Preparation method of 1,3-divinyl-1,1,3,3-tetramethyldisilazane

A technology of tetramethyldisilazane and dimethylvinylchlorosilane, applied in the field of battery electrolyte additives, can solve problems such as unsatisfactory effect, loss of environment, pollution, etc., so as to prevent serious losses and environmental pollution, improve Productivity, the effect of avoiding complex operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 2mol of dimethylvinyl chlorosilane to the reaction kettle, feed ammonia to it for reaction, the amount of ammonia is controlled to be 2:3.4 molar ratio of dimethyl vinyl chlorosilane and ammonia, within 2 hours Access 99%,

[0022] A. Control the reaction pressure to 5 kg NH 3 Pressure, 130 ° C reaction, the reaction time is 6h, after the reaction, add dichloroethane to dissolve the product;

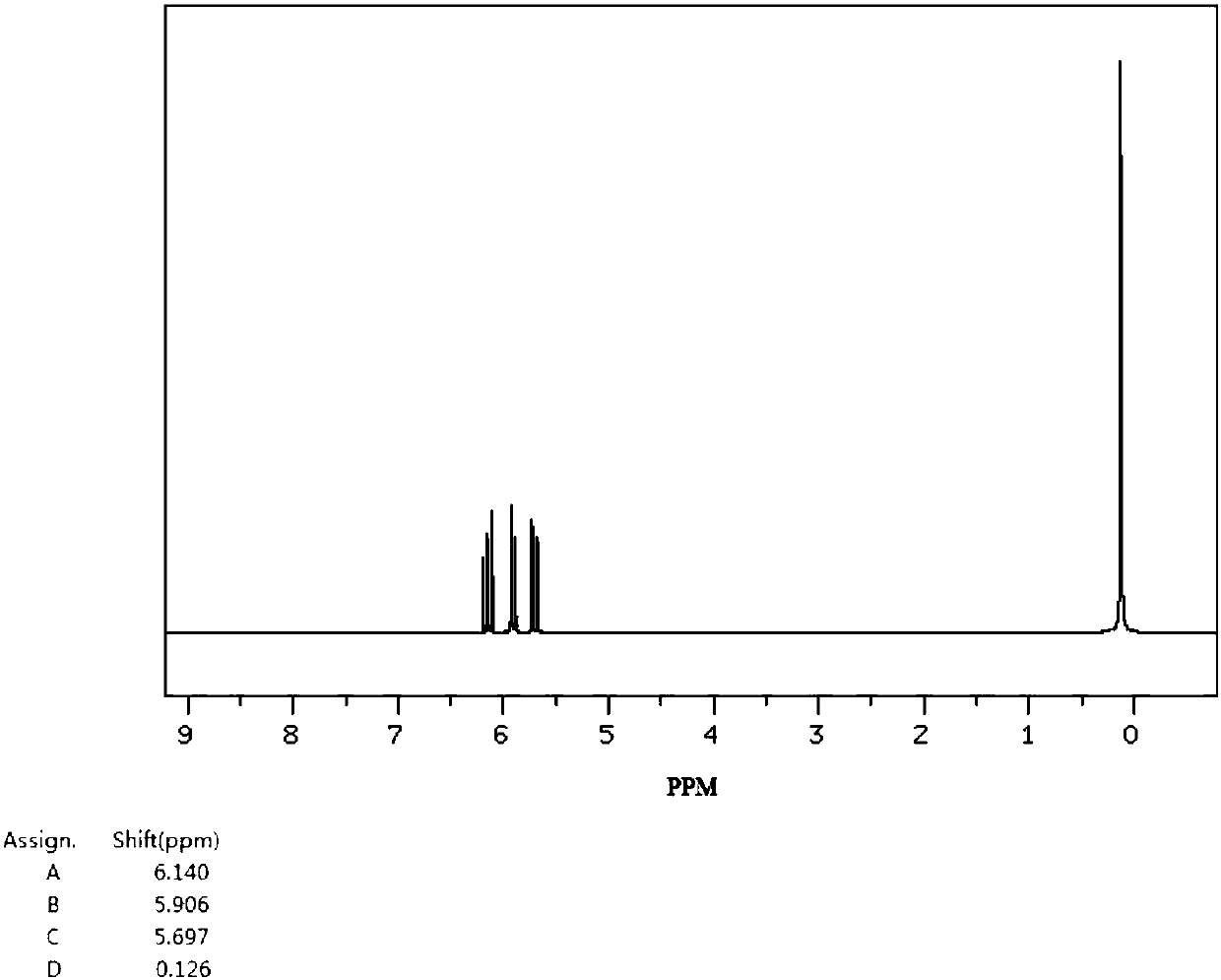

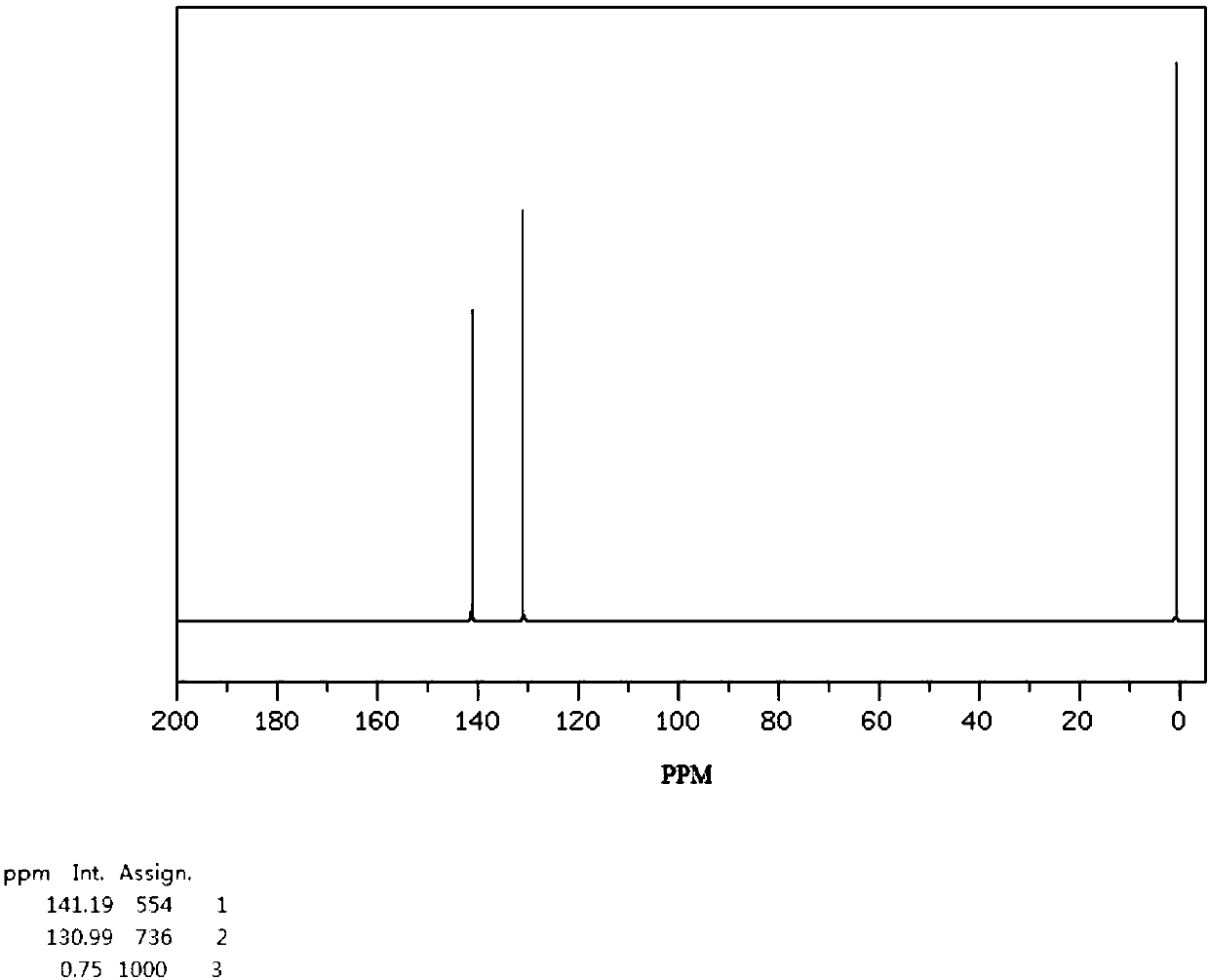

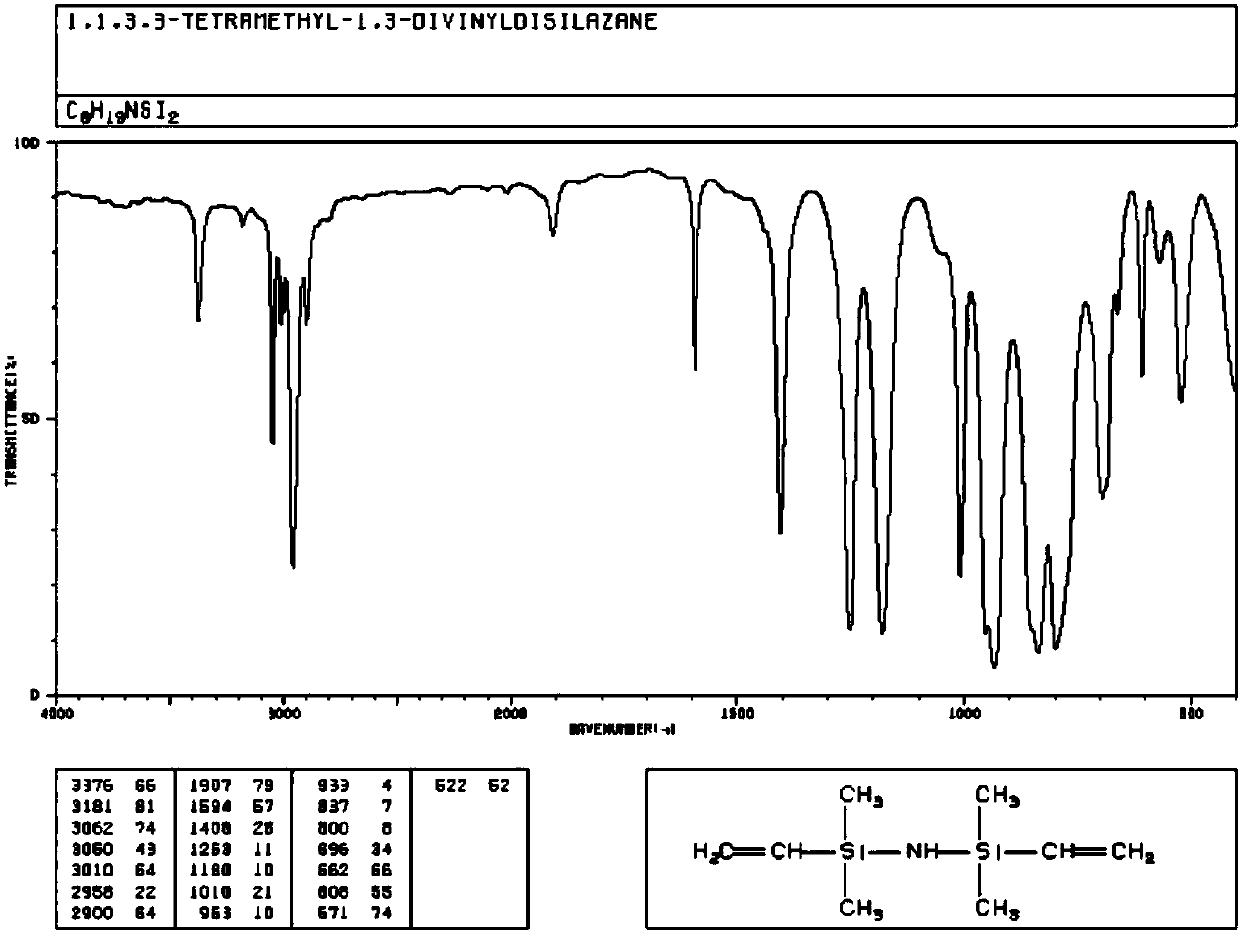

