Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Control stirring speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurea-based lubricating grease with high mechanical stability and preparation method thereof

The invention belongs to the field of polyurea-based lubricating grease, and in particular provides polyurea-based lubricating grease with high mechanical stability and a preparation method thereof. The polyurea-based lubricating grease consists of the following components in percentage by weight: 70 to 90 percent of base oil and 10 to 30 percent of polyurea-based lubricating grease thickening agent, wherein the polyurea-based lubricating grease thickening agent is prepared by mixing diisocyanate and organic amine and directly thickening the base oil; isocyanate ions and amine ions have the same molar content; and the organic amine consists of fatty amine, naphthene amine and aromatic amine in the molar ratio of (2-4):(1-2):5. The polyurea-based lubricating grease has high mechanical stability and long service life.

Owner:长沙众城石油化工股份有限公司

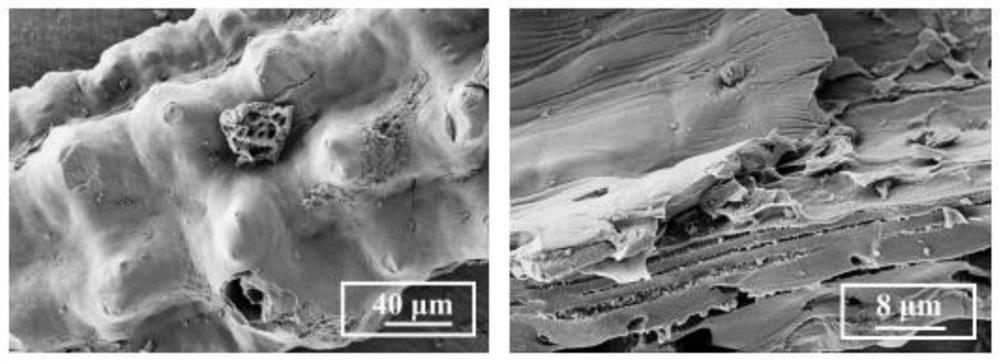

Method for preparing super-hole fibrin microsphere protein absorbing medium

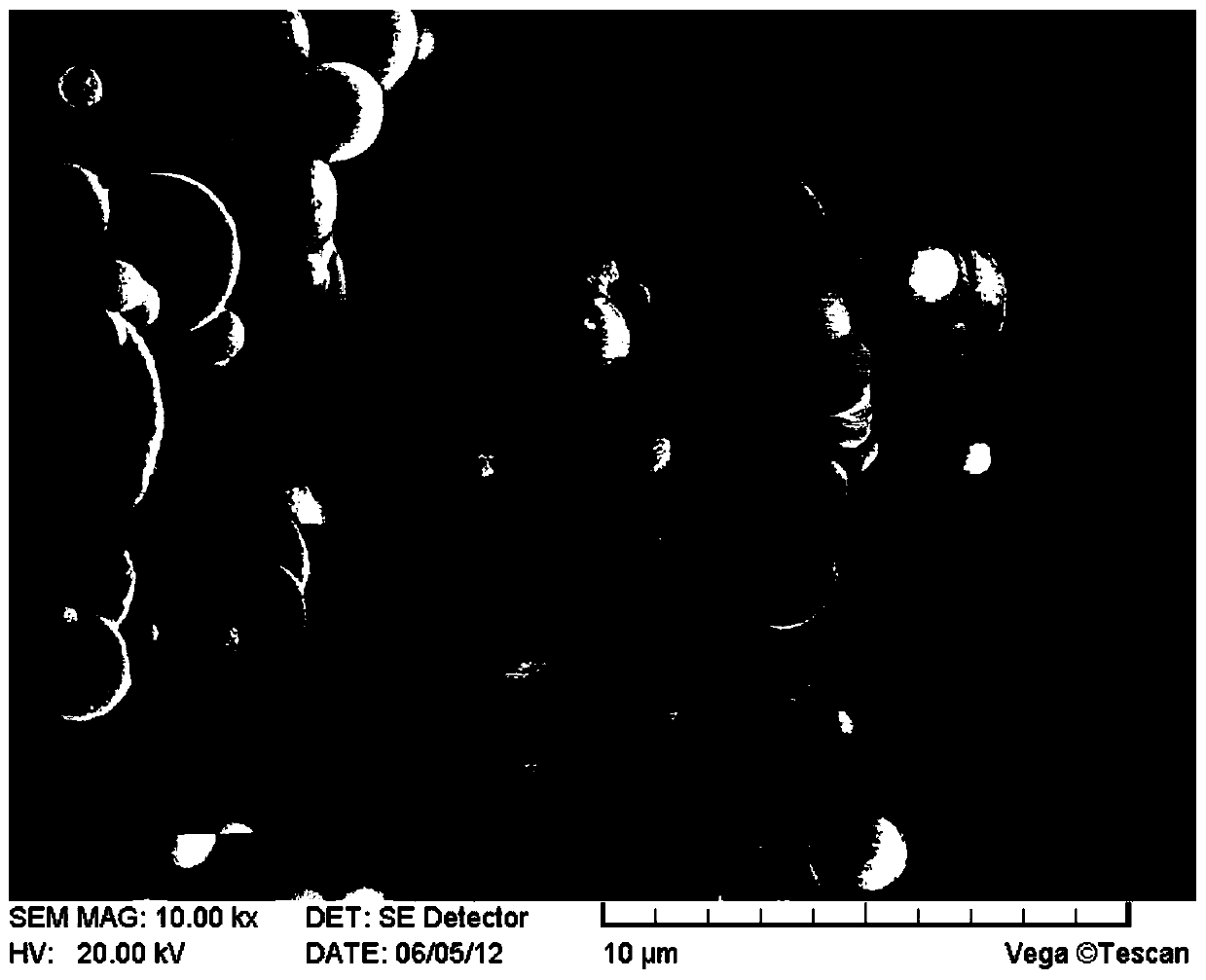

InactiveCN101036876AEvenly distributedImprove stabilityOther chemical processesPeptide preparation methodsCelluloseMicrosphere

The present invention discloses a preparation method for superporous cellulose microglobulin adsorption medium, which belongs to the preparation technology of cellulose gel medium of bioseparation engineering field. The method comprises the steps of: dispersing calcium carbonate particles to the cellulose viscose to form composite water phase; putting the viscose into the transformer oil and adding composite emulsifier potassium oleate and Span 60 and then executing agitating and emulsification; heating and curing to form particles; adding ethylene glycol diglycidyl ether and epichlorohydrin to execute double crosslinking reaction under alkaline condition; removing the calcium carbonate particles by using muriate acid and then using sodium borohydride to reducing so as to prepare superporous cellulose microglobulin adsorption medium. The medium not only maintains the advantages of the quondam cellulose gel medium but also increases a plurality of superporous, so that the resistance to pressure, the mass transfer rate and the dynamic adsorption capacity of the medium are all obviously improved, thereby, the novel superporous cellulose microglobulin adsorption medium has wide application prospect.

Owner:TIANJIN UNIV

Method for preparing high density core material coated with thin shell medium of agarose gel

InactiveCN1457919AUniform densityDensity regulationIon-exchange process apparatusOther chemical processesEpoxyThin shells

The present invention discloses the technology of preparing gel carrier microballoon with loaded inert grain. The preparation process includes preparing suspension, emulsifying and coating reaction, and curing and crosslinking process. The preparation process features that the glass bead is dispersed inside the water solution of agarose to prepare suspension; the suspension is then added into salad oil while adding emulsifier Span-80 and stirring for emulsification and coating reaction to lower temperature fast to form microballoon; and epoxy chloropropane is then added for crosslinking at alkaline condition and sodium borohydride is added for reduction to prepare dispersed medium with particle size 40-500 mincrons and agerose content 20-70 wt%. The dispersed medium exhibits certain density and particle size distribution and has high density in expanding bed, column efficiency, adsorption capacity and thus wide application.

Owner:TIANJIN UNIV

Method for purifying gibberellin GA3 and preparing water-soluble pulvis of gibberellin GA3

InactiveCN102246756AImprove finenessPromote precipitationBiocidePlant growth regulatorsAcetic acidEthyl ester

The invention provides a method for purifying gibberellin GA3 and preparing water-soluble pulvis of gibberellin GA3. The invention brings forward control of purity and particle size of gibberellin GA3 and utilization of complex formulation to prepare water-soluble pulvis of gibberellin GA3. According to the invention, a mixed solvent of tetrahydrofuran / ethyl acetate / water is used for recrystallization of a crude product of gibberellin GA3, which enables a reasonable process and simple operation and enables purity of the product in one operation to be more than 98.5% and yield of the product to be more than 90%; the technology of complex formulation is employed and gibberellin GA3 is made to be rapidly dissolved in a water phase and to form a stable disperse phase through using of accessories like an acidic buffer reagent, a dispersant and a surfactant, thereby enabling gibberellin GA3 to be easier to store and transport and more convenient to use and drug effects and the utilization rate to be improved.

