Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82results about How to "Reduce the number of rinses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

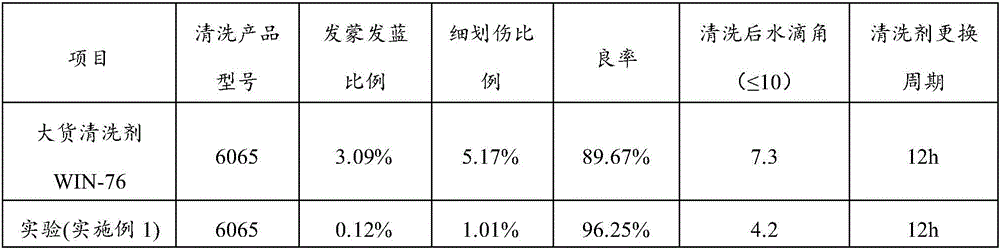

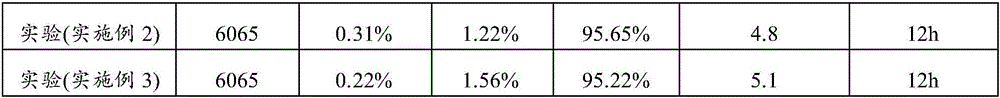

Glass cleaning agent and use method thereof

InactiveCN106753873AAlkaline Weak HumidityFlat surfaceInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsPotassium hydroxideCleansing Agents

The invention provides a glass cleaning agent. The glass cleaning agent is prepared from potassium hydroxide, sodium hydroxide, potassium carbonate, an anion ion surfactant, a non-ionic surfactant, a chelating agent, an alcohol ester type organic solvent, a solubilizer and water. Compared with the prior art, the glass cleaning agent has the advantages that the alkalinity is weak, and the wetting property is strong; under the mutual matching of components, the surface of cleaned glass is smooth, stubborn dirt can be removed, the damage to a glass surface layer is avoided, a defective rework procedure is reduced, and the machine and labor cost and the material cost are effectively reduced; the fine scratching of the glass surface is reduced, the fuzziness and bluing of the glass surface are avoided, the surface can be quickly flushed and cleaned, the residue is avoided, the rinsing frequency is reduced, the components can be completely decomposed, the pollution to environment is avoided, and the glass cleaning agent is suitable for glass heat-bending mobile phone front and back cover plates.

Owner:LENS TECH CHANGSHA

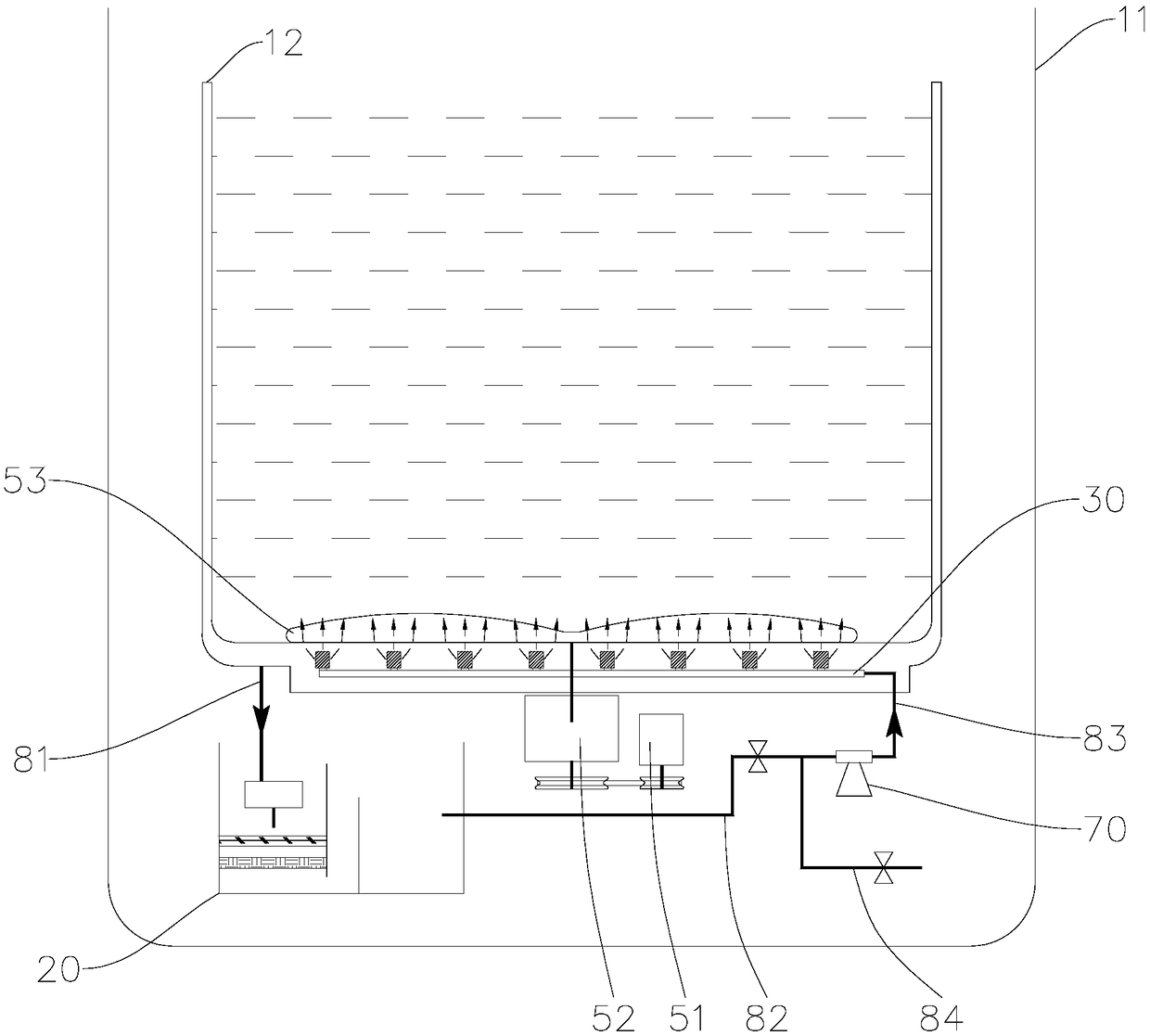

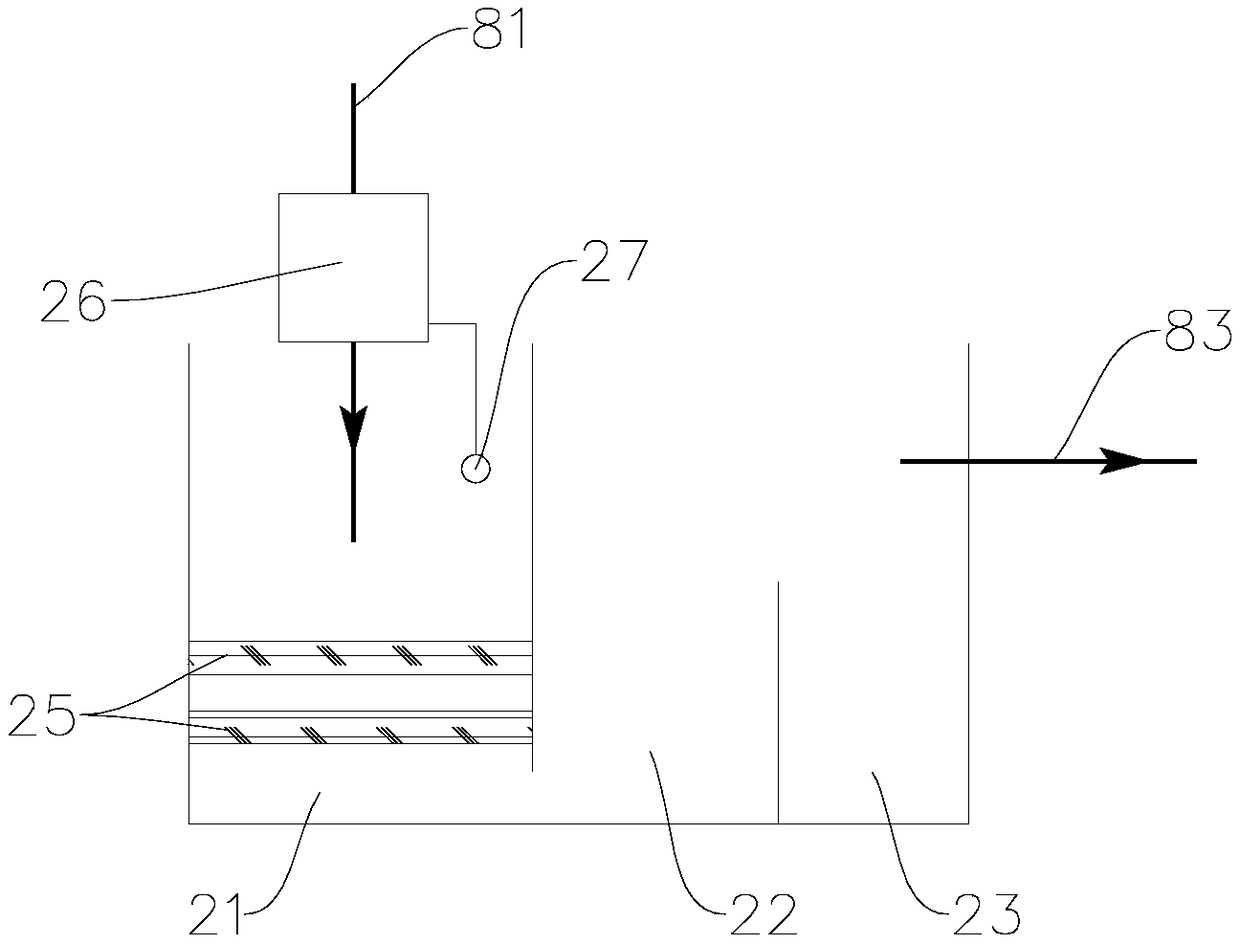

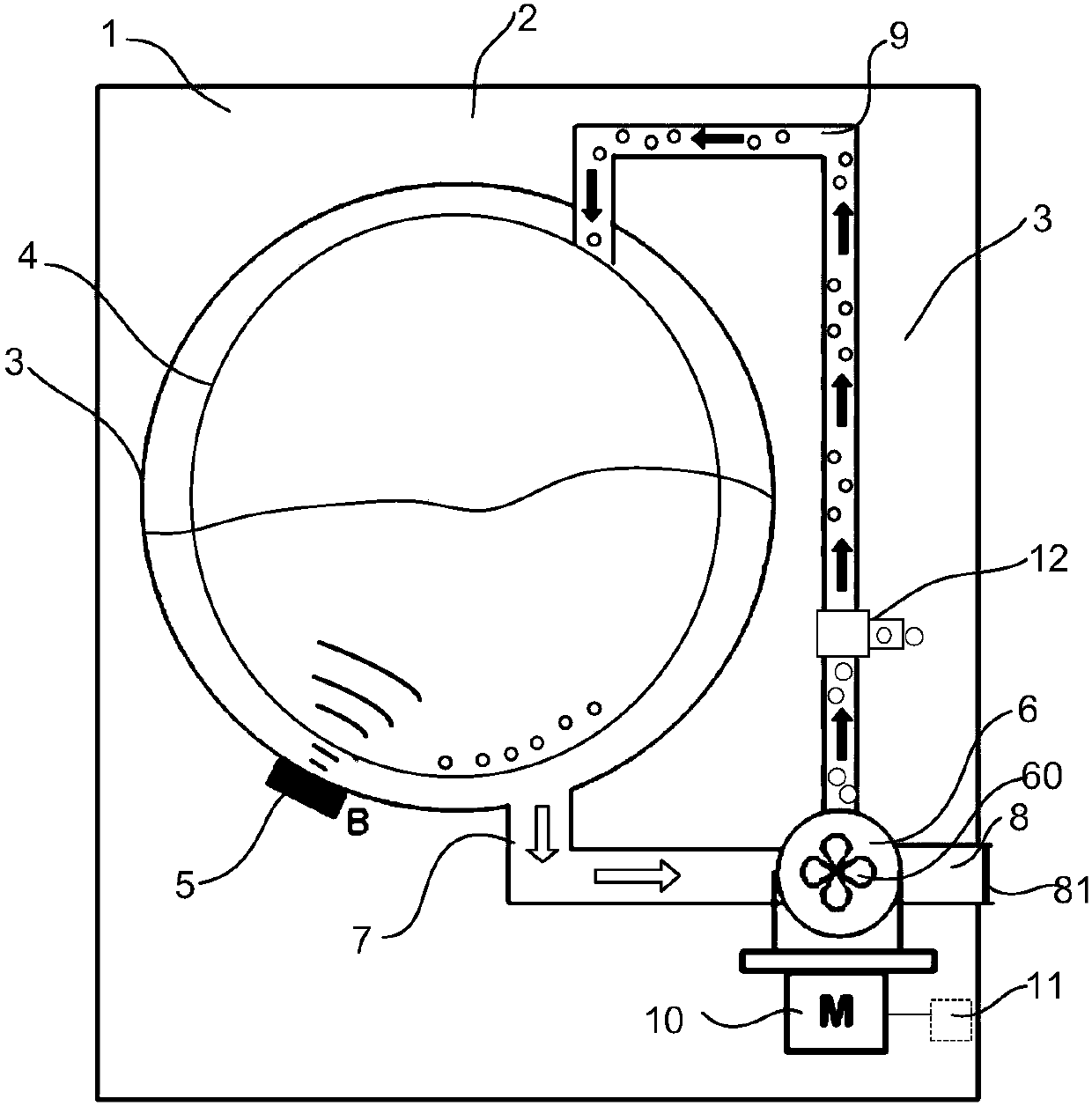

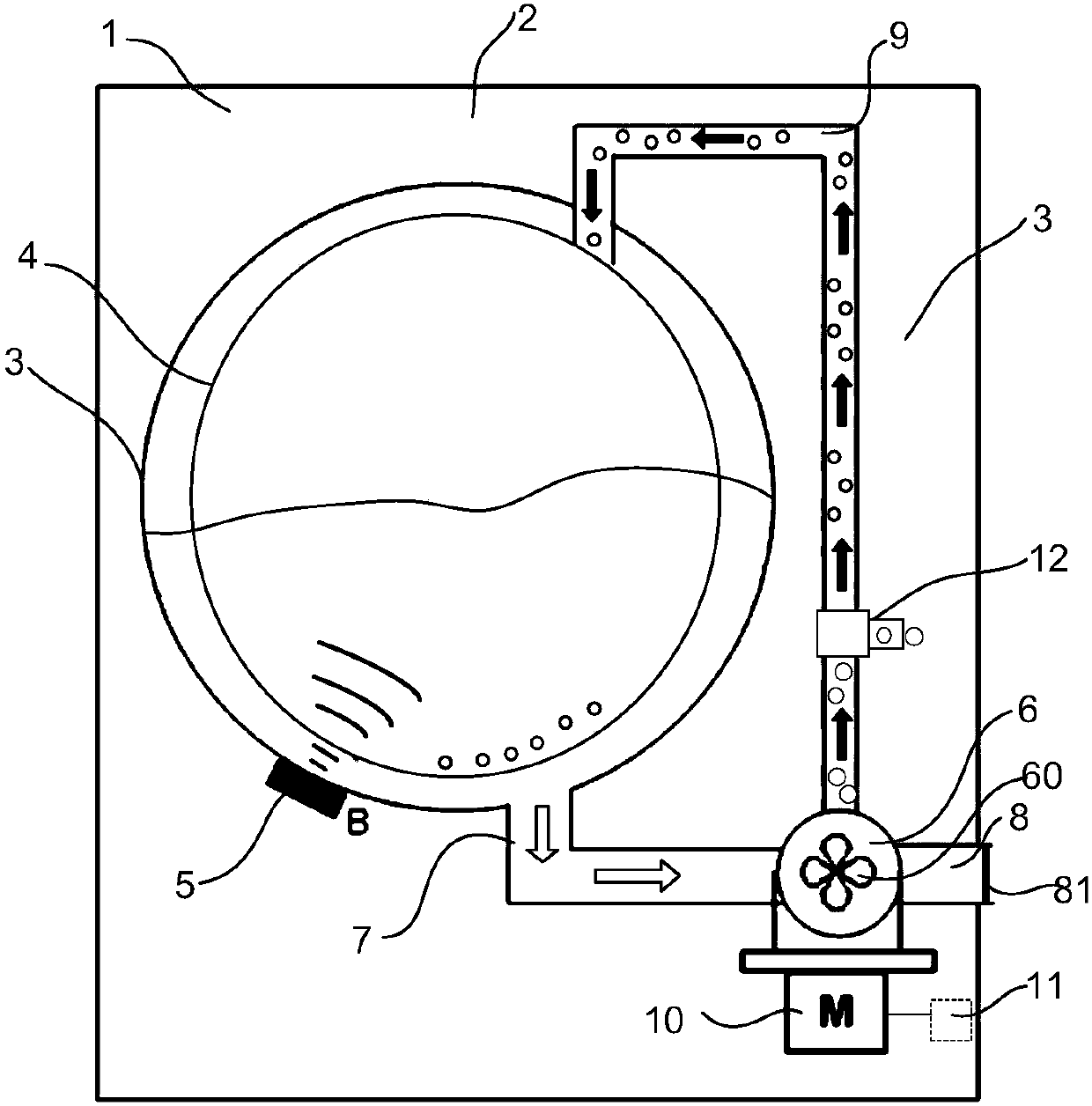

Washing machine filter device based on micro-nano gas explosion

InactiveCN108842384AReduce usageImprove washing effectOther washing machinesWashing machine with receptaclesMicro nanoGas explosion