[0023] B. Adding the above product into hydroquinone, tert-butylcatechol and copper naphthenate in a total amount of 0.05% of the product mass, carry out molecular distillation at a temperature of 160-163° C. and 760 mmHg to obtain a colorless transparent liquid. The product content is 98.95%, and the yield is 98%. The tested product density is 0.819g / cm 3 , ammonium chloride is 0, tetramethyldivinyldisiloxane content is 0.1%, the 1H NMR of the product: 400MHz, CDCl 3 Such as figure 1 Shown, 13C NMR: CDCl 3 Such as figure 2 As shown, the infrared spectrum is as image...

Embodiment 2

[0025] Add 2mol of dimethylvinyl chlorosilane to the reaction kettle, feed ammonia to it for reaction, the amount of ammonia is controlled to be the molar ratio of dimethyl vinyl chlorosilane to ammonia 2:3.3, within 2 hours Access 99%,

[0026] A. Control the reaction pressure to 3 kg NH 3 Pressure, 150 ° C reaction, the reaction time is 1h, after the reaction, add dichloroethane to dissolve the product;

[0027] B. Add the above product into hydroquinone, tert-butylcatechol and copper naphthenate in a total amount of 0.08% of the product mass, carry out molecular distillation at a temperature of 160-163° C. and 760 mmHg to obtain a colorless transparent liquid. The product content is 98.83%, and the yield is 97.6%. The tested product density is 0.82g / cm 3 , ammonium chloride is 0, and the content of tetramethyldivinyldisiloxane is 0.12%.

Embodiment 3

[0029] Add 2mol of dimethylvinyl chlorosilane to the reactor, feed ammonia to it for reaction, the amount of ammonia is controlled to be 2:3.1 molar ratio of dimethyl vinyl chlorosilane to ammonia, within 2 hours Access 99%,

[0030] A. Control the reaction pressure to 2 kg NH 3 Pressure, 140 ° C reaction, the reaction time is 4h, after the reaction is completed, add dichloroethane to dissolve the product;

[0031] B. Add the above product into hydroquinone, tert-butylcatechol and copper naphthenate in a total amount of 0.1% of the product mass, carry out molecular distillation at a temperature of 160-163° C. and 760 mmHg to obtain a colorless transparent liquid. The product content is 98.86%, and the yield is 98.2%. The tested product density is 0.821g / cm 3 , ammonium chloride is 0, and the content of tetramethyldivinyldisiloxane is 0.11%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com