Owner:JIANGXI LIFENG BIOLOGICAL TECH

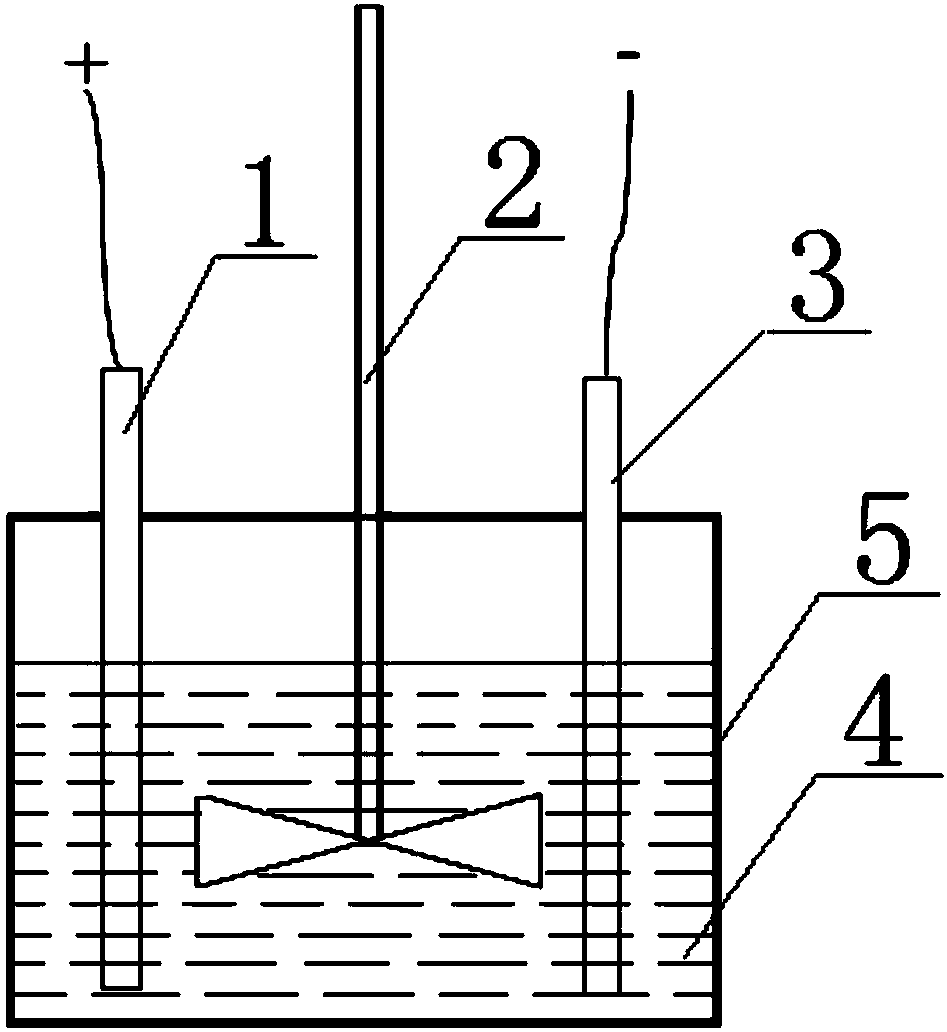

Electrochemical oxidation method and device for calcium sulfite in flue gas desulfurization ash

InactiveCN108118359AOxidation is fast and effectiveImprove oxidation efficiencyCellsCalcium sulfiteElectrochemistry

The invention discloses an electrochemical oxidation method and device for calcium sulfite in flue gas desulfurization ash and belongs to the technical field of material treatment. The method comprises the following steps: S101, weighing a certain amount of flue gas desulfurization ash to be added into an electrolytic cell, adding water, and stirring to form flue gas desulfurization ash slurry, wherein a ration of water to material in the flue gas desulfurization ash slurry is (10-100):1; S102, respectively inserting an inert anode and an inert cathode into the flue gas desulfurization ash slurry, connecting direct current, and controlling the current density to be 80-150A / m<2>; and S103, stirring while performing electrolysis on the flue gas desulfurization ash slurry, controlling the stirring time to be 15-60 minutes, and disconnecting the power supply after set control time is reached. According to the method disclosed by the invention, the flue gas desulfurization ash and the watercan be blended according to a certain ratio, the direct current is connected by virtue of inert electrodes, lots of high-active oxygen atoms are produced nearby the electrodes by utilizing an electrochemical method, the calcium sulfite in the flue gas desulfurization ash is rapidly and effectively oxidized, and the oxidation efficiency and effect are improved.

Owner:安徽马钢嘉华新型建材有限公司

Preparation method of hydrogenated styrene-butadiene-styrene block copolymer

The invention relates to the field of high polymer synthesis and in particular discloses a preparation method of a hydrogenated styrene-butadiene-styrene (SBS) block copolymer. The preparation methodof the hydrogenated styrene-butadiene-styrene block copolymer is characterized by comprising the following steps: under the protection of inert gas, taking organic lithium as a catalyst; putting styrene into a cyclohexane solvent and carrying out first-section polymerization reaction; meanwhile, adding a composite-structure regulator; then adding butadiene and carrying out second-section polymerization reaction; after polymerization is finished, adding the styrene and carrying out third-section polymerization reaction to obtain a basic adhesive SBS for hydrogenation; carrying out hydrogenationreaction on the basic adhesive for the hydrogenation by adopting a homogeneous-phase rhodium series catalyst to obtain a product. The preparation method provided by the invention has the advantages of reasonable technology design, less dosage of a hydrogenation catalyst, high catalyst activity and selectivity, moderate reaction conditions and high product purity and yield, and is suitable for being widely popularized and applied.