The invention discloses a washing machine filter device based on micro-nano gas explosion, and relates to the technical field of washing machines. The device comprises a barrel body for containing washing water and a filter unit, the filter unit is communicated with an inner cavity of the barrel body through a water inlet pipe, the filter unit is connected with a micro-nano bubble generator through a connecting pipe, the micro-nano bubble generator is connected with a water outlet unit, the water outlet unit comprises a water outlet pipe connected with a water outlet of the micro-nano bubble generator, and the other end of the water outlet pipe is communicated with the inner cavity of the barrel body. Micro-nano bubbles can be introduced into filtered washing water and released in the barrel body, the washing effect can be enhanced, the consumption of a detergent is lowered, and the water consumption for rinsing and the rinsing frequency are lowered.

Owner:陈浩航

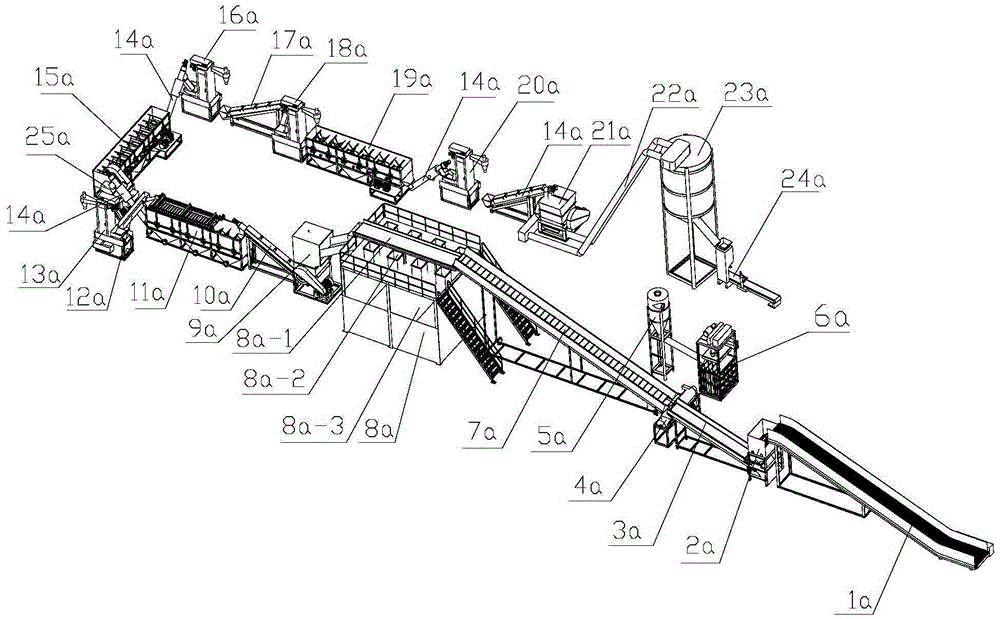

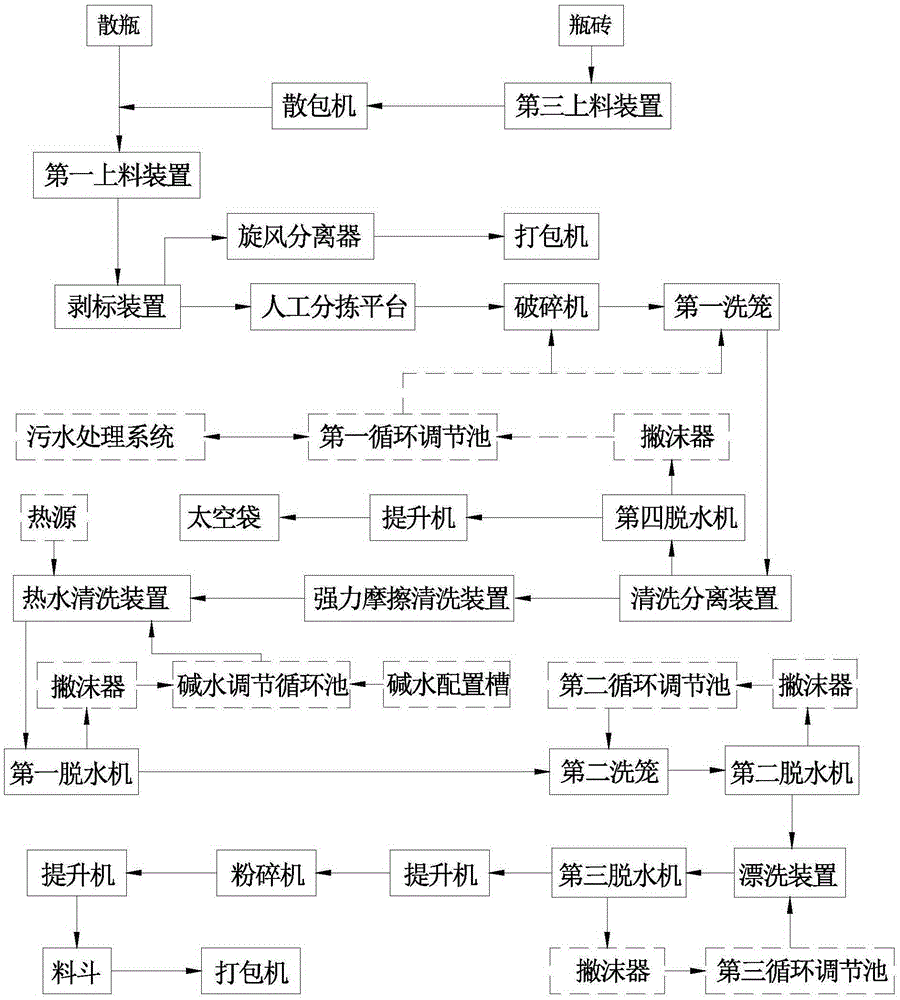

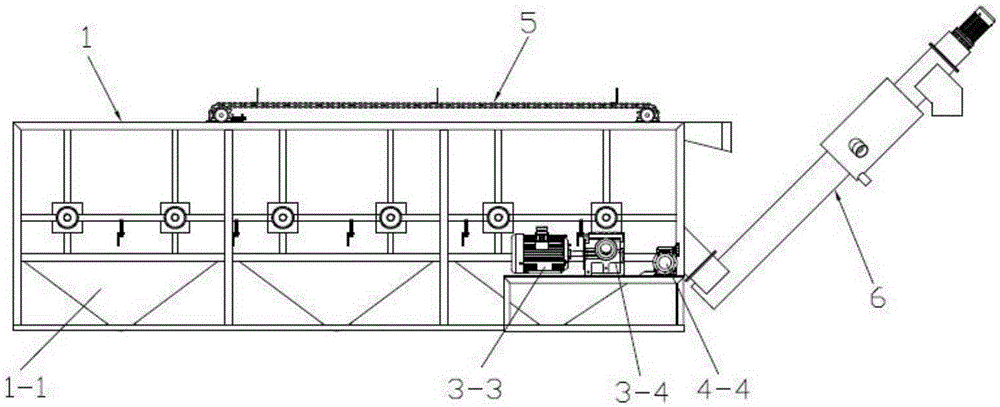

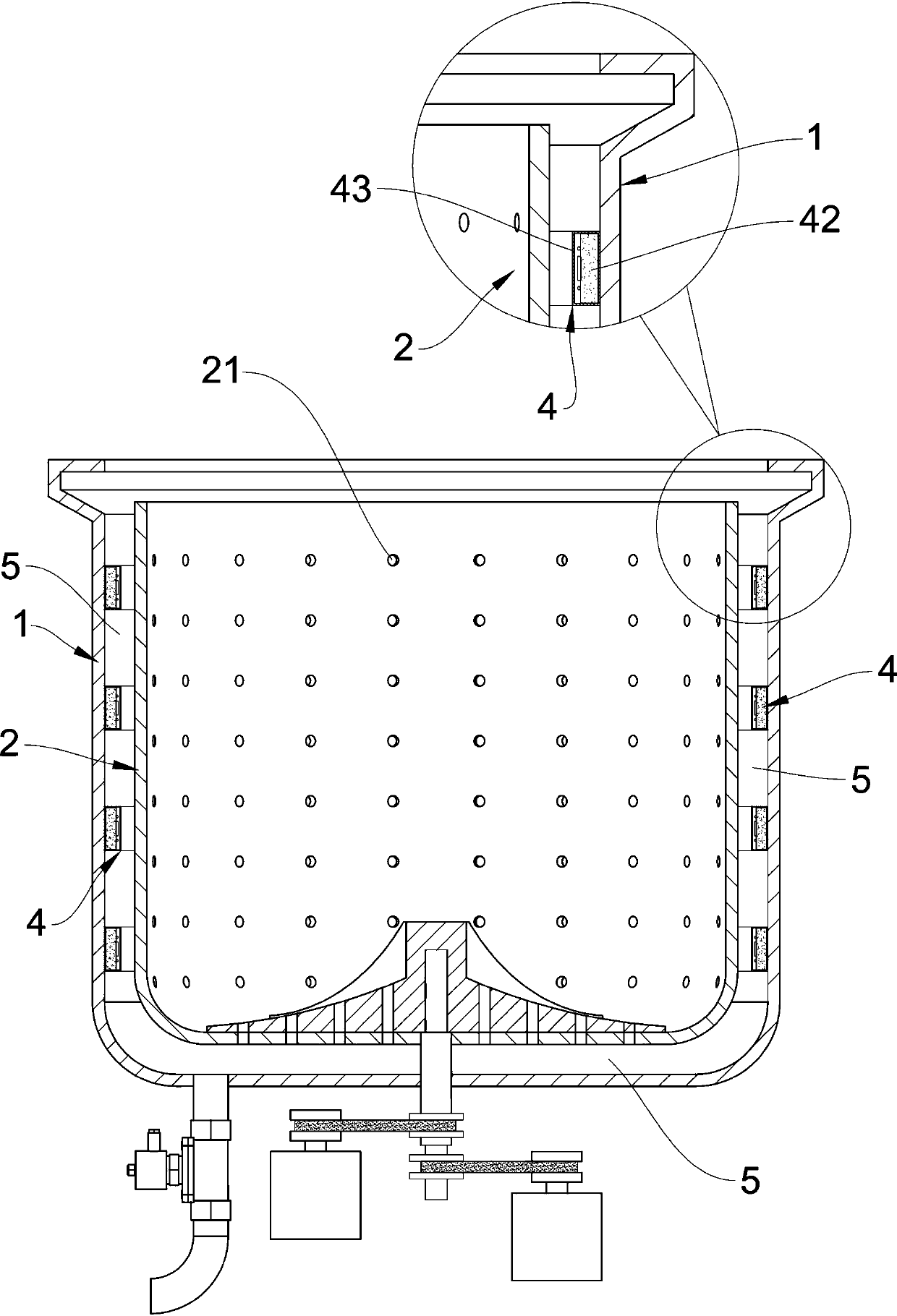

Recycle production line and recycle technology of PET (Polyethylene Terephthalate) bottles

ActiveCN105291304ADrop in timeImprove cleaning efficiencyPlastic recyclingCleaning using liquidsProduction linePolyethylene terephthalate

The invention discloses a recycle production line and a recycle technology of PET (Polyethylene Terephthalate) bottles. The recycle production line comprises a first feeding device, a label removing device, a second feeding device, a manual sorting platform, a crusher, a first washing cage, a cleaning and separating device, a high-strength friction cleaning device, a hot-water cleaning device, a first dehydrator, a second washing cage, a second dehydrator, a rinsing device, a third dehydrator and a packer; the cleaning and separating device, the hot-water cleaning device and the rinsing device separately comprise a water tank, stirring cleaners and a mesh screen; each mesh screen tank is formed by sequentially connecting a plurality of arc-shaped mesh screen tank units with upward openings in series along the horizontal direction; a stirring cleaner is arranged above each arc-shaped mesh screen tank unit; each stirring cleaner comprises a rotary shaft and a stirring plate arranged on the rotary shaft; and the rotary shaft of each stirring cleaner is connected with a stirring cleaning driving mechanism. By adopting the production line, the cleaning of fragments is good in effect, high in speed and high in production efficiency.

Owner:冯愚斌

Washing methods of automatic washing machine and automatic washing of using the method

InactiveCN1796646AReduce secondary pollutionImprove cleaning ratioControl devices for washing apparatusWashing machine with receptaclesWater savingInlet valve

A washing method of automatic washer includes controlling water inlet valve to let washer flow water in continuously; checking whether water level in washer is reached on water overflow level or not and starting up timing if water overflow level is reached as well as closing water inlet valve when timing is on preset time; enabling to drain out oil stain in clothes, washing powder foam, detergent foam and floated ¿C dirt from overflow outlet before water is discharged when washing procedure is finished in order to raise cleaning ration.

Owner:HISENSE HOME APPLIANCES GRP CO LTD

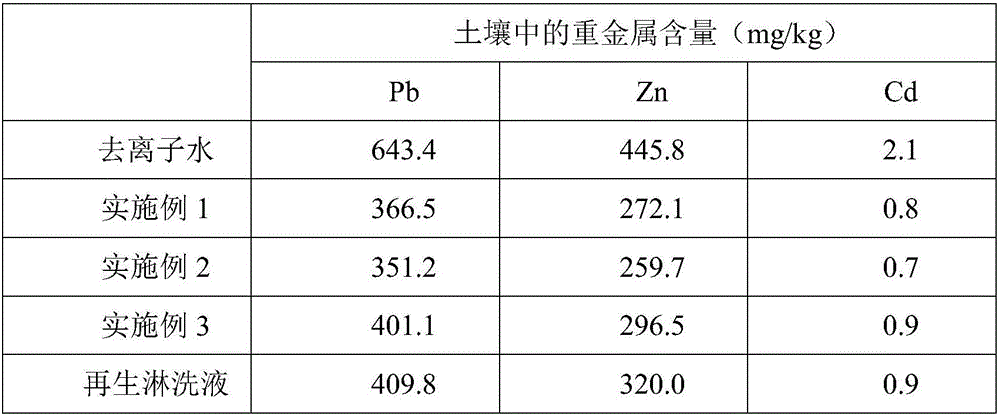

Compound chemical leaching method for efficient remediation of heavy metal contaminated soil

The invention relates to the field of soil remediation, in particular to a compound chemical leaching method for efficient remediation of heavy metal contaminated soil. Natural organic acid and iron salt are used as main raw materials to prepare a compound leacheate, and the technical problems that an existing soil remediation eluent is high in cost and low in efficiency and can cause secondary pollution easily are solved. According to the compound chemical leaching method, the heavy metal contaminated soil is remediated, the heavy metal content in the soil can be reduced quickly, and a good remediation effect is achieved. Waste liquid generated after leaching is disposed through a regenerant, and the primary regeneration efficiency can reach 80% or over.

