Secondary roasting furnace for carbon products and roasting method of secondary roasting furnace

A technology of secondary roasting and carbon products, which is applied in the field of roasting furnaces, can solve the problems of unstable product quality, high production and operation costs, and low utilization rate of volatile matter, and achieve the goals of shortening heating time, small production capacity and reducing fuel consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

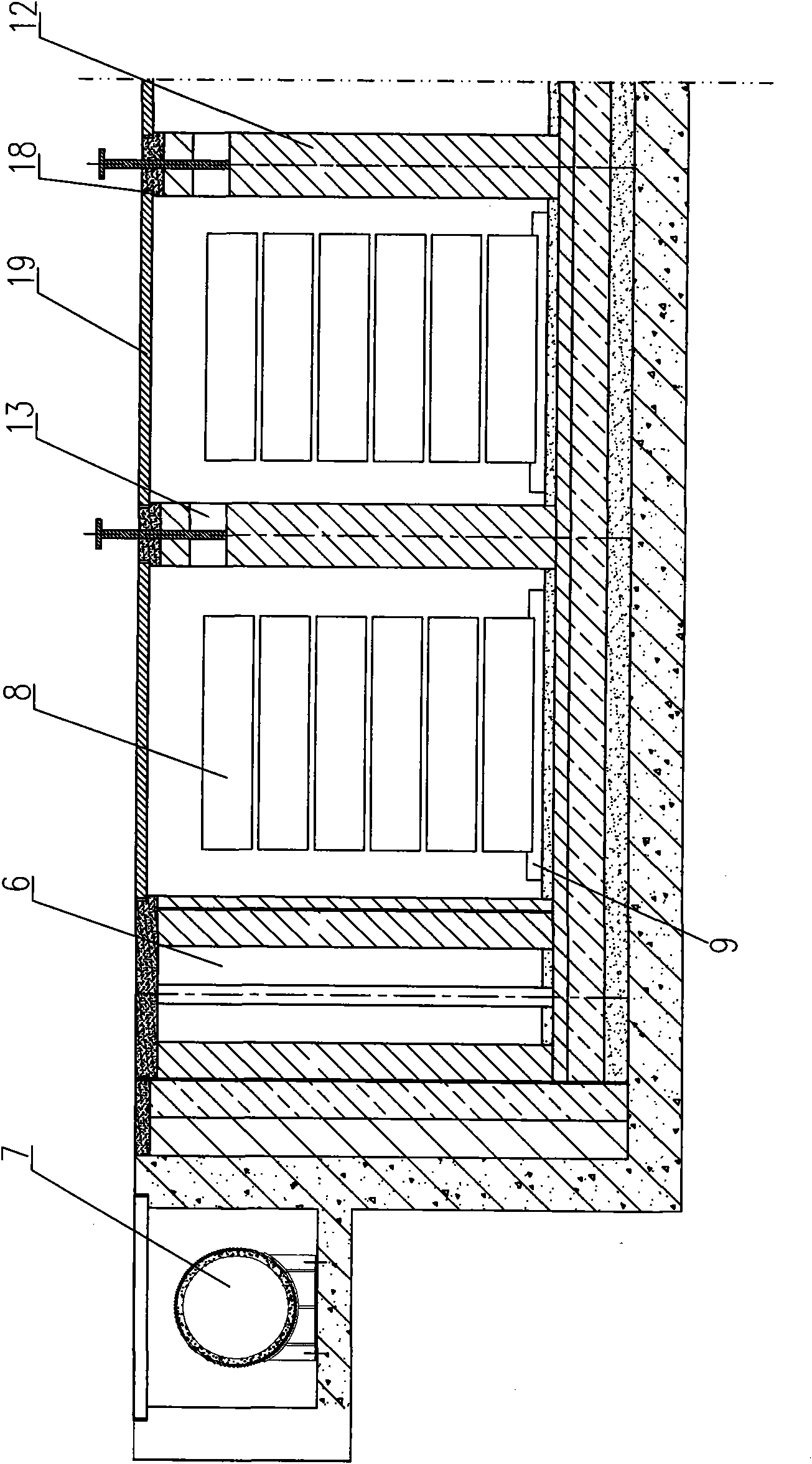

[0042] Such as Figure 1-4As shown, the secondary roasting furnace for carbon products of the present invention is characterized in that its structure is as follows: two rows of furnace chambers are arranged symmetrically on both sides of the furnace centerline 3 in the furnace body, and each row of furnace chambers is composed of 2 to 100 furnace chamber monomers 1 , each single furnace chamber 1 is divided into n-1 material boxes 2 by n fire passage walls 4, where n is the number of fire passages in one furnace chamber, and the number of fire passages in each furnace chamber is 3 to 21 , the material box is a rectangular cavity. In this embodiment, there are five flue walls 4 for each single furnace chamber, and four material boxes. The wall 12 and the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com