Owner:SHANDONG YUHUANG CHEM CO LTD

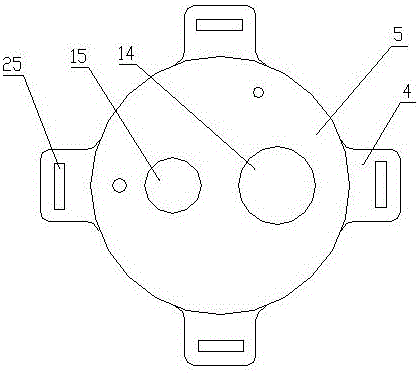

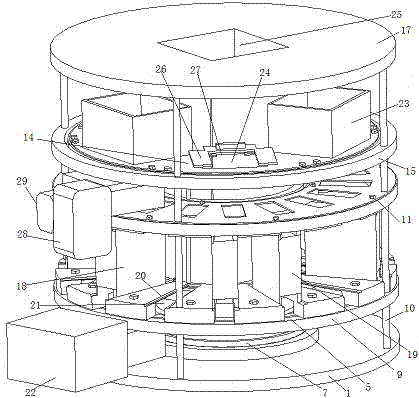

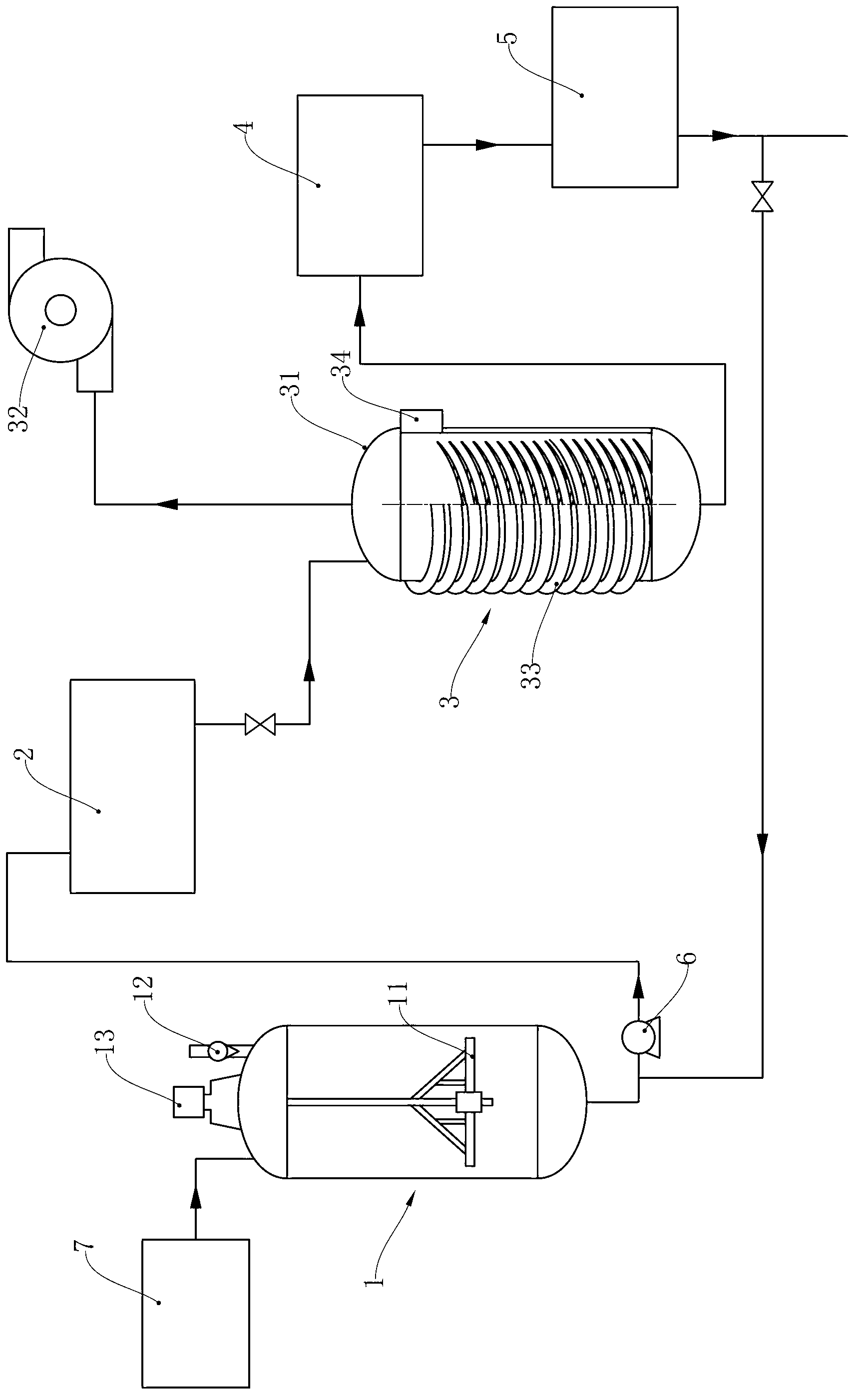

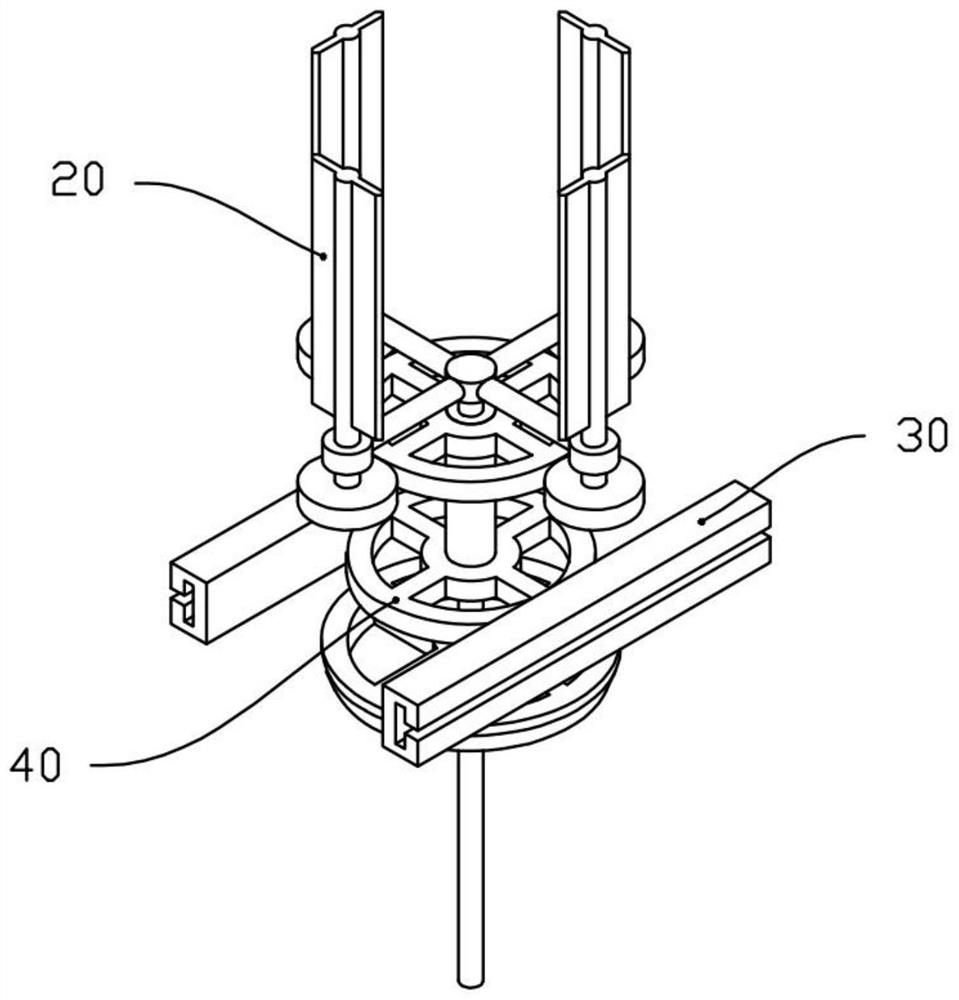

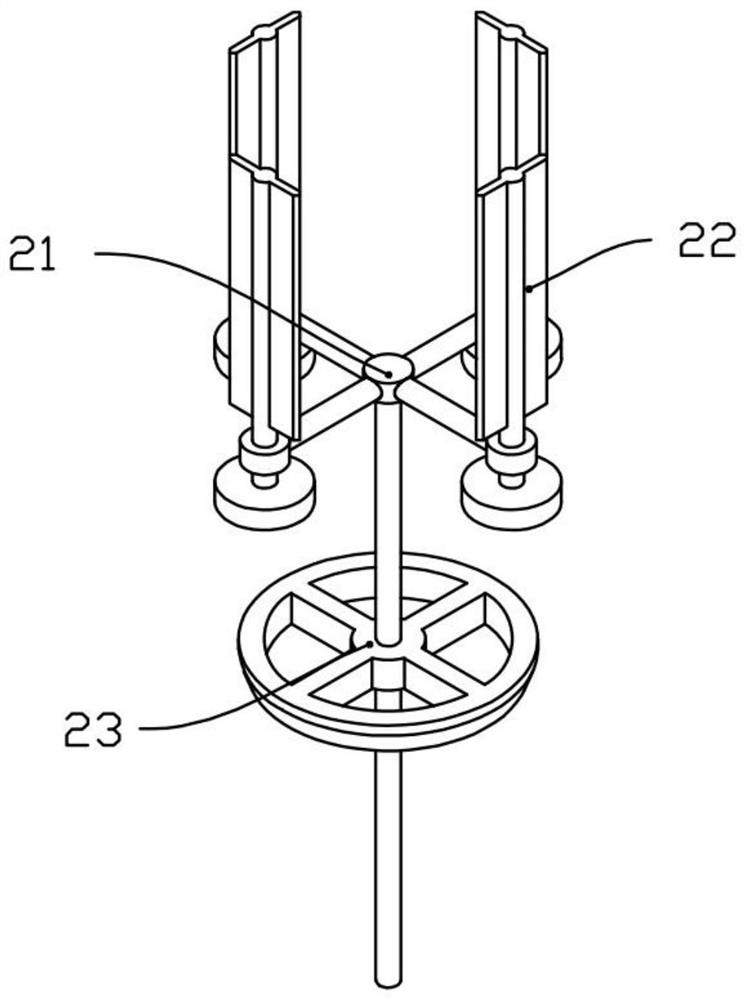

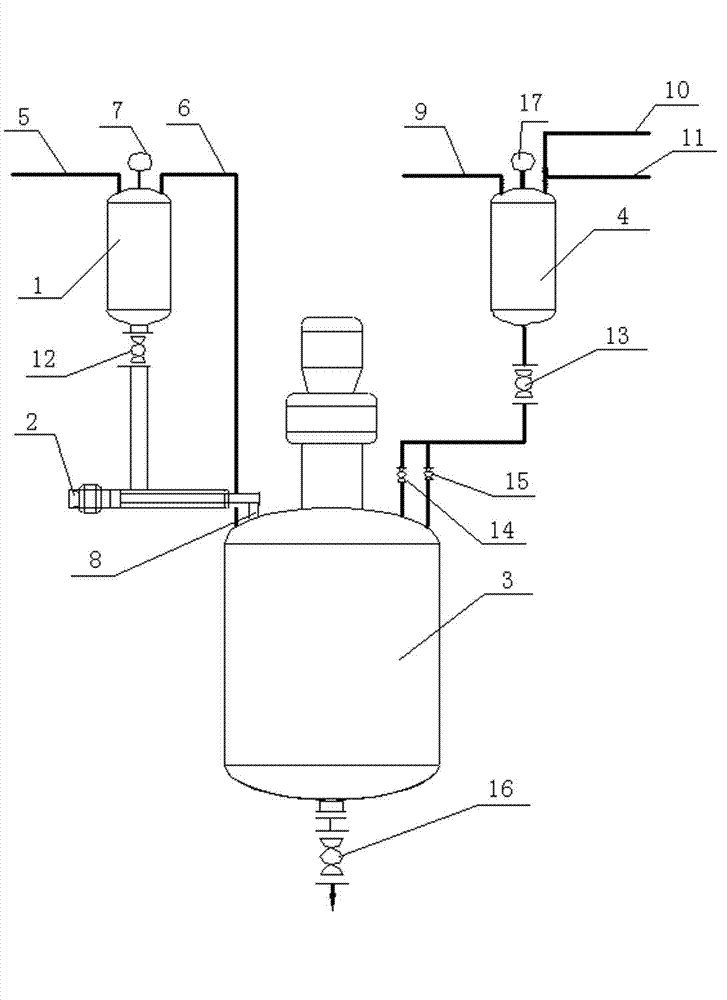

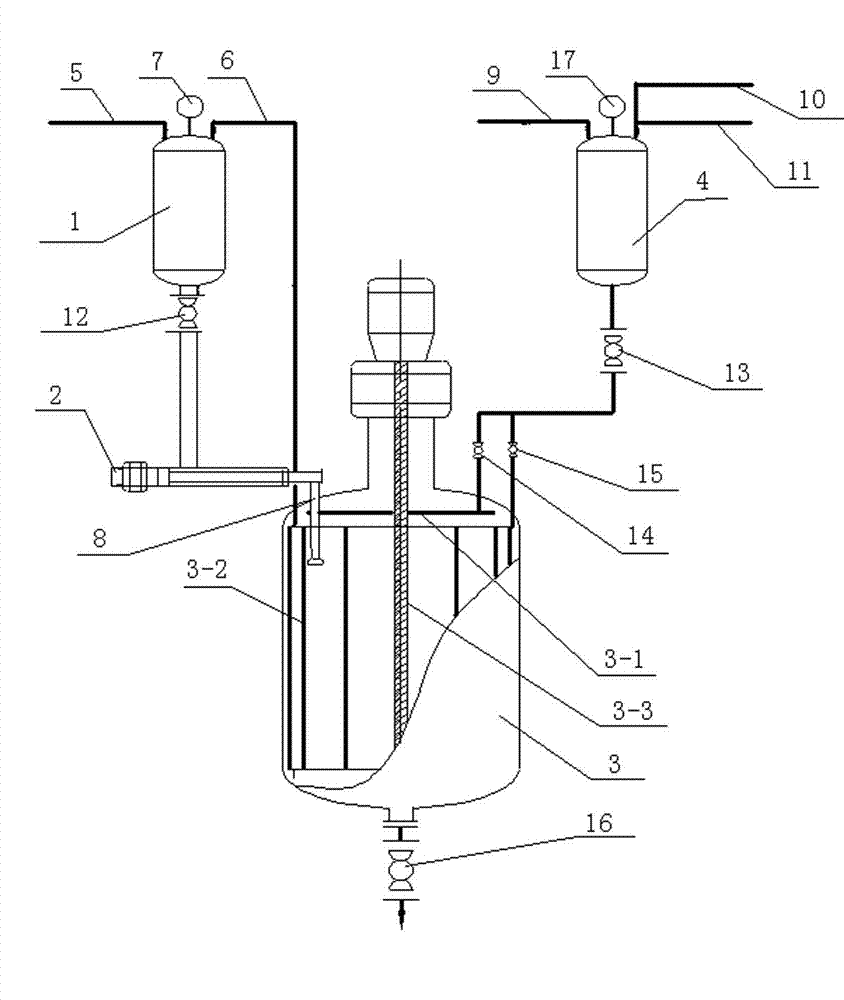

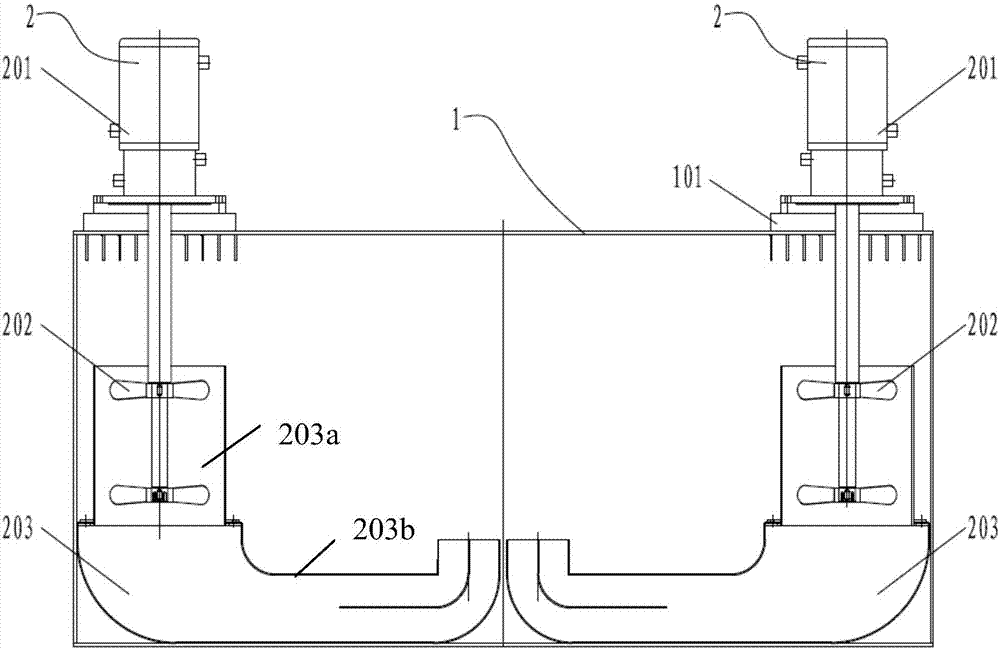

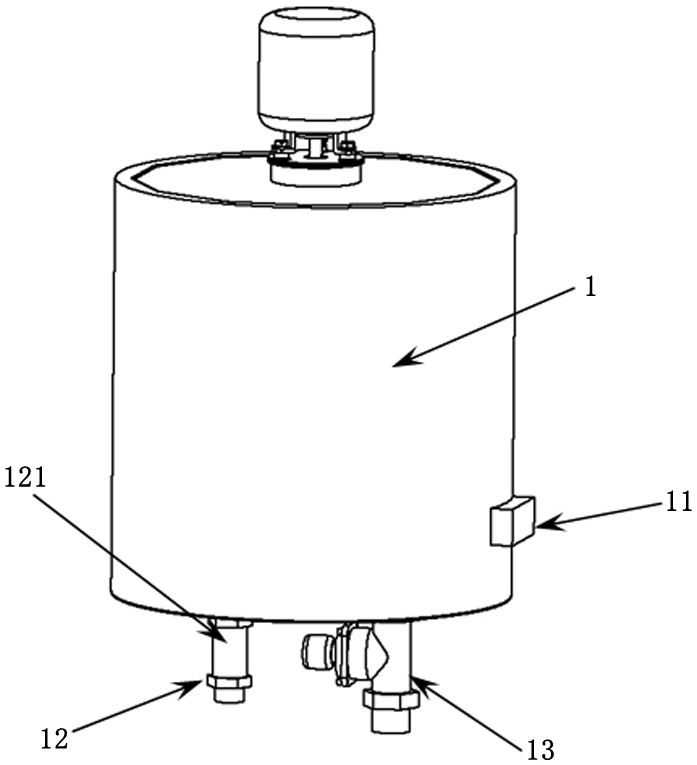

Ternary precursor preparation system

PendingCN110451587ADense grainGood sphericityCell electrodesTransportation and packagingAmmonium hydroxideChemistry

The invention discloses a ternary precursor preparation system which comprises a blending system, a synthesis control system, an aging system, a washing filter pressing system and a drying system, wherein the blending system comprises a mixed salt preparing kettle and an additive solution preparation tank; the synthesis control system comprises a reaction kettle, an alkali storage tank and an ammonium hydroxide storage tank; the reaction kettle communicates with the mixed salt preparation kettle; the alkali storage tank communicates with the reaction kettle through the ammonium hydroxide storage tank; the aging system comprises an aging kettle; the aging kettle communicates with the reaction kettle and the additive solution preparation tank respectively; the aging kettle is internally provided with a stirring device; the aging kettle is further provided with a jacket; the washing filter pressing system comprises a filter press and a mother liquid transfer tank; the aging kettle communicates with the sealed filter press and the mother liquid transfer tank respectively; and the drying system comprises a hot air circulation baking oven for drying a washed and filtered product. By adopting the system, precursor granules which are dense in granule, good in sphericity and narrow in particle size distribution can be prepared.

Owner:东莞市宏湖智能装备有限公司

Method for improving quality of capsanthin product

The invention discloses a method for improving the quality of a capsanthin product, comprising the following steps of: selecting capsanthin resin as an initial raw material; feeding the capsanthin resin in a mixer; adding water in the mixer, wherein the weight ratio of the capsanthin resin to water is 1: (0.05-0.2); stirring and mixing at a temperature of 40-50DEG C and at a rotating speed of 100-250rpm to obtain a mixed solution; cooling the mixed solution to be 30-40DEG C; centrifugally separating by using a centrifugal machine and collecting a clarified solution; and finally, carrying out gingerol and residue removal on the clarified solution to obtain a capsanthin finished product. The capsanthin finished product prepared by the method has favorable flowability; the phenomenon that precipitation demixing after the capsanthin product is placed for a long time is avoided; the content of a centrifugal precipitation is controlled within 2 percent; and the content of acetone insoluble substance of phospholipids is reduced below 1 percent.

