Integral method and apparatus for continuous ammonium-sulfate production and flue desulfuration

A technology of ammonium sulfate and ammonium sulfite, which is applied in the field of comprehensive treatment to achieve the effects of comprehensive utilization, elimination of environmental pollution, and realization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] The desulfurization of embodiment 1, flue gas and desulfurization product produce the continuous process of solid ammonium sulfate

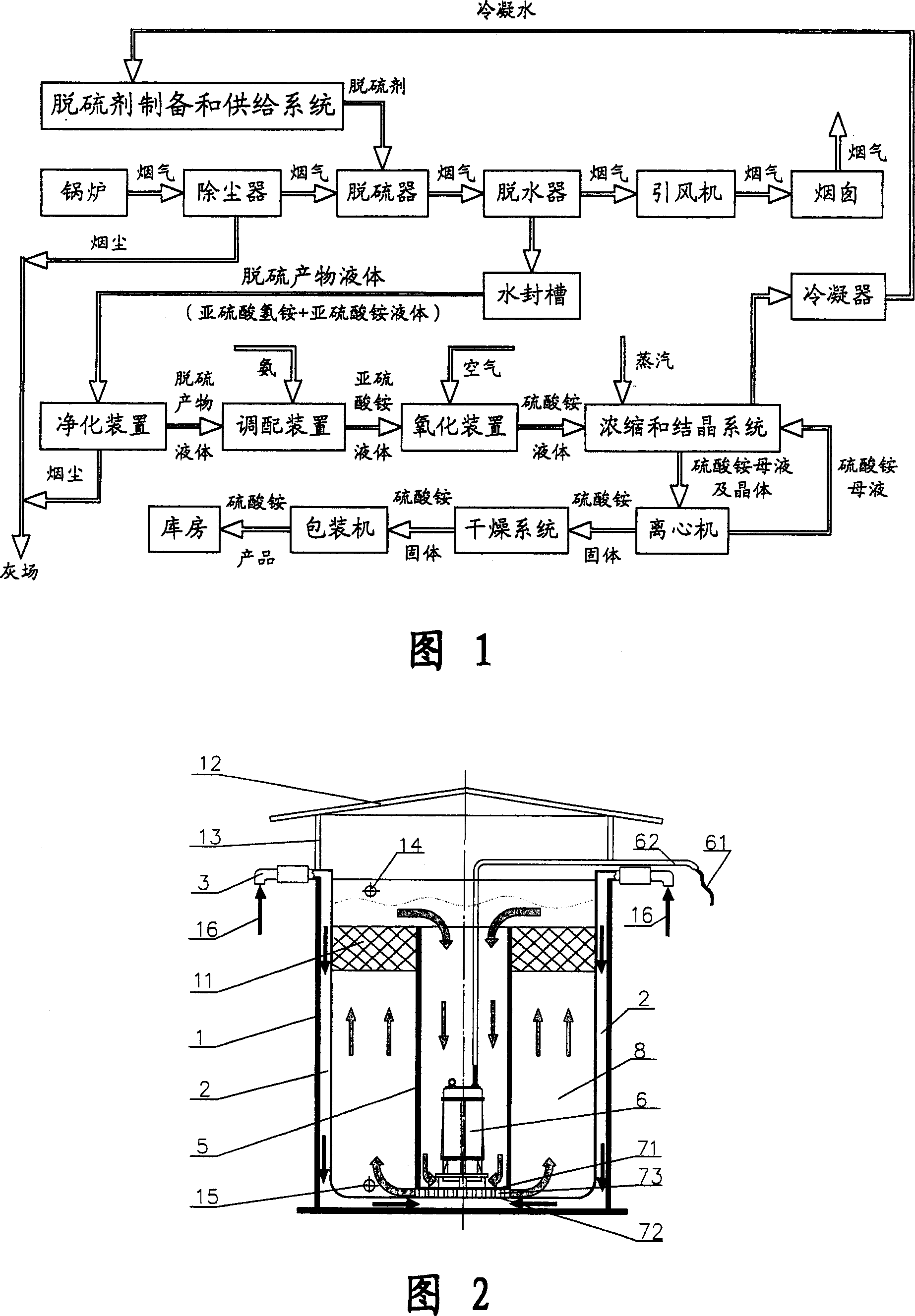

[0071] Please also refer to the flowchart in Figure 1.

[0072] The flue gas from the burner (such as a boiler) enters the desulfurization device after being dedusted by the dust collector. At the same time, the ammonia water used as the desulfurization agent is also input into the desulfurization device through the desulfurization agent supply system, and the sulfur dioxide gas in it is reacted during the contact with the flue gas. The mixed aqueous solution of ammonium sulfite and ammonium bisulfite can realize flue gas desulfurization. In this process, it is best to make the ammonia water pass through the atomizer first and then enter the desulfurization device, and fully mix and contact with the flue gas along the flow.

