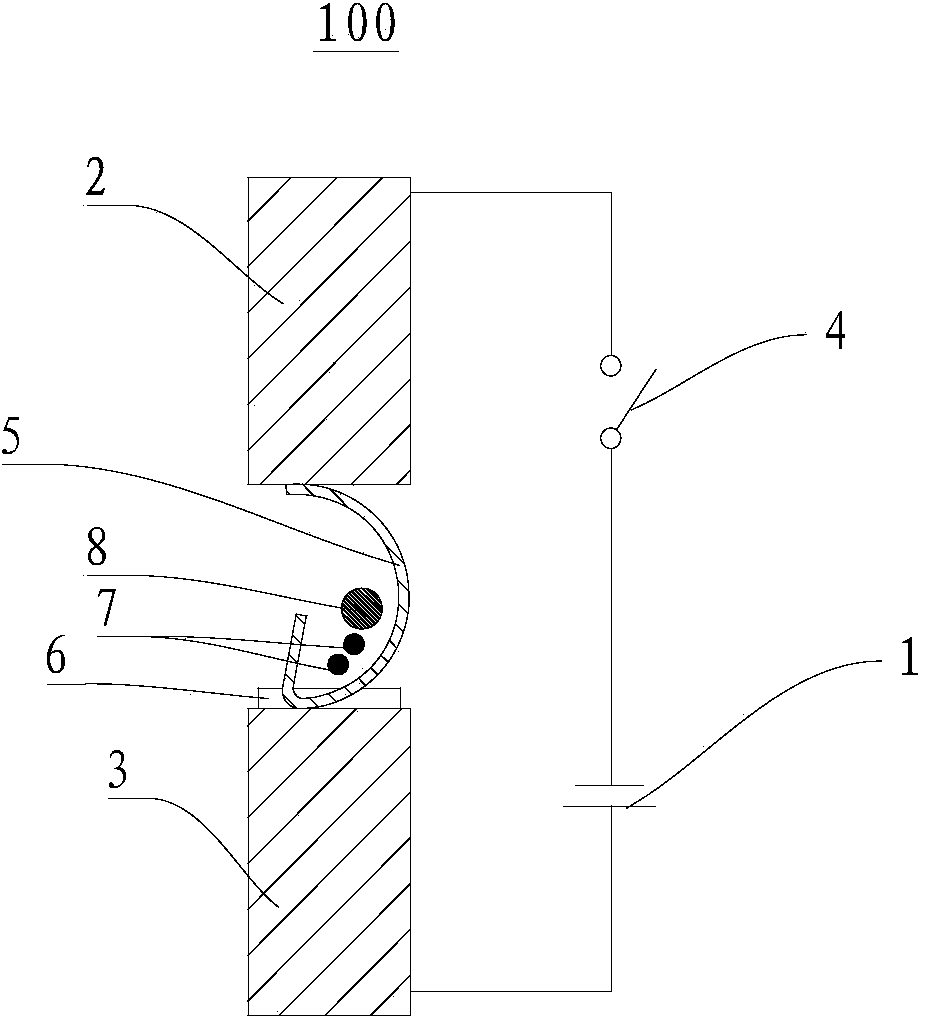

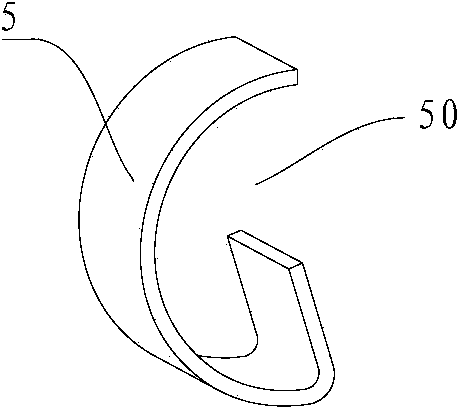

Lead connection device and connection method

ActiveCN103441615AEliminate pollutionReduce labor intensityManufacturing dynamo-electric machinesSolderingFusion welding

The invention discloses a lead connection device and connection method. The lead connection device comprises a power source, a top electrode, a bottom electrode, a switch and a metal wrapping piece. The top electrode is connected with the power source and can move vertically. The bottom electrode is located below the top electrode and connected with the power source. The switch is arranged on a circuit where the top electrode is connected with the power source or on a circuit where the bottom electrode is connected with the power source. The metal wrapping piece is an annular piece provided with a notch, the metal wrapping piece is arranged between the top electrode and the bottom electrode so that the power source, the top electrode, the bottom electrode and the metal wrapping piece can form a current loop, and the top electrode drives the metal wrapping piece to deform when moving vertically so that the upper end and the lower end of the notch can make contact with each other. The lead connection device can greatly reduce labor cost and labor intensity of operation staff, greatly improve production efficiency, eliminate potential quality hazards such as faulty soldering and fusion welding incompletion caused by human factors in the prior art, and avoid environmental pollution caused by burn-in.