Owner:青岛赛特生物科技有限公司

Polystyrene extruding machine

A polystyrene extruding machine comprises an extrusion pipe, a motor, a screw, an extrusion head, a feeding cabin, a heat supply device, and a fluid pressure balancing device, wherein the motor is mounted at one end of the extrusion pipe; the other end of the extrusion pipe is connected with the fluid pressure balancing device; the end of the extrusion pipe close to the motor is provided with a feeding opening; the screw is connected with the motor, and is mounted in the extrusion pipe; a vertical pulley cone is fixed onto the screw; a cycloid needle-type stirrer is fixed onto a horizontal pulley cone meshed with the vertical pulley cone; the heat supply device is mounted on the outer surface of the extrusion pipe; the fluid pressure balancing device comprises a discharging barrel, a hydraulic barrel, and a slide bar; the fluid pressure balancing device is connected with the extrusion head. The polystyrene extruding machine is reasonable in design and simple in structure, can effectively avoid mechanical failure and the output of a rejected product and a degraded product, is low in cost and easy to maintain, and can increase economic benefits for an enterprise.

Owner:JIANGSU SAIBAOLONG PETROCHEM

Solidifying point determining device

ActiveCN106645268AEasy and secure bucklePrevent rotationInvestigating phase/state changeEngineeringMagnetic stirrer

The invention relates to a solidifying point determining device which comprises an ice bath device, a refrigeration device and a cold trap where an ice bath tank is arranged. The ice bath device comprises the ice bath tank, a determining pipe, a determining pipe stirring rod which is inserted into the determining pipe and an ice bath tank stirring rod which is inserted into the ice bath tank, wherein the determining pipe is outwards communicated with a feeding branch pipe which inclines upwards, the feeding branch pipe is arranged between an air sleeve plug and a determining pipe upper cover, and a branch pipe plug for sealing the feeding branch pipe is arranged at the top end of the feeding branch pipe. The refrigerating device comprises a compressor, a condenser, a capillary tube and a coiled tube type evaporator, wherein the compressor, the condenser, the capillary tube and the coiled tube type evaporator are sequentially and circularly connected through a refrigerating fluid pipeline. A magnetic stirrer is arranged on the lower side of the bottom of the cold trap. The solidifying point determining device further comprises a digital backmann thermometer, an electric control device and an ice bath temperature sensor. The invention further discloses a method for determining a solidifying point through the solidifying point determining device. The solidifying point determining device has the advantages that an experiment temperature and the stirring speed can be conveniently controlled and a serious surfusion phenomenon can be avoided.

Owner:HENAN INST OF ENG

Trifluoromethanesulfonic acid production device and method

PendingCN112679392APut an end toImprove efficiencyCellsOrganic compound preparationPotassium fluorideTriflic acid

The invention relates to a trifluoromethanesulfonic acid production device and method, and belongs to the technical field of organic chemical engineering. The method comprises the following steps: reacting a methanesulfonyl chloride aqueous solution with potassium fluoride to obtain a methanesulfonyl fluoride crude product, carrying out reduced pressure distillation and phase separation, carrying out reduced pressure distillation again, electrolyzing the obtained methanesulfonyl fluoride pure product and anhydrous hydrogen fluoride in an electrolyzer, cooling the electrolyzed gas, introducing the cooled gas into a sodium fluoride tower, collecting the cooled gas by using a cold trap device, carrying out hydrolysis reaction on the obtained trifluoromethanesulfonyl fluoride and a potassium hydroxide solution, carrying out extraction separation on a reaction product, and recrystallizing to obtain potassium trifluoromethanesulfonate; and carrying out acidolysis reaction on potassium trifluoromethanesulfonate and excessive concentrated sulfuric acid to obtain a trifluoromethanesulfonic acid crude product, and distilling the trifluoromethanesulfonic acid crude product to obtain purified trifluoromethanesulfonic acid. Methylsulfonyl fluoride can be rapidly prepared and purified, unqualified products generated in the preparation process can be fluorinated again, and the production efficiency and quality are effectively improved.

Owner:PERIC SPECIAL GASES CO LTD

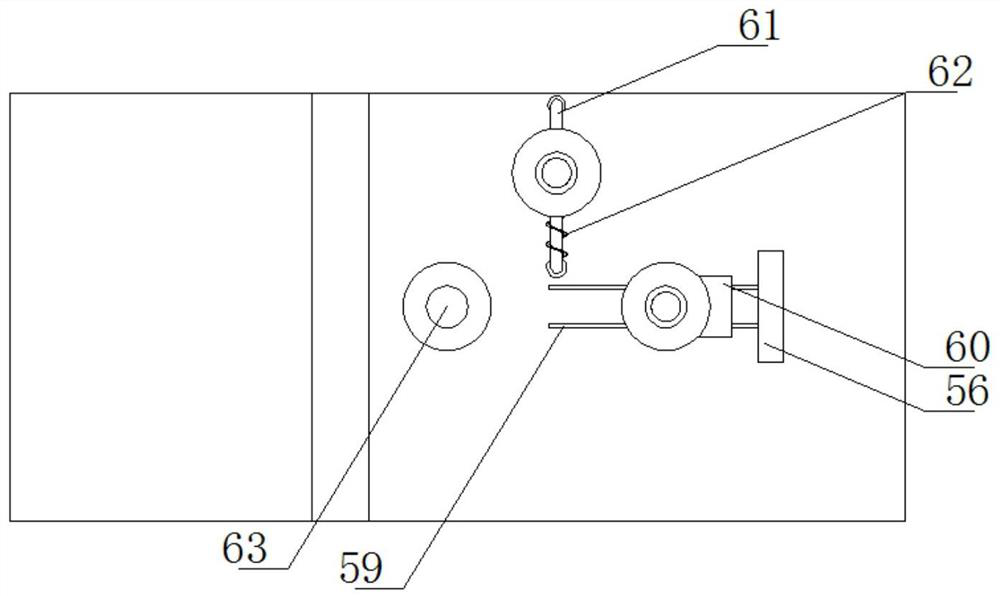

Electric feeding system and electric cooking system

ActiveCN106983349AControl releaseControl stirring speedCooking vesselsLoading/unloadingElectric machineryEngineering

The invention discloses an electric feeding system comprising a rack, a first annular rotary disc and a second annular rotary disc. A material guiding canister traverses an inner hole of the first annular rotary disc and an inner hole of the second annular rotary disc and is fixed on the rack. Liquid feeding boxes and / or power feeding boxes are distributed on the first annular rotary disc and are driven by a first motor for feeding. Open feeding boxes are distributed on the second annular rotary disc and are driven by a second motor for feeding. The electric feeding system can be driven by the motors to automatically put liquid, powder and granular materials, and is convenient to operate, and manpower is saved. The electric feeding system and en enclosed stirring smoke evacuation system can form an electric cooking system.

Owner:王伟

Equipment for treating H-acid production wastewater

InactiveCN102701505ASolving a long-standing technical problem that is intractableEffective neutralizationChemical industryEnergy based wastewater treatmentDistillationEvaporation

The invention relates to equipment for treating H-acid production wastewater. The equipment comprises a neutralization pot, an elevated tank, an evaporation pot, a crystallization tank and a centrifuge which are connected in sequence, wherein a material transferring pump for adding roughly treated feed liquid into the elevated tank is arranged between the neutralization pot and the elevated tank. A new road is opened, water is evaporated in a distillation mode by skillfully utilizing the characteristic that organic matters and the water in the wastewater have different boiling points, the organic matters and inorganic salts are separated, sticky colloidal organic matters and solid inorganic salts are separated in a centrifuging mode, the organic matters are combusted or further separated, the solid inorganic salts containing a large amount of ammonium sulfate can be directly used as a fertilizer, and waste is turned into wealth, so that the long-term technical problem that H-acid waste liquid is difficult to treat is solved.

Owner:SHANDONG YUYUAN GROUP

Building wall waterproof agent and processing device and processing method thereof

ActiveCN113351075AControl stirring speedRotating receptacle mixersTransportation and packagingActive agentPolyethylene glycol

The invention relates to waterproof agent processing, and in particular, relates to a building wall waterproof agent and a processing device and processing method thereof. The processing method of the building wall waterproof agent includes the steps that: step 1, a feeding support and a pushing mechanism rotate together, and the feeding support sequentially adds building wall waterproof agent raw materials into a stirring barrel according to the proportion; step 2, a stirring mechanism stirs the raw materials in the stirring barrel, the pushing mechanism pushes an operation mechanism to move, and the operation mechanism drives the stirring barrel to move; and step 3, the transmission ratio between the stirring mechanism and a speed change mechanism is changed, and then the stirring speed of the stirring mechanism for different raw materials is controlled. The invention relates to the building wall waterproof agent. The building wall waterproof agent comprises the following raw materials in parts by weight: 50-60 parts of an inorganic waterproof agent, 20-30 parts of methyl alkoxy silicone oil, 5-10 parts of polyethylene glycol, 0.2-1 part of an emulsifier, 1-2.5 parts of an anti-corrosion agent, 6-9 parts of an early strength agent, and 3-10 parts of a surfactant.

