Solidifying point determining device

A technology for measuring device and freezing point, applied in the field of thermal analysis, can solve the problems of inconvenient control of experimental temperature, inconvenience of stirring speed, influence of experimental efficiency, etc. The effect of opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

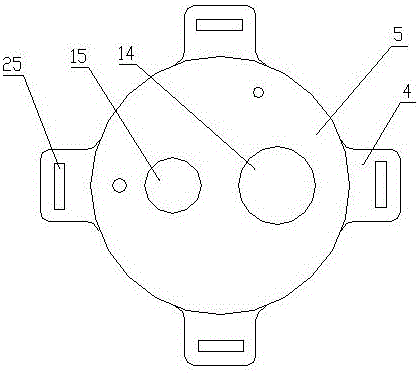

[0047] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the freezing point determination device of the present invention includes an ice bath device, a refrigeration device, and a cold trap 22 for placing the ice bath device. The ice bath device includes an ice bath tank 1, a measuring tube 12, and a measuring tube inserted into the measuring tube 12. Tube stirring rod 9 and ice bath stirring rod 6 inserted into ice bath 1,

[0048] The upper end of the ice bath 1 is provided with an ice bath upper cover 5, the ice bath upper cover 5 is buckled and connected with the ice bath 1, and the ice bath upper cover 5 is provided with a large test tube hole 14 and a small measuring tube 12 The test tube hole 15, the large test tube hole 14 is inserted with an air sleeve 2, the upper end of the air sleeve 2 is provided with an air sleeve plug 13 for sealing the air sleeve 2, and the measuring tube 12 is inserted through the air sleeve plug 13 In the air sleeve 2, there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com