Owner:GUANGDONG MEIZHI PRECISION MFG

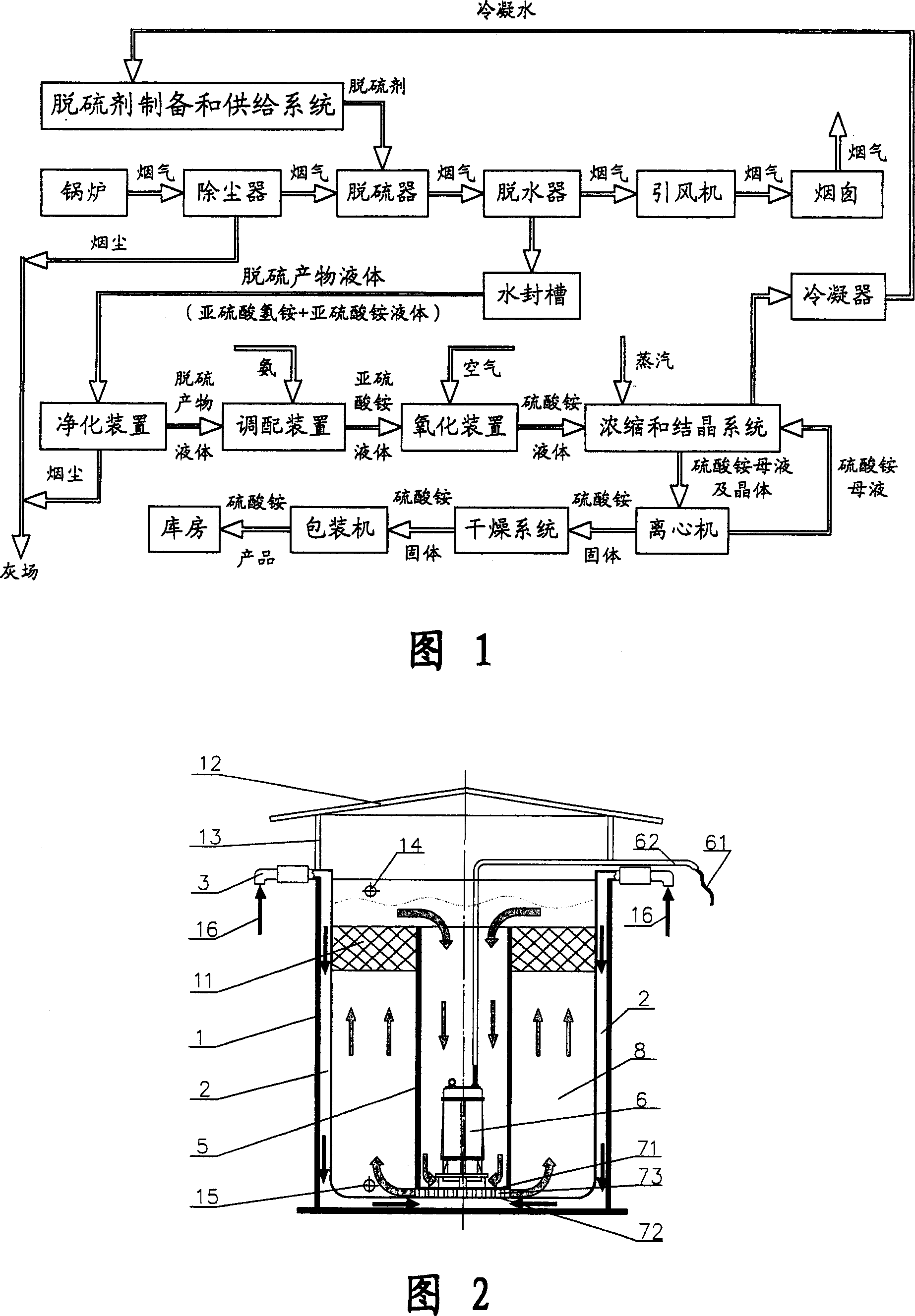

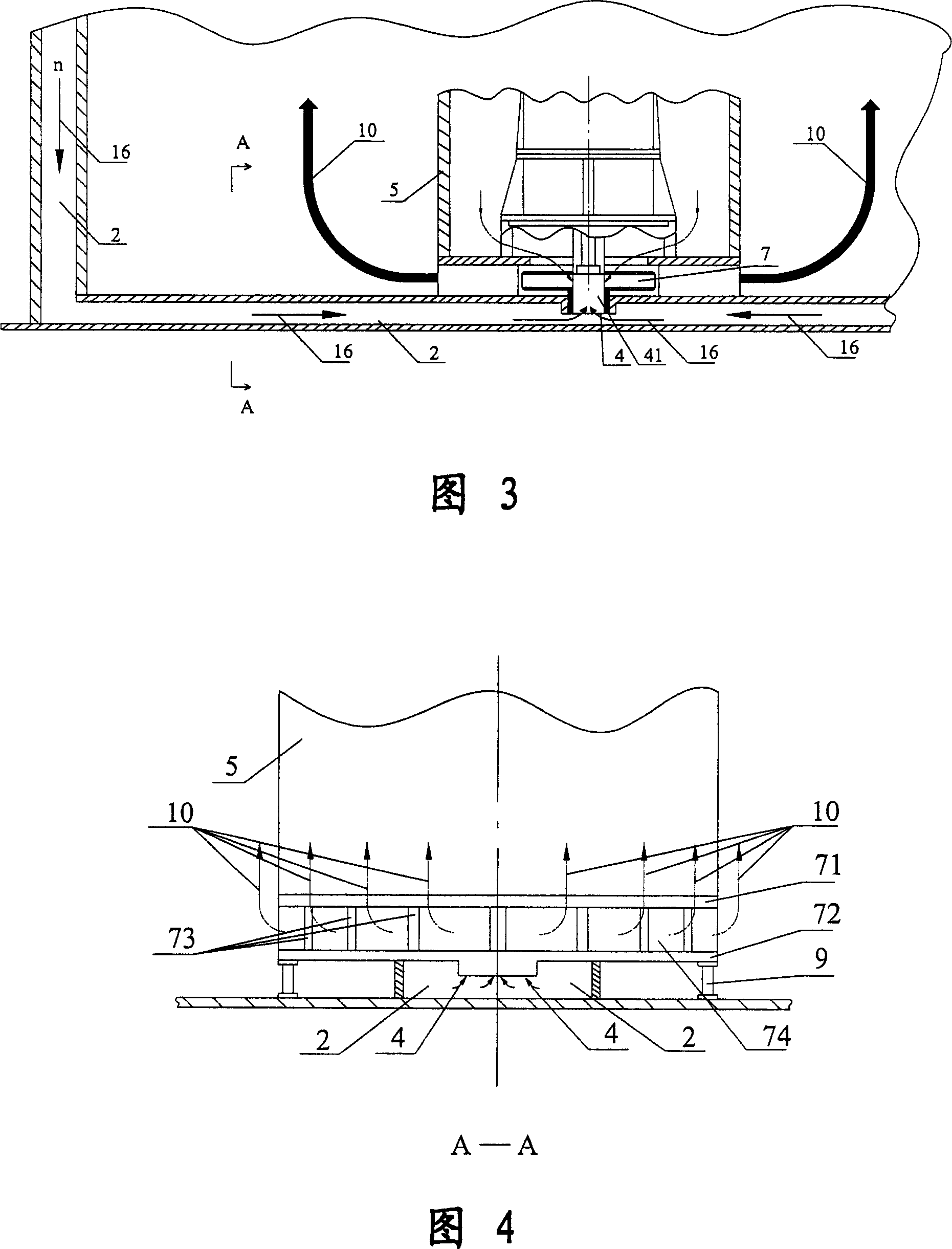

Integral method and apparatus for continuous ammonium-sulfate production and flue desulfuration

InactiveCN1981913AEliminate environmental pollutionImplement resourcesDispersed particle separationExhaust gasFlue

A process for desulfurizing fume and continuously preparing ammonium sulfate from the desulfurized product includes such steps as filling ammonia water in fume, reaction between ammonia water and SO2 in fume to generate the mixed solution of ammonium sulfite and ammonium hydrogen sulfite, adding ammonia, reacting on ammonium hydrogen sulfite to generate ammonium sulfite, oxidizing reaction between the solution of ammonium sulfite and air or oxygen to generate the solution of ammonium sulfate, evaporating for concentrating while crystallizing, centrifugal separation and drying.