Owner:安徽开盛津城建设有限公司

Concrete stirring machine

InactiveCN106272976AControl stirring speedStirring speed is fastCement mixing apparatusSold ingredients supply apparatusSpiral bladeDrive shaft

The invention discloses a concrete stirring machine, which comprises a variable-frequency power supply motor, a rotating shaft, stirring blades, a feeding port, a filter sieve, a stirring barrel, an unloading system, a spiral blade, a transmission shaft, a material conveying barrel, a transmission motor, a bottom turnplate, a turnplate motor, supporting legs, a push plate and a discharging port, wherein the left end of the rotating shaft is in line connection with the variable-frequency power supply motor; the stirring blades are arranged on the rotating shaft in a longitudinally symmetrical mode; the bottom turnplate is fixedly arranged at the lower end of the stirring barrel; a cantilever supporting beam is jogged with the unloading system; the transmission shaft is fixedly connected with the spiral blade; the transmission motor is arranged at the bottom end of the material conveying barrel; the lower part of the bottom turnplat is fixedly connected with the turnplate motor; the supporting legs are fixedly arranged on the left and the right of the bottom turnplate; and the push plate communicates with the internal part of the discharging port. The concrete stirring machine is provided with an automatic conveying belt, and materials are loaded by a spiral conveyer, so cost and labor can be effectively saved; and the concrete stirring machine has high automation degree and a good stirring effect, and effectively increases the concrete stirring speed.

Owner:陈伟江

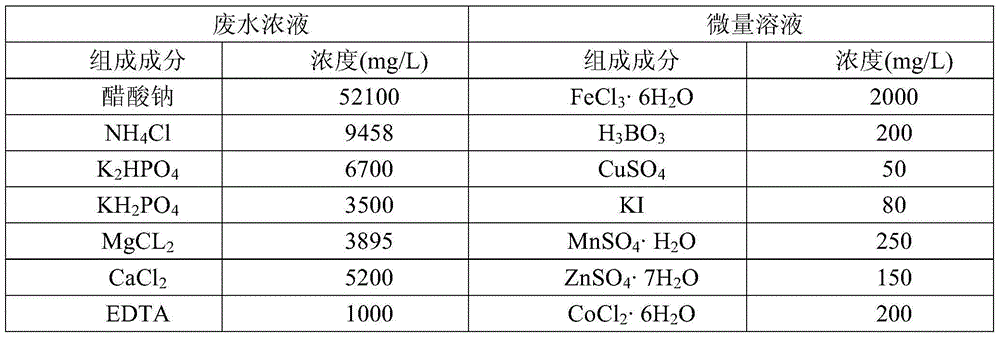

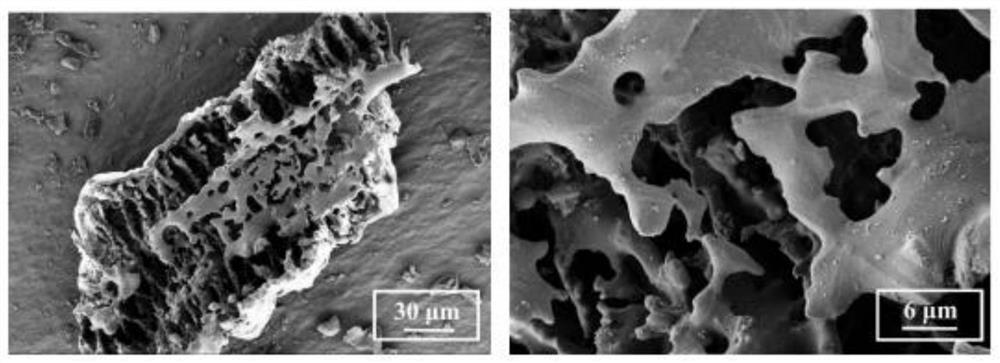

Culture method of sulfur synergy denitrification simultaneous nitrogen and phosphorous removal granular sludge

ActiveCN104098172AEvenly distributedImprove performanceTreatment with anaerobic digestion processesActivated sludgeGrowth phase

The invention belongs to the technical field of biological treatment of wastewater and particularly relates to a culture method of sulfur synergy denitrification simultaneous nitrogen and phosphorous removal granular sludge. The culture method of the sulfur synergy denitrification simultaneous nitrogen and phosphorous removal granular sludge is divided into three stages as follows: a sludge acclimation stage, a granular sludge growth stage and a granular sludge mature stage. According to the culture method, mechanical stirring is adopted, the stirring speed is controlled, and activated sludge is evenly distributed, so that the formed granular sludge is stable in performance, good in impact resistance and high in adaptability to external environment change, organic matters, nitrogen and phosphorus are effectively removed in one reactor, and sulfate radicals are involved in the whole process to play a synergistic role.

Owner:SUN YAT SEN UNIV

Wooden activated carbon adding device of camellia oleosa seed oil refining process

InactiveCN102965194AGuarantee hygienic requirementsEvenly distributedFatty-oils/fats refiningOil and greaseActivated carbon

The invention provides a wooden activated carbon adding device of a camellia oleosa seed oil refining process. The wooden activated carbon adding device comprises a wooden activated carbon temporary storage tank, a wooden activated carbon quantitative adder, an oil grease mixing tank and an oil grease temporary storage tank, wherein the upper part of the wooden activated carbon temporary storage tank is connected with a pipeline of a wooden activated carbon suction tube; the wooden activated carbon temporary storage tank is externally connected with a vacuum pipeline; a discharging opening at the lower part of the wooden activated carbon temporary storage tank is connected with the wooden activated carbon quantitative adder; the oil grease mixing tank is externally connected with the vacuum pipeline; a capturing device is arranged at the upper part inside the oil grease mixing tank; a backwashing pipeline is arranged below the capturing device; the oil grease mixing tank is internally provided with an agitating device connected with a speed-regulating controller; the upper part of the oil grease temporary storage tank is connected with a dry compressed air pipeline and an oil feeding pipeline; the oil grease temporary storage tank is externally connected with the vacuum pipeline; and a discharging opening at the lower part of the oil grease temporary storage tank is connected with the capturing device and the backwashing pipeline through different pipelines. The wooden activated carbon adding device of the camellia oleosa seed oil refining process has the advantages of compact structure, good sealing performance, no dust pollution of a working environment, high working efficiency, and uniformity of mixing wooden activated carbon with oil grease.

Owner:湖南林之神生物科技有限公司 +1

Vacuum furnace quenching oil cooling system used for thermal treatment

ActiveCN106967873ACool evenlyFlexible adjustment of cooling speedHeat treatment process controlQuenching devicesOil coolingQuenching

The invention provides a vacuum furnace quenching oil cooling system used for thermal treatment. The vacuum furnace quenching oil cooling system comprises a quenching oil tank. A water cooling wall and multiple sets of quenching oil stirring and lifting devices penetrating the water cooling wall are arranged on the top wall of the quenching oil tank. The quenching oil stirring and lifting devices extend into the quenching oil tank downwards and are used for lifting quenching oil in the quenching oil tank to the position of the water cooling wall so that the quenching oil can be cooled. Compared with the prior art, the vacuum furnace quenching oil cooling system has the following remarkable technical effects that it is ensured that the quenching oil in the quenching oil tank is uniformly cooled, the stirring speed of stirrers can be flexibly controlled, and therefore the cooling speed of the quenching oil is flexibly regulated.

Owner:江苏石川岛丰东真空技术有限公司

Synthesis method of cefminox sodium

The invention aims at providing a synthesis method of cefminox sodium. The synthesis method specifically comprises the following steps: firstly, mixing 7beta-amino-7alpha-methoxy-3-[(1-methyl-1H-5-tetrazolyl)-mercapto methyl]-3-cephem-4-methyl diphenyl carboxylate and dichloromethane (7-MAC), and bromoacetamide bromine under a certain condition to obtain 7beta-bromoacetyl amino-7alpha-methoxy-3-[(1-methyl-1H-5-tetrazolyl)-mercapto methyl]-3-cephem-4-methyl diphenyl carboxylate; then removing a carboxylic acid protection group to obtain 7beta-bromoacetyl amino-7alpha-methoxy-3-[(1-methyl-1H-5-tetrazolyl)-mercapto methyl]-3-cephem-4-carboxylic acid; then enabling the 7beta-bromoacetyl amino-7alpha-methoxy-3-[(1-methyl-1H-5-tetrazolyl)-mercapto methyl]-3-cephem-4-carboxylic acid to react withD-cysteine hydrochloride to obtain the cefminox sodium. According to the synthesis method provided by the invention, the product yield and purity of the synthesized cefminox sodium are high; phosphoric acid loaded activated carbon is used as a solid catalyst and is easy to separate from a reaction system, and the formation of acid waste liquid is avoided.

Owner:GUANGDONG LIGUO PHARMACY

Method for coating surface of wave-absorbing material with magnetic metal film

InactiveCN110541162AWill not change shapeSmooth responseLiquid/solution decomposition chemical coatingChemical platingFiltration

The invention belongs to the technical field of material modification, and particularly discloses a method for coating the surface of a wave-absorbing material with a magnetic metal film. The coatingprocess is completed through a plating solution A and a plating solution B, and surface of the wave-absorbing material is coated with the magnetic metal film in a chemical plating mode. The chemical plating comprises the following steps: 1, adjusting the pH value of the plating solution B to 10-12, and heating the plating solution B to 75-95 DEG C; 2, adding the material to be coated into the plating solution B with stirring the plating solution B, specifically, the stirring speed is 150-250 r / min; and 3, keeping stirring the plating solution B, then dropwise adding the plating solution A intothe plating solution B, and after the dropwise addition is finished, carrying out suction filtration to obtain modified wet powder, specifically, the dropping speed of the plating solution A is 20-45d / min. According to the method, the surface of the wave-absorbing material can be coated with the magnetic metal film with good continuity, compactness and uniformity.