Owner:东莞中科土壤科技开发有限公司

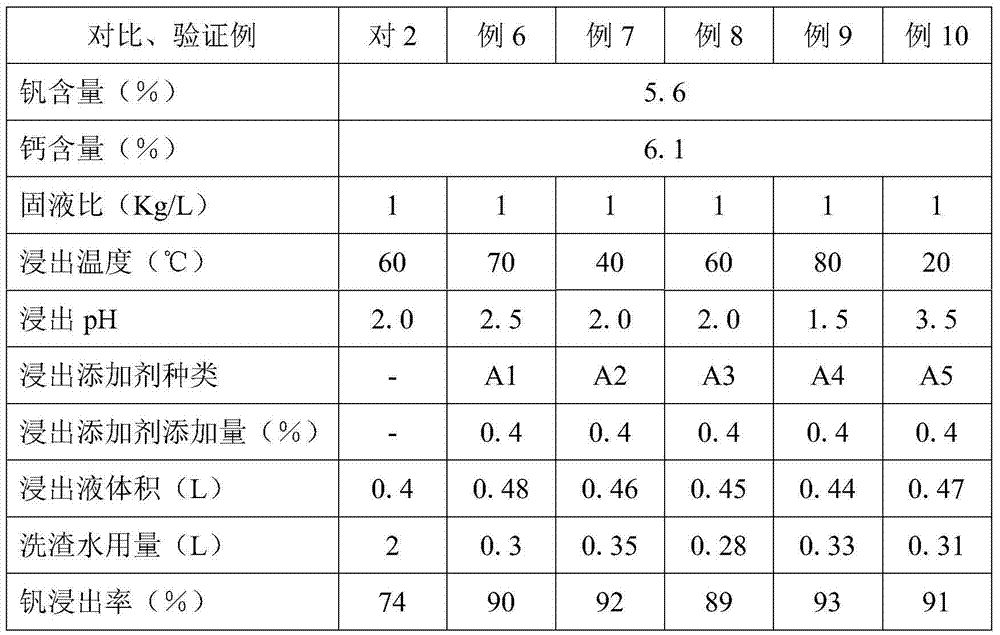

Method for improving leaching rate of calcification roasting vanadium slag and improving filtering effect

InactiveCN104745828AIncrease contact angleImprove leaching rateProcess efficiency improvementUreaPolyacrylic acid

The invention provides a method for improving the leaching rate of calcification roasting vanadium slag and improving the filtering effect. The method comprises the following steps: (1) crushing the vanadium slag subjected to calcification roasting, and then fully mixing the vanadium slag with water to prepare ore slurry; (2) adjusting the acidity of the ore slurry by using sulfuric acid so as to perform leaching on the vanadium slag subjected to calcification roasting; (3) filtering to separate the ore slurry after leaching so as to obtain vanadium leachate and to-be-washed tailings; and (4) performing drip washing on the to-be-washed tailings by using water, and collecting the slag washing water. The method has the improvement that a small amount of a leaching additive namely polyacrylic acid, sodium citrate, polydimethylsiloxane, potassium sodium tartrate or urea is also added in the ore slurry in the step (1). Compared with the prior art, the method provided by the invention has the advantages that the vanadium leachate is increased, the vanadium leaching rate is improved, and the output-input ratio for recycling the slag washing water is relatively high.

Owner:CHONGQING UNIV

Ultraviolet-resistant washing emulsion

InactiveCN101096616AImprove hydrophilicityImprove lipophilicityCationic surface-active compoundsDetergent compounding agentsFiberUltraviolet

The invention discloses an ultraviolet-resistant laundry emulsion, which comprises the following parts: 5%-15% aliphatic alcohol polyoxyethylene ether sodium sulfate, 2%-25% alkyl glycoside, 4%-18% alcohol ether carboxylate, 3%-38% coconut oil diglycollic amide, 2 %-36% sulfonate olefin, 0.5%-1.5% thickener, 2.5%-5% compliance agent and 0.5%-2.5% sun-screening agent with certain technical allocation. The invention can adsorb most of ultraviolet on the cloth, which improves the ultraviolet-resistant effect of textile effectively.

Owner:TIANJIN HAOJING TECH DEV

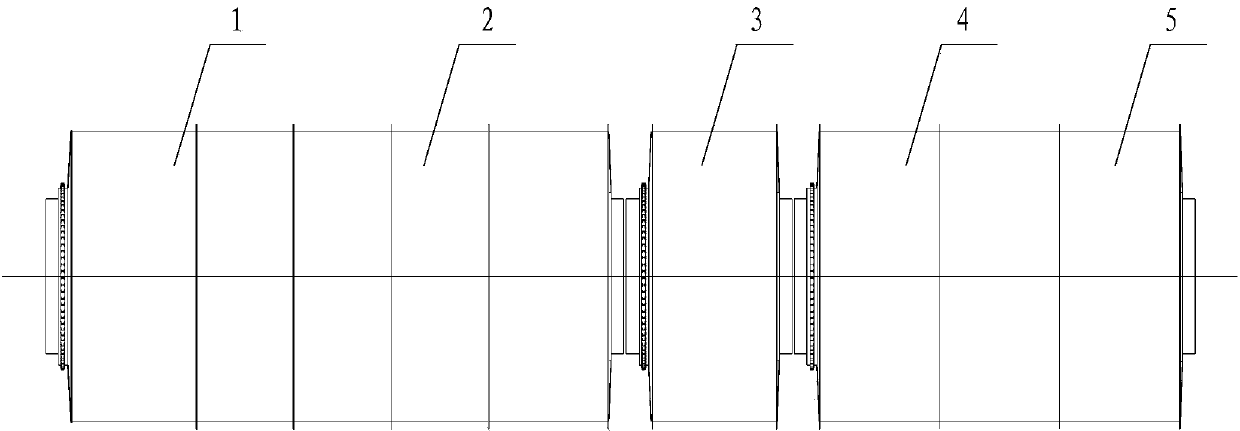

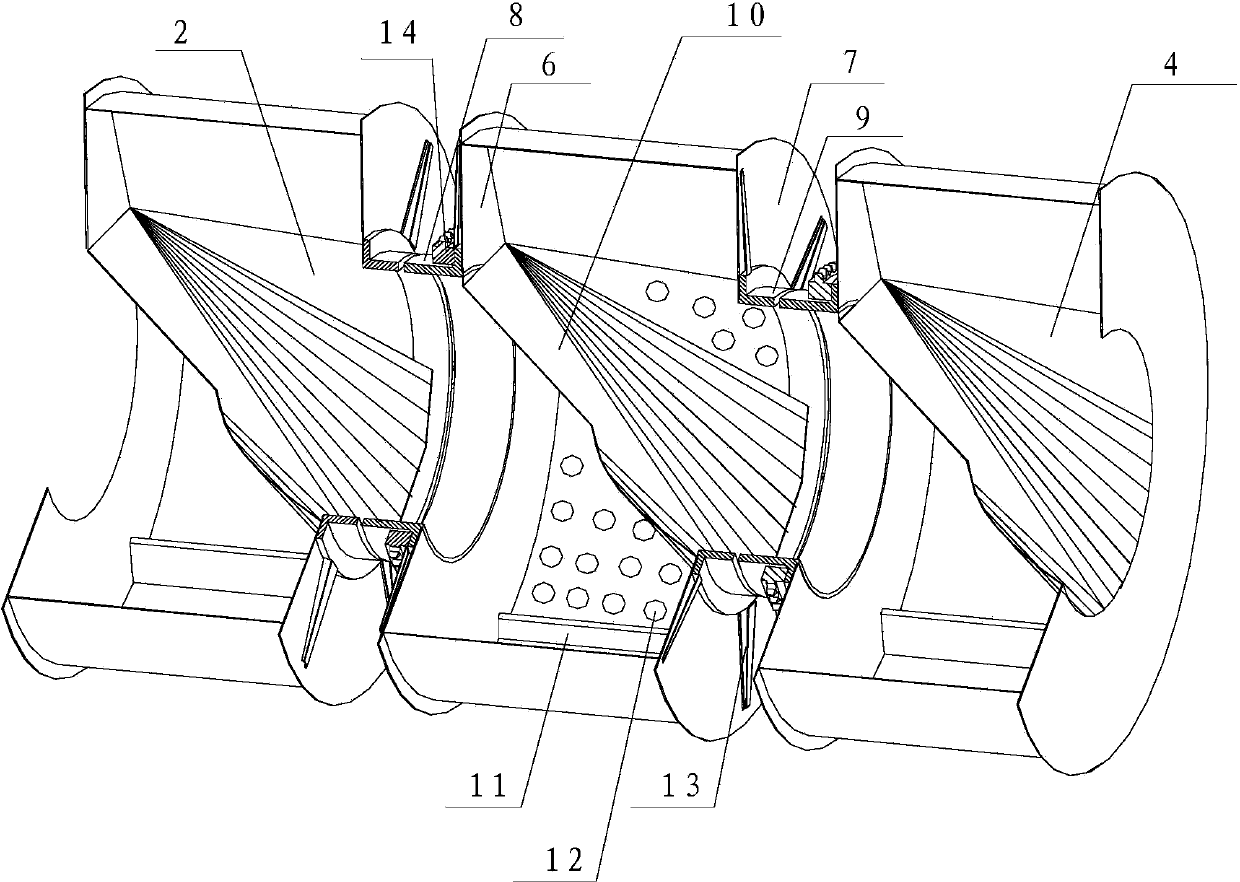

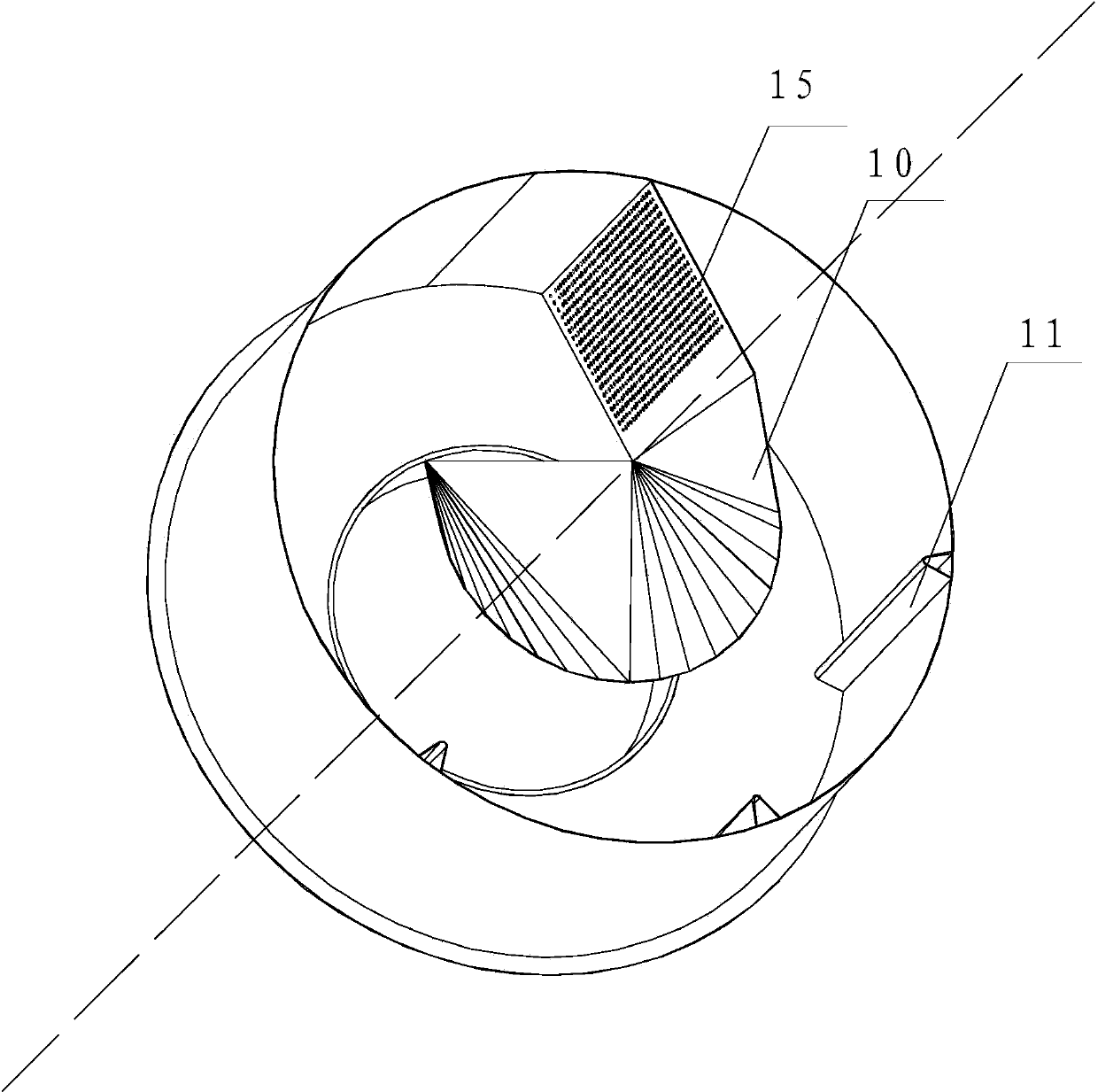

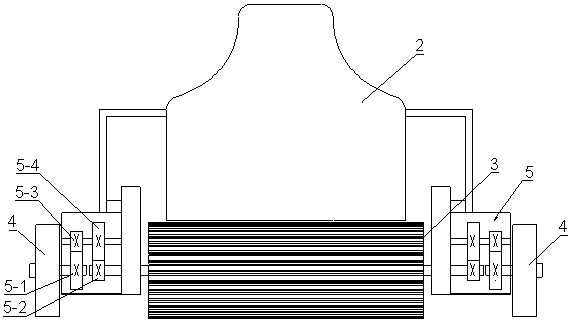

Tunnel type continuous washing machine

InactiveCN103726256AReduce the amount of sewageImprove washing effectOther washing machinesTextiles and paperAfter treatmentEngineering

The invention relates to a tunnel type continuous washing machine, and belongs to the field of washing equipment. The tunnel type continuous washing machine comprises a pre-washing area, a main washing area, a rinsing area and an after-treatment area, wherein a dewatering area is inserted between the main washing area and the rinsing area and comprises an inner barrel and an outer barrel; two panels are respectively fixed at an inlet and an outlet of the inner barrel; an inlet supporting steel ring and an outlet supporting steel ring are respectively fixed on surfaces, which are not fixed on the inner barrel, of the inlet panel and the outlet panel; the inlet supporting steel ring, the outlet supporting steel ring and the inner barrel are integrated; an optional one of the inlet supporting steel ring and the outlet supporting steel ring is connected with an external driving device; a conveying screw plate is fixed in the inner barrel; a through hole is formed in the inner wall of the inner barrel; and the inner barrel of the dewatering area is driven by an independent motor to rotate. By using the tunnel type continuous washing machine, the rinsing efficiency can be effectively improved; water consumed during rinsing is reduced; resources are saved; dewatered cloth grasses are easily rinsed cleanly; and a washing effect is obviously improved.