Owner:柴焕

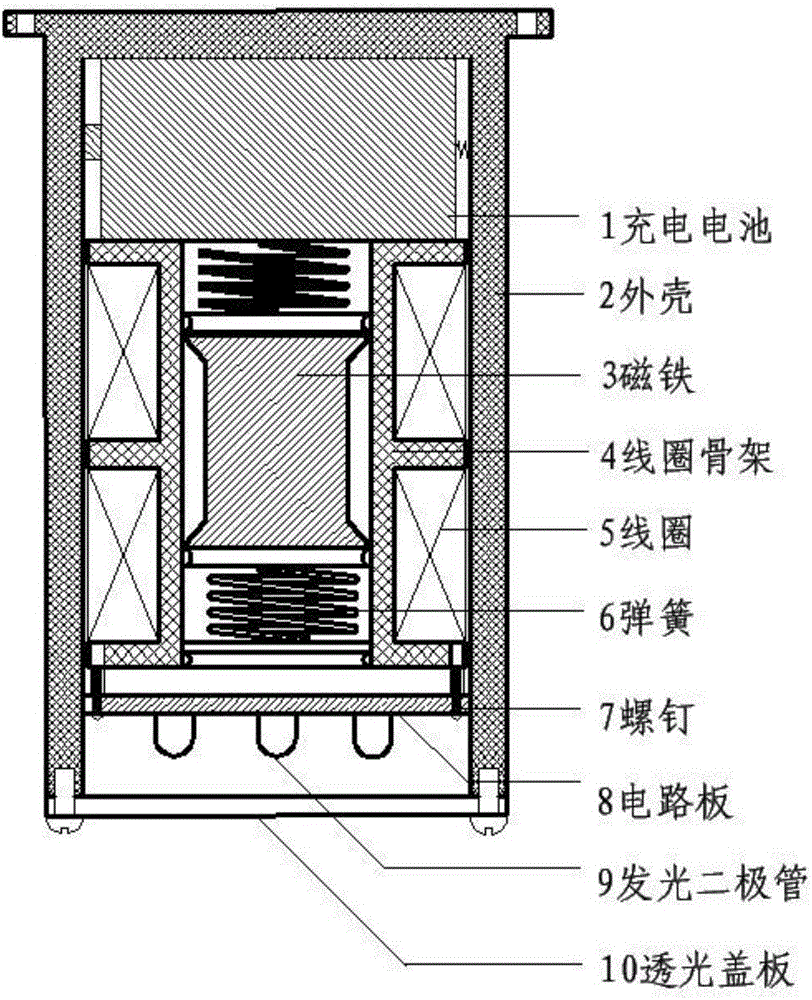

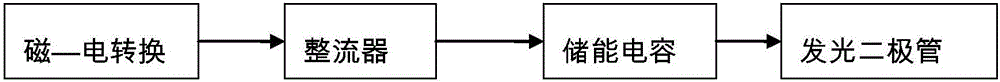

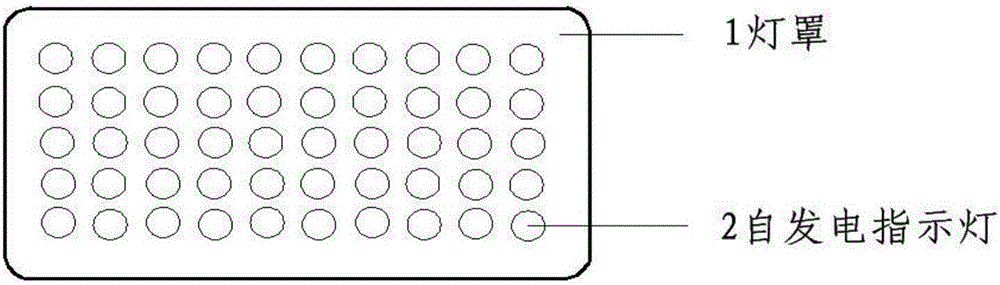

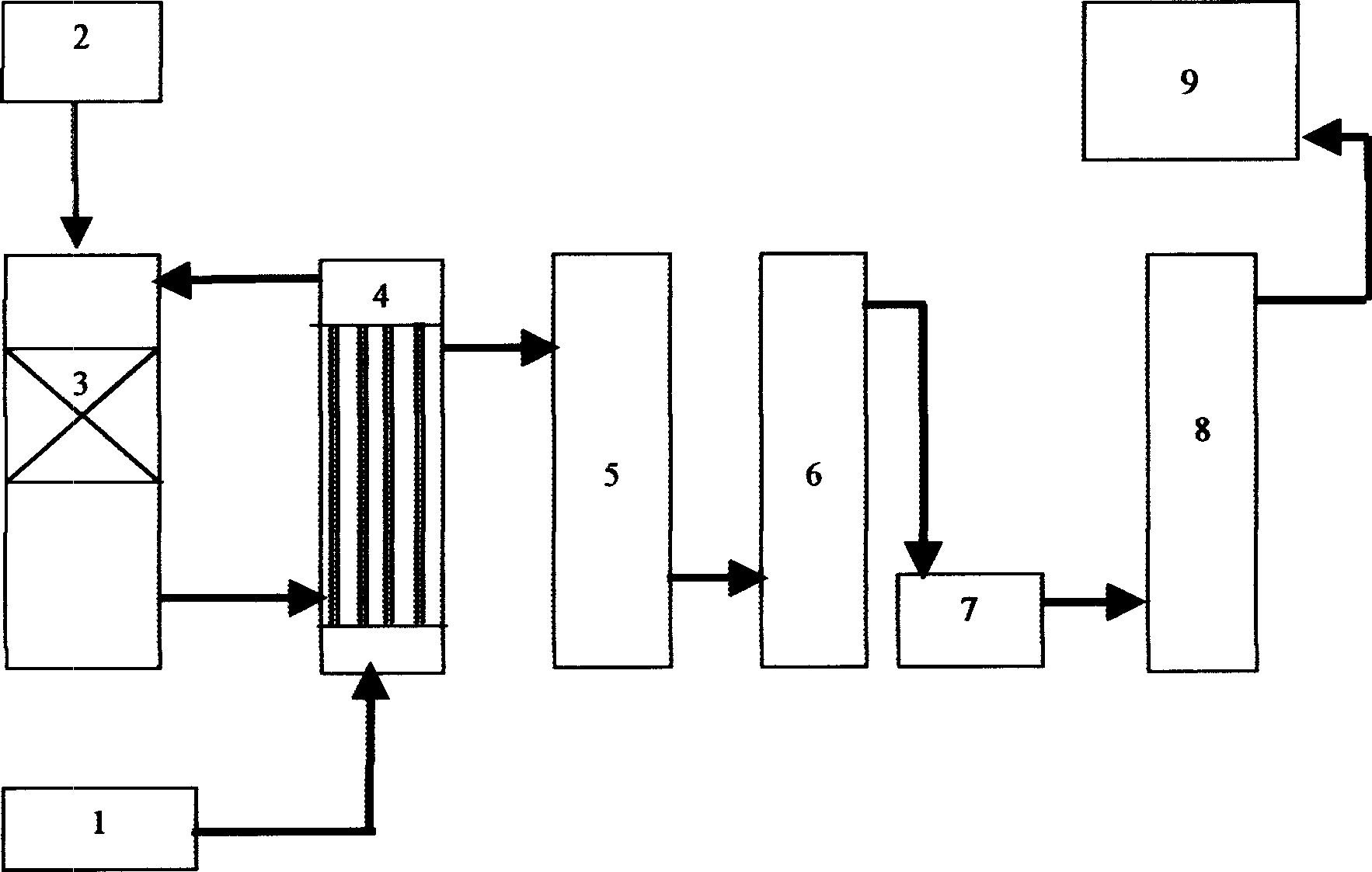

Vibration self-generating indicator lamp

InactiveCN106655700AAvoid safety hazardsEliminate environmental pollutionBatteries circuit arrangementsElectric powerElectrical energy storageHollow cylinder

The invention provides a vibration self-generating indicator lamp, which is a small, closed and independent self-generating lighting device. The specific structure is as follows: a housing is a cylindrical cavity shell with an opening in one end; the opening of the housing is covered with a fixed partition plate; a coil skeleton is a hollow cylinder; a groove for winding a coil is formed in the outer side wall of the hollow cylinder around the circumferential direction of the cylinder; a magnet is a steel and magnetized cylindrical permanent magnet; the coil skeleton is coaxially arranged in a cylindrical cavity of the housing and is located between the inner bottom surface of the housing and the fixed partition plate; the magnet is arranged at the hollow part of the coil skeleton; two ends of the magnet are fixedly connected with the inner bottom surface of the housing and the fixed partition plate through springs respectively; the coil is wound into the groove in the outer side wall of the coil skeleton; two ends of the coil are connected with a circuit board through wires; the circuit board completes the functions of rectification and electric energy storage; the stored electric energy is input into a rechargeable battery to drive a light-emitting diode to emit light; and the light-emitting diode is arranged outside the fixed partition plate.