Owner:中国人民解放军火箭军工程大学

Injection molding process of plastic basin

The invention discloses an injection molding process of a plastic basin. The process comprises the following raw materials in parts by weight: 32 parts of polyester chips, 5 parts of amino resin, 3 parts of butadiene, 3-4 parts of lignin, 1 part of methyl cellulose, 11 parts of polyvinyl alcohol, 9 parts of glacial acetic acid and 7 parts of benzoic acid. An injection molding preparation is carried out by sequentially placing the polyester chips, the amino resin, the butadiene, the lignin and the methyl cellulose into a stirring cylinder to be stirred, and a reinforcing agent is added during stirring. According to the injection molding process of the plastic basin, firstly, hardness of a finished product formed by injection molding is higher, the finished product is not easily broken, theservice life of the plastic basin is prolonged, and gas with peculiar smell or toxicity is not generated in the preparation process; and secondly, integrity of injection molding and uniformity of internal materials of the finished product can be improved, hardness of the finished product is further improved at the same time, and impact hardness, stretching strength and the tensile strength of theplastic basin can be improved, so that a better application prospect is achieved.

Owner:YINGSHANG LONGYUYANG IND & TRADE

Preparation method of washing power for rapidly cleaning food oil stains

InactiveCN107129888AGood decontamination effectSimple processSurface-active detergent compositionsDetergent mixture composition preparationMicrowaveSodium dodecylbenzenesulfonate

A preparation method of washing powder capable of quickly cleaning food grease stains comprises the following steps: mixing and stirring 10 to 30 parts of sodium dodecylbenzene sulfonate, 5 to 10 parts of sodium alkylbenzene sulfonate and 2 to 3 parts of water, Then add 40~50 parts of sodium carbonate, 10~20 parts of sodium sulfate, 5~10 parts, 5~10 parts of 4A zeolite, 1~2 parts of carboxymethyl cellulose sodium, 0.5~1 part of enzyme preparation, 1~2 parts Stir with water, and finally add 0.5 to 1 part of soap grains and stir to obtain a paste product. After ultrasonic treatment, microwave drying is carried out. The process of the present invention is simple, no spray drying is required, equipment investment is small, energy consumption is low, and the obtained preparation The obtained washing powder has good decontamination effect, has no adverse effect on the environment after washing and drainage, has low water content, is not easy to agglomerate, and has high activity.

Owner:孔晓静

A preparation method of a composite support for a propylene high temperature polymerization catalyst, a component of the propylene high temperature polymerization catalyst and the propylene high temperature polymerization catalyst

The invention relates to a preparation method of a composite support for a propylene high temperature polymerization catalyst, a component of the propylene high temperature polymerization catalyst andthe propylene high temperature polymerization catalyst. The composite support is prepared by a chemical reaction of a molten magnesium chloride alcohol adduct and a silica gel support treated by Lewis base. The composite support with good spherical shape and uniform particle distribution can be obtained by compounding a molten magnesium halide alcohol adduct with treated SiO2 through mechanical stirring. A titanium-containing catalyst and a cocatalyst prepared by the composite support exhibits excellent performance when used in olefin polymerization, especially in propylene polymerization athigh temperature (>=93 DEG C). The catalyst has high polymerization activity. An obtained high temperature polymer is good in particle form. Products have high bulk density and good stereoregularity.

Owner:PETROCHINA CO LTD

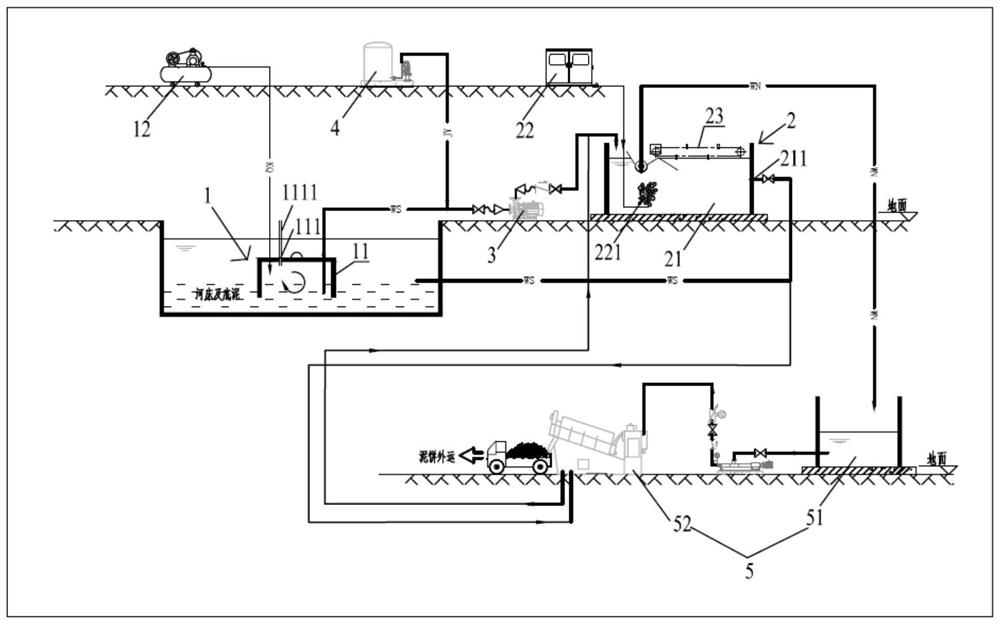

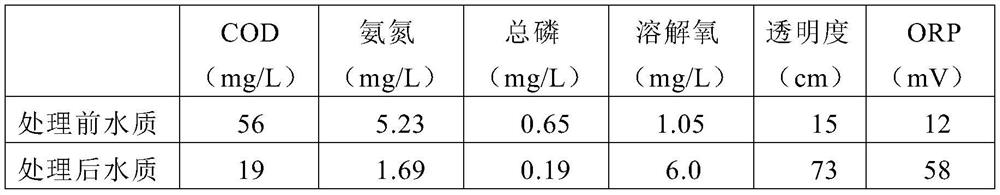

System and method for treating endogenous pollutants in water

InactiveCN111747559AAvoid releaseImprove water qualityWater treatment parameter controlSpecific water treatment objectivesPollutantSilt

The invention provides a water endogenous pollutant treatment system which comprises a flushing device, an air floatation separation device, a dosing device and a sludge treatment device. Compared with the prior art, the method has the advantages that air-flushing rotational flow washing, dosing flocculation and micro-nano bubble air floatation are adopted for cooperative treatment, so that the problems that in the prior art, the sludge amount is large, the treatment cost is high, the water quality is slowly improved, and the water quality cannot be effectively improved are solved; by adoptingthe treatment system disclosed by the invention, light organic pollutants in the bottom mud can be effectively removed, a large amount of heavy mud and sand are prevented from being removed, the desilting amount is remarkably reduced, and the sludge generation amount is only 1 / 10 of that of a traditional desilting method. According to the invention, the purposes of sludge elution, pollutant separation and clear water returning to the river are synchronously achieved, and the water quality of the water body is rapidly improved. In addition, the invention further provides a water endogenous pollutant treatment method.

Owner:DONGGUAN UNIV OF TECH +1

Silicon dioxide-carbon composite material as well as preparation method and application thereof

ActiveCN113178564AWide variety of sourcesLow priceSecondary cellsNegative electrodesCarbon compositesElectrical battery

The invention discloses a silicon dioxide-carbon composite material as well as a preparation method and application thereof, and relates to the technical field of lithium ion batteries. The preparation method comprises the following steps of S1, carrying out acid pickling pretreatment on the rice husks through an acid solution; S2, drying and crushing the rice husks; S3, calcining rice husks under the protection of inert gas to prepare a silicon dioxide-carbon composite material, wherein in the step S1, the concentration of the acid solution is 3-9wt%; and the temperature of the acid solution is 30-70 DEG C. According to the present invention, a stable ratio of silicon dioxide to organic matters is obtained by controlling the concentration of a citric acid solution, the solution temperature, the stirring speed and the stirring time through an acid pickling pretreatment process, and the silicon dioxide-carbon composite material with the proper ratio is obtained after carbonization treatment; the preparation method is simple and easy to implement, is low in cost and is free of pollution; the prepared silicon dioxide-carbon composite material is used as a negative electrode material of a lithium ion battery, and has the advantages of large specific capacity, high cycling stability, long cycle life and the like.