[0073] The desulfurization product enters the dehydration device to separate the flue gas, the aqueous solution is ...

Embodiment 2

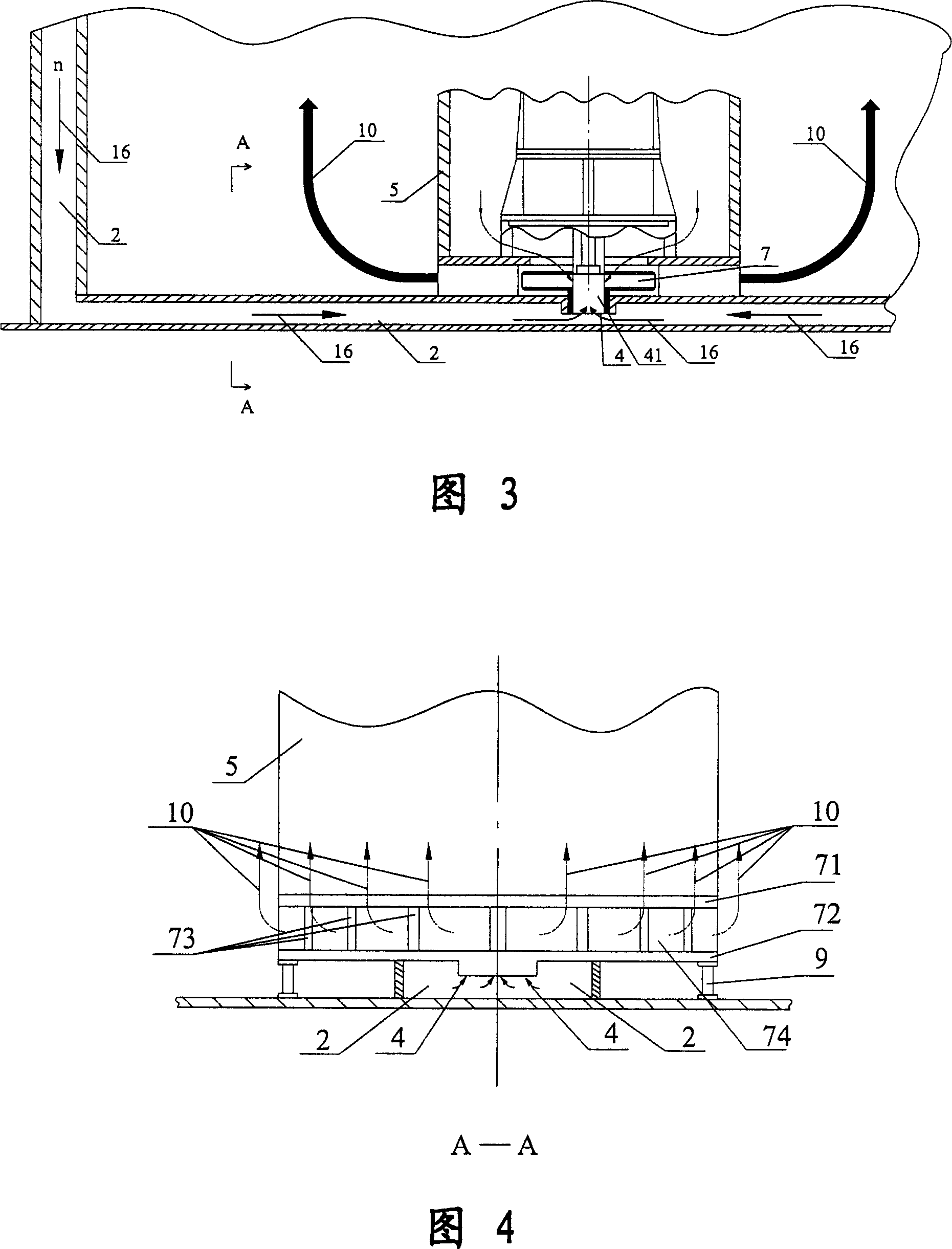

[0079] Embodiment 2, the concrete structure of oxidation device and oxidation reaction

[0080] Please refer to Fig. 2-Fig. 4, which are schematic diagrams of the reaction device for oxidizing ammonium sulfite solution into ammonium sulfate solution according to the present invention. An air supply pipe 2 is arranged along the inner wall of the tank body 1. As shown in the figure, the air supply pipe 2 is set through the bottom of the tank body and extends upward along the inner wall to communicate with the outside world to form two air or oxygen inlets. Air filtering and muffler device 3 (such as air filter and muffler) are set at the place, and the air supply pipe 2 is provided with an air outlet 4 (see Fig. 2 ) at an appropriate position at the bottom of the tank body; The liquid guide tube 5 of upper end opening, forms reaction chamber 8 between its tube wall and tank inner wall, as shown in Figure 2, in this embodiment, guide tube 5 is positioned at the center of tank bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com