Owner:罗瑞琪

Coal gas purifying method

The present invention is characterized by that it adopts the high temperature produced by adding proper quantity of industrial pure oxygen and small quantity of hot gas into uncooled hot gas to make them produce reaction to make the tar, naphthalene, benzene, organic sulfur and ammonia, etc. being in gas be cracked and converted into CO, H2, N2 and H2S, and can remove H2S at normal temperature. Said method can be used for purifying coke oven gas and non-anthracite gas, can make coke oven gas be raised by about 10%-25%.

Owner:苏大为 +1

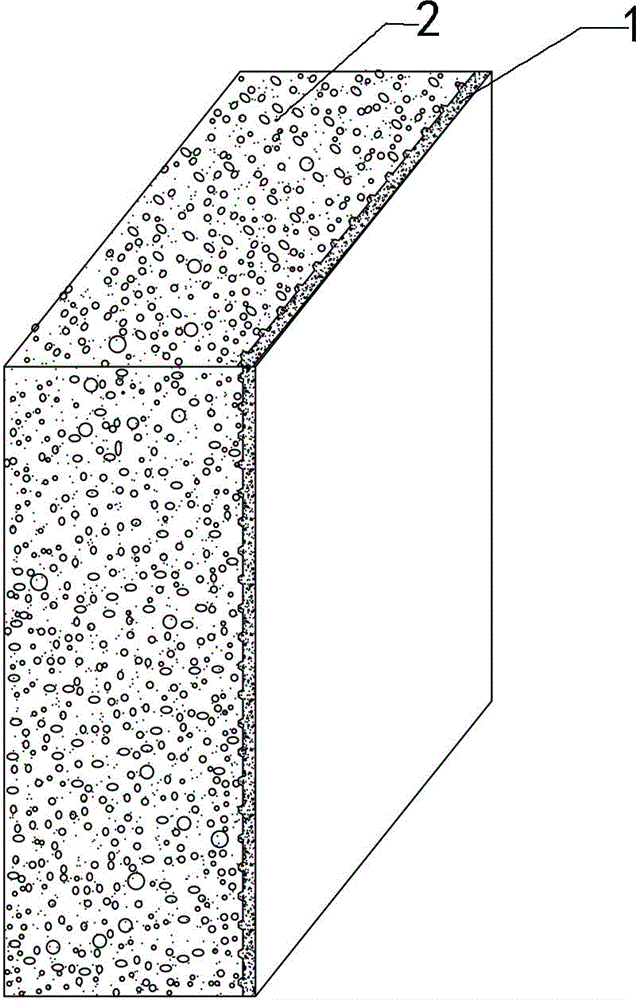

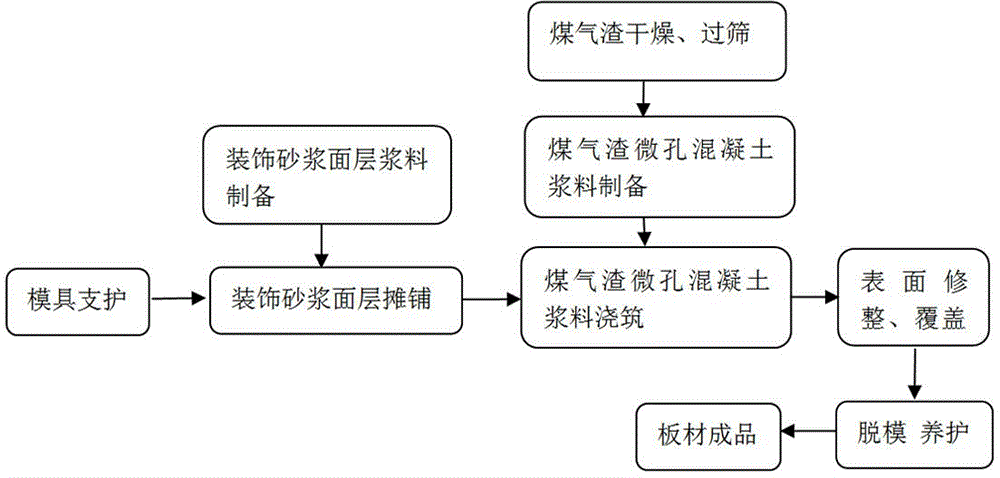

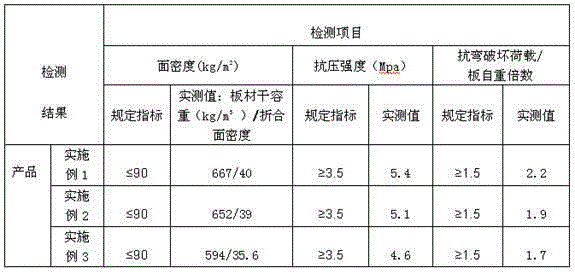

Coal-based gas dreg light-weight micro-pore concrete composite sheet material and preparation method thereof

InactiveCN104675010AEliminate environmental pollutionEliminate building energy savingsSolid waste managementClimate change adaptationIndustrial wasteHeat conservation

The invention provides a coal-based gas dreg light-weight micro-pore concrete composite sheet material and a preparation method thereof. The composite sheet material is formed by compounding a decorative mortar surface layer and a light-weight micro-pore concrete heat-preservation layer; coal-based gas dreg discharged in an industrialized process is taken as light-weight aggregate, has good heat-preservation performance, light weight, heat insulation performance and high specific strength, is wholly made from inorganic materials, and has the characteristics of nonflammable property and good durability; the defects that a heat preservation system of current frequently-used sheet materials, such as polystyrene plates, is flammable, the outer decoration easily forms swelling and falls and the service life is extremely lower than that of a building are overcome; and more importantly, industrial waste dreg is recycled so that the cost of the sheet material is extremely reduced, dual benefits of eliminating environment pollution and saving building energy are realized, non-renewable natural building material resources are protected, and the sheet material has real and long-lasting meanings on national economy and livelihood of people.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Thin coal seam mined-out area paste body filling construction method

