Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Contains less" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

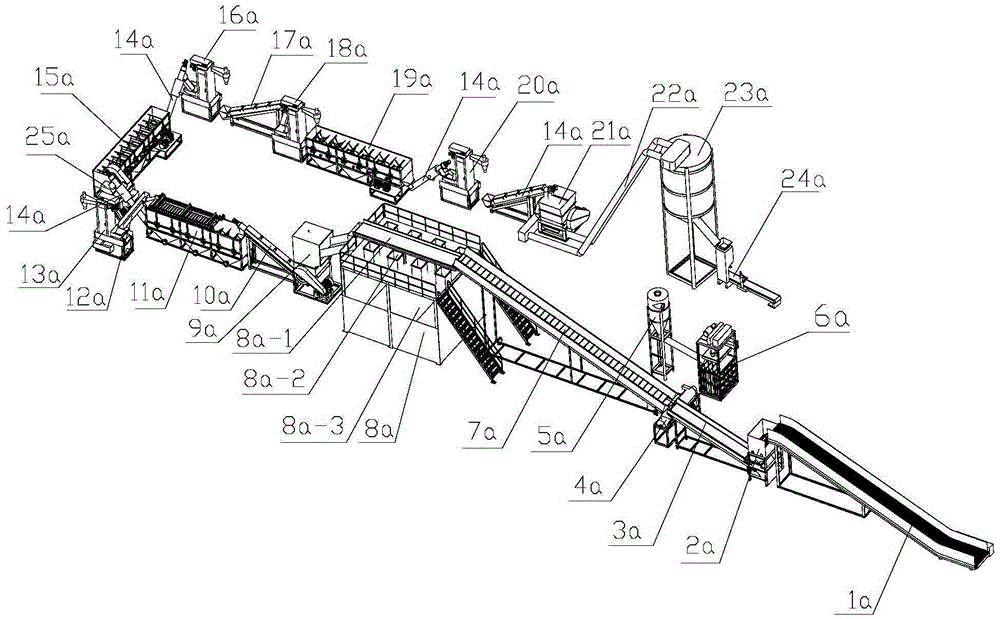

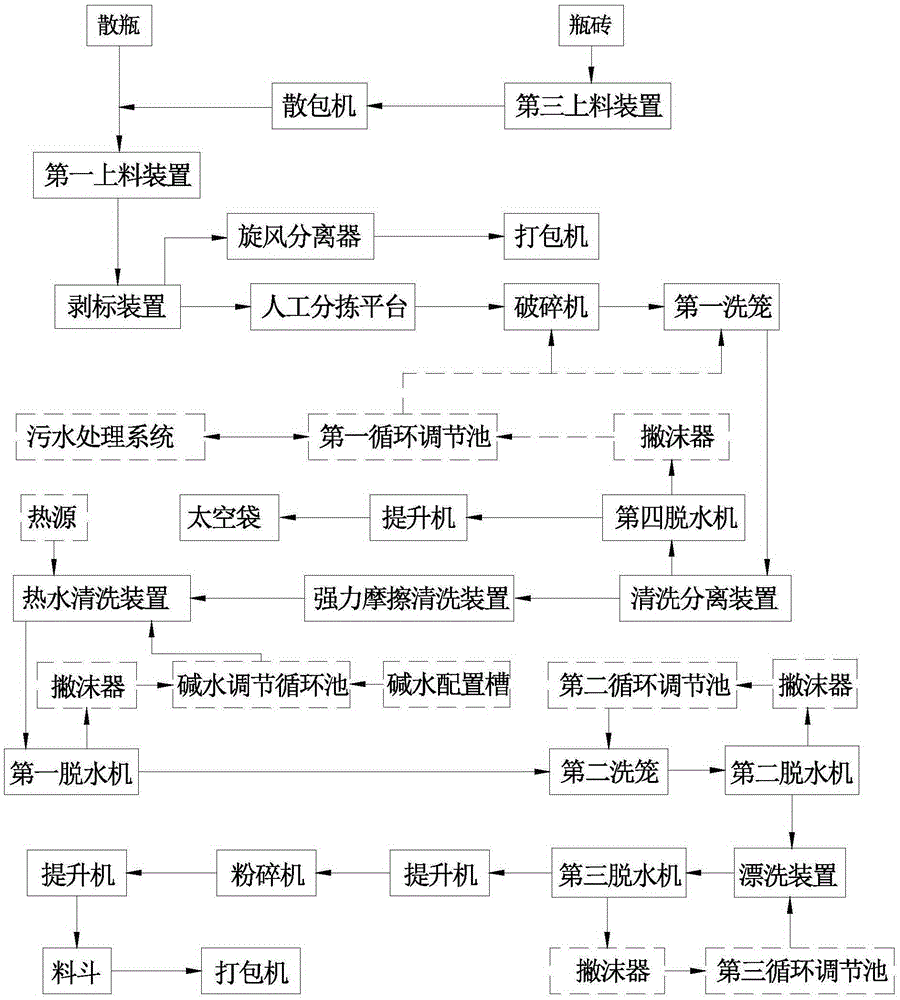

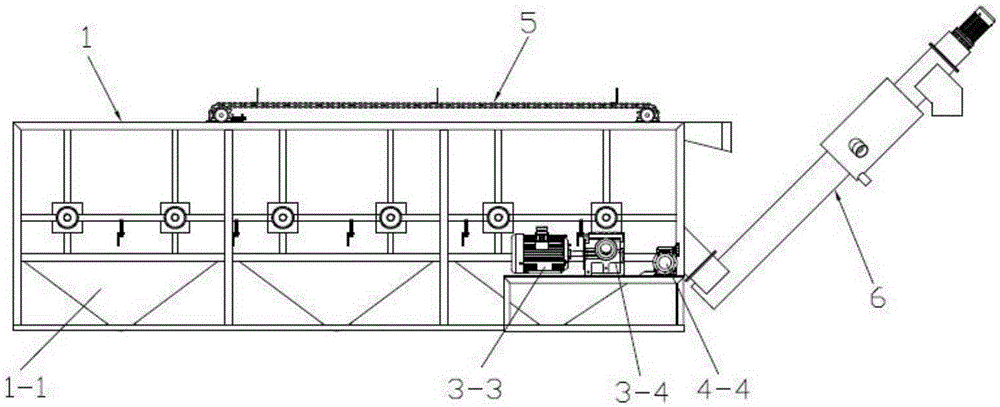

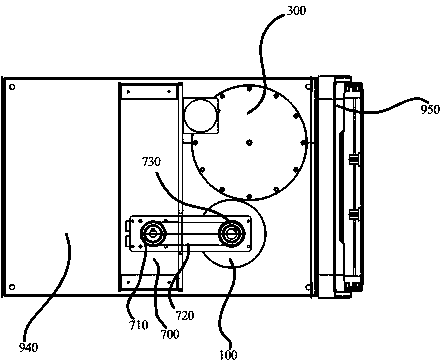

Recycle production line and recycle technology of PET (Polyethylene Terephthalate) bottles

ActiveCN105291304ADrop in timeImprove cleaning efficiencyPlastic recyclingCleaning using liquidsProduction linePolyethylene terephthalate

The invention discloses a recycle production line and a recycle technology of PET (Polyethylene Terephthalate) bottles. The recycle production line comprises a first feeding device, a label removing device, a second feeding device, a manual sorting platform, a crusher, a first washing cage, a cleaning and separating device, a high-strength friction cleaning device, a hot-water cleaning device, a first dehydrator, a second washing cage, a second dehydrator, a rinsing device, a third dehydrator and a packer; the cleaning and separating device, the hot-water cleaning device and the rinsing device separately comprise a water tank, stirring cleaners and a mesh screen; each mesh screen tank is formed by sequentially connecting a plurality of arc-shaped mesh screen tank units with upward openings in series along the horizontal direction; a stirring cleaner is arranged above each arc-shaped mesh screen tank unit; each stirring cleaner comprises a rotary shaft and a stirring plate arranged on the rotary shaft; and the rotary shaft of each stirring cleaner is connected with a stirring cleaning driving mechanism. By adopting the production line, the cleaning of fragments is good in effect, high in speed and high in production efficiency.

Owner:冯愚斌

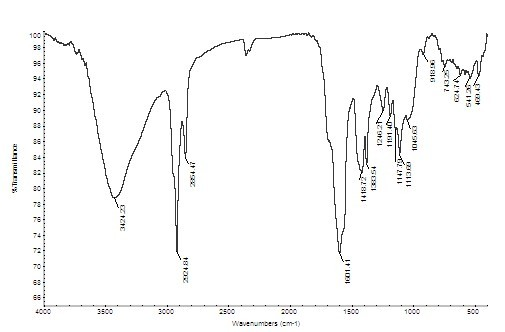

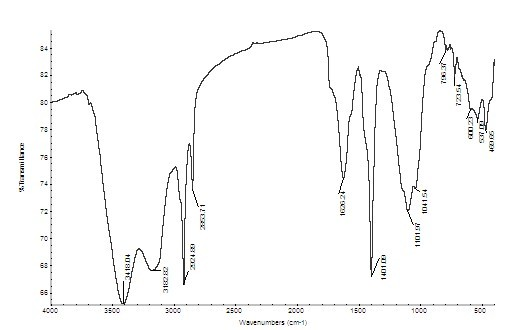

Method for preparing hydrocarbons matter with biological oil and fat

InactiveCN101343552AConsistent structureGrowing conditions require extensiveLiquid hydrocarbon mixture productionBio-feedstockOil and greaseKerosene

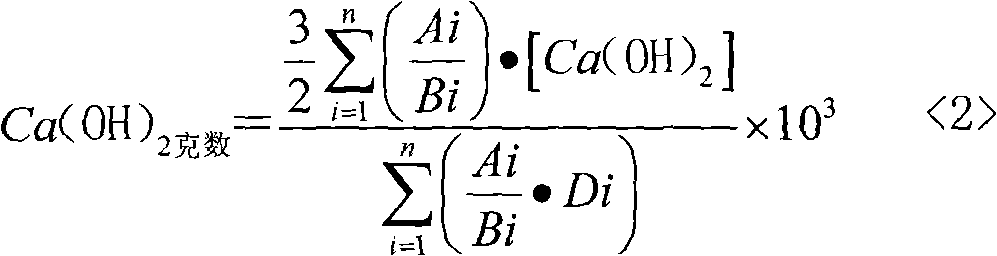

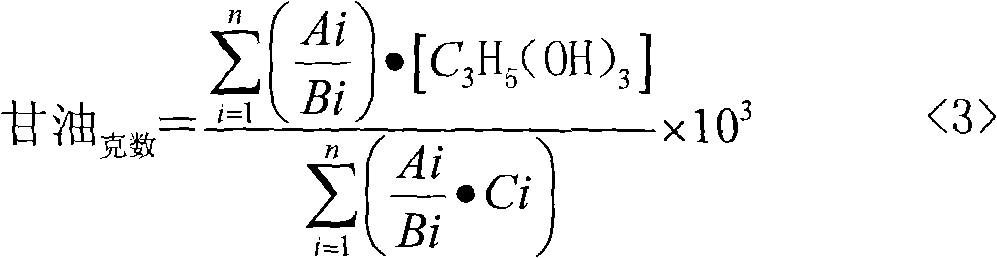

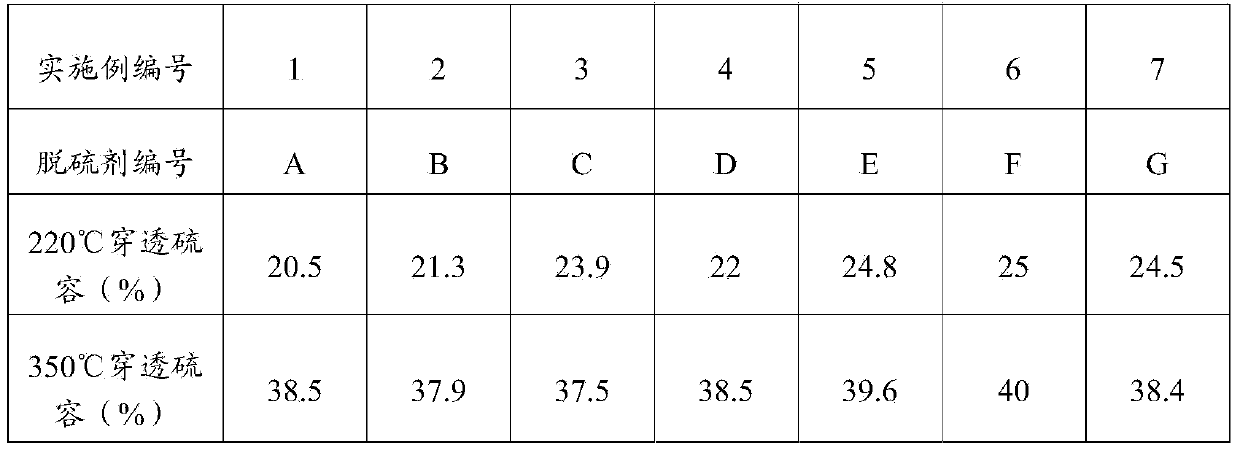

The invention relates to a method for preparing hydrocarbon substance equals to diesel oil, gasoline and aviation kerosene through inducting the calcium soap process of decarboxylation by utilizing biological grease, which belongs to the biological fuel oil field. The method comprises the following steps in sequence: the process of extracting biological grease; the process of full hydrogenation; the process of full calcium saponification; the process of extracting glycerin; the process of decarboxylation; the process of catalytic cracking. The preparation of biological oil with the biological grease of the invention has the advantages: firstly, the structure and the composition of the basic molecule of the biological oil is identical with that of the real petroleum fuel; secondly, the technical routes are completely various, the invention adopts the inductive decarboxylation of the full saturation fatty acid calcium soap; thirdly, the selection of the raw material of the grease does not collide with the national grain and oil security strategy; fourthly, the impurities contained are less; fifthly, calcium hydroxide produces calcium carbonate after being used, and the latter can be deoxidized into calcium hydroxide after being processed, and can be reused after being purified, which complies with the principles of the circular economy and the environmental economy.