Owner:SHANGHAI WEISHI MACHINERY

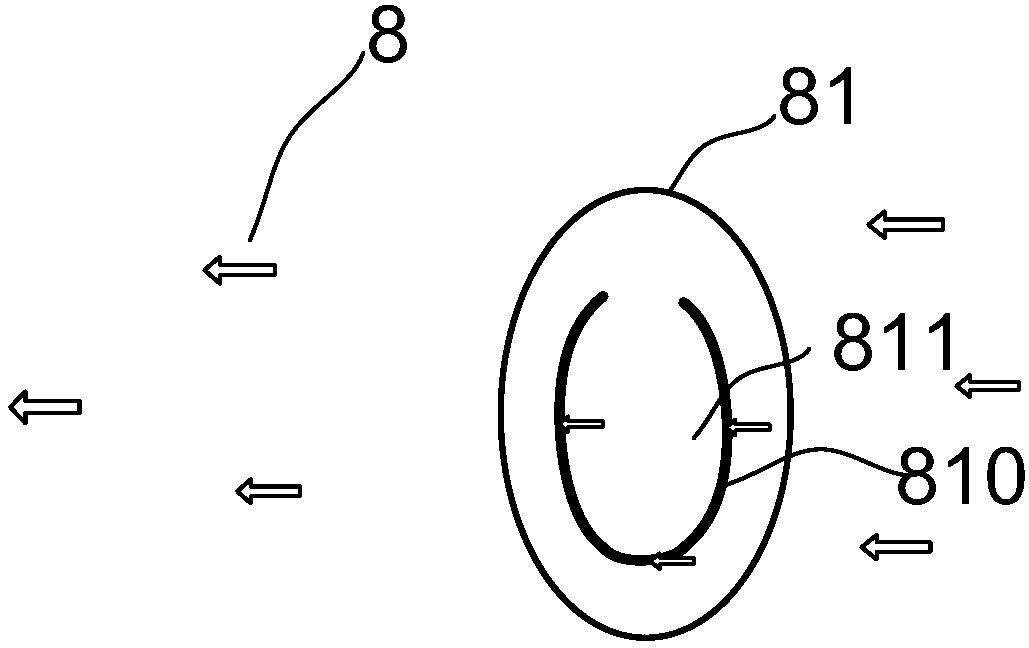

Automatic washing powder putting device

InactiveCN102995359APrecise deliveryStable deliveryOther washing machinesTextiles and paperImpellerElectricity

The invention relates to an automatic washing powder putting device. The device comprises a solvent box, an upper cover of the solvent box, and a powder leakage hole in a bottom disc. The device is characterized in that an impeller is arranged in the solvent box; a motor supplies kinetic energy to the impeller so as to drive the impeller to rotate; and a dissolving box is arranged on the other side of the powder leakage hole and is provided with a water inlet and a liquid leakage hole. According to the invention, the dissolving box can be used for fully dissolving washing powder, thus improving the purifying capacity of the washing powder, and avoiding waste caused by the inaccuracy of the quantity of the washing power manually put by a user; and the time for dissolving the washing power in a washing machine before is shortened since the washing powder is fully dissolved, so that the washing time of the washing powder is prolonged, and within the same set time, the frequency of rinsing is reduced and water and electricity are saved to achieve the aim of energy conservation. The automatic washing powder putting device conforms to green design and is energy-saving and man-machine.

Owner:NANJING ZHONGJINGKE ELECTRONICS TECH

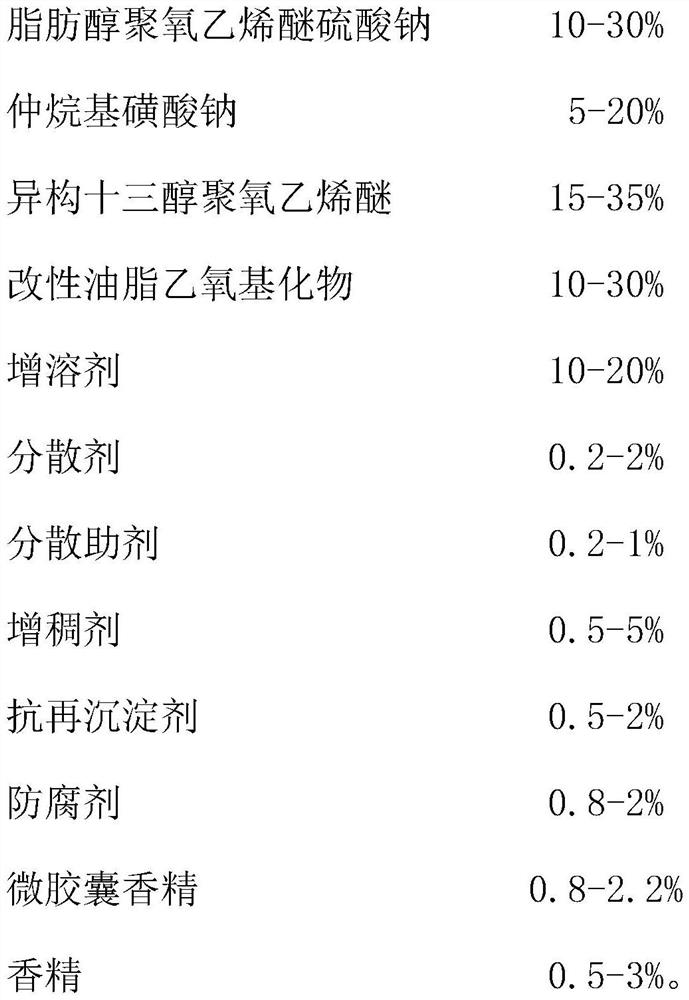

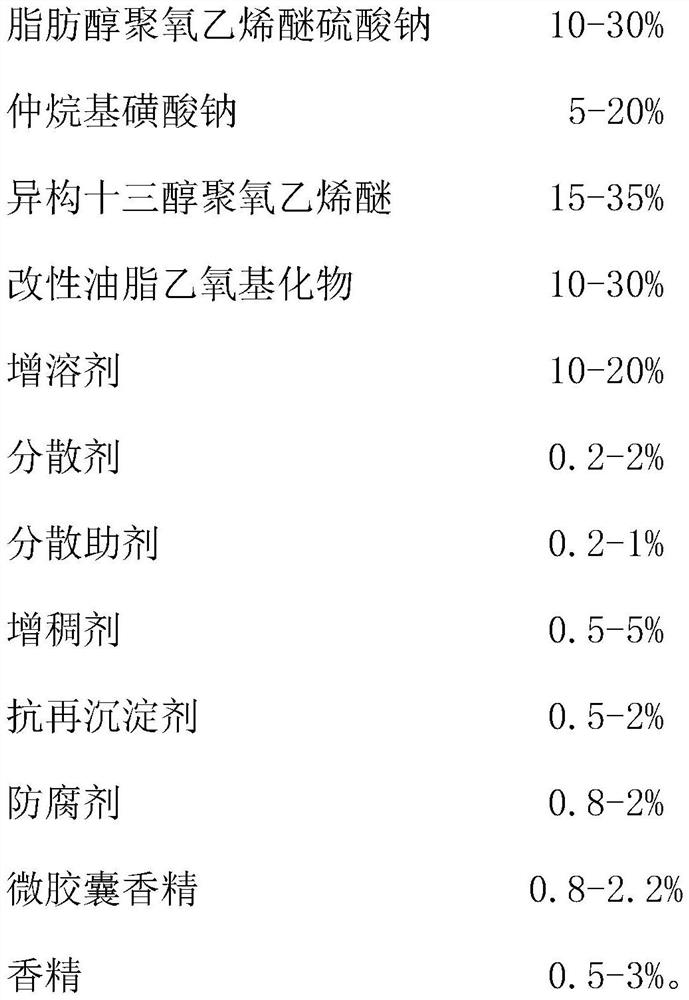

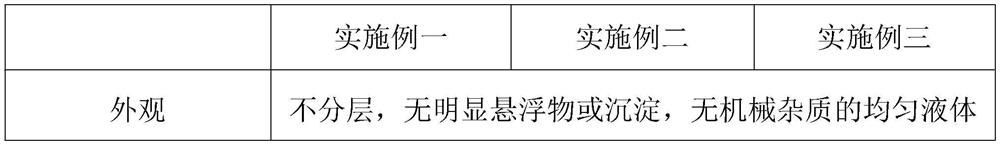

Stable long-acting fragrance-retaining laundry condensate bead and preparation method thereof

InactiveCN111808694AGood compatibilityLow foaming powerInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSulfonatePreservative

The invention relates to the technical field of daily chemical detergents, and provides a stable long-acting fragrance-retaining laundry condensate bead. The stable long-acting fragrance-retaining laundry condensate bead comprises, by mass, 10-30% of fatty alcohol-polyoxyethylene ether sodium sulfate, 5-20% of secondary alkyl sodium sulfonate, 15-35% of iso-tridecanol polyoxyethylene ether, 10-30%of modified grease ethoxylate, 10-20% of a solubilizer, 0.2-2% of a dispersing agent, 0.2-1% of a dispersing aid, 0.5-5% of a thickening agent, 0.5-2% of an anti-reprecipitation agent, 0.8-2% of preservative, 0.8-2.2% of microcapsule essence and 0.5-3% of essence. According to the formula, a solution system which is stable and good in suspension effect is formed, the microcapsule essence can stably exist in a material body, and the problems that in the prior art, the microcapsule essence and a laundry condensate bead liquid material body are prone to layering, and the unstable phenomenon exists are solved.

Owner:FUJIAN HENGAN HLDG CO LTD +1

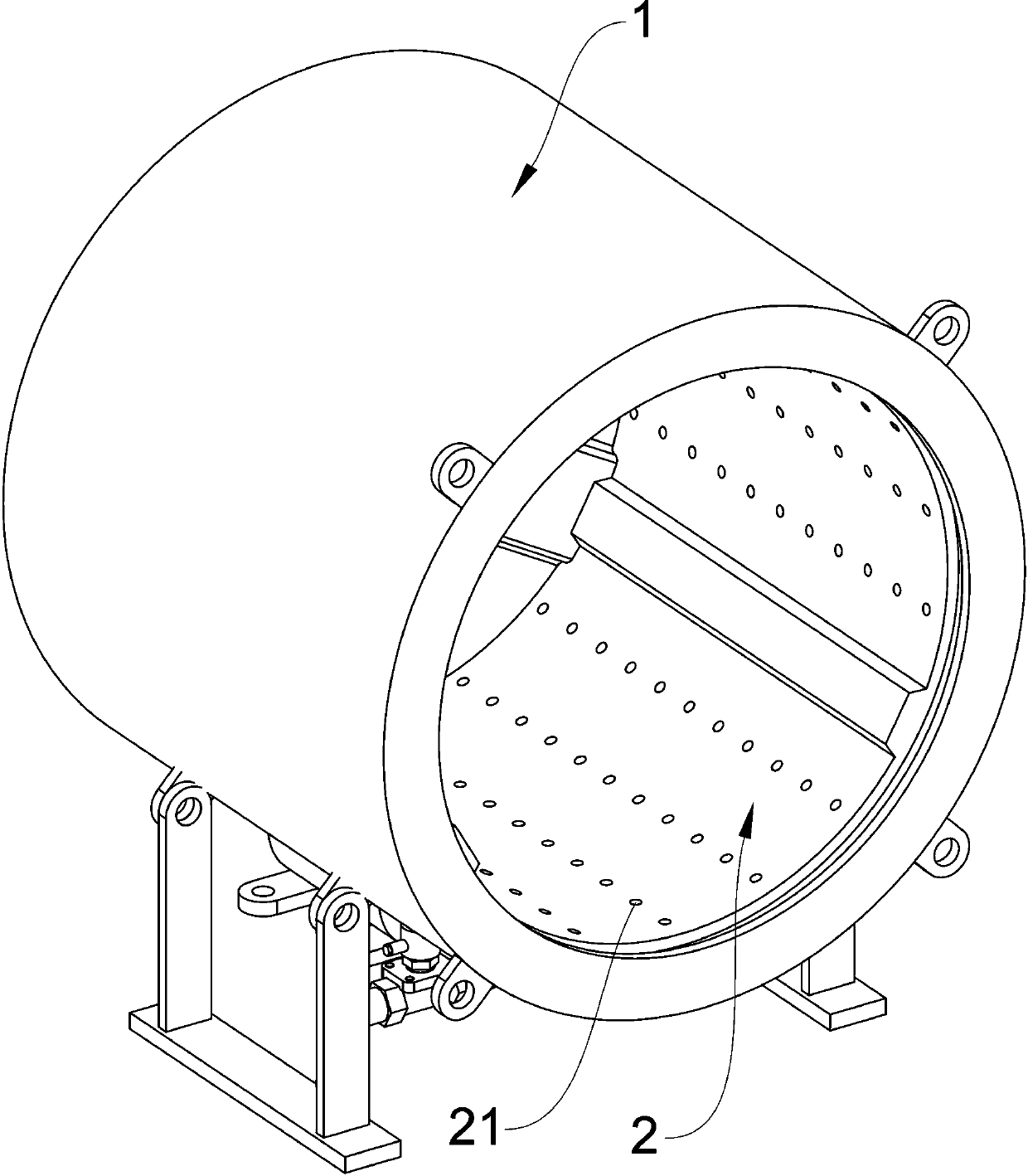

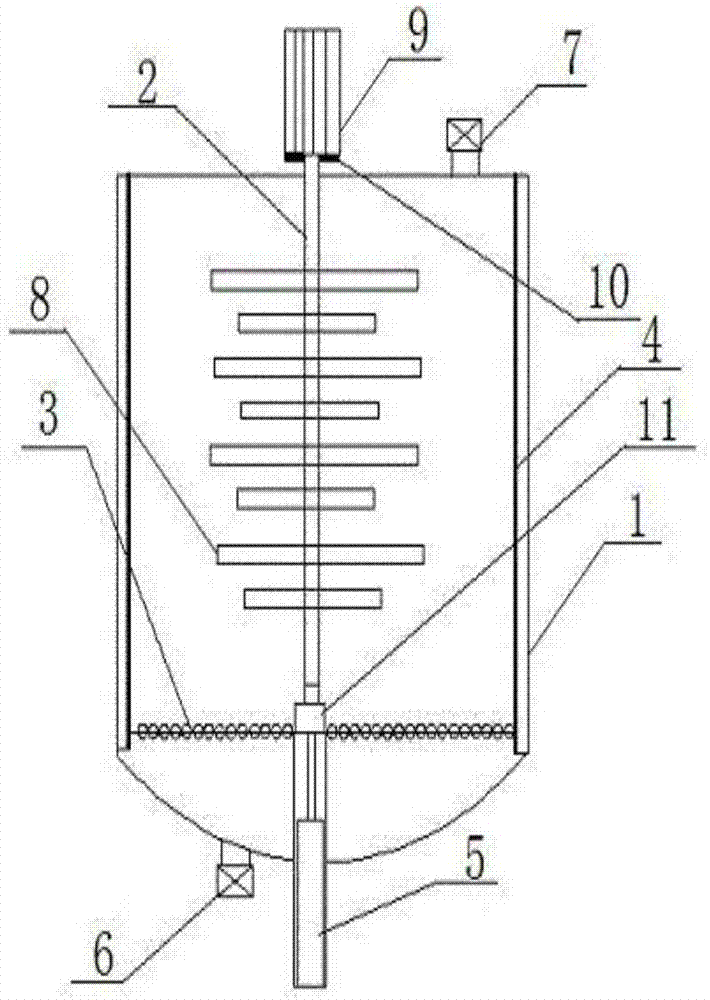

Minced fish rinsing device and rinsing method thereof

InactiveCN101703092AImprove work efficiencyContinuously workingFish washing/descalingClimate change adaptationRinse waterEngineering

The invention aims to disclose a minced fish rinsing device and a rinsing method thereof. The minced fish rinsing device comprises a device body; a mesh container whose surface is full densely distributed with of meshes is arranged in the device body; the center of the mesh device is provided with a rotary paddle which is driven to rotate by a rotating shaft; the device body is provided with a water injector used for filling rinsing water into the device body and the mesh container; and the bottom of the mesh container is respectively provided with a pumping port and a sewage draining exit via pipelines. The minced fish rinsing device and the rinsing method thereof have high working efficiency; minced fish is fully mixed with rinsing lotion, thus cleanly rinsing, saving water, reducing rinsing times, and saving equipment investment. The minced fish rinsing device can continuously work continuously, greatly lightens labor intensity greatly and realizes the purposeaim of the invention.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