ActiveCN106988780AEliminate environmental pollutionReduce investment and use costsMaterial fill-upCoalPollution

The invention discloses a thin coal seam mined-out area paste body filling construction method. The construction method is characterized in that down hole seeping water is held by a water sac and then is filled back in a mined-out area, the water filling water sac is utilized to occupy part of space of the mined-out area, correspondingly a method of reducing the filling size of a paste body is conducted to fill the mined-out area, and the water filling water sac is finally solidified in a filling body of the whole mined-out area and becomes a component of the whole filling body. The water filling water sac is a rubber sac and is provided with a through hole for being inserted by a filling steel pipe, the injecting water of the water sac is directly taken from the down hole seeping water, the down hole water damage is eliminated, and the pollution due to outside discharging of down hole waste water is eliminated. The thin coal seam mined-out area paste body filling construction method has the characteristics of safety and reliability, environmental protection technology, simple operation, relatively low filling cost and the like.

Owner:SHANDONG UNIV OF SCI & TECH

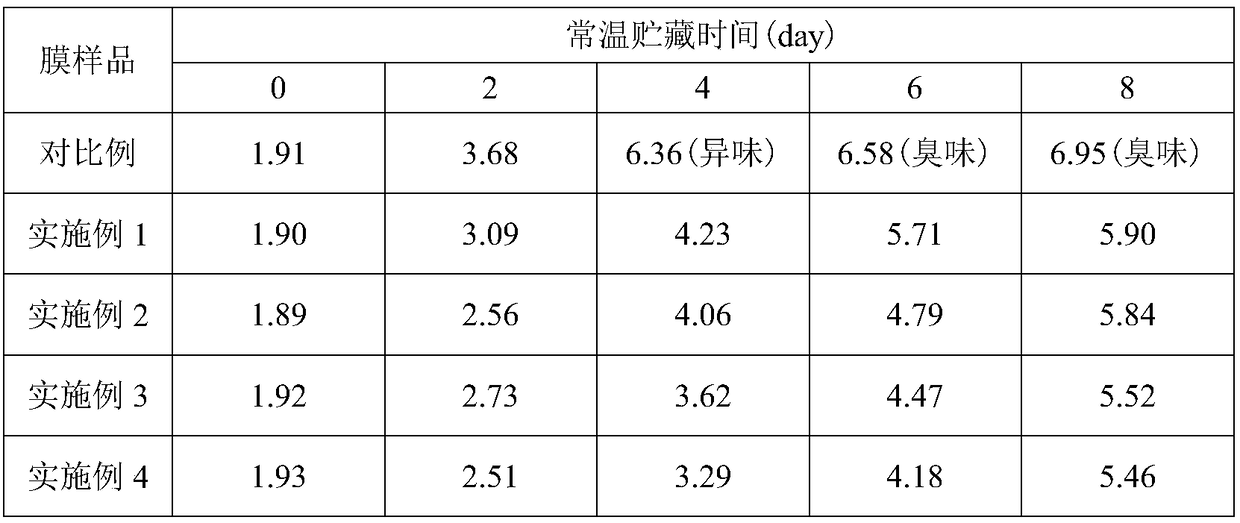

Tea leaf residue modified oxidized cellulose composite film, and preparation method and application thereof

ActiveCN109293959AWide variety of sourcesLow priceMeat/fish preservation using chemicalsChemical reactionComposite film

The invention discloses a tea leaf residue modified oxidized cellulose composite film, and a preparation method and an application thereof. The tea leaf residue modified oxidized cellulose composite film is obtained by an imine chemical reaction of an aldehyde group in a selectively oxidized cellulose molecule and an amino group in tea leaf residue. The tea leaf residue modified oxidized cellulosecomposite film prepared in the invention has good mechanical strength, biodegradability and anti-oxidation performance, is safe and sanitary, can be used for fresh-keeping of fresh pork at room temperature, and can prolong the shelf life of foods.