Owner:任大鹏

Method for recycling zinc oxide waste desulfurizers and co-producing ammonium sulfate

ActiveCN103626221AAvoid Zinc LossImprove recycling ratesZinc oxides/hydroxidesDispersed particle separationAmmonium sulfateEnvironmental chemistry

The invention provides a method for recycling zinc oxide waste desulfurizers and co-producing ammonium sulfate, which comprises the following steps: roasting zinc oxide waste desulfurizers at 850-900 DEG C so as to obtain an inactive zinc oxide material; dissolving the inactive zinc oxide material in water so as to obtain fluid, adding a sulfuric acid into the fluid, and after the mixture is completely reacted, filtering the obtained product, so that filter residue and zinc sulfate filtrate are obtained; adding solid ammonium bicarbonate into the zinc sulfate filtrate, reacting at 30-40 DEG C, and in the process of reacting, controlling the pH value of the solution to be 6.8-6.9 until the reaction is completed; keeping the pH value of the solution after the reaction is completely unchanged, raising the temperature of the solution to 60-70 DEG C, and continuing to age the solution under the condition of heat preservation, so that an basic zinc carbonate filter cake and an ammonium sulfate solution are obtained; washing, drying and roasting the basic zinc carbonate filter cake so as to obtain active zinc oxide; and evaporating the ammonium sulfate solution so as to recycle ammonium sulfate. The method for recycling zinc oxide waste desulfurizers and co-producing ammonium sulfate, which is disclosed by the invention, has the advantages of low treatment cost, low environmental pollution, and high zinc recycle rate.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

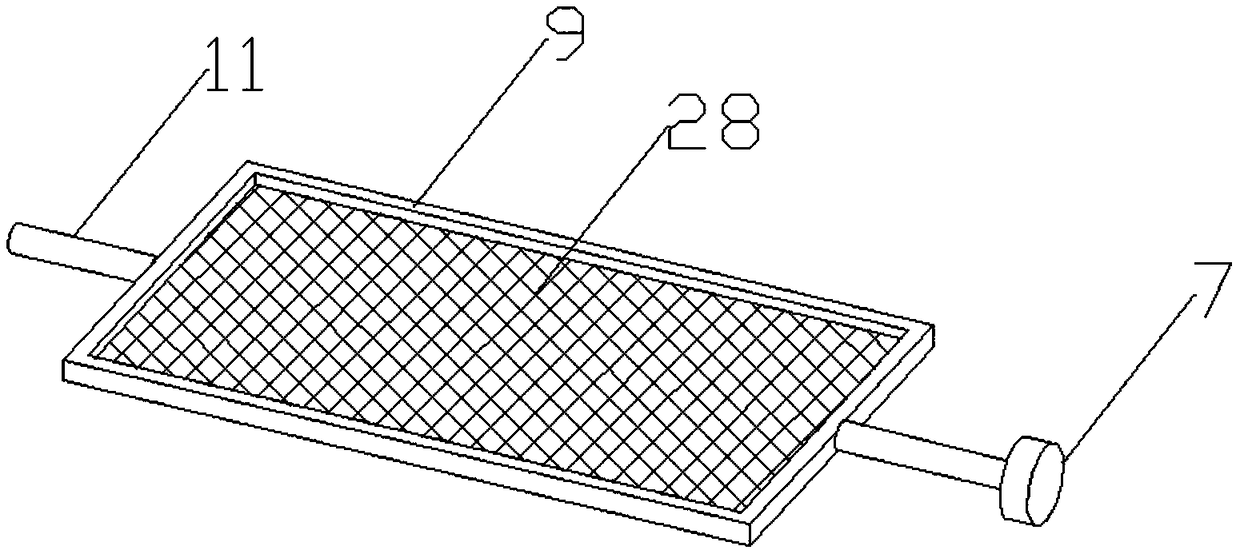

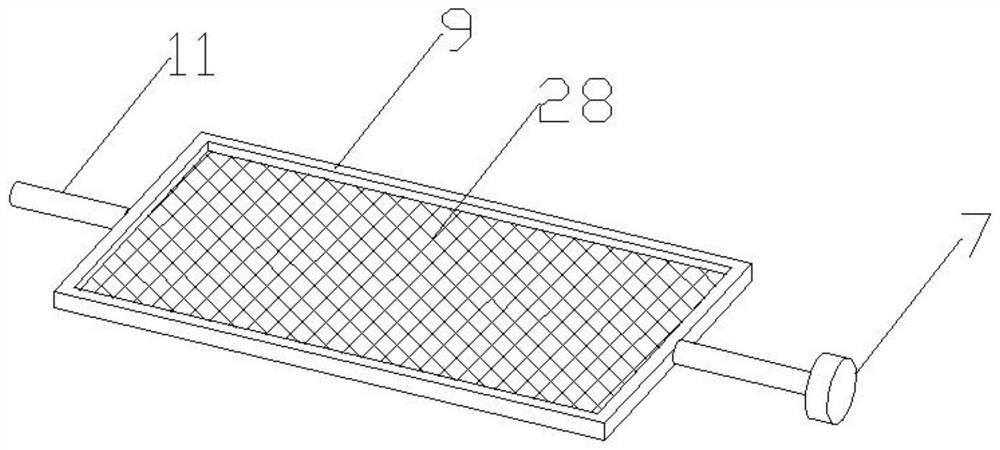

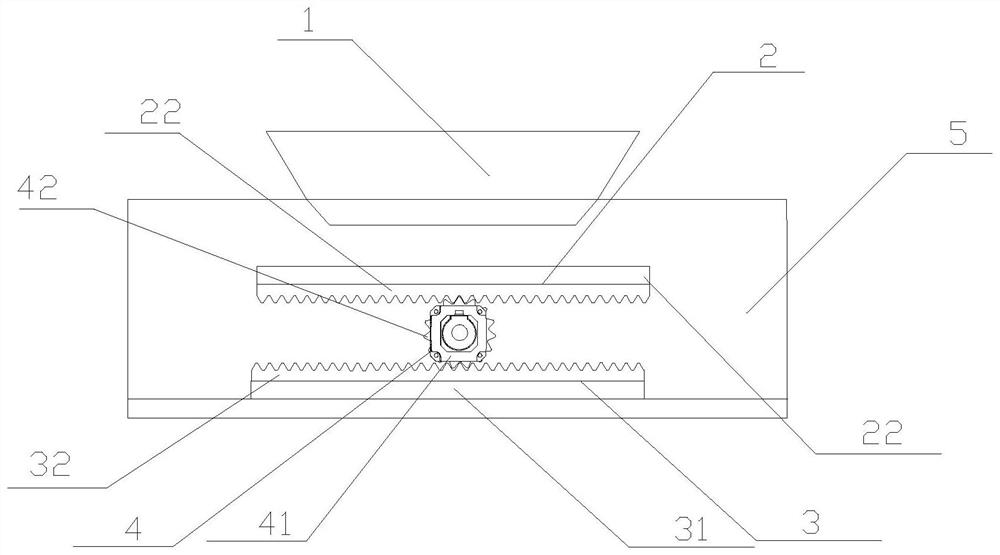

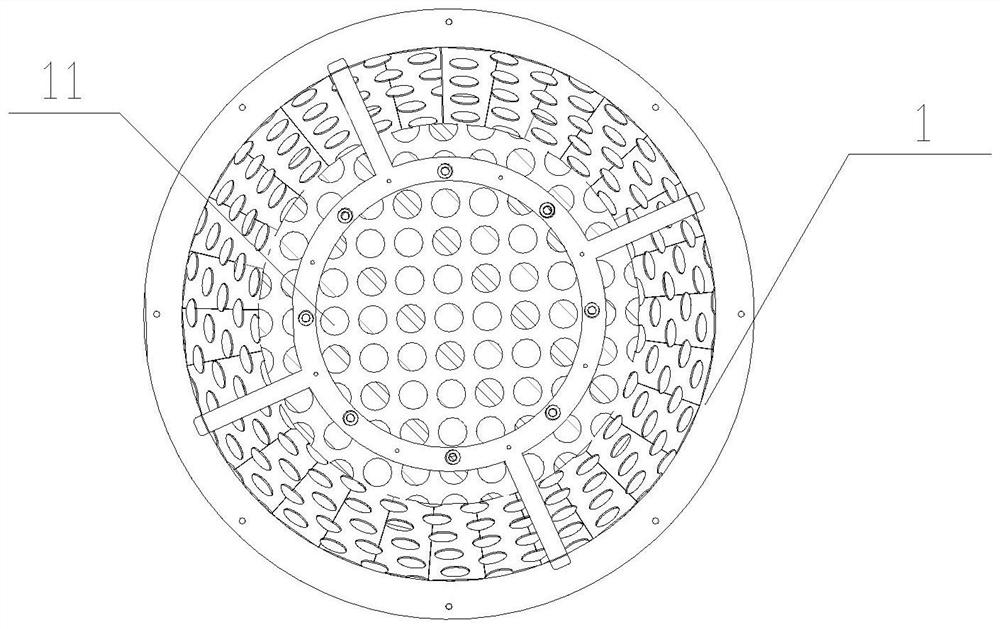

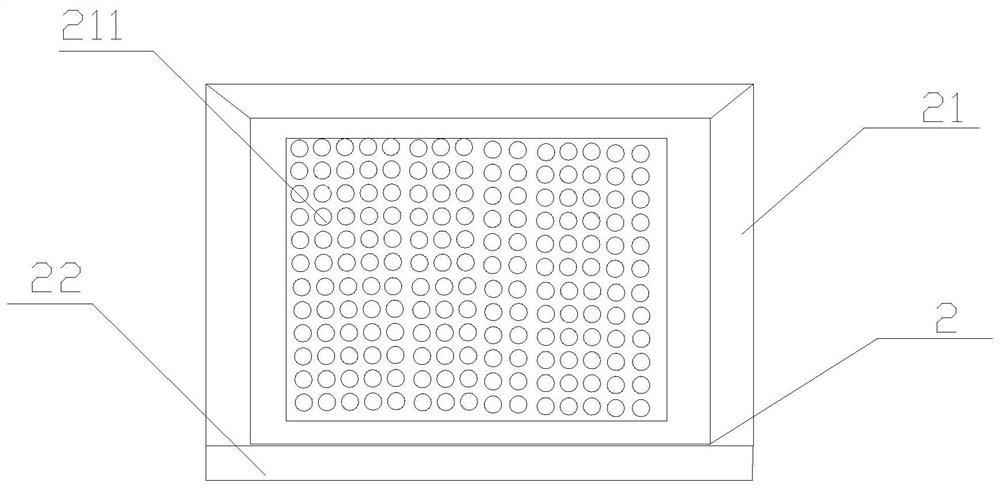

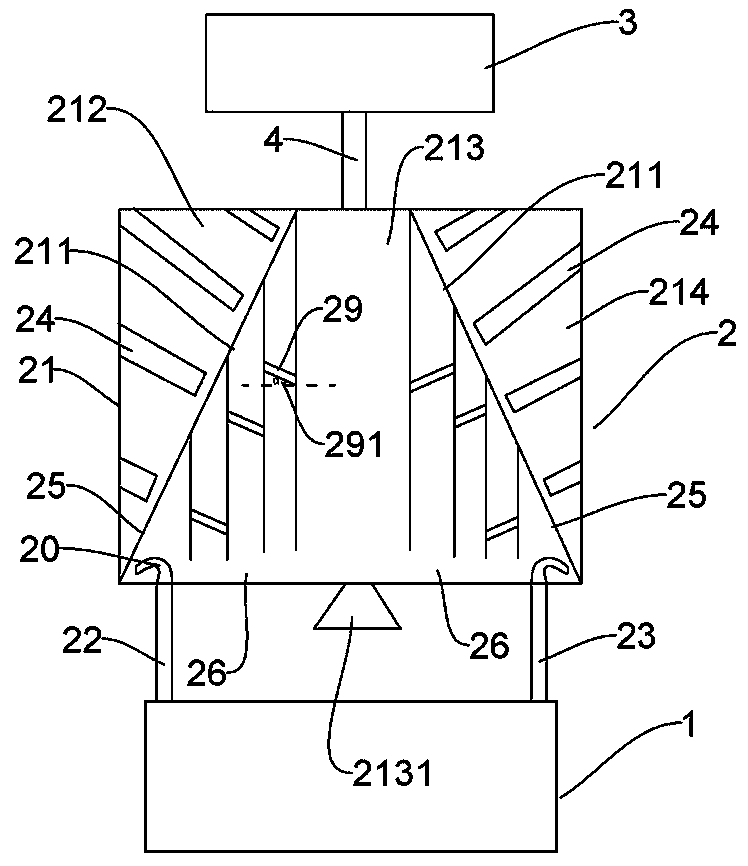

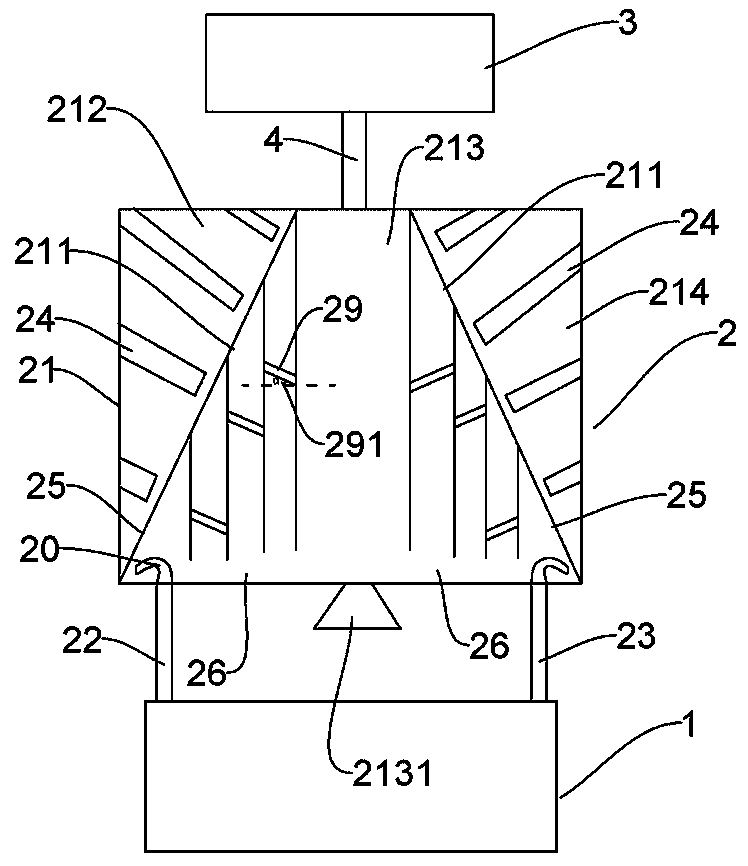

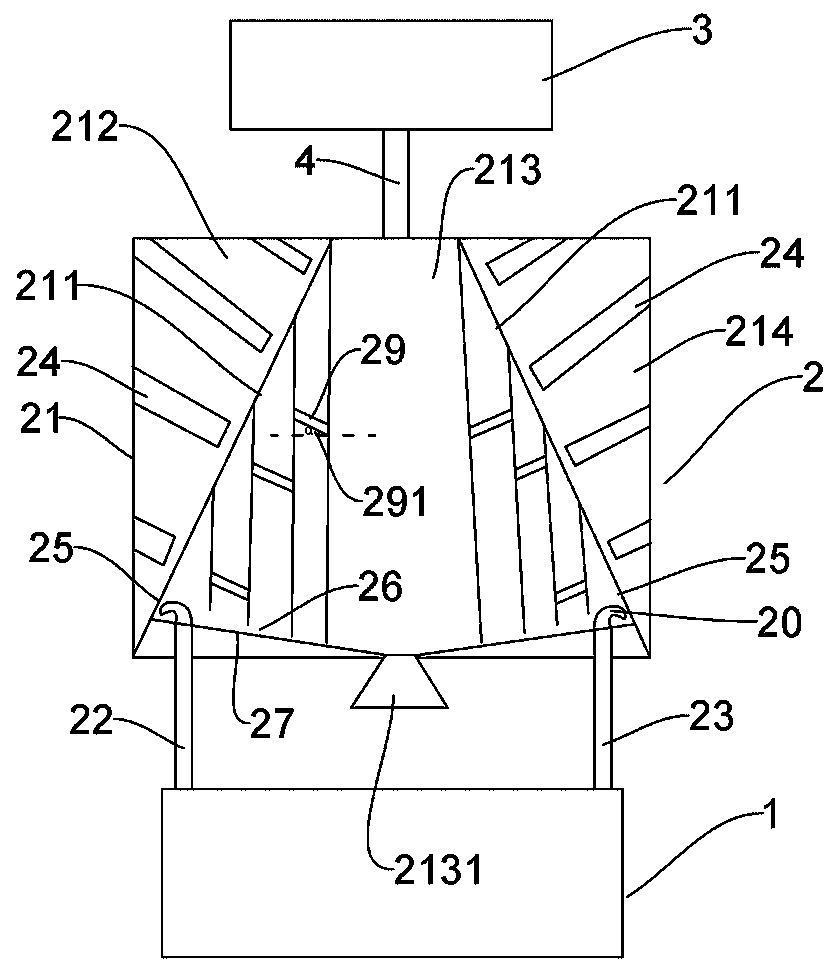

Sieving and drying device for metal powder

ActiveCN108889608ATo achieve the screening effectRealize quantitative screeningSievingTransportation and packagingScreening effectEngineering

The invention discloses a sieving and drying device for metal powder, include a hot air fan, sieve powder box, distribution box and dispersing box, An upper end of that dispersion box is provide witha motor 2 and a feeding port, A taper stirring drum is arrange in that dispersion box, the main shaft of the motor 2 is provided with a stirring shaft, the lower end of the conical stirring drum is provided with a blanking pipe, A low end of that blanking pipe is communicate with the distribution box, A control valve is arranged on the feeding pipe, A run wheel is arranged in the material distribution box, two grooves are symmetrically arranged on the runner, the upper end side of the sieve powder box is provided with a mounting seat, A motor 1 is arranged on the mounting seat, the main shaftof the motor is provided with an eccentric wheel, A screen net frame is arranged in the screen powder box, a screen net is arranged on the inner side of the screen net frame, a bracket is arranged onthe bottom of the screen powder box, and a recovery box is arranged on the upper end of the bracket. The device realizes the quantitative screening of the powder, ensures the screening effect and efficiency of the screen net, and the treated powder contains less impurities and the water content of the powder is low.