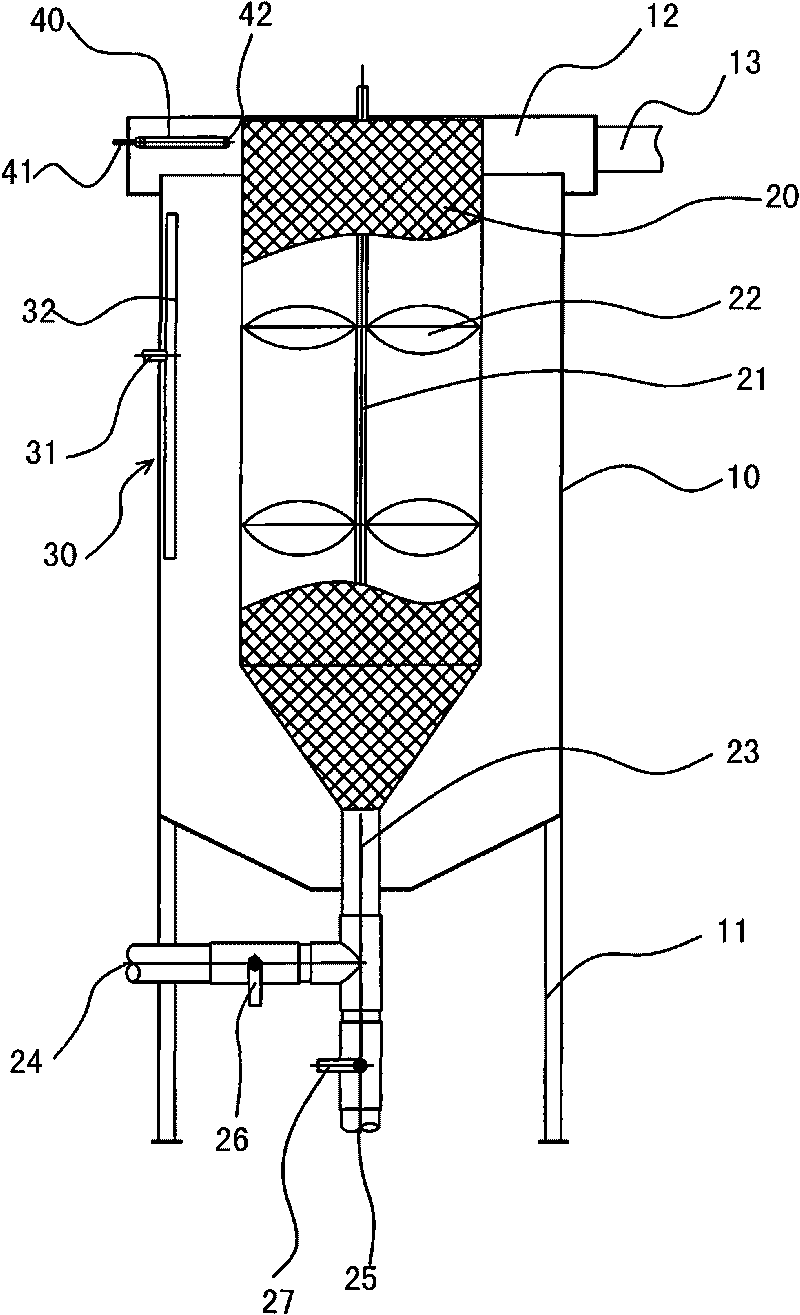

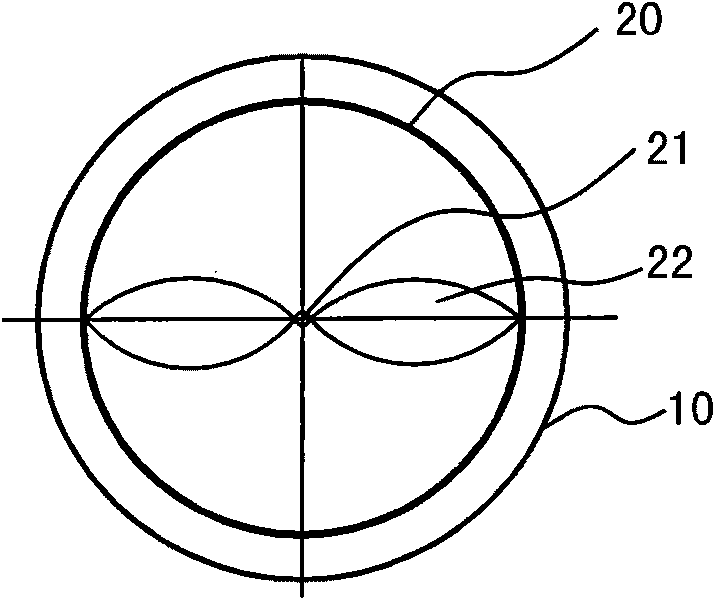

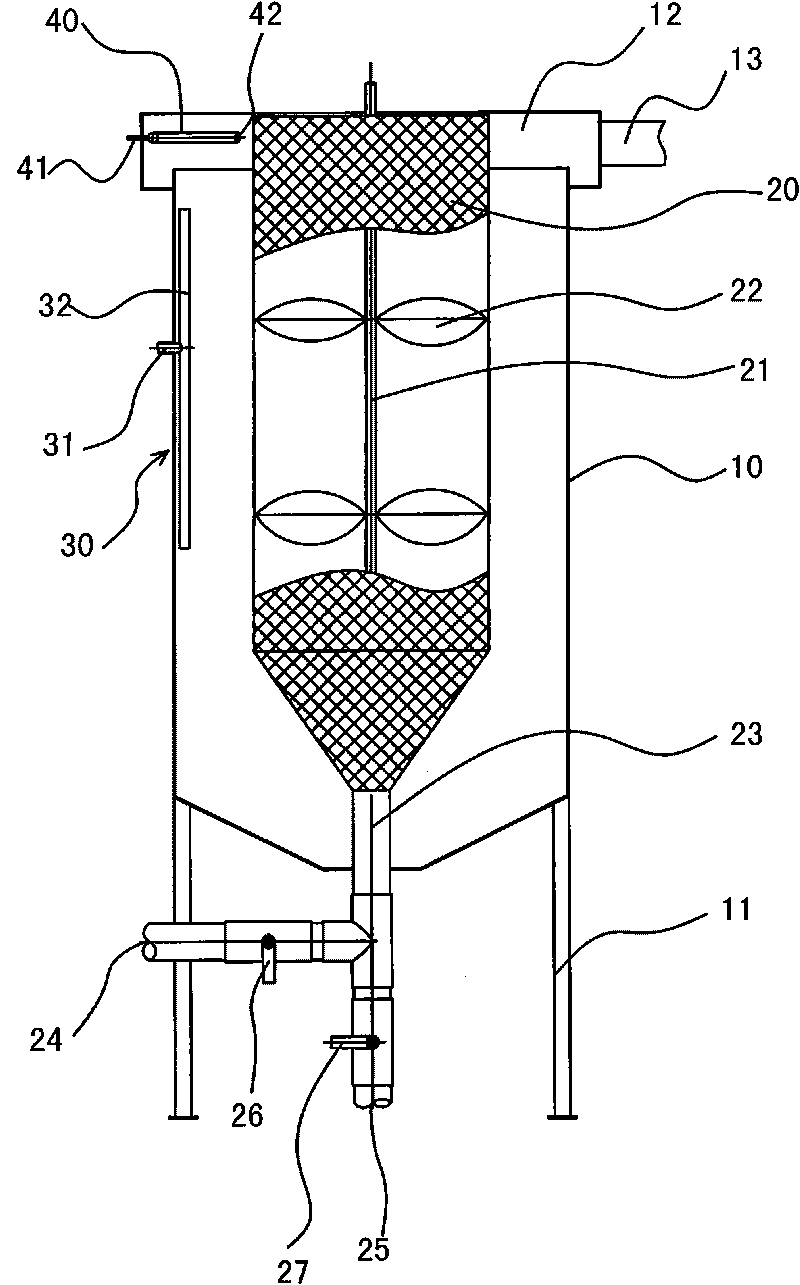

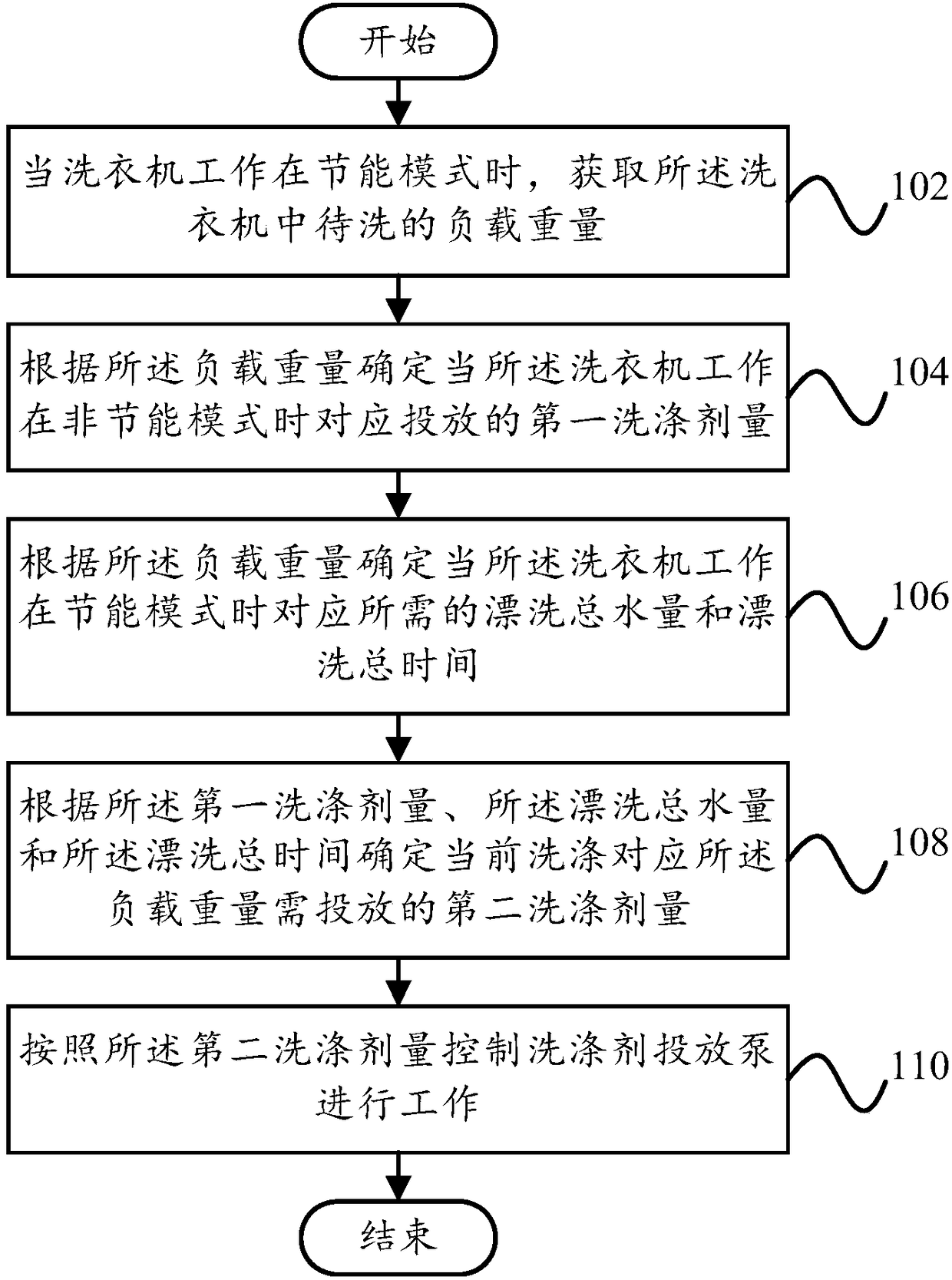

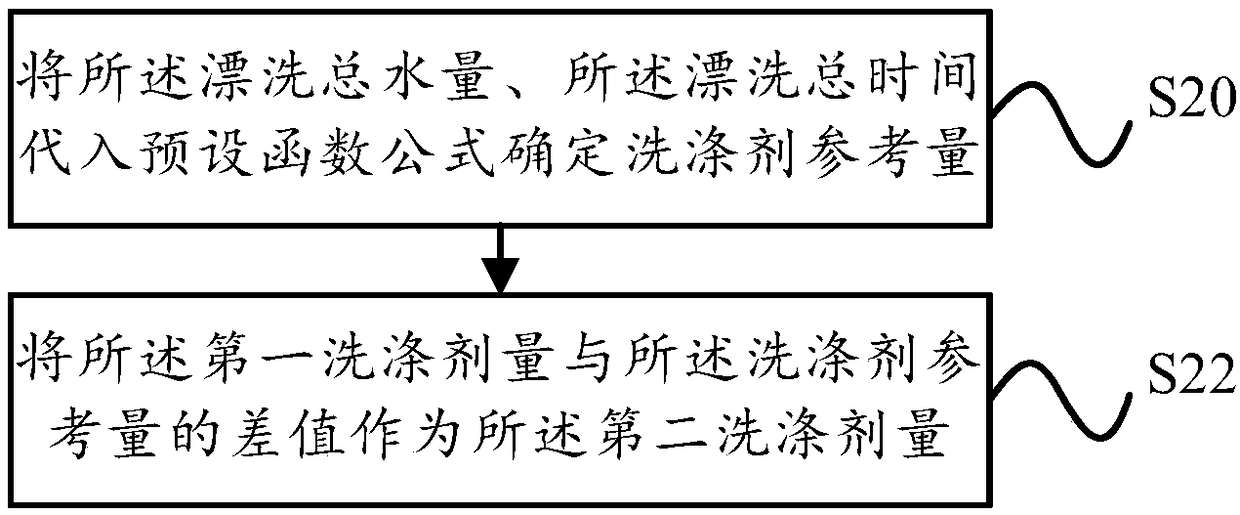

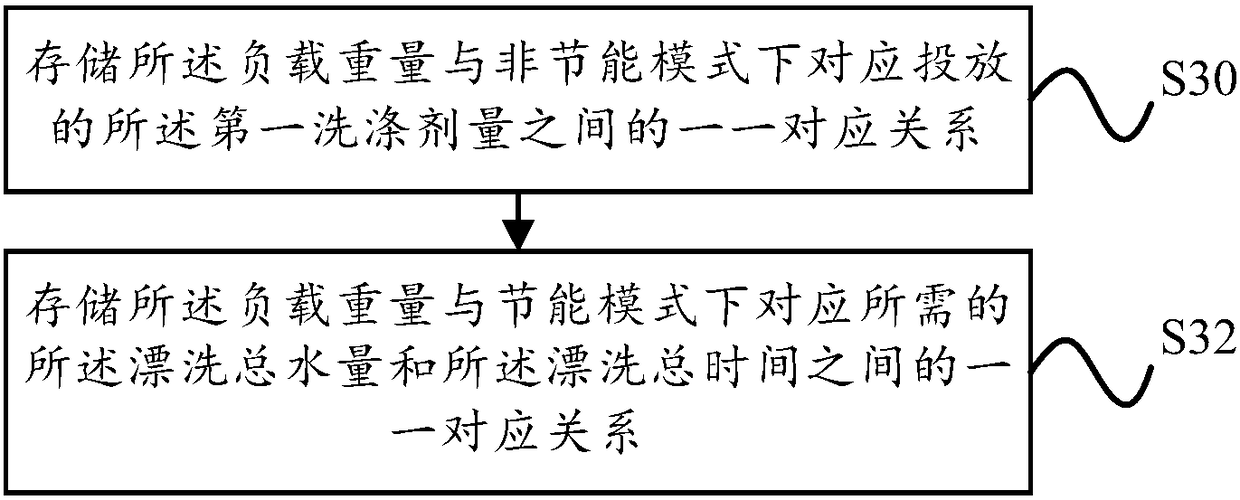

Control method and control device for automatic detergent delivery, and washing machine