Owner:ANHUI AGRICULTURAL UNIVERSITY

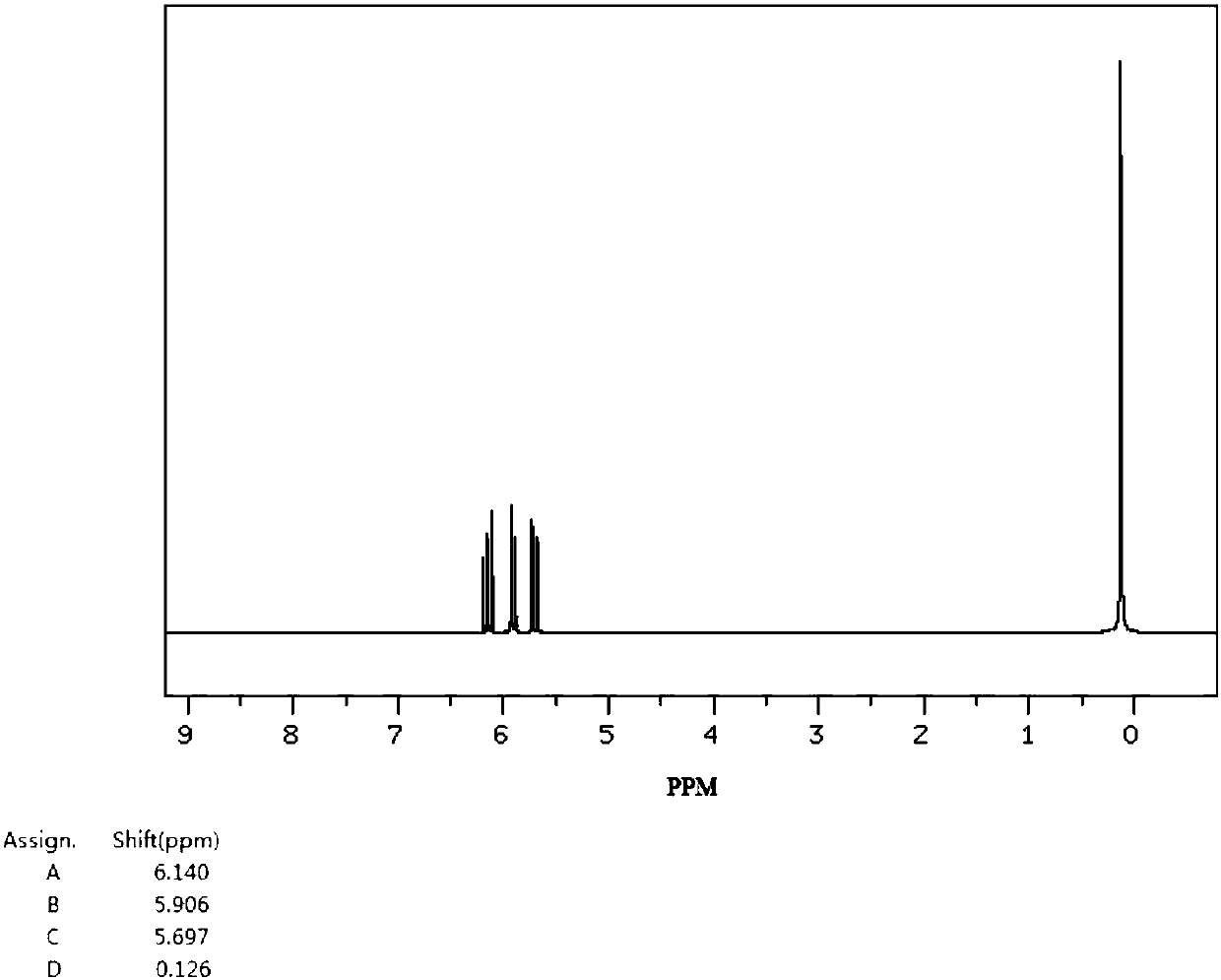

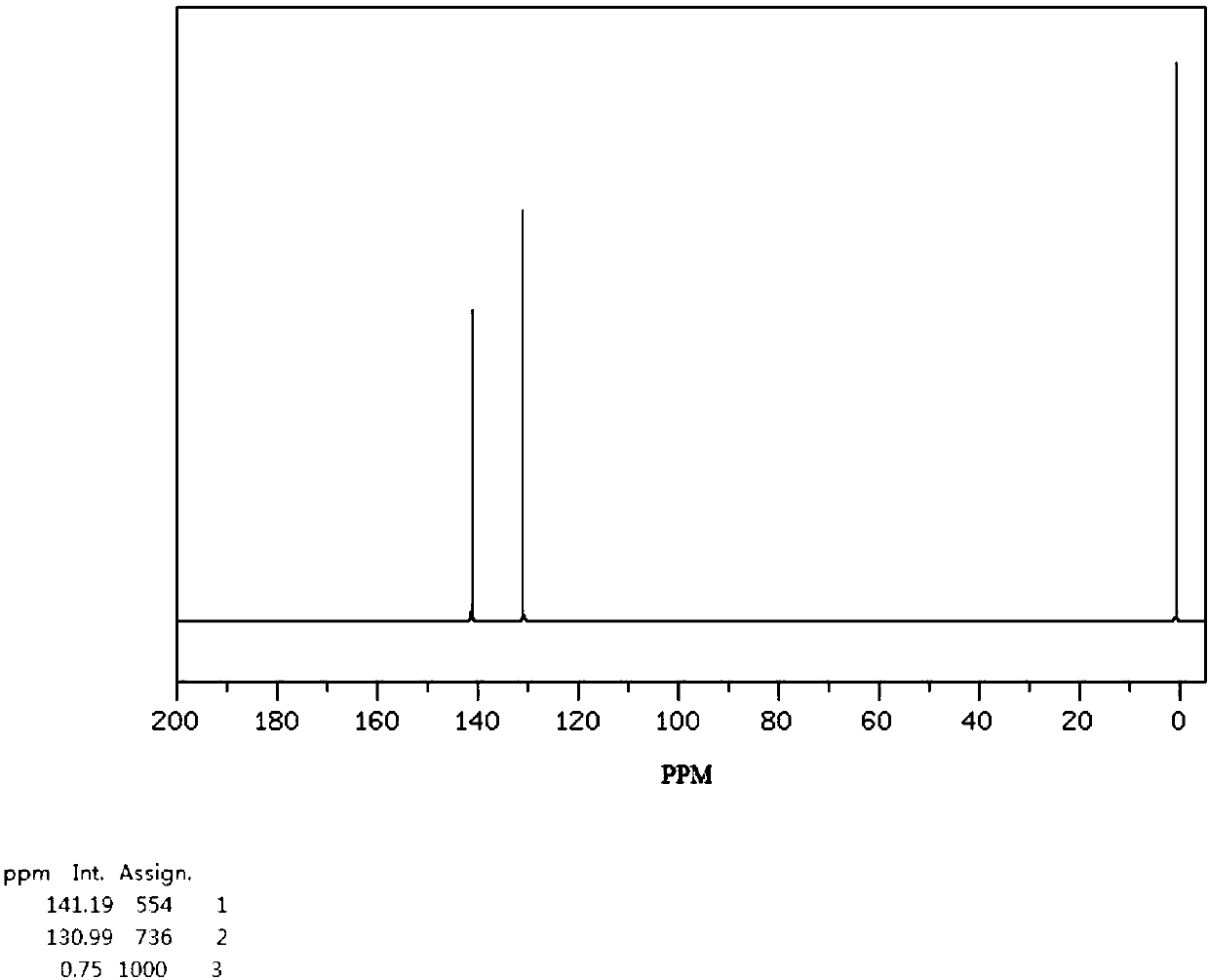

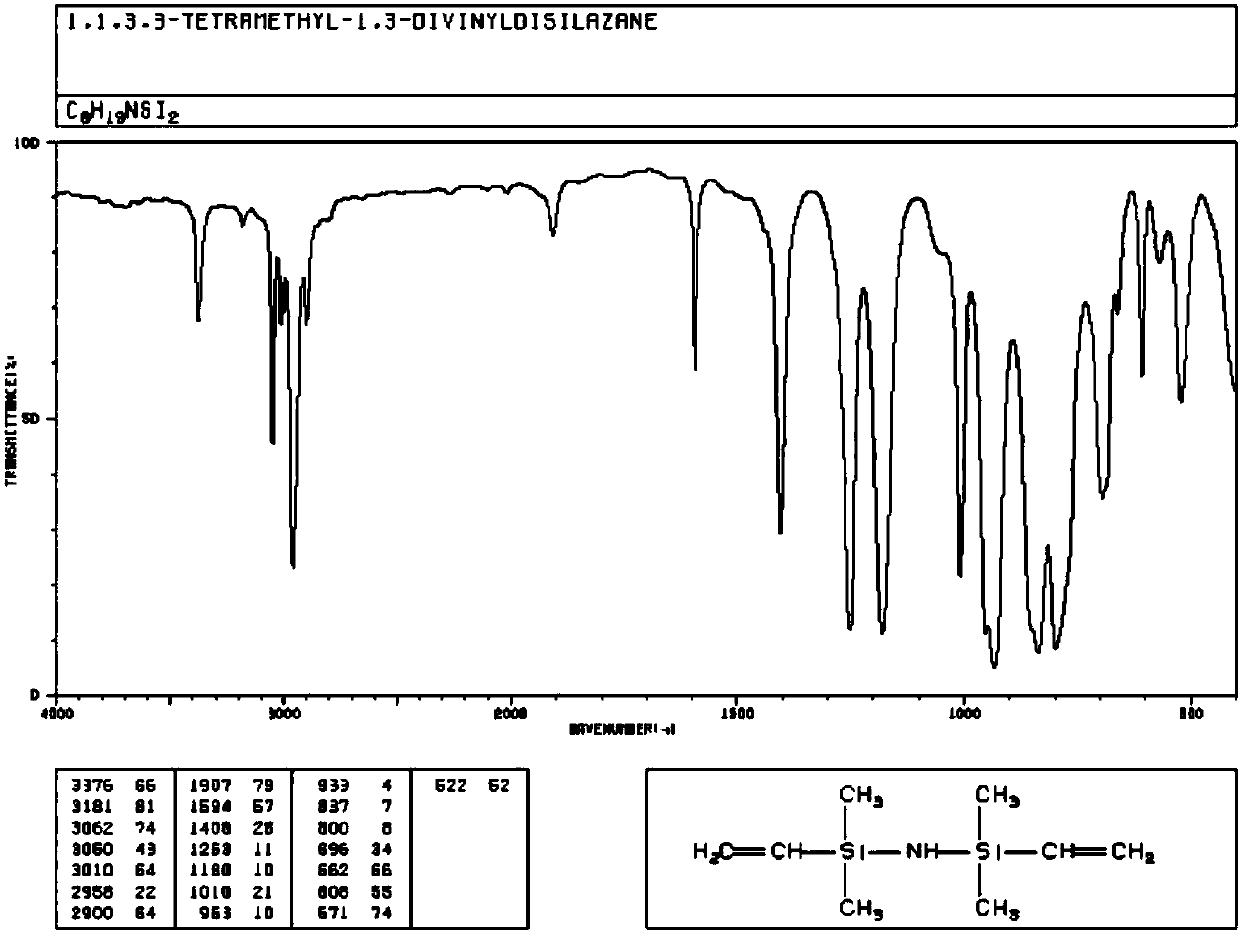

Preparation method of 1,3-divinyl-1,1,3,3-tetramethyldisilazane

InactiveCN109776596ALow costPut an end to lossGroup 4/14 element organic compoundsSecondary cellsDistillationDigestion

The invention relates to a preparation method of 1,3-divinyl-1,1,3,3-tetramethyldisilazane and belongs to the technical field of battery electrolyte additives. The preparation method takes trimethyl-vinyl chlorosilane as a raw material, and ammonia is introduced into trimethyl-vinyl chlorosilane for reaction. The preparation method comprises the following steps: A, controlling pressure to 2-5 kg NH3 pressure, performing the reaction at 80-150 DEG C for 1-6 hours, and after the reaction ends, adding a dichloroethane digestion product, and B, adding the product into a polymerization inhibitor, and performing molecular distillation under the condition of a temperature of 35-85 DEG C and a vacuum degree of 1-5 Pa to obtain colorless and clear liquid. The preparation method is simple; through combination of temperature control and post-treatment operation, and prepared 1,3-divinyl-1,1,3,3-tetramethyldisilazane is high in yield and purity and more suitable for the battery electrolyte additives.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com