Owner:芜湖市晨睿建材有限公司

Production process of dry lotus root starch

The invention discloses a production process of dry lotus root starch and belongs to a processing technology for agricultural and sideline products. The dry lotus root starch is produced by using dry lotus roots as raw materials. The production process comprises the specific flows of raw material pretreatment, soaking, squeezing, pulp washing, pulp bleaching, dehydration and washing, and drying. The production process has the beneficial effects that the dry lotus root starch is high in purity, small in nutrient loss, pure in taste, short in production period, and suitable for large-scale production; moreover, the production process is easy to control.

Owner:臧英迪

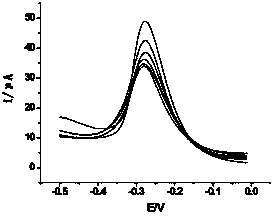

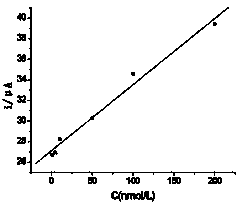

Method for detecting pesticide residue amount of chlorpyrifos in vegetables

InactiveCN104458883ALow costQuick responseMaterial electrochemical variablesChlorpyrifosPesticide residue

The invention provides a method for detecting the pesticide residue amount of chlorpyrifos in vegetables. The method is realized by applying a nano-graphene-modified electrode. The method comprises the following steps: pretreating the electrode; constructing an electrochemical sensor interface; detecting a standard chlorpyrifos and establishing a standard curve; treating a vegetable sample; and detecting the sample by using a differential pulse voltammetry, and calculating the content of the chlorpyrifos in the vegetables according to the standard curve of the chlorpyrifos. The method provided by the invention has the advantages of fastness in response, short detection time, easiness in operation, good selectivity, strong influence capability by interfering substances, high sensitivity and readiness and low detection limit, conforms to the development of a fast detection technology for the pesticide residue in China and can meet the requirement of the internationalization for detecting the pesticide residue amount in the vegetables, and the cost of instruments is low.

Owner:杨秋慧 +1

Preparation method of captan

ActiveCN112645864AEasy to operateGreat production flexibilityOrganic chemistryAir quality improvementImideWastewater

The invention relates to the technical field of pesticide synthesis, and particularly discloses a preparation method of captan. The preparation method comprises the following steps: S1, dissolving 1, 2, 3, 6-tetrahydrophthalimide in an alkaline solution to form a mixed solution, and cooling the mixed solution; S2, carrying out condensation reaction on perchloromethyl mercaptan and the mixed solution cooled in the step S1 in a tower reactor, and introducing compressed air for bubbling to form flooding entrainment; and S3, separating the flooding entrainment from the mixed solution obtained in the step S2, and heating, filtering, washing and drying the mixed solution obtained after separation to obtain the captan. The process is simple, the generated impurities are low, the generated wastewater is less, the product yield is high, and the prepared captan is good in quality and high in purity.

Owner:YINGDE GREATCHEM CHEM

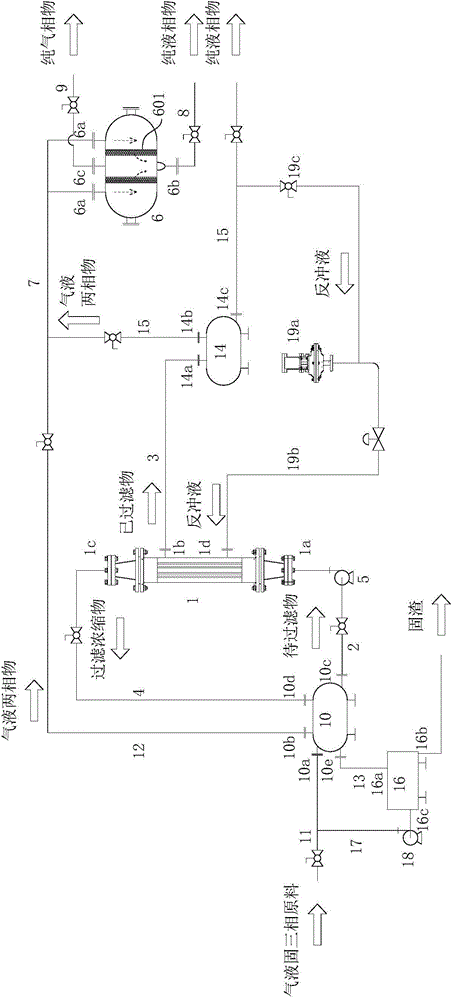

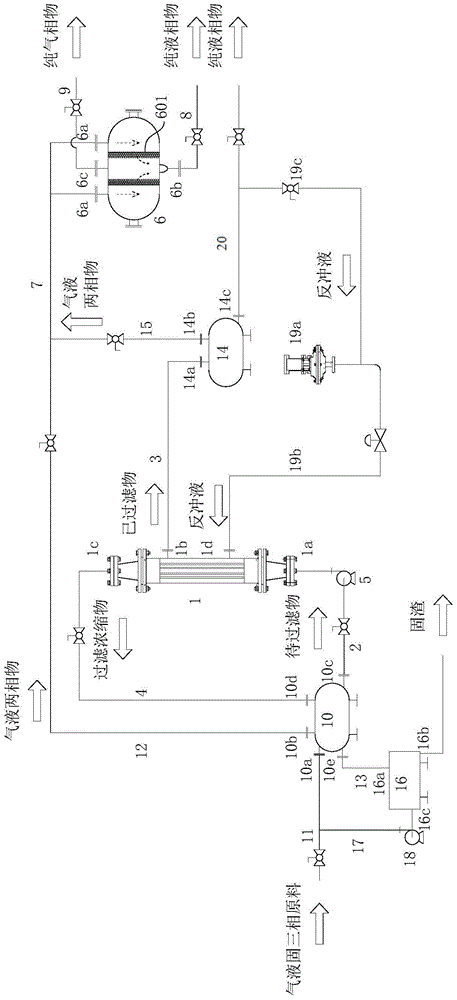

Gas, liquid and solid three-phase separation system

ActiveCN104474773AEfficient separationFully utilizeMultistage water/sewage treatmentFiltration circuitsCross-flow filtrationSlurry

The invention discloses a gas, liquid and solid three-phase separation system which can be used for realizing high-efficiency separation of three phases of gas, liquid and solid. The system comprises a cross flow filter, a gas and liquid coalescer, a front flow dividing container, a rear flow dividing container and a slurry concentrator, wherein a to-be-filtered material charging hole of the cross flow filter is connected with an output end of a to-be-filtered material conveying pipe; a filtered material discharging hole is connected with an input end of a filtered material conveying pipe; a filtered and concentrated material discharging hole is connected with the input end of a concentrated material refluxing pipe; a gas and liquid two-phase material charging hole of the gas and liquid coalescer is connected with the input end of a gas and liquid two-phase material conveying pipe; a gas and liquid two-phase material discharging hole of the front flow dividing container is connected with the input end of the gas and liquid two-phase material conveying pipe; a to-be-filtered material discharging hole is connected with the input end of the to-be-filtered material conveying pipe; the filtered and concentrated material charging hole is connected with the output end of the concentrated material refluxing pipe; a bottom slurry discharging hole is connected with a slurry conveying pipe; the filtered material charging hole of the rear flow dividing container is connected with the output end of the filtered material conveying pipe; the gas and liquid two-phase material discharging hole is connected with the gas and liquid two-phase material conveying pipe; and a to-be-treated slurry charging hole of the slurry concentrator is connected with the slurry conveying pipe.

Owner:CHENGDU INTERMENT TECH

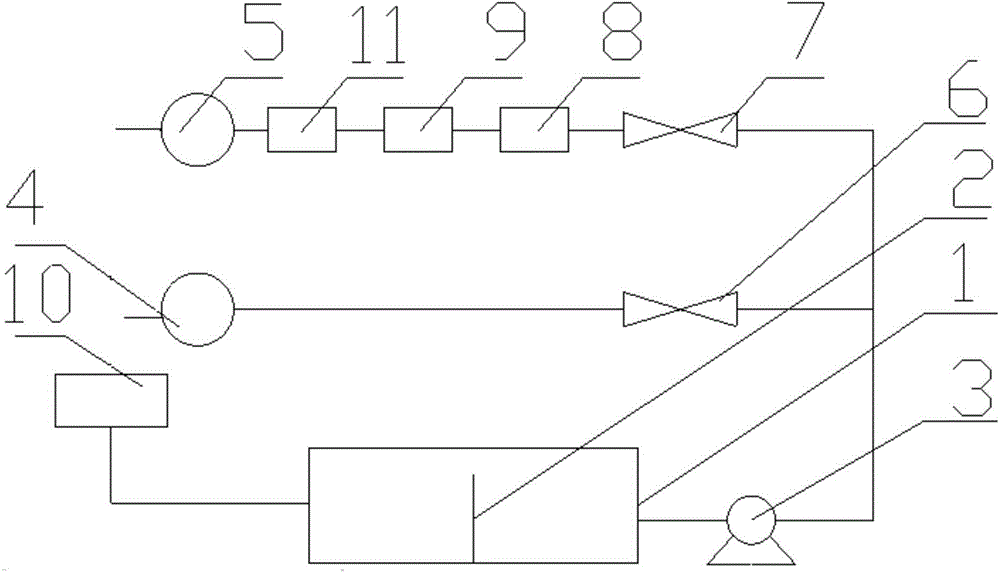

Cutting fluid circulating system used for ultrasonic inspection of numerical-control machine tool

InactiveCN104625877ASupply functionReduce manufacturing costMeasurement/indication equipmentsMaintainance and safety accessoriesNumerical controlEngineering

The invention provides a cutting fluid circulating system used for ultrasonic inspection of a numerical-control machine tool. The cutting fluid circulating system comprises a settler, a lifting pump, a first nozzle, a second nozzle and a fluid collection pan. A filter plate is arranged in the settler, and a settler inlet and a settler outlet are arranged in two sides of the filter plate respectively. The settler outlet is communicated with the inlet of the lifting pump through a pipeline, the outlet of the lifting pump is communicated with the first nozzle and the second nozzle respectively through pipelines, a first throttle valve is arranged on a pipeline between the lifting pump and the first nozzle, and a second throttle valve, a filter and a pressure relief valve are arranged on a pipeline between the lifting pump and the second nozzle; the fluid collection pan is arranged below a worktable of the numerical-control machine tool and used for collecting cutting fluid on the worktable of the numerical-control machine tool, and the outlet of the fluid collection pan is provided with a filter screen and is communicated with the inlet of the settler through a pipeline. The cutting fluid circulating system used for ultrasonic inspection of the numerical-control machine tool meets the machining and detecting requirements and good filtering effect of the cutting fluid.

Owner:蚌埠市金林数控机床制造有限公司

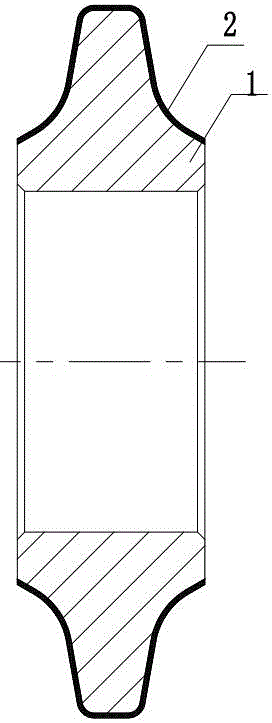

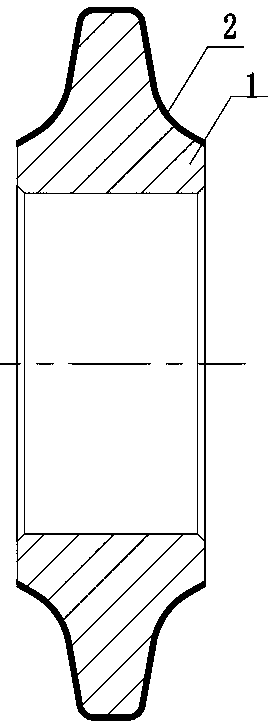

Cutter ring of electroplated diamond hobbing cutter and processing technology of cutter ring

InactiveCN106521322AImprove toughnessHigh compressive strengthElectrolytic coatingsFurnace typesHobbingWorking life

The invention discloses a cutter ring of an electroplated diamond hobbing cutter. The cutter ring comprises a cutter ring matrix and a diamond wear-resistant layer electroplated onto the outer surface of the circumference of the cutter ring matrix, wherein the cutter ring matrix comprises the raw materials in percentage by mass: 0.38-0.48% of C, 0.6-0.8% of Si, 1.20-1.55% of Mn, 2.7-3.5% of Cr, 2.6-3.4% of Mo, 1.05-1.40% of V, less than or equal to 0.02% of impurities P, less than or equal to 0.02% of impurities S and the balance Fe. The invention also discloses a processing technology of the cutter ring of the electroplated diamond hobbing cutter. The processing technology disclosed by the invention is simple in method as well as high in operability and efficiency; and the cutter ring of the electroplated diamond hobbing cutter, processed by using the processing technology, is not only meticulous in surface and low in impurity content, but also high in wear resistance and long in working life.

Owner:HUANGHE S & T COLLEGE

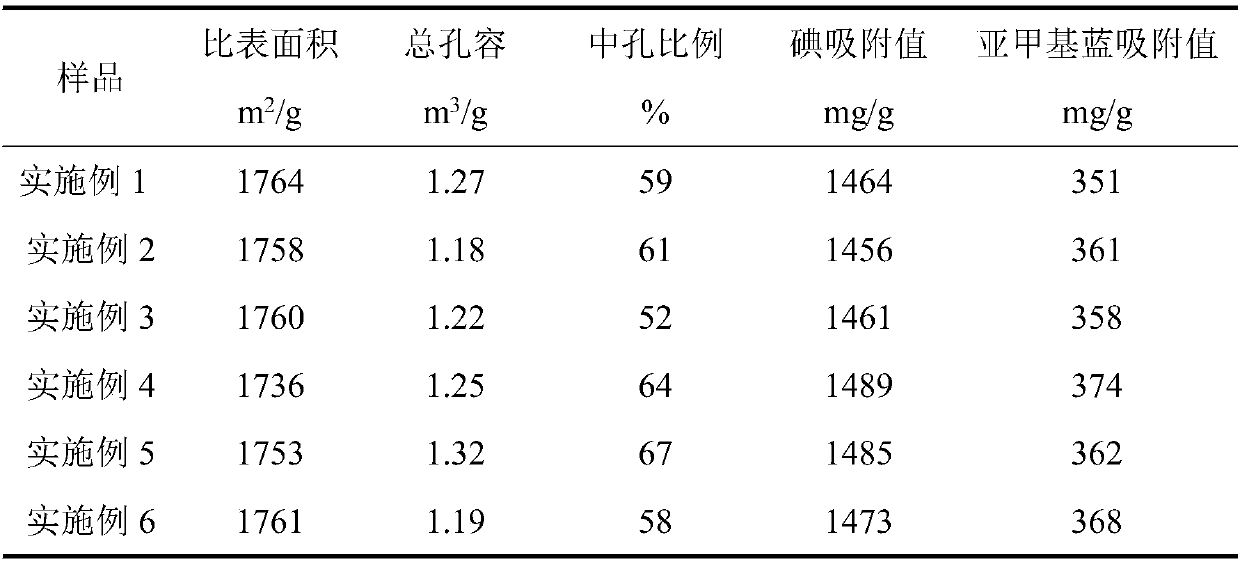

Method for preparing activated carbon by taking coconut shells as raw materials

InactiveCN109250714ALarge specific surface areaImprove adsorption capacityCarbon compoundsActivated carbonCombustion

The invention discloses a method for preparing activated carbon by taking coconut shells as raw materials. The method comprises the following steps: S1, mixing of the raw materials; S2, high-temperature carbonization; S3, activation; S4, rinsing and airing: rinsing the activated materials obtained in S3, and drying the rinsed materials to obtain dried materials; S5, pulverizing; S6, mixing: mixingthe pulverized materials obtained in S5 with bentonite and water according to the following parts by weight: 100-125 parts of pulverized materials, 24-36 parts of bentonite and 18-24 parts of water,thereby obtaining mixture; S7, granulating: S8, secondary physical activation: putting the dried granules obtained in S7 into an external combustion type converter, raising the temperature until the production temperature in a hearth is 620-650 DEG C, and introducing high-temperature water vapor for secondary activation to obtain materials after secondary activation; and S9, cooling and sieving. The activated carbon prepared by the method disclosed by the invention is higher in specific surface area and better in adsorption performance.