ActiveCN108930128AWays to improve dosageImprove washabilityOther washing machinesControl devices for washing apparatusRinse waterProcess engineering

The invention provides a control method and a control device for automatic detergent delivery, and a washing machine. The control method for automatic detergent delivery comprises: when the washing machine operates in an energy saving mode, acquiring weight of to-be-washed load in the washing machine; determining first detergent amount delivered correspondingly according to the load weight when the washing machine operates in a non-energy saving mode; and determining a total amount of rinsing water and total rinsing time required correspondingly according to the load weight when the washing machine operates in the power saving mode; determining, according to the first detergent mount, the total amount of rinsing water, and the total rinsing time, second detergent amount required to be delivered corresponding to the load weight of current washing; controlling a detergent dispensing pump to operate according to the second detergent amount. The technical scheme can effectively improve conditions of unclean and residual detergent caused by energy-saving water consumption or reduction of the number of dehydration times through improving automatic delivery of the detergent, so as to achieve an optimal washing effect.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

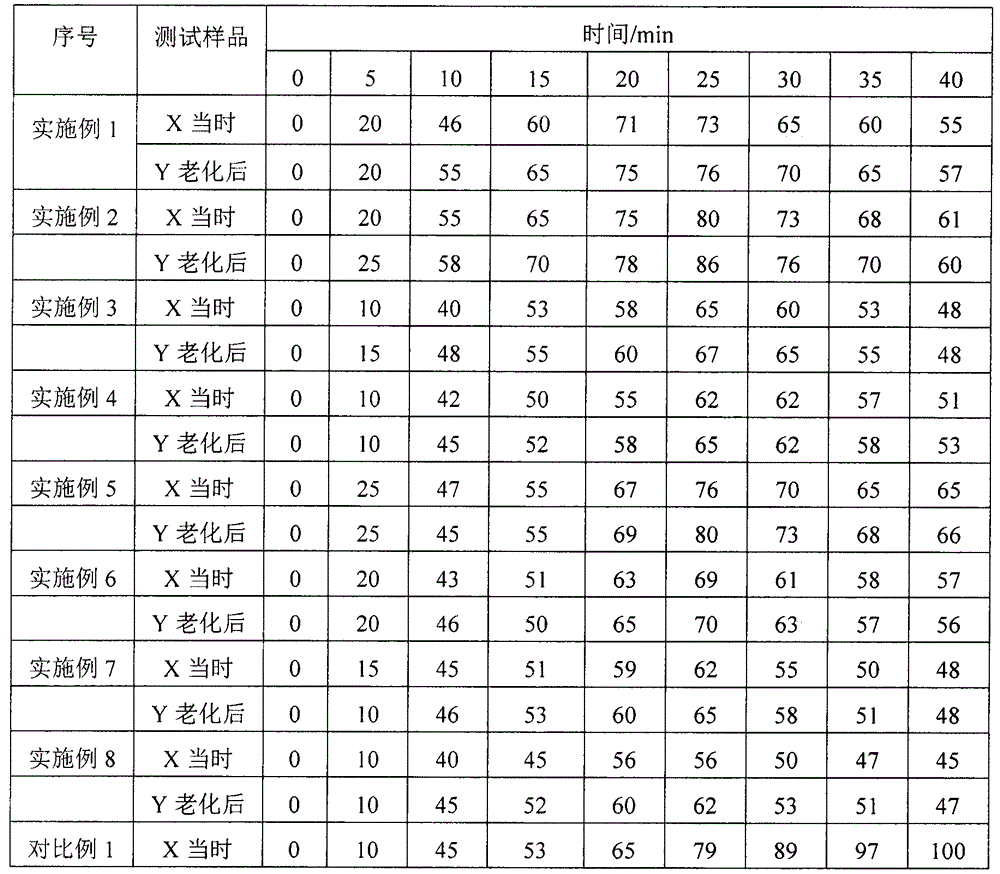

Nanoparticle photocatalysis board, its preparation method and application thereof

InactiveCN102513074AReduce manufacturing costGood effectInorganic/elemental detergent compounding agentsLaminationNanoparticle coatingDesorption

The invention provides a nanoparticle photocatalysis board, its preparation method and application thereof. The nanoparticle photocatalysis board comprises a substrate and a photosensitive nanoparticle coating that is cured on the substrate. The preparation method consists of: subjecting the substrate to ultrasonic cleaning and drying it in the air, and applying a light curing adhesive uniformly in a darkroom environment, then conducting drying treatment so as to obtain a light curing rubber board; spraying the photosensitive nanoparticles on the light curing rubber board uniformly, then placing it in an ultraviolet light environment for curing, thus obtaining the nanoparticle photocatalysis board, which can be applied in removing residual washing agents in washed clothes. The photocatalysis board provided in the invention has the advantages of low preparation cost, low particle desorption rate, current scour resistance, and no loss of the activity of the nanoparticles. The method of the invention is simple and operated at normal temperature, and it reduces the cost as well as improves production efficiency.

Owner:YUNNAN UNIV

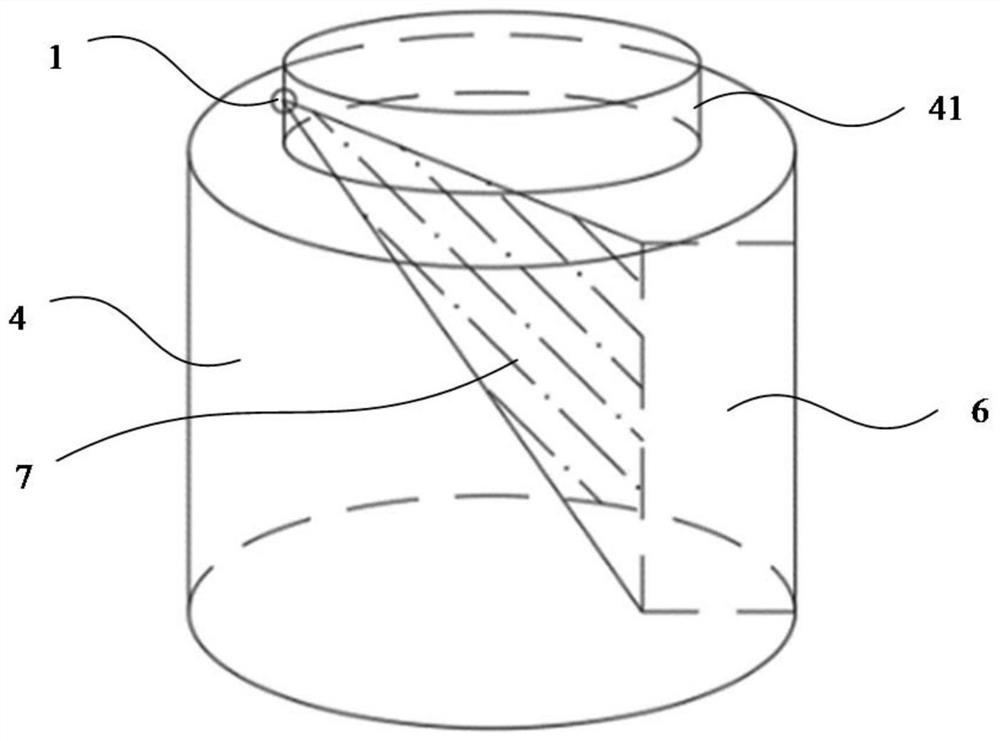

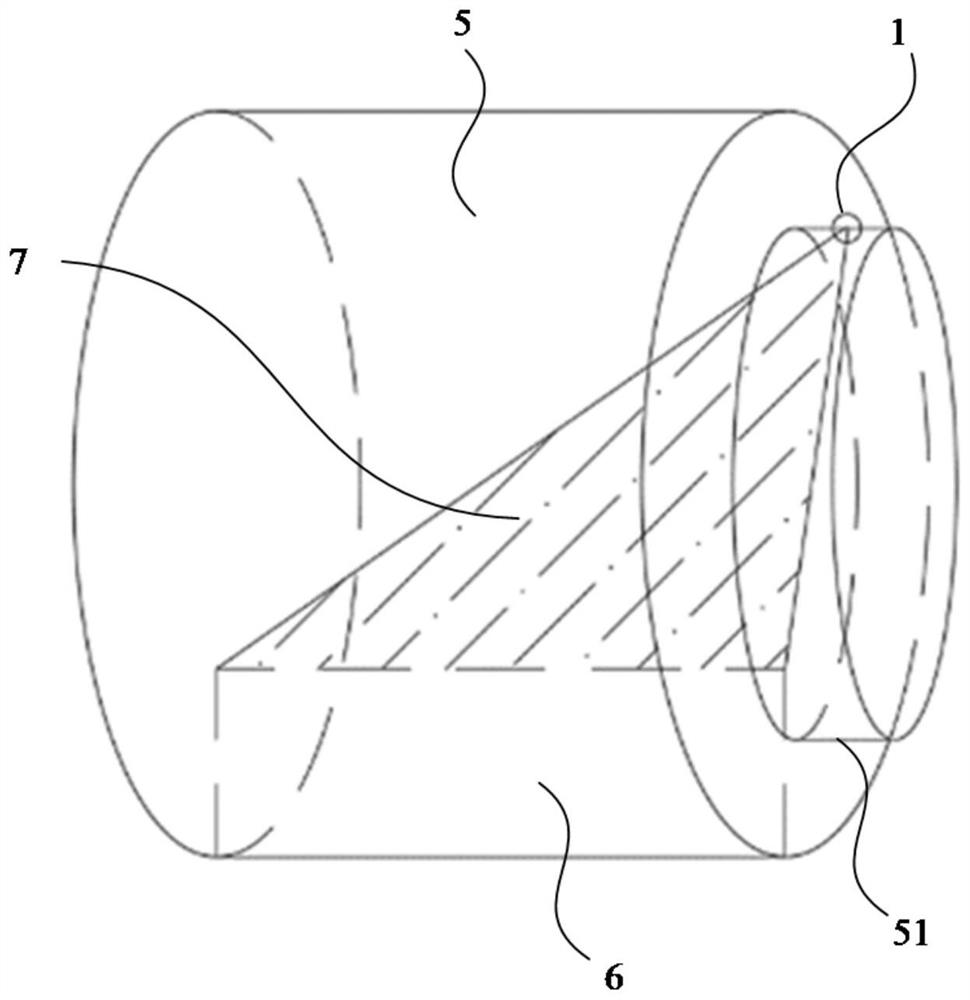

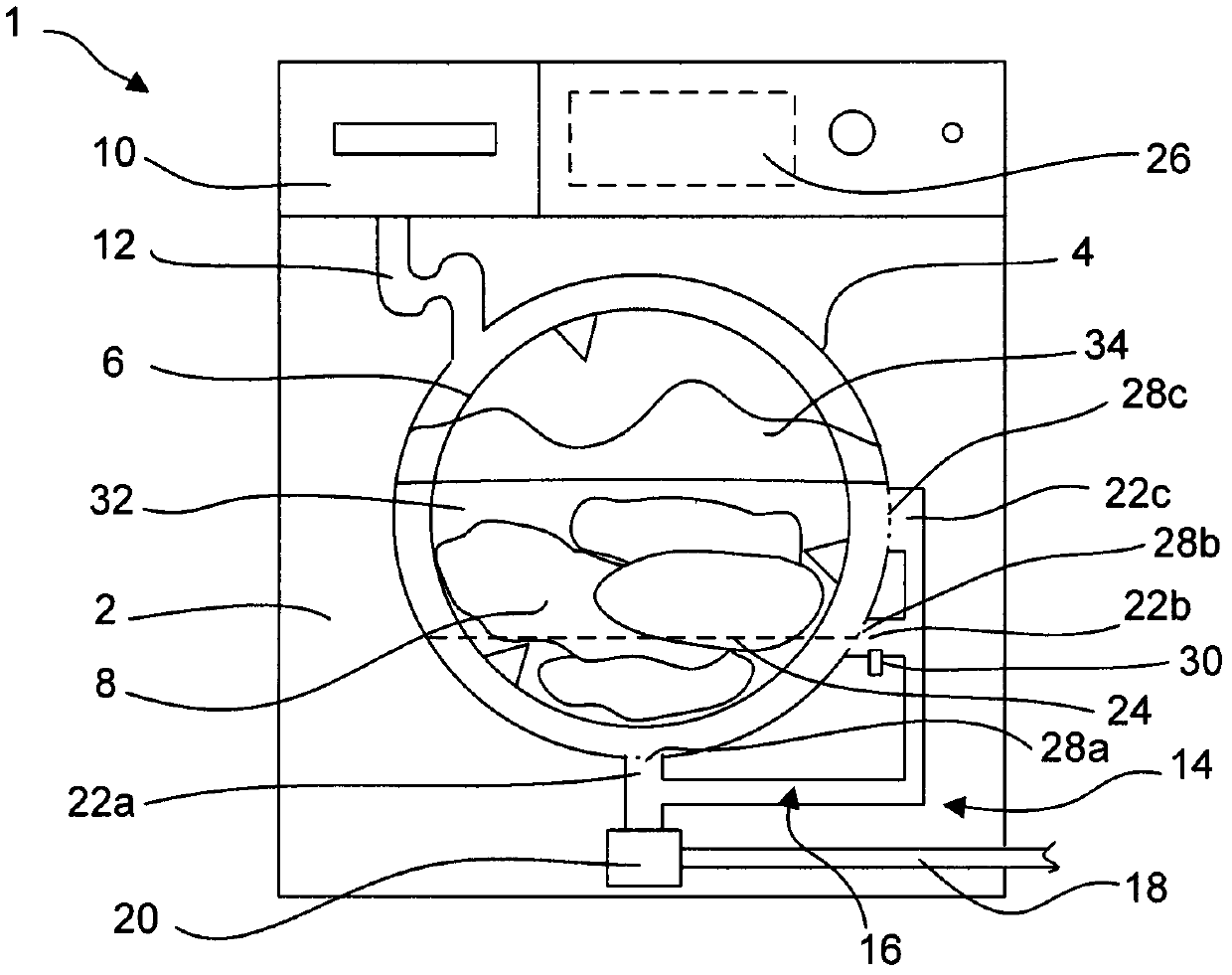

Spraying device and washing machine

PendingCN113373657AEmission reductionReduce the number of rinsesSpray nozzlesOther washing machinesWater savingLaundry washing machine

The invention belongs to the technical field of washing machines, and particularly relates to a spraying device and a washing machine. The invention aims to solve the problem that an existing washing machine needs to perform rinsing and dewatering for multiple times to reduce residual stains and detergent on clothes, so that the washing time is long. The spraying device comprises a spraying head and a first water inlet branch pipe, wherein the first water inlet branch pipe is used for introducing clean water into the spraying head. A spraying opening of the spraying head sprays curtain-shaped water flow, the curtain-shaped water flow continuously sprays clothes, and the clean flowing water continuously replaces sewage containing the detergent and the stains in the clothes, so that the content of the residual detergent and stains in the clothes is gradually reduced, the rinsing frequency and time in the washing process are shortened, the total washing time is shortened, and the washing efficiency is improved; and electricity and water are saved, sewage discharge is reduced, and energy conservation and emission reduction are facilitated.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

Preparation method for powder defoaming agent

ActiveCN104941260ASlow release rateImprove liquidityFoam dispersion/preventionActive matterBuffer solution

The invention relates to a preparation method for a powder defoaming agent. A buffer solution is directly added into a carrier, so that the problem that fluidity is poor is solved, and meanwhile the problem that defoaming stability becomes poor after long-time storage is solved. In addition, a gelling agent is added into defoaming active matter to make the liquid defoaming active matter become pasty and swells after meeting water, so that the defoaming active matter is slowly released and has a better defoaming effect at the later period of washing, and accordingly rinsing frequency is reduced.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Chopstick washing machine with high-temperature disinfection function

InactiveCN105769090AEasy to cleanShorten cleaning timeWashing controlling processesTableware washing/rinsing machine detailsSolubilityWater use

The invention discloses a chopstick washing machine with a high-temperature disinfection function. The chopstick washing machine comprises a shell, a pipeline, a connector, an electric control system, a structure device, a functional device and a connection device, wherein the electric control system comprises a circuit board, an ultrasonic generator and a temperature sensor; and the functional device comprises a water returning nozzle and a heating pipe. The chopstick washing machine is used for washing through ultrasonic waves; the solubility of a washing solution and the cavitation effect of ultrasonic waves are improved through heating, and sterilization and disinfection are carried out through heating to a high temperature so that the washing effect of the chopstick washing machine is relatively good; a mini-type water pump is used as a core water circulating system so that the technical effect that water is supplied for one time and can be used for a plurality of times is realized; a wireless device is wirelessly connected with intelligent equipment of a user, so that the user can be more flexibly and conveniently use the washing machine; and the chopstick washing machine has relatively good washing effect and relatively less water use amount and is relatively safe and convenient to use.