Owner:陈庆

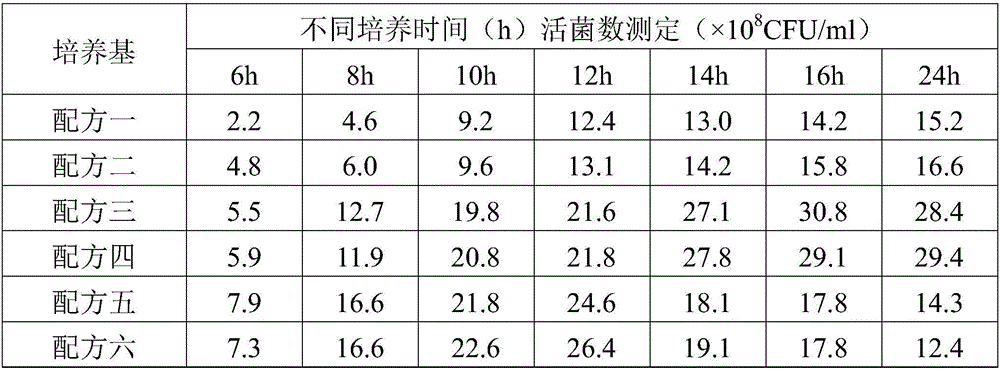

High-density fermentation and culture method of Haemophilus parasuis

InactiveCN106434480APromote growthControl stirring speedBacteriaMicroorganism based processesHigh densityHaemophilus

The invention provides a high-density fermentation and culture method of Haemophilus parasuis. The stirring rate, dissolved oxygen, pH value and culture time in the culture process are controlled by using a high-density fermentation tank culture technique, thereby being beneficial to the growth of Haemophilus parasuis; and thus, the viable count is not lower than 10<9> CFU / ml. When the Haemophilus parasuis solution cultured by the technique is used for preparing an inactivated vaccine, the inactivated vaccine has favorable safety and immune efficacy.

Owner:YEBIO BIOENG OF QINGDAO

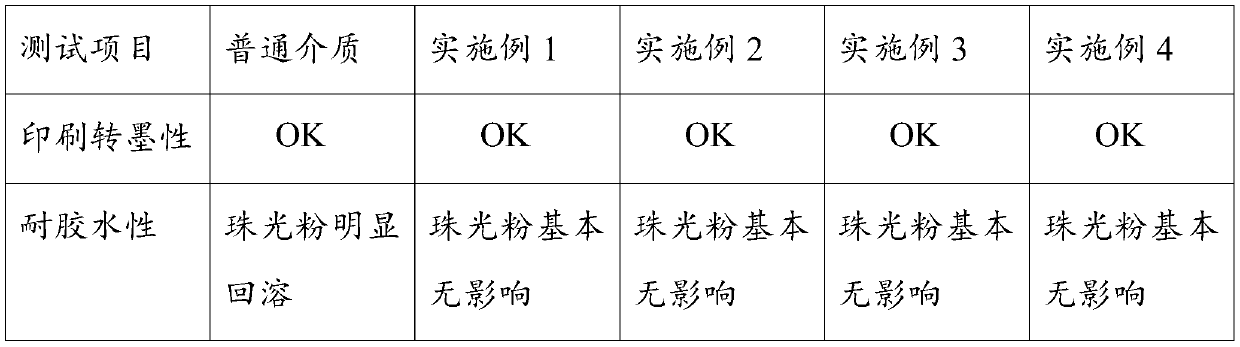

Water-based pearlescent medium used for water-based printing ink of decorative paper and preparation method of medium

The invention discloses a water-based pearlescent medium used for water-based printing ink of decorative paper. The water-based pearlescent medium used for the water-based printing ink of the decorative paper comprises the following components: 4-5% of casein, 73-80% of water, 1-2% of caprolactam, 0-1% of a pH adjuster, 10-15% of water-based polyurethane resin, 0.5-2% of an antifoaming agent, and0.5-2% of a water-based preservative, wherein a sum of the contents of each component is 100%, the casein adopts fresh milk grade casein, and the pH value of the above solution is 8.5-9.0. Through theabove manner, the medium provided by the invention can effectively solve above problems, and effectively protects pearl powder in the glue pouring process, the pearl powder does not easily fall off to be dissolved into glue, the viscosity of the printing ink is not increased, and the medium has obvious technical advantages.

Owner:昆山大世界油墨涂料有限公司

Vertical dual-layer heating stirrer

InactiveCN104941482AShorten the lengthEffective penetrationRotary stirring mixersMixer accessoriesTemperature controlAir filter

The invention belongs to the field of stirring machinery, and particularly relates to a vertical dual-layer heating stirrer. The vertical dual-layer heating stirrer comprises a machine case, a controller, a baffle plate A, a baffle plate B, a baffle plate C, a sealing plate, a discharge opening, a feeding opening, a hinge A, a sealing cover, a sealing pad, a hinge B, a sealing lock A, a sealing lock B, a hand buckle, a monitor, an air filter, a draught fan, an air flue, a thermal baffle A, a thermal baffle B, a video camera A, a thermometer A, a video camera B, a thermometer B, a motor, a rotating shaft, a reduction gearbox, a motor wheel, a chain, a chain wheel, a base, a main shaft, a stabilizer, a plummer block, a hand wheel, a blade A, a blade B, a blade C, a blade D, a blade E, a blade F, a heat dissipation layer A, a heat dissipation tube A, a heater A, a heat dissipation layer B, a heat dissipation tube B, a heater B, a heater C, a heater D and a hinge C, wherein an on-off key A, an on-off key B, an on-off key C, an image display screen, a temperature display screen, an image pick-up switch A, an image pick-up switch B and a temperature control key are arranged on the controller.

Owner:TIANJIN CHUANHAO PLASTICS

Method for reducing viscosity of ferroferric oxide

The invention discloses a method for reducing viscosity of ferroferric oxide. The method comprises the following steps: performing the water adding, the beating and the dispersing on an industrial-grade ferroferric oxide filter cake material, adding the above ferroferric oxide and water to a reaction barrel so as to form serous fluid of which the concentration is 15-25%, controlling a temperatureto be 85-90 DEG C, and adding alkaline liquor to control a PH value of feed liquid to be 9.7-9.9, and stirring in a high speed for 2-3 hours. The method is simple, the ferroferric oxide can be rapidlyreduced without adding any metal ions or oxides, and the viscosity of the ferroferric oxide can be reduced to 40-50 KU.

Owner:NANTONG DISONG TEXTILE CO LTD

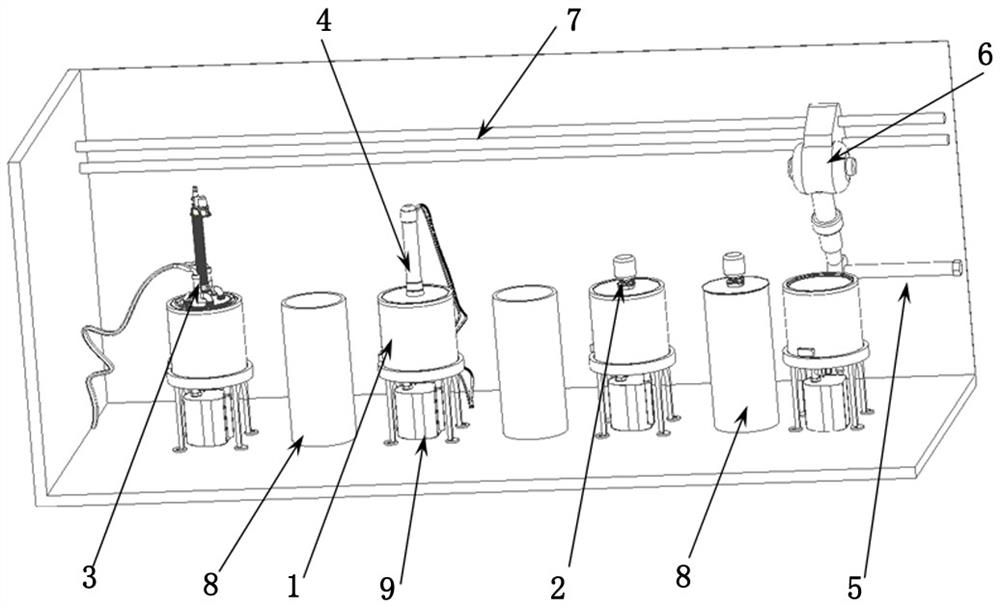

Test equipment for lubricating grease production or reprocessing

ActiveCN113694806AEasy programmingLow costShaking/oscillating/vibrating mixersRotary stirring mixersOil and greaseAutomatic control

Test equipment for lubricating grease production or reprocessing comprises at least one kettle body, a stirring device, a cooling device, a discharging device and a clamping mechanism used for clamping the stirring device, the cooling device or the discharging device and moving the stirring device, the cooling device or the discharging device to a designated position. The clamping mechanism is arranged on a guide rail through a moving module. The moving module drives the clamping mechanism to reciprocate in the guide rail direction. According to the scheme, through innovative design, a whole set of grease production or re-conditioning equipment is provided, the test processes of stirring, heating, cooling, conditioning and the like of lubricating grease can be completed under automatic control, and grease samples can be automatically discharged after being inspected to be qualified. The equipment has the advantages of being safe to operate and low in cost, can be installed in an unmanned workshop, is completely operated by a manipulator, and does not need manual on-site operation from feeding, stirring operation to discharging, so that on one hand, inaccurate test results caused by improper manual operation are avoided, and on the other hand, operators are protected from being hurt by related chemical substances to human bodies.

Owner:郑州众城润滑科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com