Owner:JINGZHOU HUARONG ACTIVATED CARBON CO LTD

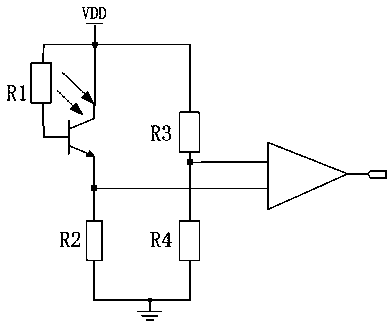

Simple light guide switching circuit

InactiveCN103532535AEqual resistanceHigh control sensitivityElectronic switchingAudio power amplifierLight guide

The invention discloses a simple light guide switching circuit which comprises a phototransistor, an amplifier, a resistor R1, a resistor R2, a resistor R3 and a resistor R4, wherein the two ends of the resistor R1 are connected with a base and a collector of the phototransistor respectively; the collector of the phototransistor is connected with a power supply, and an emitter of the phototransistor is grounded through the resistor R2; after the resistor R3 is connected in series with the resistor R4, a common end is grounded; the other common end is connected with the collector of the phototransistor; an input end of the amplifier is connected with the emitter of the phototransistor; and another input end of the amplifier is connected between the resistor R3 and the resistor R4. The circuit has the advantages that the circuit is high in control sensitivity and simple, and facilitates miniature integration.

Owner:CHENGDU HONGSHAN TECH

A screening and drying device for metal powder

ActiveCN108889608BTo achieve the screening effectRealize quantitative screeningSievingRotary stirring mixersElectric machineStructural engineering

The invention discloses a sieving and drying device for metal powder, which comprises a hot air blower, a powder sieving box, a material distribution box and a dispersion box. Conical mixing drum, the main shaft of the second motor is provided with a stirring shaft, the lower end of the conical mixing drum is provided with a feeding pipe, the lower end of the feeding pipe is connected with the distribution box, and the feeding pipe is provided with Control valve, a runner is provided in the distribution box, two grooves are symmetrically arranged on the runner, a mounting seat is provided on the side of the upper end of the powder sifting box, and a motor 1 is provided on the mounting seat. The main shaft of the motor is provided with an eccentric wheel, the powder sieving box is provided with a screen frame, the inside of the screen frame is provided with a screen, the bottom of the powder screening box is provided with a bracket, and the upper end of the bracket is provided with a Recycling box, this device realizes the quantitative screening of powder, ensures the screening effect and efficiency of the screen, the powder after processing by this device contains less impurities, and the powder has low water content.

Owner:芜湖市晨睿建材有限公司

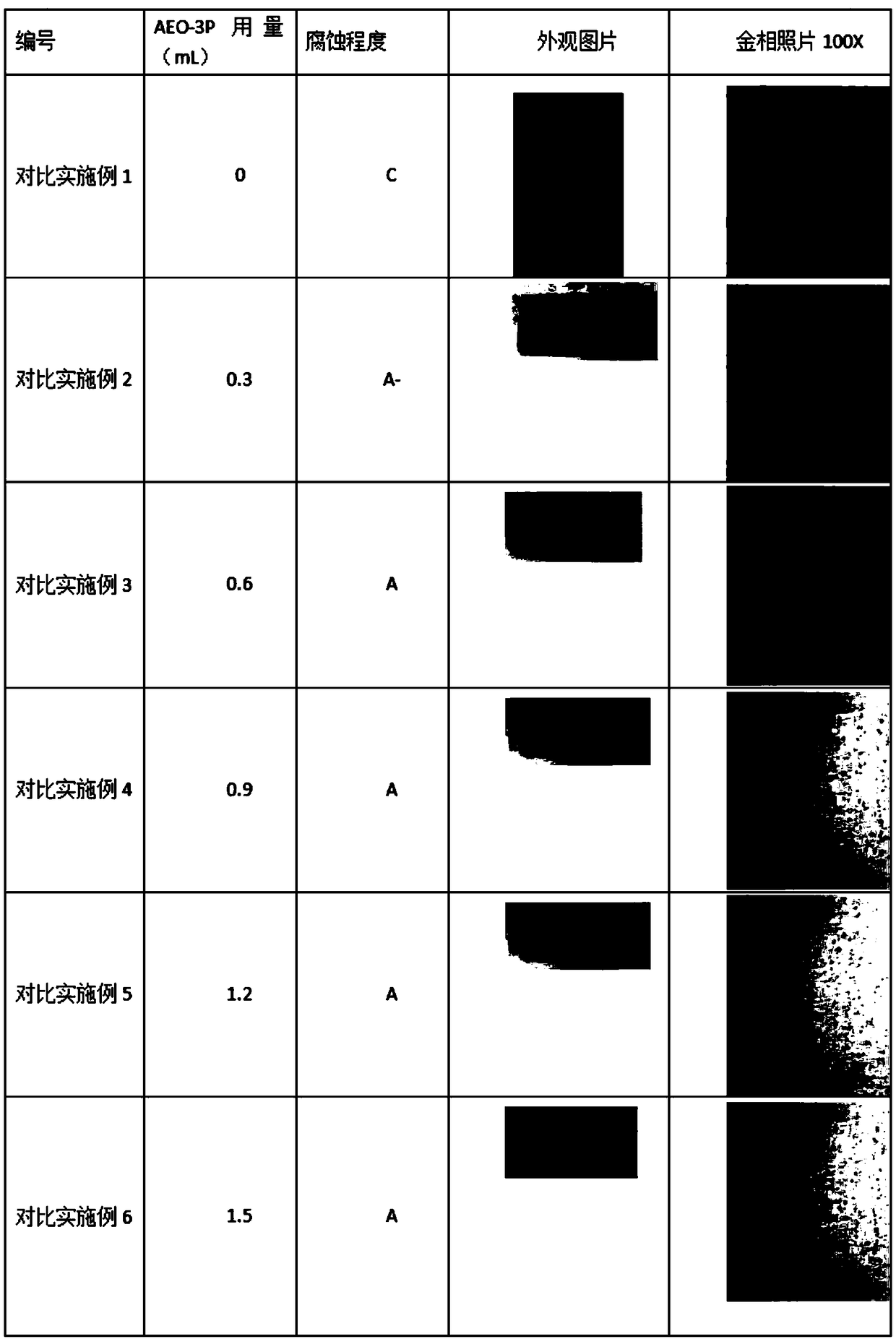

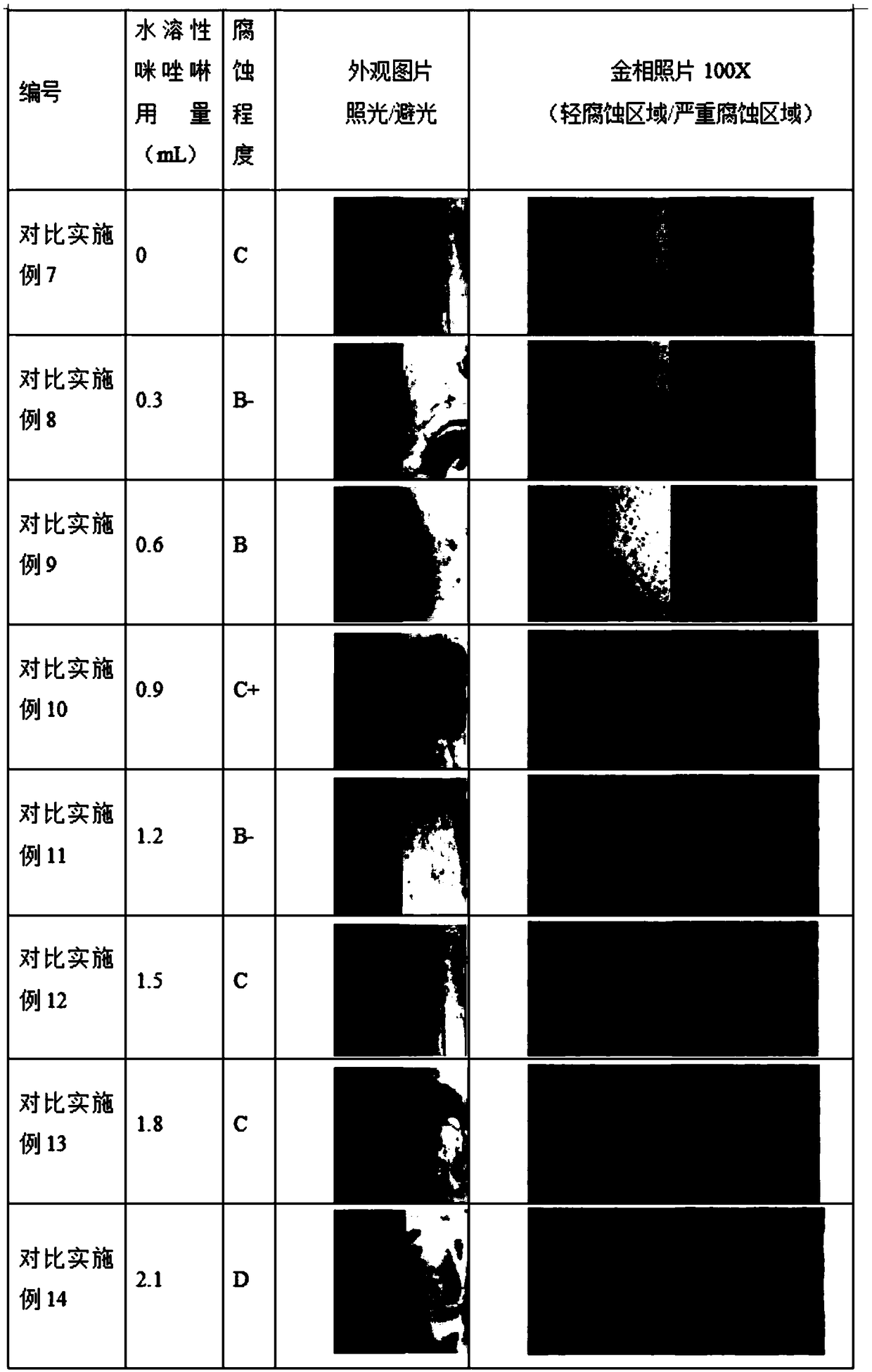

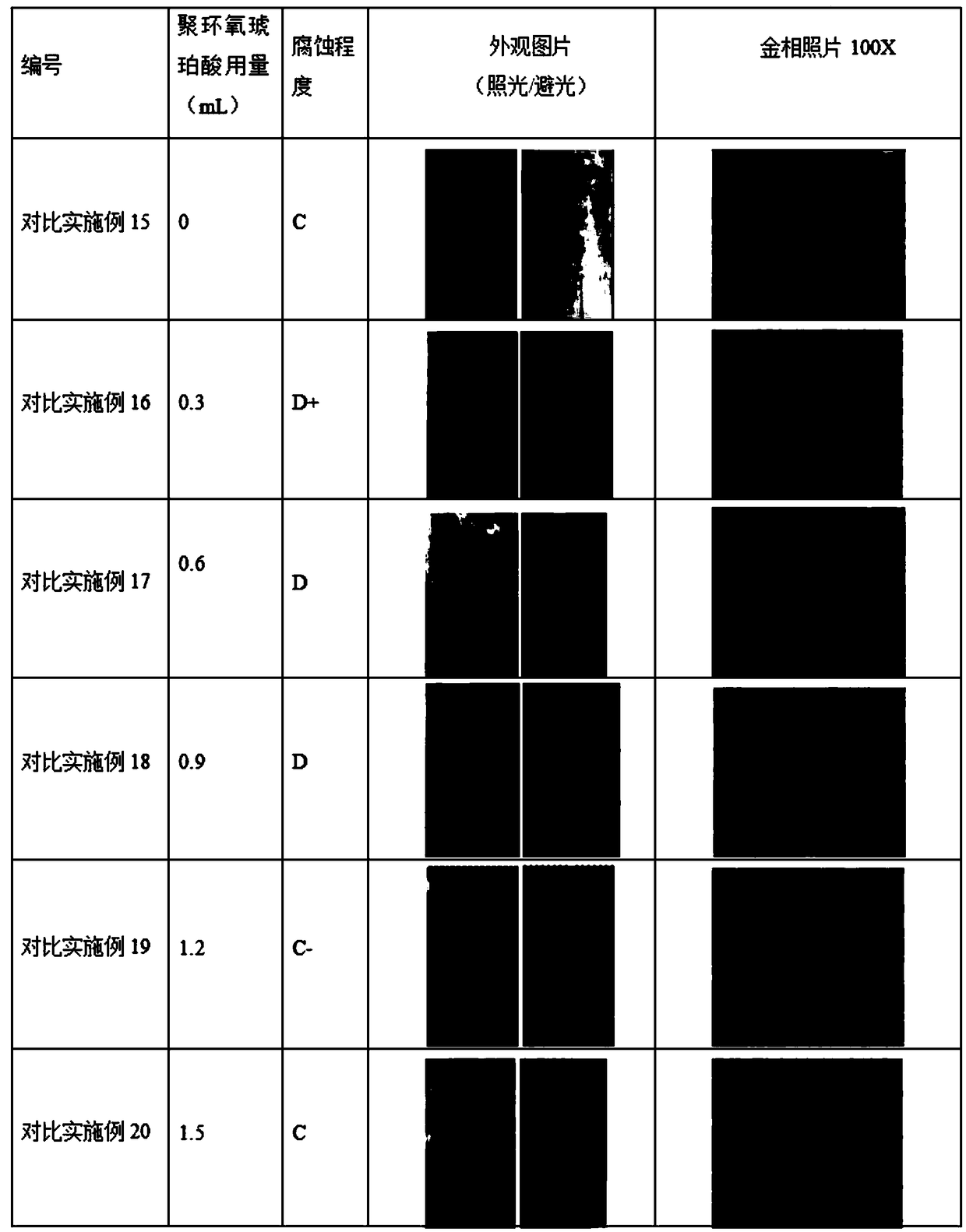

Corrosion inhibitor for 7075 aluminum alloy, micro-emulsification processing stock solution and preparation method thereof

InactiveCN109234740AEmission reductionGood corrosion inhibition effectAdditivesPhosphoric Acid EstersPhosphate

The invention belongs to the technical field of metal processing fluid, aims at solving the problem that the processing fluid for 7075 aluminum alloy is excessively high in phosphorus content, and discloses a corrosion inhibitor for the 7075 aluminum alloy. The corrosion inhibitor for the 7075 aluminum alloy is prepared from 0.05 to 0.3 part by volume of phosphorus-containing corrosion inhibitor and 0.1 to 1.5 parts by volume of phosphorus-free corrosion inhibitor; the weight percentage of fatty alcohol-polyoxyethylene ether phosphate in the phosphorus-containing corrosion inhibitor is greaterthan or equal to 95 percent; the phosphorus-free corrosion inhibitor is a water-soluble imidazoline corrosion inhibitor or polyepoxysuccinic acid corrosion inhibitor; and the weight percentage of imidazoline cationic compound in the water-soluble imidazoline corrosion inhibitor is greater than or equal to 20 percent, and the weight percentage of polyepoxy succinate in the polyepoxysuccinic acid corrosion inhibitor is greater than or equal to 40 percent. The water-soluble imidazoline corrosion inhibitor or polyepoxysuccinic acid with no corrosion inhibition effect or poor corrosion inhibitioneffect for 7075 aluminum alloy is compounded with fatty alcohol-polyoxyethylene ether phosphate, so that the same and even better corrosion inhibition effect can be achieved by utilizing less phosphorus compound, and the phosphorus emission amount can be reduced.