Owner:SUZHOU LUZHIYAO TECH

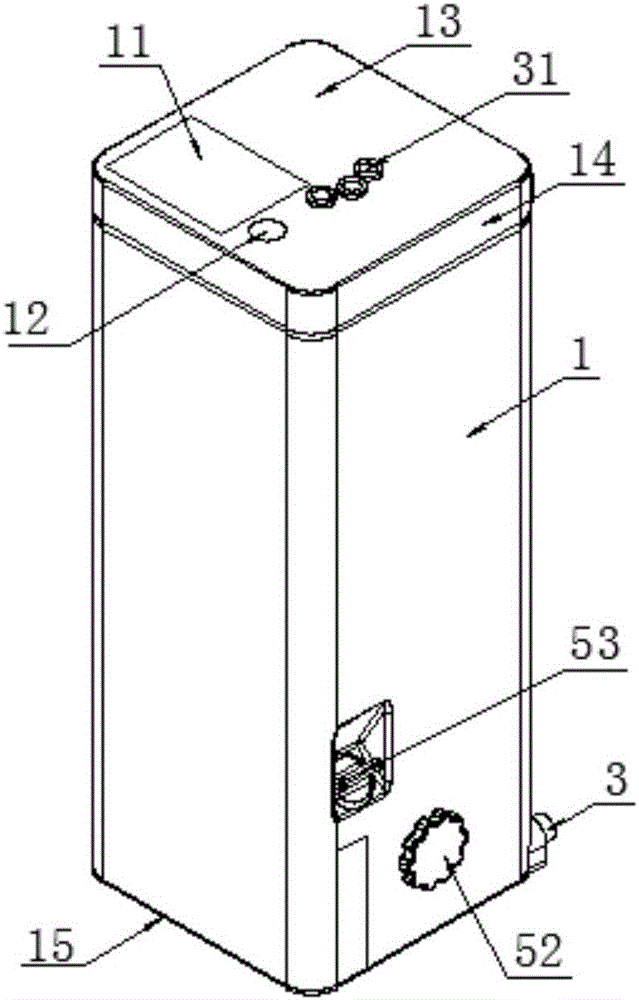

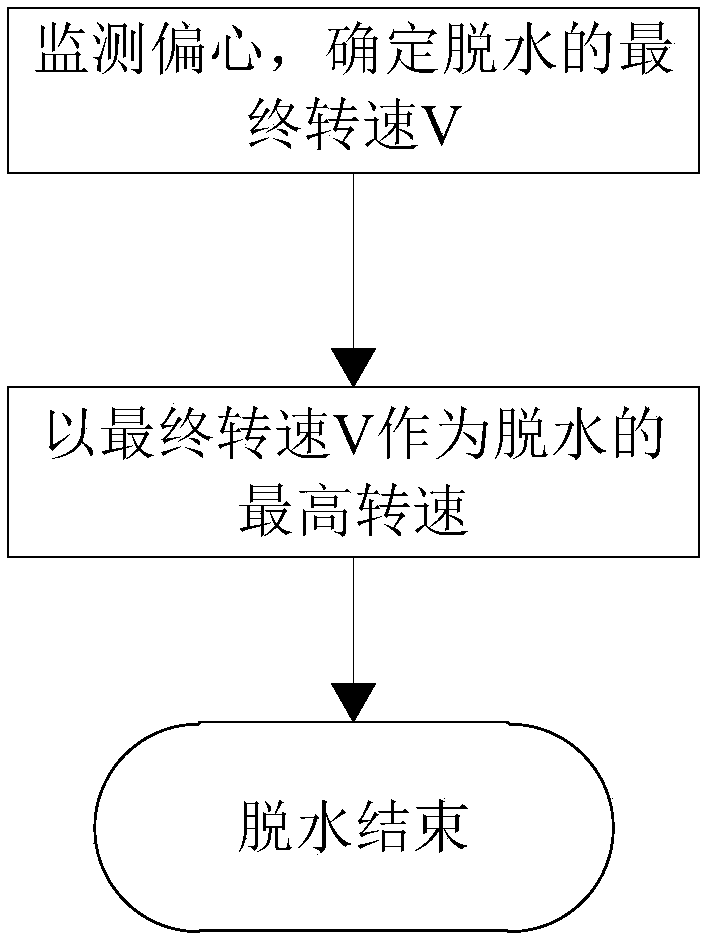

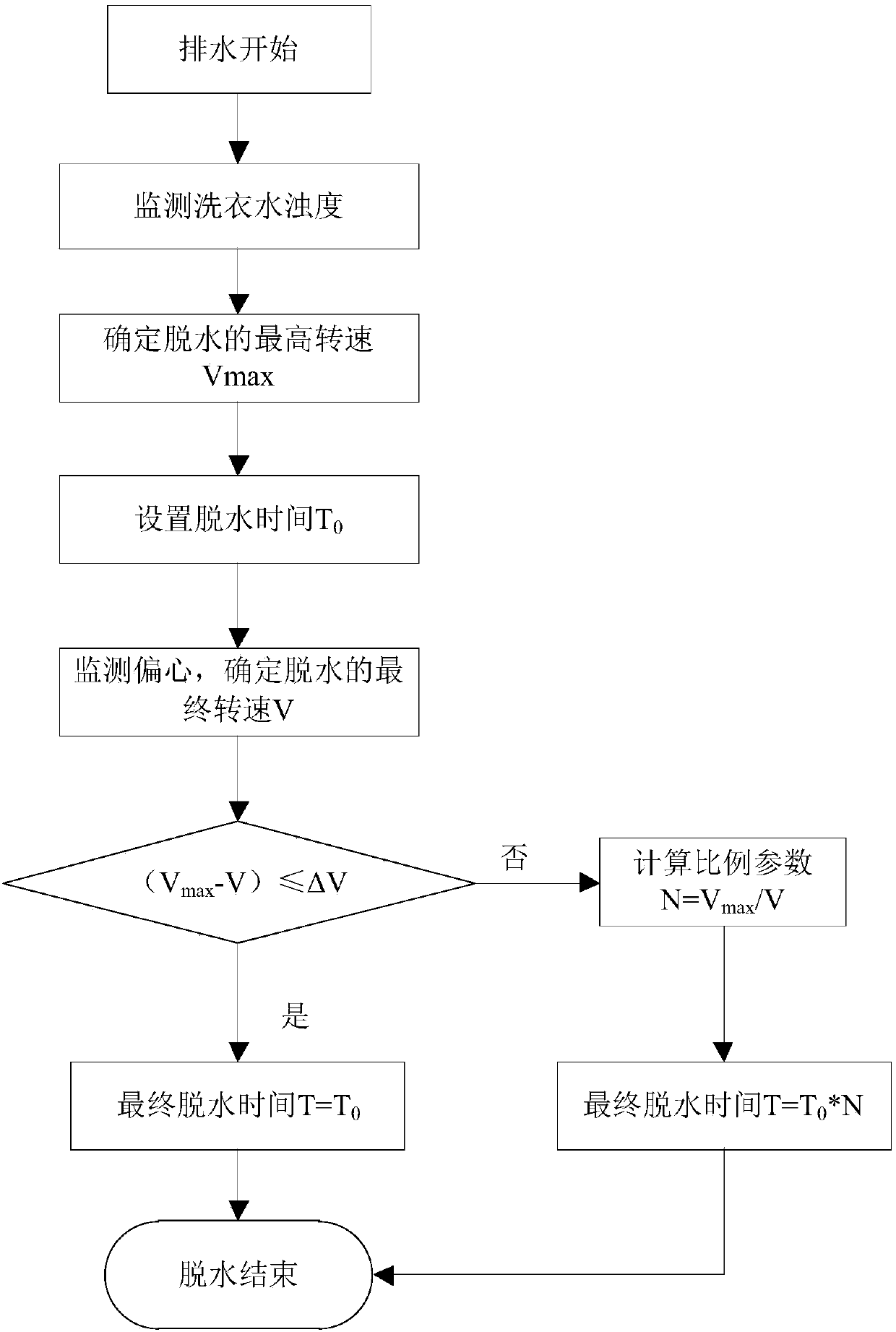

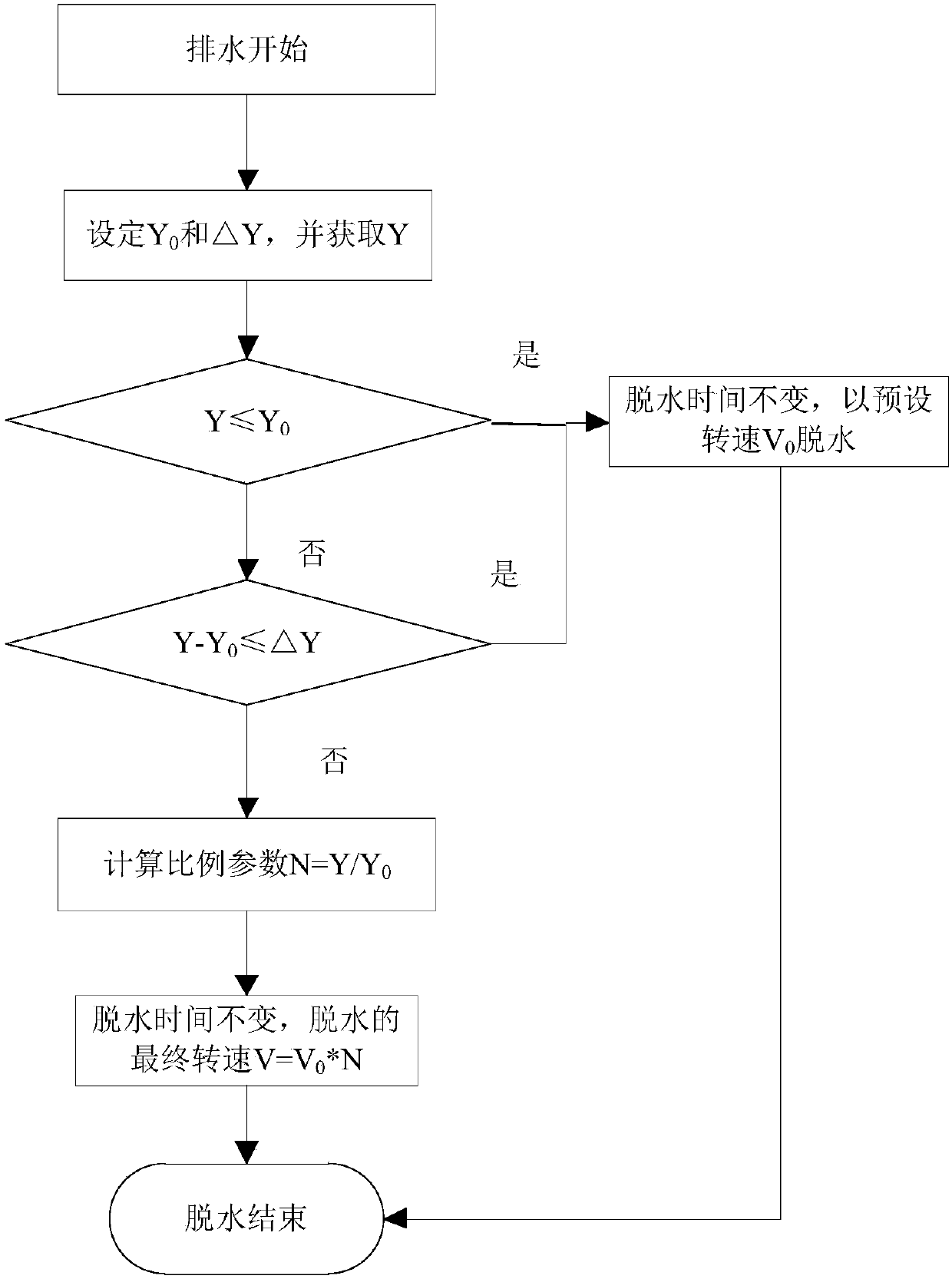

Washing machine dehydration control method and washing machine

ActiveCN107815815AReduce the number of rinsesConserve waterControl devices for washing apparatusTextiles and paperProcess engineering

The invention discloses a washing machine dehydration control method and a washing machine, and belongs to the field of washing machine program control. The dehydration control method of the washing machine comprises the steps of monitoring whether clothes washing water exists in a washing drum or not, and if not, making the washing machine conduct direct dehydration according to a set dehydrationrotation speed and dehydration time; if yes, starting drainage, monitoring the turbidity of the clothes washing water and making the washing machine conduct dehydration by adjusting the speed and time according to the adjustable dehydration rotation speed and / or dehydration time according to the turbidity of the clothes washing water. By means of the washing machine dehydration control method, the dehydration rotation speed and time are determined by monitoring the turbidity of the clothes washing water, when clothes are dirty or too much detergent is put, more dirt and detergent can be thrown out, the rinsing frequency is reduced, water is saved, and the clothes cleanness after washing is improved. By means of the washing machine conducting dehydration according to the washing machine dehydration control method, the electric consumption is small, and requirements for energy saving and environment protection are met.

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +1

Washing technology of down feather

InactiveCN107268090AReduce the number of timesFast cleaningInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsDisinfectantChemistry

The invention discloses a water washing process of down. The process of cleaning down is divided into two major processes of initial washing and rinsing. The down is degreased by adding warm water at 50-55 degrees Celsius and a part of impurities in the down are washed away. The cold water with 84 disinfectant is used to disinfect and bleach the down for the first time, and the warm water at 50-55 degrees Celsius with 3% detergent, 1% deodorant, and 2.5% antibacterial agent is added to decontaminate and remove the down. Oil, deodorization and re-disinfection. The detergent, deodorant, antibacterial agent and 84 disinfectant in the down are removed by multiple rinsing, so that the cleanliness of the down is above 1000 degrees. Use a low-speed centrifuge to remove the water in the down and remove the residual sewage in the down. This can reduce the number of times for rinsing the down, which not only speeds up the cleaning speed, but also reduces the amount of water used for rinsing.