Owner:高雨沛

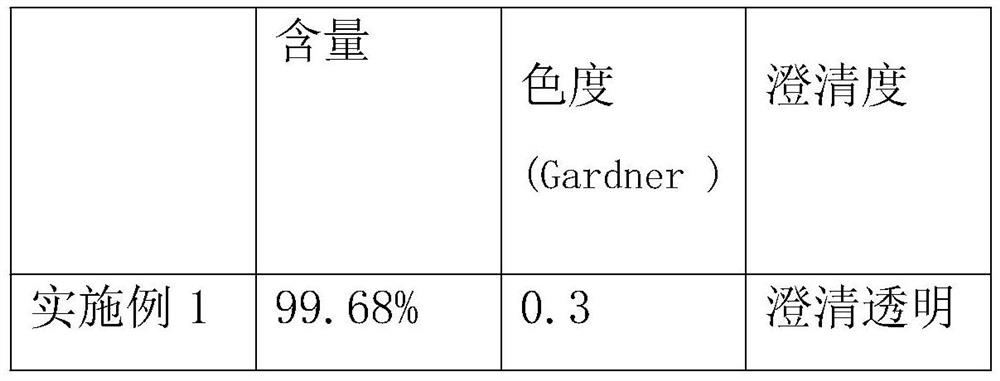

Method for preparing L-glutamic acid chelated potassium monohydrate

InactiveCN106117069ATo solve the demand for high chelation L-potassium glutamate monohydrateImprove securityOrganic compound preparationOrganic chemistry methodsOrganic solventFiltration

The invention discloses a method for preparing L-glutamic acid chelated potassium monohydrate. The method comprises the following steps of performing a reaction by using potassium carbonate or potassium hydroxide, and L-glutamic acid as raw materials, and by using water of which the temperature is 70-80 DEG C as a solvent, clarifying a solution, adjusting the pH value of reaction liquid to 7.5-8.5, continuing a reaction at 80-85 DEG C for 2-4 hours, decoloring reaction liquid, performing filtration, performing concentration to a Baume degree of 36-38 degree Be, and then performing cooling to 15-20 DEG C; and adding L-glutamic acid chelated potassium monohydrate crystals as seed crystals to concentrated liquid, maintaining the temperature to be 15-20 DEG C, performing stirring for crystallization, performing discharging, performing centrifugation so as to obtain crude products, rinsing every 100 kg of the crude products with 5-10 L of deionized water, and drying solids so as to obtain products of which the chelating degree is 95% or above. According to the method disclosed by the invention, an organic solvent is not used, so that the safety coefficient of production environment is increased, and the cost of the raw materials is substantially reduced; the products are free from solvent residues, and moisture is easy to control; and besides, investment on equipment and sites can be reduced.

Owner:宜兴市前成生物有限公司

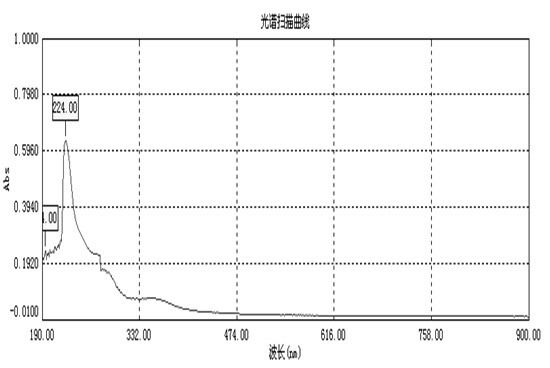

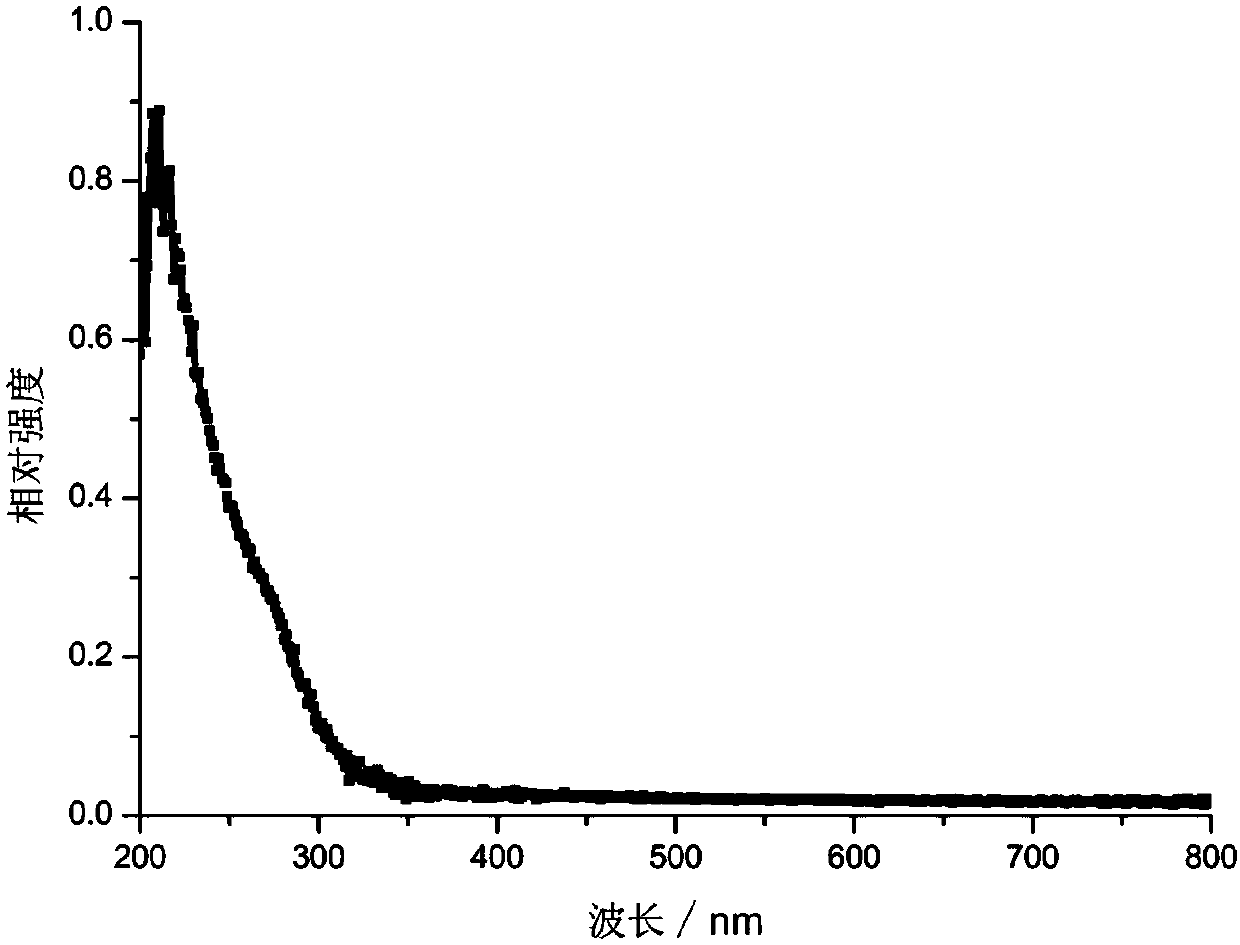

A kind of preparation method of uncaria total alkali hydrolyzate

InactiveCN102274319AGood water solubilityGood desalination effectNervous disorderDigestive systemTotal Base NumberSolubility

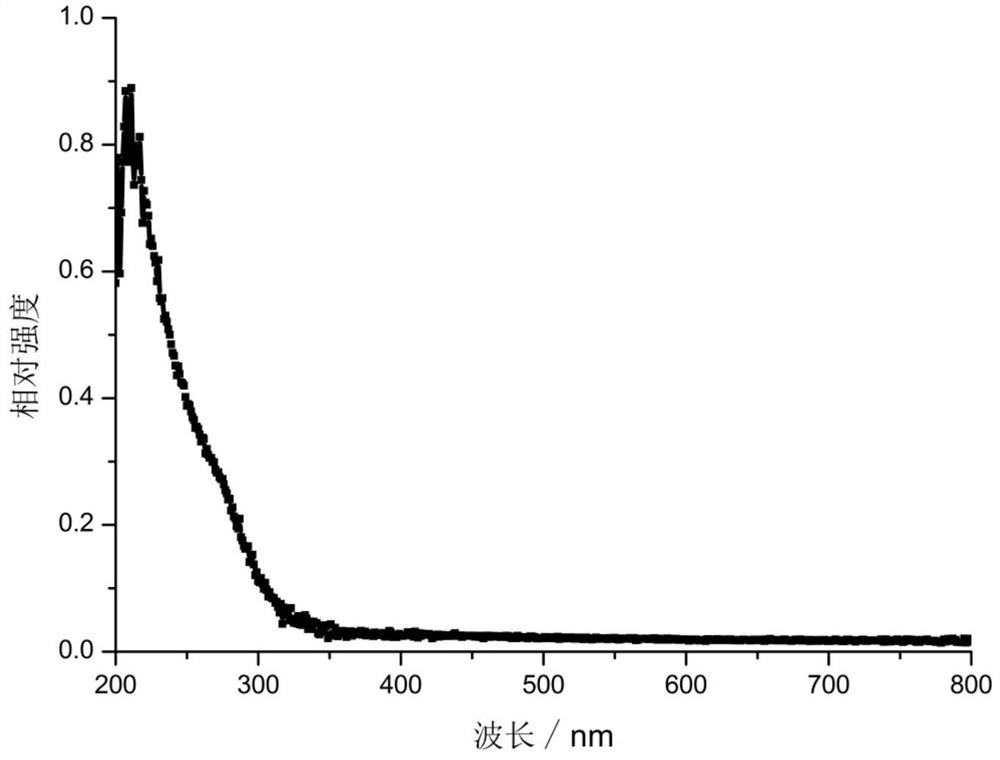

The invention provides a preparation method of a rhomotoxine hydrolysis product. The method comprises the following steps of: performing ester hydrolysis, amide hydrolysis and acidification on rhomotoxine serving as a reaction substrate; and performing resin desalination and a subsequent process to obtain the rhomotoxine hydrolysis product. The preparation method has the advantage that: the obtained rhomotoxine hydrolysis product is water-soluble and is easy for a human body to absorb. On the other hand, the rhomotoxine hydrolysis product can be adsorbed on resin, so that the hydrolysis product can be purified by using resin; and the resin can be recycled without being regenerated, so that the production process is simplified, the production cost is lowered, and the realization of continuous production is facilitated. The method has the advantages of simple reaction process, high efficiency, easiness for controlling, simple process, low energy consumption and high product purity. The rhomotoxine hydrolysis product prepared with the method has characteristic absorption at the position of 224 nanometers, high water solubility and low toxicity, and can well keep the drug action.

Owner:FUJIAN AGRI & FORESTRY UNIV

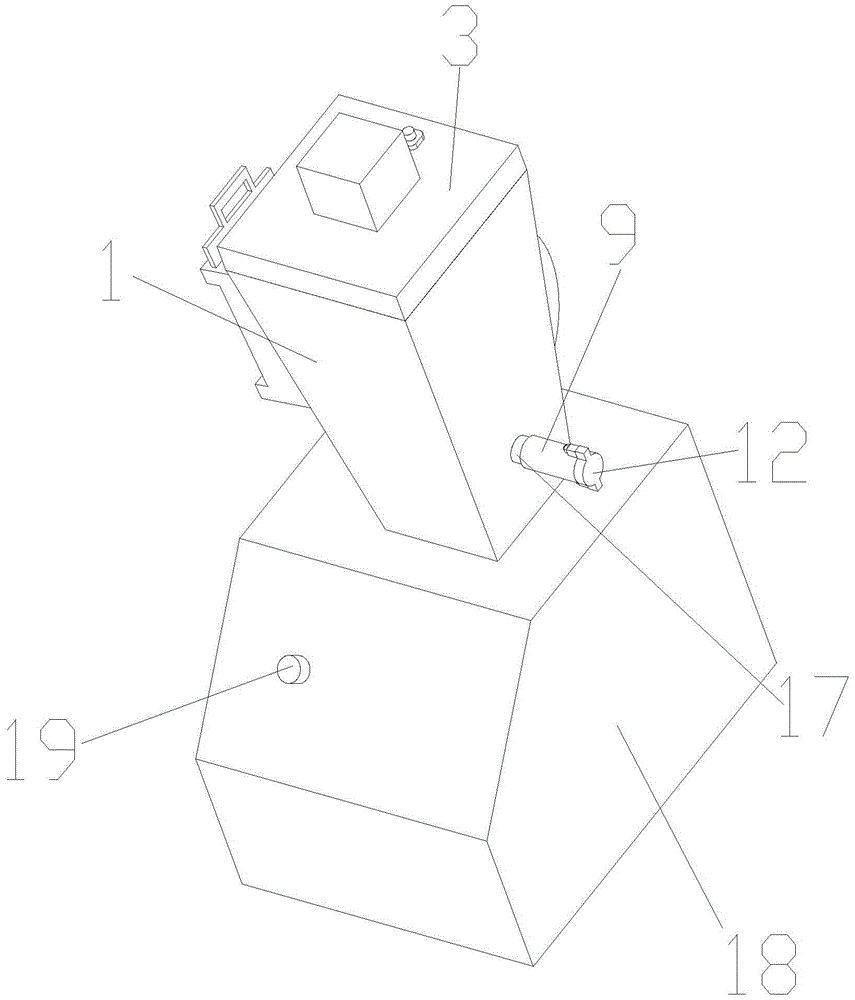

Fungus extraction equipment

PendingCN109456881AHigh purityContinuous cycle filtrationBioreactor/fermenter combinationsBiological substance pretreatmentsTransmitted powerWaste management

The invention provides fungus extraction equipment. The fungus extraction equipment comprises a mixing barrel, a filtering plate and a containing barrel matched with the mixing barrel in an insertingmode, a separation film is arranged in the mixing barrel, the separation film divides the mixing barrel into a mixing cavity and a filtering cavity, a primary filtering film is arranged at the bottomend of the mixing barrel, and a stirring rod and a driving member capable of transmitting power to the stirring rod to enable the stirring rod to rotate are arranged in the mixing barrel. The containing barrel is connected with the filtering plate, a secondary filtering film is arranged in the filtering plate, and a power device for enabling fecal liquid to circulate between the containing barreland the filtering plate is arranged between the containing barrel and the filtering plate. The fungus extraction equipment solves the problems of low extraction purity and low efficiency in the priorart for extracting beneficial bacteria.

Owner:QINGDAO PHAESTUS IS ENG CO LTD

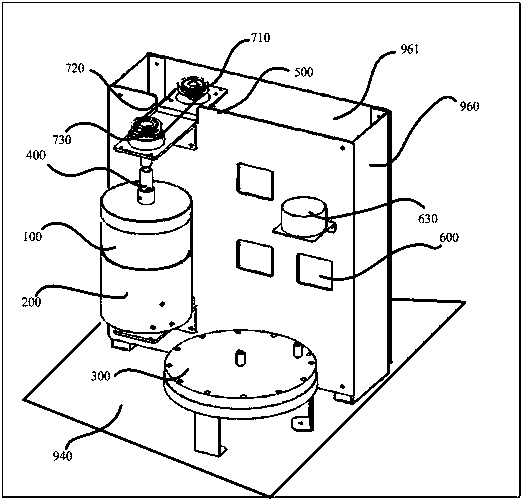

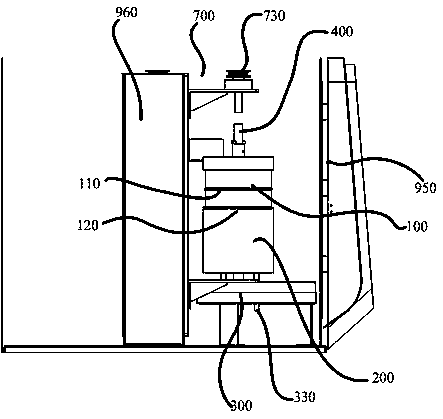

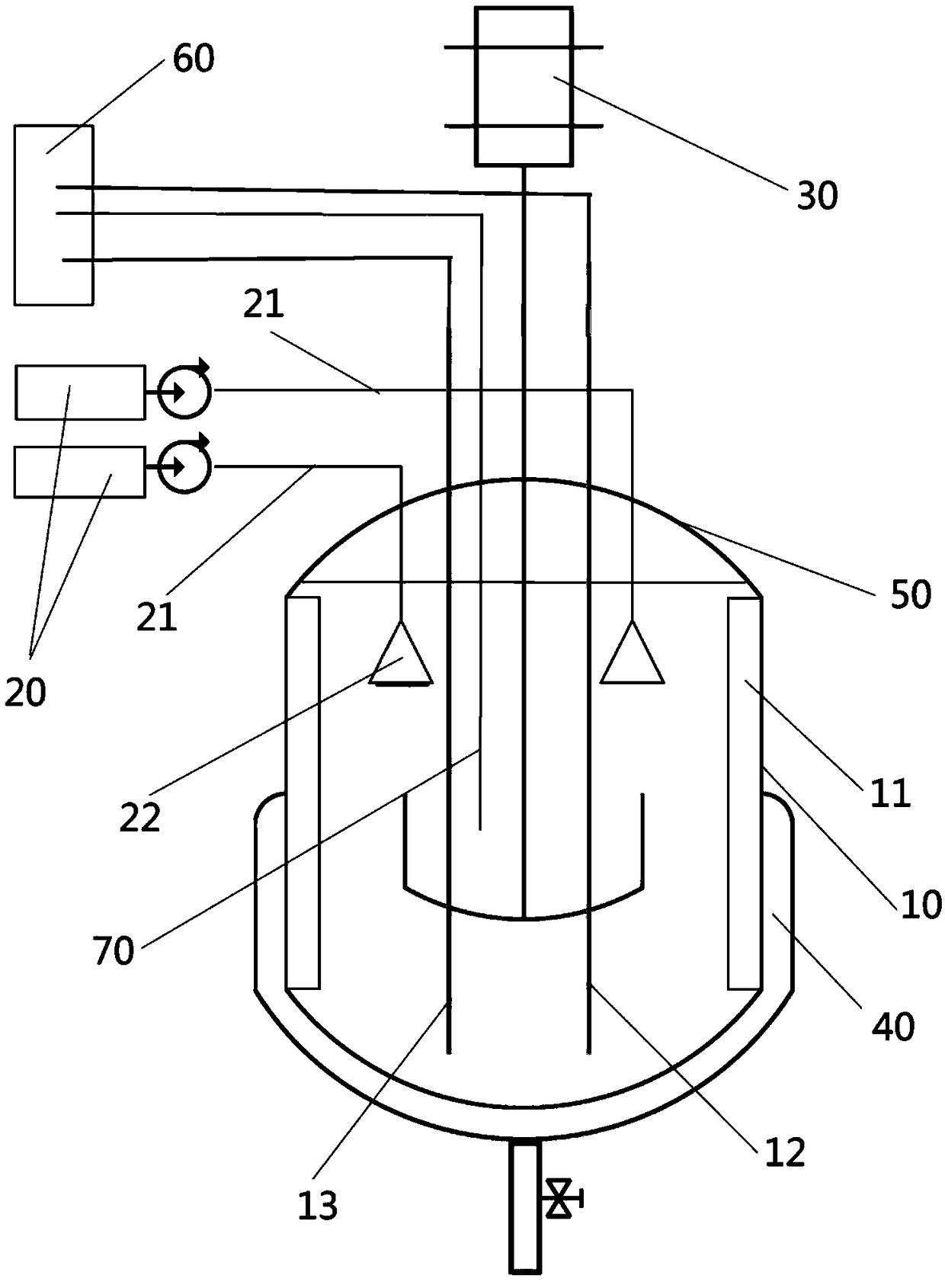

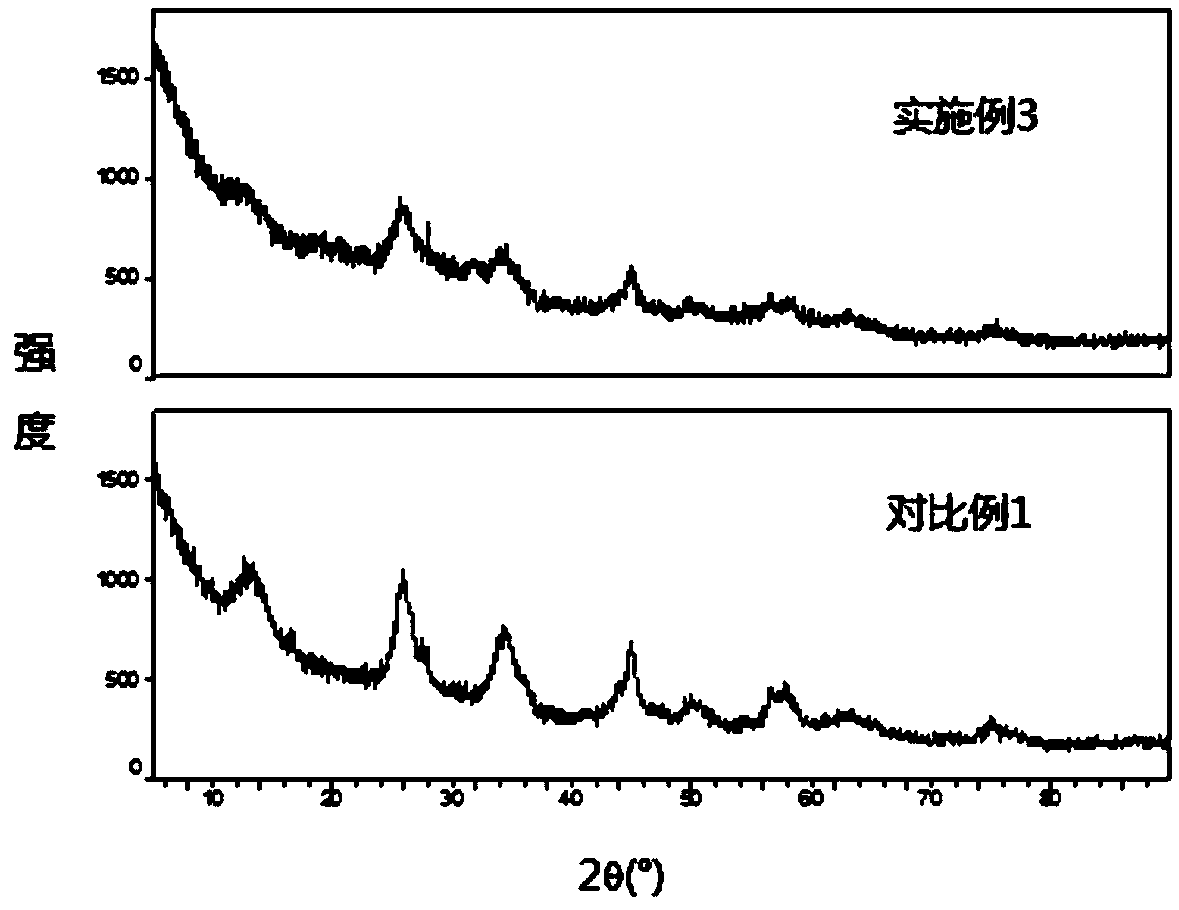

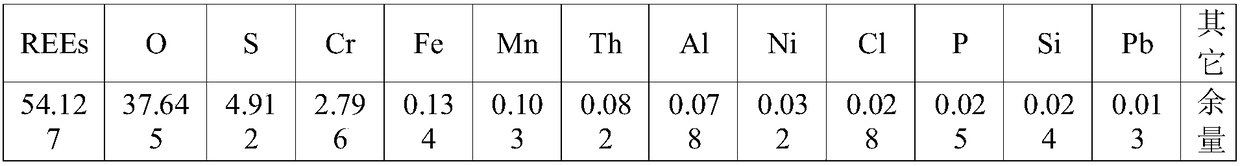

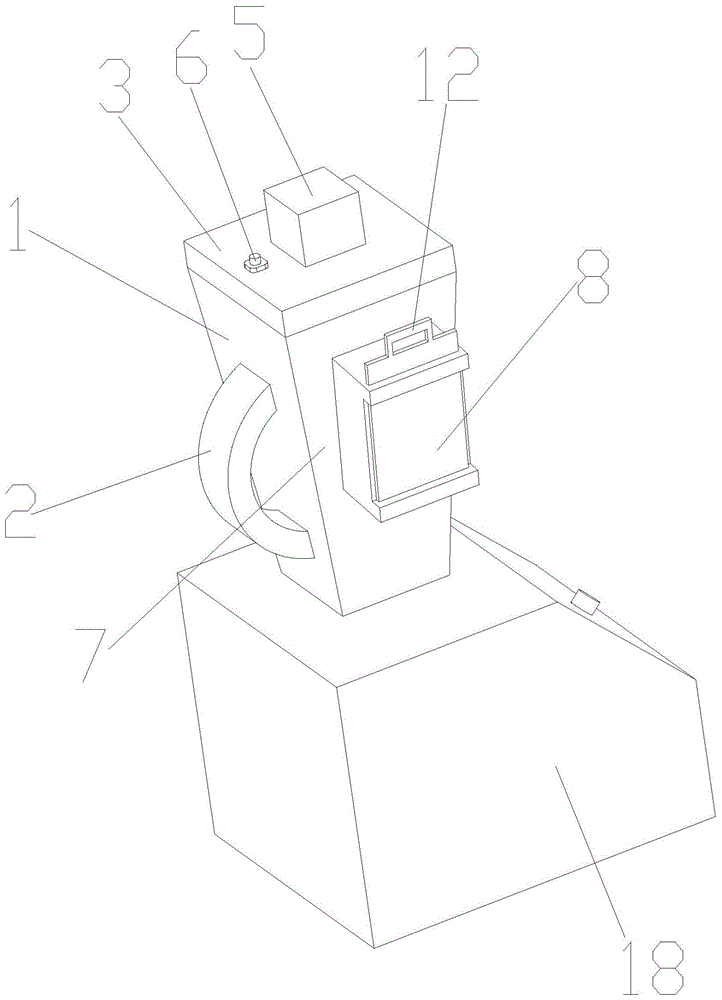

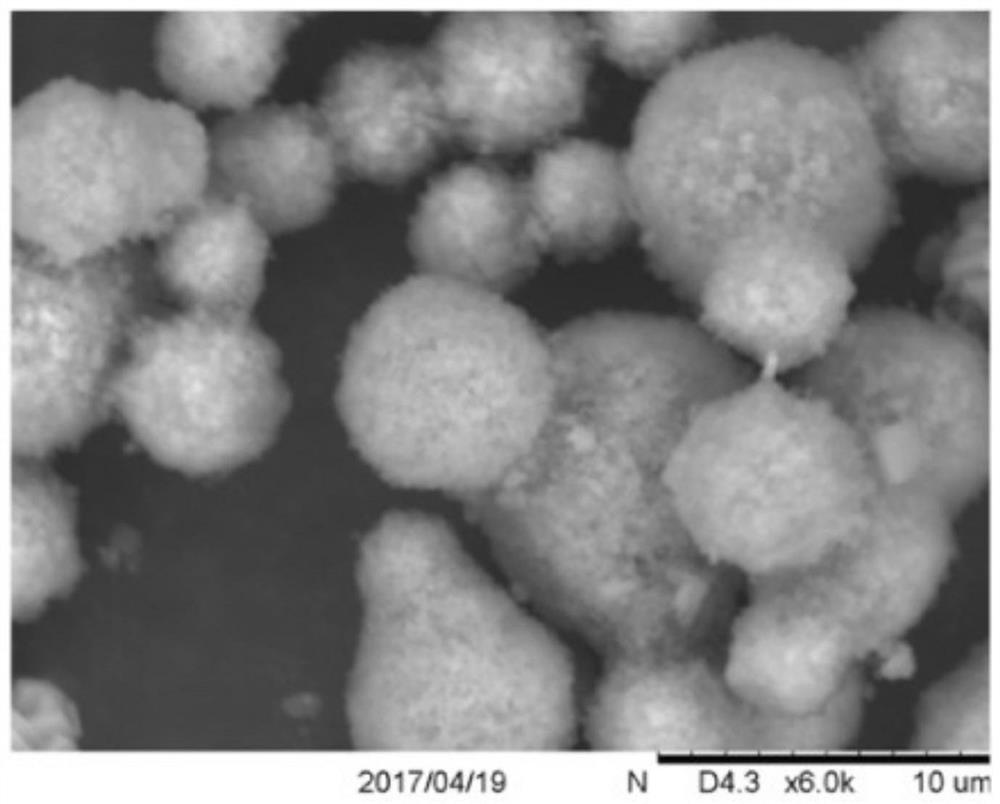

Rare earth precipitation device and rare earth precipitation method

PendingCN109022767AIncrease pressurePromote formationProcess efficiency improvementRare earthImpurity

The invention provides a rare earth precipitation device and a rare earth precipitation method. The rare earth sedimentation device comprises a precipitation container, a feeder, a stirrer and a sealing cover; the precipitation container is provided with a body and a containing cavity defined by the body; the feeder is used for supplying rare earth liquid and a precipitating agent to the containing cavity of the precipitation container; the stirrer is provided with a stirring paddle, and the stirring paddle is arranged in the containing cavity; and the sealing cover is detachably arranged at the top of the body to seal the containing cavity. According to the rare earth precipitation device and the rare earth precipitation method, through the arrangement of the sealing cover, the pressure in a reaction space is increased, the forward implementation of a precipitation reaction is strengthened, the formation of crystallites is promoted, meanwhile, the growth rate of precipitated crystalsis decreased, precipitated samples are relatively small in particle size and low in crystallization rate, and fewer impurities are contained in the precipitated samples; then closed operation can improve the operating environment, the precipitating agent and the rare earth liquid participate in the reaction in a relatively stable ratio, and the use efficiency of the precipitating agent is improved; and finally, the closed operation can increase the stirring strength, liquid-phase pH distribution is uniform, and crystal particle size growth is promoted to be more uniform.

Owner:CHINA ENFI ENGINEERING CORPORATION

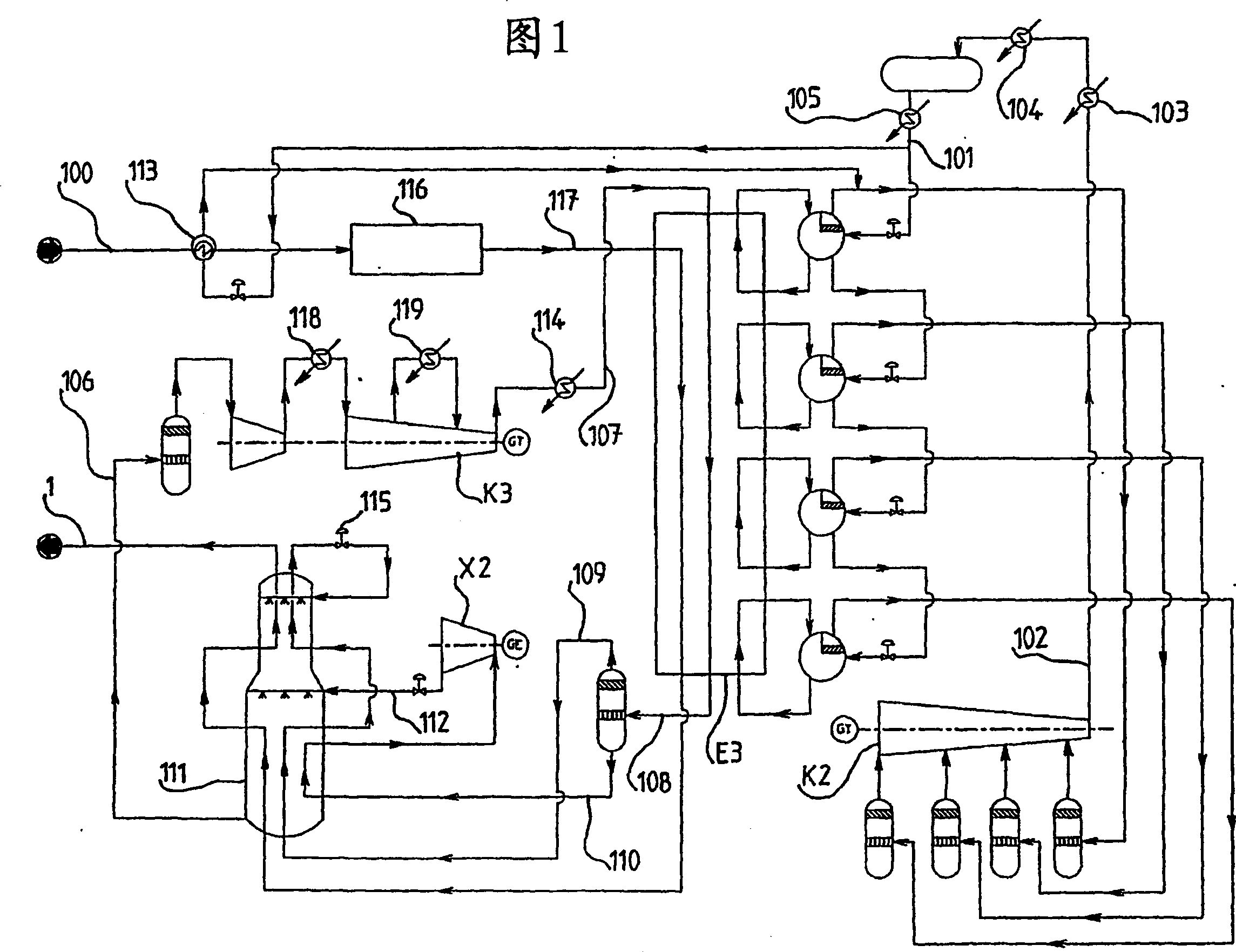

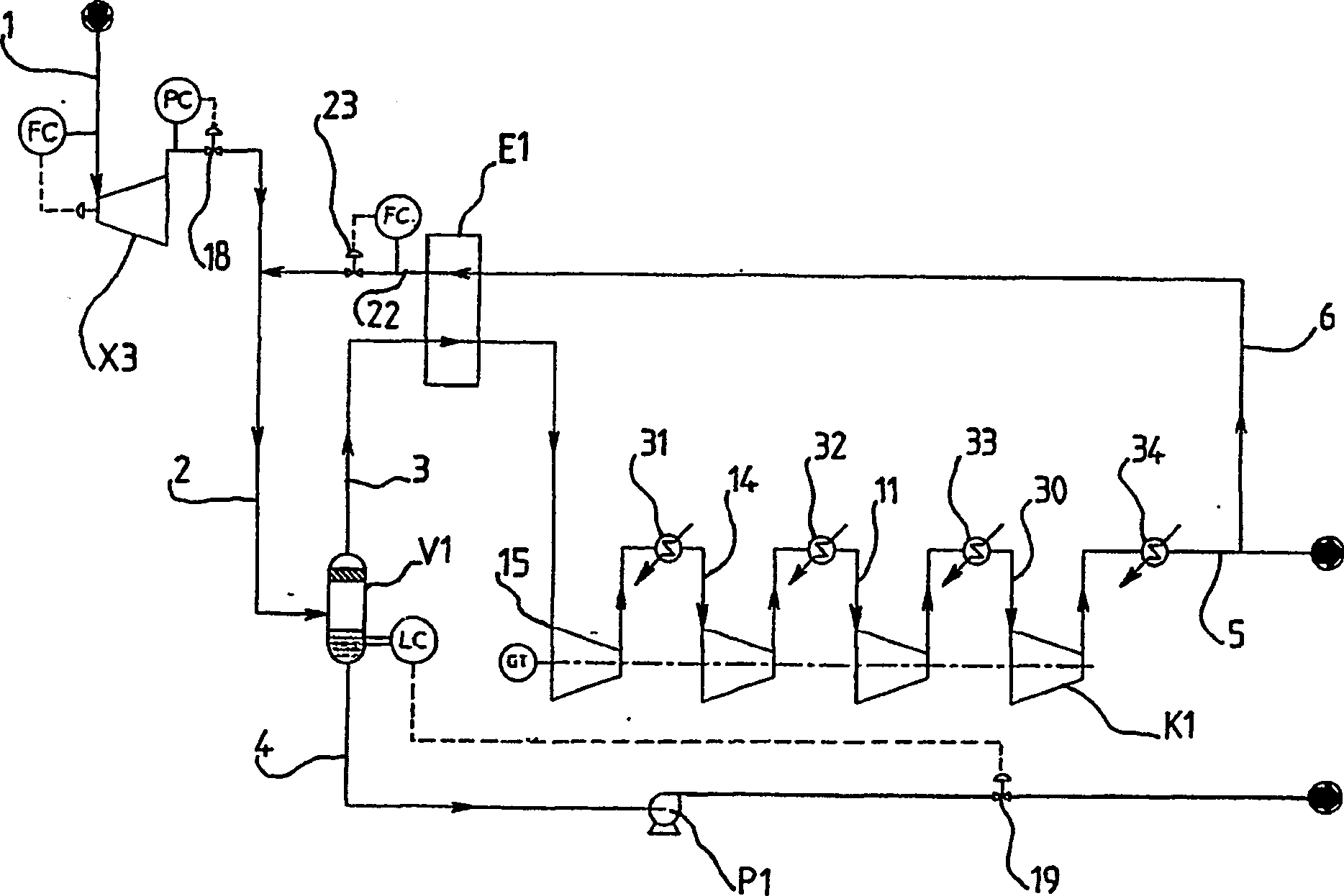

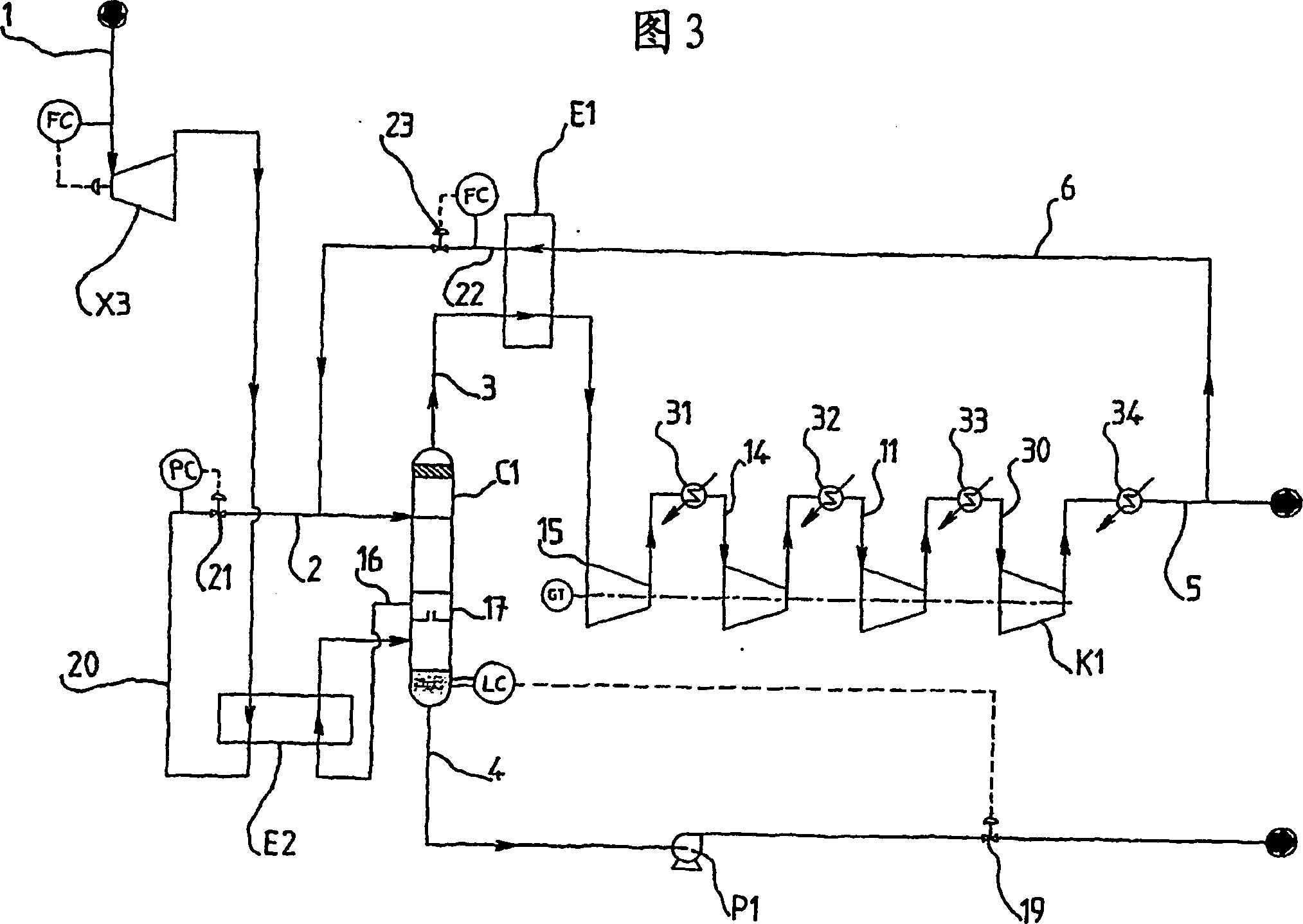

Method for refrigerating liquefied gas and installation therefor

The invention concerns a method for refrigerating liquefied natural gas under pressure (1), comprising a first step wherein the LNG (1) is cooled, expanded and separated (a) in a first base fraction (4) which is collected, and (b) a first top fraction (3) which is heated, compressed in a compressor (K1) and cooled into a first compressed fraction (5) which is collected; a second compressed fraction (6) is drawn from the fuel gas (5), cooled then mixed with the cooled and expanded LNG (1). The invention is characterised in that it comprises a second step wherein the second compressed fraction (6) is compressed and cooled, and a flux is (8) drawn and cooled, expanded and introduced in the compressor (K1). The invention also describes other embodiments.

Owner:TECH FRANCE SA

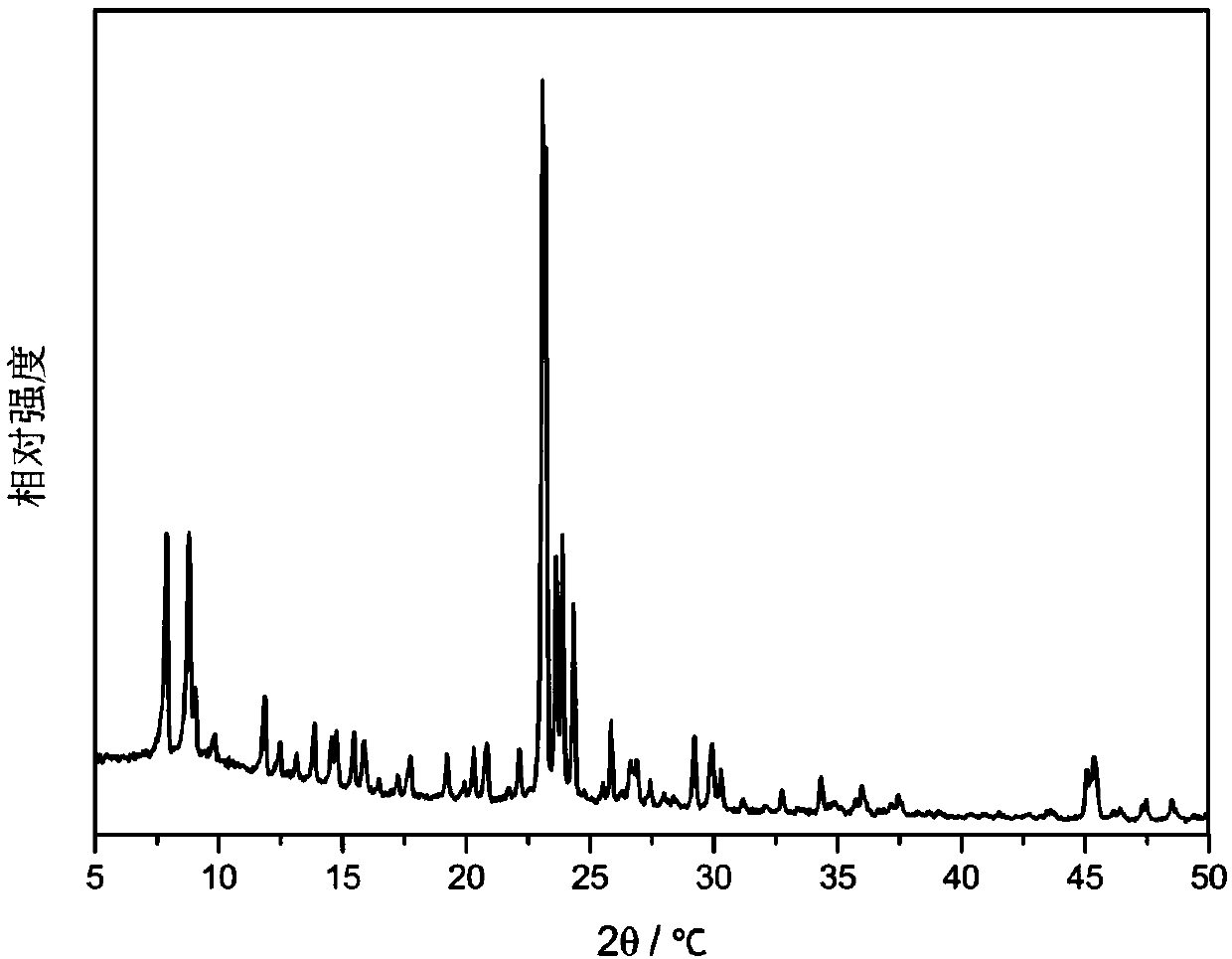

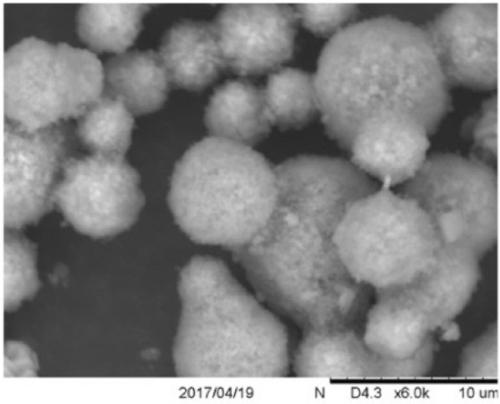

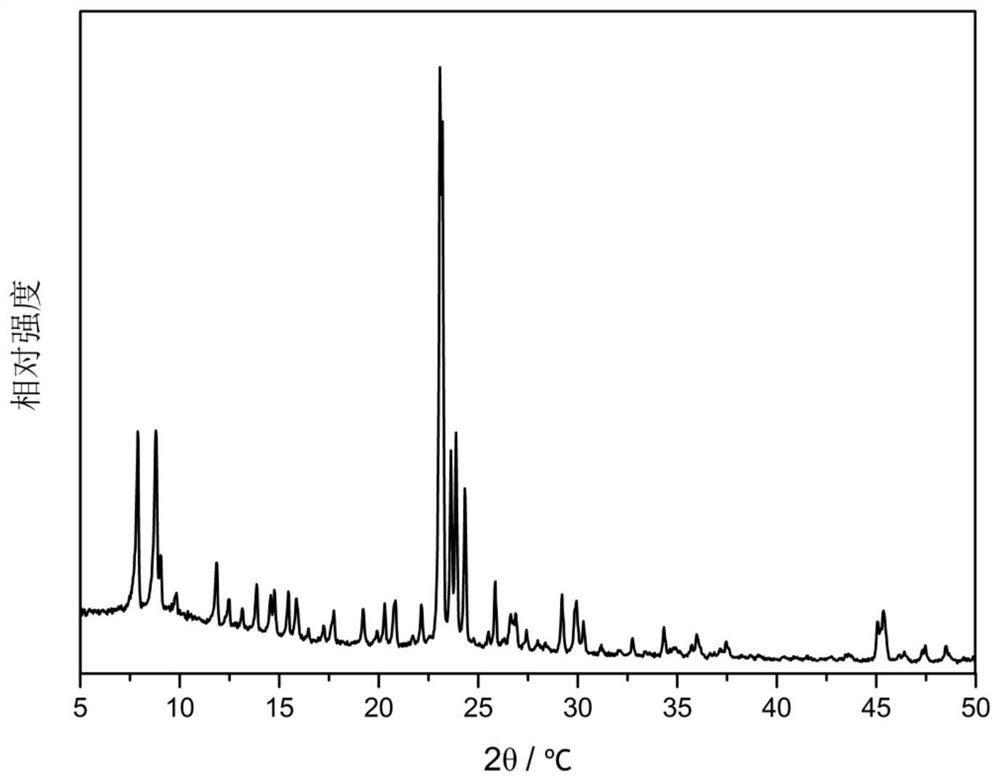

Method for preparing hierarchical pore titanium-silicon TS-1 molecular sieve

ActiveCN111186843APrevent precipitationReduce generationMolecular sieve catalystsMolecular-sieve metallophosphatesMolecular sievePolyester

The invention discloses a method for preparing a hierarchical pore titanium-silicon TS-1 molecular sieve. According to the method, titanic acid polyester polyol is used as a titanium source, and titanium is linked to a polymer, so that titanium is difficult to hydrolyze, precipitation of TiO2 can be prevented, and generation of non-framework titanium is reduced; and the titanic acid polyester polyol can be used as a titanium source and can also be used as a mesoporous template agent in the synthesis process, so that the obtained TS-1 molecular sieve has a mesoporous structure and has an important promotion effect on expanding the application of the TS-1 molecular sieve in the field of catalysis.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Liquid organic fertilizer processing method

InactiveCN113860958AIncrease profitContains lessBio-organic fraction processingMicroorganism based treatmentTap waterAgricultural engineering

The invention provides a liquid organic fertilizer processing method, and relates to the technical field of liquid fertilizer processing. The liquid organic fertilizer processing method comprises the following steps: S1, preparing raw materials; the raw materials comprise kitchen garbage, algae, ferment and tap water. S2, crushing and mixing the kitchen garbage and algae; compressing kitchen garbage and algae through a hydraulic machine, collecting liquid generated during compression, then smashing the liquid through a smashing machine, and then mixing the kitchen garbage and the algae; s3, packaging and fermenting the organic fertilizer; putting the mixed kitchen garbage and algae into a fermentation vat, adding a proper amount of ferment and tap water, and sealing the fermentation vat; and S4, filtering the organic fertilizer. According to the invention, the kitchen garbage and the algae are used as raw materials, so that the utilization rate of resources is effectively improved, and garbage which is not easy to degrade is removed twice, so that the liquid fertilizer contains less garbage.

Owner:TARIM UNIV

Method for preparing 2-ethylhexyl 4-(dimethylamino)benzoate through hydrogenation by taking water as solvent

ActiveCN111606817AImprove conversion and selectivityEasy to filterOrganic compound preparationAmino-carboxyl compound preparationSolventProcess engineering

The invention relates to the field of fine chemical engineering, in particular to a method for preparing 2-ethylhexyl 4-(dimethylamino)benzoate through hydrogenation by taking water as a solvent. Themethod for preparing 2-ethylhexyl 4-(dimethylamino)benzoate through hydrogenation by taking water as a solvent is characterized by comprising the following steps: (1) adding water, 4-nitro-benzoic acid 2-ethyl-hexyl ester and an active nickel catalyst into a reactor in proportion; (2) performing heating, introducing hydrogen, and carrying out heat preservation and pressure maintaining reaction until no hydrogen is absorbed; (3) cooling, namely adding paraformaldehyde into the reactor, and supplementing the active nickel catalyst in proportion; (4) heating, introducing hydrogen, and carrying out heat preservation and pressure maintaining reaction until hydrogen is not absorbed; (5) continuing to preserve heat and pressure for several hours, terminating the reaction, and sampling and analyzing; (6) after the catalyst is filtered, recycling, activating and reusing the catalyst, standing for layering, discharging a water layer into a sewage system, and feeding an oil layer into a distillation tower; and (7) heating, rectifying and purifying by the distillation tower until the product specification is met, and barreling and packaging.

Owner:浙江优创材料科技股份有限公司

Formula of green ecological feed for middle-aged pigs

InactiveCN108576441AHas a bactericidal effectReduce the risk of getting sickFood processingAnimal feeding stuffAnimal sciencePumpkin seed

The invention discloses a formula of a green ecological feed for middle-aged pigs. The formula comprises the following raw materials in parts by mass: 50-75 parts of corn, 17-26 parts of soybean meal,5-9 parts of wheat bran, 0.8-3 parts of soybean oil, 4-22 parts of green feed, 6-8 parts of pumpkin seeds, 5-8 parts of watermelon peel, 0.8-1 part of herba dendrobii, 4-5 parts of stir-fried cape jasmine fruits, and 4-12 parts of a nutrient regulator for live pigs. The green ecological feed solves the problem that chemical substances such as antibiotics need to be added into feeds for middle-aged pigs in the prior art in order to improve pig immunity and to stimulate pig growth, and simultaneously solves the problem that no feed specifically aims at the breeding of middle-aged pigs.

Owner:云南能博万生物技术开发有限公司

Grassland white-mushroom sauce

The invention discloses grassland white-mushroom sauce. The grassland white-mushroom sauce comprises the following materials in parts by weight: 10-20 parts of dried grassland white mushroom, 56-84 parts of fresh pleurotus eryngii, 8-12 parts of vegetable oil, 4-6 parts of soybean paste, 0.8-1.2 parts of salt black bean, 4-6 parts of salt, 0.1-0.3 part of chopped peanuts, 0.1-0.3 part of shelled melon seed, 0.01-0.08 part of seasoning and 0.01-0.05 part of spice. The grassland white-mushroom sauce disclosed by the invention has specific flavor of grassland dried mushroom and the taste like eating meat, and simultaneously has the advantage of compact tissue of pleurotus eryngii, and brittle and refreshing taste like eating abalone.

Owner:内蒙古草原汇香食品科技有限公司

An electroplated diamond hob cutter ring and its processing technology

InactiveCN106521322BImprove toughnessHigh compressive strengthElectrolytic coatingsFurnace typesHobbingWear resistant

The invention discloses a cutter ring of an electroplated diamond hobbing cutter. The cutter ring comprises a cutter ring matrix and a diamond wear-resistant layer electroplated onto the outer surface of the circumference of the cutter ring matrix, wherein the cutter ring matrix comprises the raw materials in percentage by mass: 0.38-0.48% of C, 0.6-0.8% of Si, 1.20-1.55% of Mn, 2.7-3.5% of Cr, 2.6-3.4% of Mo, 1.05-1.40% of V, less than or equal to 0.02% of impurities P, less than or equal to 0.02% of impurities S and the balance Fe. The invention also discloses a processing technology of the cutter ring of the electroplated diamond hobbing cutter. The processing technology disclosed by the invention is simple in method as well as high in operability and efficiency; and the cutter ring of the electroplated diamond hobbing cutter, processed by using the processing technology, is not only meticulous in surface and low in impurity content, but also high in wear resistance and long in working life.

Owner:HUANGHE S & T COLLEGE

A structure-improved fruit juice machine

The invention relates to a structurally-modified juicer. The front of a control base is provided with a switch. The top of the control base is provided with a cup. A cutting mechanism disposed at the bottom of the cup is connected with a drive device arranged in the control base. The cup is connected with an upper cover integrally. The bottom of the upper cover is provided with a screw cutting shaft which is connected with a motor spindle arranged at the upper end of the upper cover. A start button is provided over the upper cover and connected with a motor. One side of the cup is provided with a feed rack which is provided with a feed opening. The feed opening is provided with a retaining plate which can move up and down. The lower portion of one side, corresponding to the feed rack, of the cup is provided with a juice outlet. The juice outlet is sleeved with a juice outgoing tube. A filter mesh is arranged within the juice outgoing tube. Positioners are fixed to two sides of the juice outgoing tube. A fixing cover is arranged at an outlet of the juice outgoing tube. The fixing cover is fixed to the outlet of the juice outgoing tube. The structurally-modified juicer is high in juicing efficiency, the juice made with the juicer is clean and has low impurity content, and the actual drinking needs of people are met.

Owner:SUZHOU ZHONGTUO PATENT OPERATION MANAGEMENT CO LTD

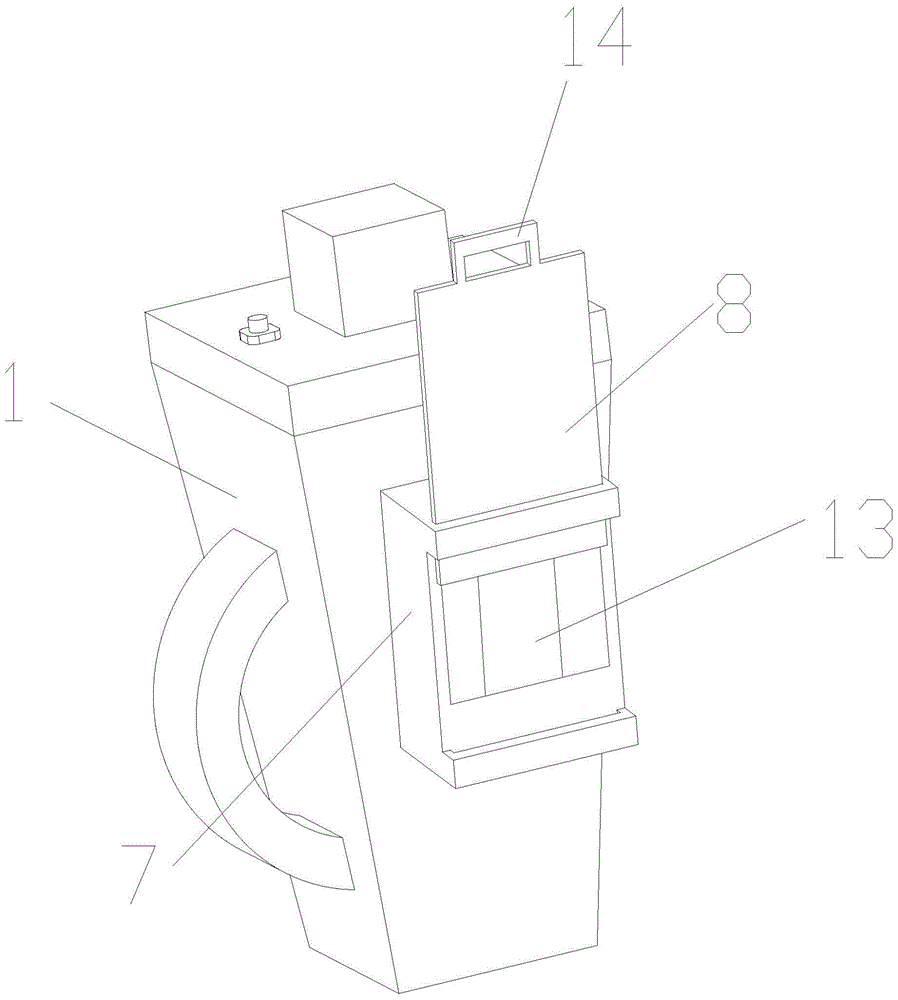

Lubricating oil filtering device

InactiveCN111991889ARealize multiple filteringQuality improvementMoving filtering element filtersControl engineeringProcess engineering

The invention provides a lubricating oil filtering device. The device comprises a shell, a discharging box, a first filter screen structure, a second filter screen structure and a driving structure are arranged in the shell. One end of the driving structure is connected with the first filter screen structure in a meshed mode, the other end of the driving structure is connected with the second filter screen structure in the meshed mode, the second filter screen structure is located under the first filter screen structure and is parallel to the first filter screen structure, the discharging boxis arranged above the first filter screen structure, and the driving structure is in signal connection with a controller. The lubricating oil filtering device disclosed by the invention is simple in structure; the lubricating oil filtering device is simple in structure and reasonable in design, the discharging box, the first filtering net structure and the second filtering net structure complete filtering treatment of impurities in lubricating oil, repeated filtering of the lubricating oil is achieved, the filtering effect and the filtering efficiency are guaranteed, the production efficiencyis improved, and the lubricating oil treated through the lubricating oil filtering device contains few impurities and is high in quality.

Owner:ARROW LUBRICANTS CO LTD

Printing dying shaping machine waste gas recovery and treatment system

PendingCN110201480AHigh removal rateImprove recycling effectCombination devicesTextile/flexible product manufactureWaste heat recovery unitSpray nozzle

The invention discloses a printing dying shaping machine waste gas recovery and treatment system, which comprises a waste heat recovery device, a purification treatment device and an electrostatic treatment device, wherein the purification device comprises a shell communicated to the waste heat recovery device, two first separation plates are arranged in the shell to sequentially divide the shellinto a first spraying nozzle area, a spraying area and a second spraying nozzle area, both ends of the bottom portion of the spraying area are respectively communicated to the waste heat recovery device through a first communication pipe and a second communication pipe, the upper end of the spraying area is communicated to the electrostatic treatment device through a third communication pipe, thetwo spraying nozzle areas are respectively provided with a plurality of spraying nozzles, the first separation plates are respectively provided with a plurality of first through holes, a plurality ofsecond separation plates are respectively arranged below the first separation plates, a channel for water flowing is arranged between the lower end of the second separation plate and the bottom portion of the spraying area, the second separation plates are respectively provided with a plurality of second through holes, and the bottom portion of the spraying area is provided with a water outlet. According to the present invention, the system has high waste gas heat energy recovery rate, the waste gas entering the electrostatic treatment device contains less soot oil, and the service life of thedevice is long.

Owner:FUJIAN HANGGANG TEXTILE TECH CO LTD

Gas-liquid-solid three-phase separation system

ActiveCN104474773BEfficient separationFully utilizeMultistage water/sewage treatmentFiltration circuitsCross-flow filtrationThree-phase

The invention discloses a gas, liquid and solid three-phase separation system which can be used for realizing high-efficiency separation of three phases of gas, liquid and solid. The system comprises a cross flow filter, a gas and liquid coalescer, a front flow dividing container, a rear flow dividing container and a slurry concentrator, wherein a to-be-filtered material charging hole of the cross flow filter is connected with an output end of a to-be-filtered material conveying pipe; a filtered material discharging hole is connected with an input end of a filtered material conveying pipe; a filtered and concentrated material discharging hole is connected with the input end of a concentrated material refluxing pipe; a gas and liquid two-phase material charging hole of the gas and liquid coalescer is connected with the input end of a gas and liquid two-phase material conveying pipe; a gas and liquid two-phase material discharging hole of the front flow dividing container is connected with the input end of the gas and liquid two-phase material conveying pipe; a to-be-filtered material discharging hole is connected with the input end of the to-be-filtered material conveying pipe; the filtered and concentrated material charging hole is connected with the output end of the concentrated material refluxing pipe; a bottom slurry discharging hole is connected with a slurry conveying pipe; the filtered material charging hole of the rear flow dividing container is connected with the output end of the filtered material conveying pipe; the gas and liquid two-phase material discharging hole is connected with the gas and liquid two-phase material conveying pipe; and a to-be-treated slurry charging hole of the slurry concentrator is connected with the slurry conveying pipe.

Owner:CHENGDU INTERMENT TECH

A kind of method for preparing hierarchically porous titanium silicon ts-1 molecular sieve

ActiveCN111186843BEasy accessPrevent precipitationMolecular sieve catalystsMolecular-sieve metallophosphatesPolyesterMolecular sieve

The present application discloses a method for preparing a hierarchically porous titanium-silicon TS‑1 molecular sieve, using titanate-based polyester polyol as a titanium source. In the method described, titanium is attached to the polymer, which makes titanium more difficult to hydrolyze and prevents TiO 2 Precipitation to reduce the generation of non-skeletal titanium; and titanate-based polyester polyols can also be used as a mesoporous template in the synthesis process while being used as a titanium source. The application of TS‑1 molecular sieve in the field of catalysis plays an important role in promoting.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com