Owner:THE SEA FEATHER LTD CO OF LUAN

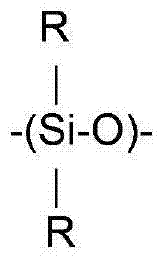

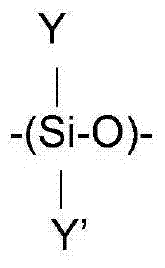

Laundry detergents

InactiveCN103249823AReduce the number of rinsesOrganic detergent compounding agentsAnionic surface-active compoundsChemistryLaundry

A laundry detergent comprises a granulated foam control composition and an anionic surfactant, wherein the granulated foam control composition comprises a foam control agent, an organic additive composition, a water soluble particulate carrier and a charged cationic polymer. The foam control agent comprises a polydiorganosiloxane fluid, a hydrophobic filler and optionally an organosilicone resin. A method of cleaning a fabric, a method of conserving water when washing fabric and a method of saving time when washing fabric are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

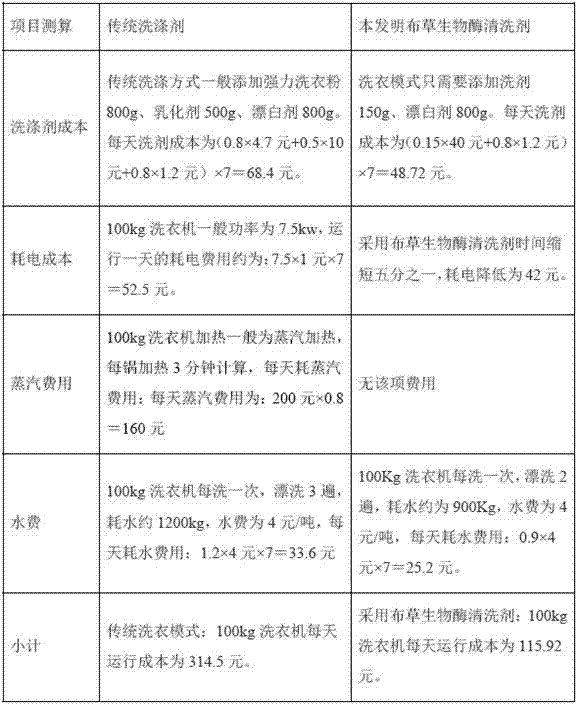

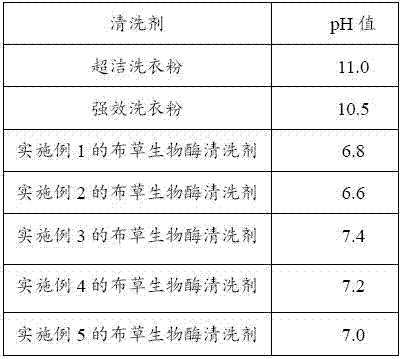

Cloth biological-enzyme cleaning agent and preparing method and application thereof

InactiveCN106929190AReduce the number of rinsesEfficient removalOrganic detergent compounding agentsNon-ionic surface-active compoundsEnzymeNonionic surfactant

The invention discloses a cloth biological-enzyme cleaning agent. The cloth biological-enzyme cleaning agent is prepared from, by weight, 20%-30% of a nonionic surfactant, 5%-10% of an anionic surfactant, 0.2%-0.5% of ethylenediamine tetraacetic acid, 1%-5% of an enzyme preparation and the balance deionized water. The cloth biological-enzyme cleaning agent is neutral, and cloth is not damaged; as a phosphorus ingredient does not exist, a water body is not polluted; when the cloth biological-enzyme cleaning agent is used for cleaning the cloth, the synergistic effects of all components are achieved, and particularly, by means of the synergistic effects between the enzyme preparation, the nonionic surfactant and the anionic surfactant, various stains on the cloth can be rapidly and effectively removed, and the cloth is as bright as new; the cloth biological-enzyme cleaning agent is small in using quantity and rinsing frequency, cleaning is carried out at the normal temperature, water and energy are saved, and the cleaning cost is saved.

Owner:ANHUI LEVEKING BIOTECH CO LTD

Clothing care machine

InactiveCN109957904AReduce usageStrong ability to remove stainsOther washing machinesTextiles and paperImpellerEngineering

The invention discloses a clothing care machine, comprising a machine body, an outer drum, an inner drum, an ultrasonic generator, a bubble generating chamber, a water inlet pipeline, an air channel,a motor, an impeller and a control device, wherein the ultrasonic generator is arranged on the wall of the outer drum; the water inlet pipeline is used for connecting the out drum with the interior ofthe bubble generating chamber; the air channel is communicated with the bubble generating chamber for providing the outside air; the impeller is arranged in the bubble generating chamber; the controldevice is configured to control the motor to dive the impeller to rotate so as to enable the air in the bubble generating chamber to be mixed with washing water for generating washing bubble water, and control the ultrasonic generator to generate high frequency ultrasonic vibration so as to enable bubbles in the washing bubble water, entering the outer drum, to be broken.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

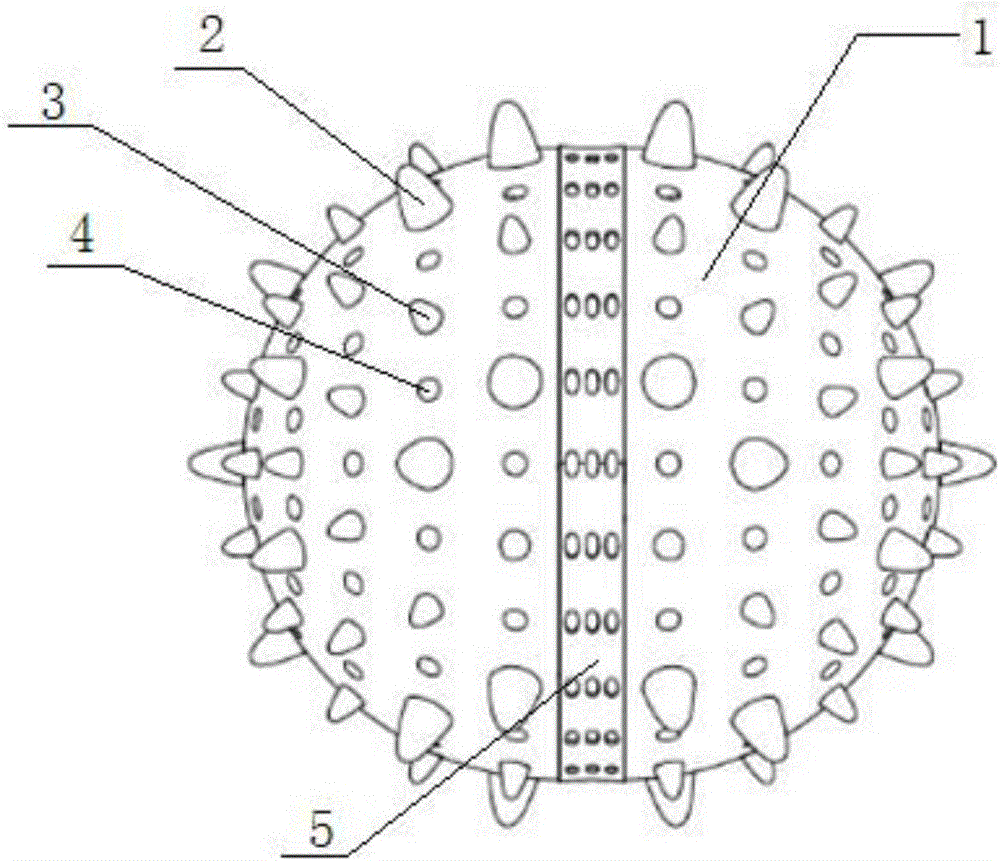

Water processor for clothes washing

ActiveCN106676838AImprove antioxidant capacityStrong reductionOther washing machinesWater/sewage treatmentImpellerLaundry washing machine

The invention relates to a water processor for clothes washing. The water processor is shaped like a hollow ball; multiple water processing stripes on which raised parts and hollow holes are arranged are disposed on the surface; a water inlet stripe is disposed at the center of the spherical surface of the water processor; and a filter ball is disposed inside. The filter ball is made of an anti-microbial ceramic material and a reduction anti-microbial material. Working principles of the water processor provided by the invention are different from working principles of an impeller washing machine and a roller washing machine; based on the high oxidation ability of ionized water, alkaline ionized water and dirt conduct a saponification reaction, so the dirt can be decomposed and stripped thoroughly; the cleaning rate is high; the dirt removal ability is high; and wear to clothes is slight. Alkaline ionized water generated during clothes washing can clean the clothes; all contact parts between a washing machine and the water can be cleaned; and sterilization effects are achieved during the cleaning, so bacteria breeding can be avoided. The water processor for the clothes washing provided by the invention has the same principles of an ozone washing machine; ozone is not generated; and ozone damage is avoided.

Owner:ZHEJIANG WATERHOR ENVIRONMENTAL PROTECTION TECH CO LTD

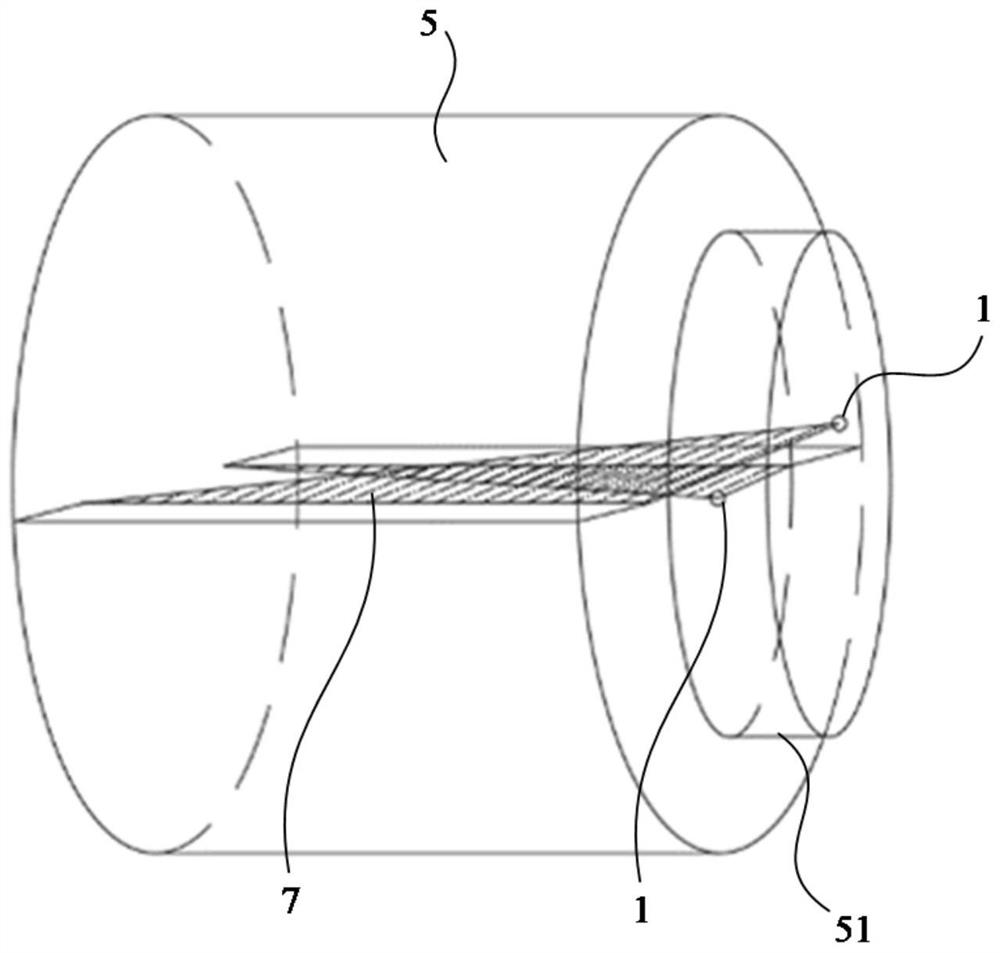

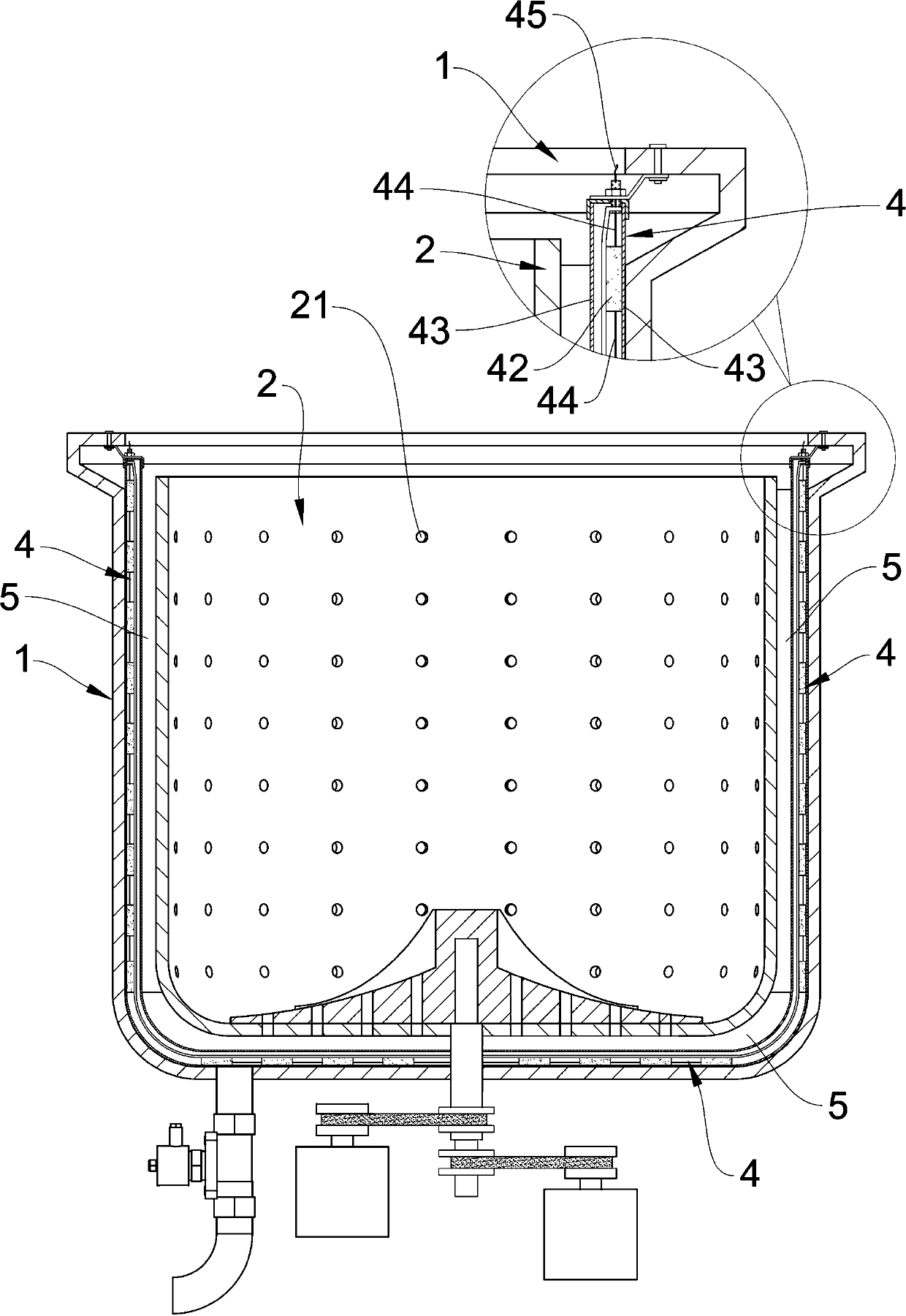

Ultrasonic washing drum device of washing machine

PendingCN109667096AImprove cleanlinessReduce deliveryOther washing machinesTextiles and paperUltrasonic cavitationCavity wall

The invention relates to an ultrasonic washing drum device of a washing machine. The ultrasonic washing drum device comprises an outer barrel body, an inner barrel body and an ultrasonic transducer module, wherein the ultrasonic transducer module is a waterproof sheet-shaped ultrasonic transducer sheet which consists of a sheet-shaped sealing covering shell and a plurality of ultrasonic transducers; the waterproof sheet-shaped ultrasonic transducer sheet is fixedly arranged on the inner cavity wall of the outer barrel body along inner cavity wall of the outer barrel body in a circular manner;or the ultrasonic transducer module is a waterproof strip-shaped ultrasonic transducer belt which is formed by coating a plurality of ultrasonic transducers through the strip-shaped sealing covering shell; and the waterproof strip-shaped ultrasonic transducer belt is fixedly arranged on the inner cavity wall of the outer barrel body along the inner cavity wall of the outer barrel body in a circular manner. According to the ultrasonic washing drum device disclosed by the invention, dirt on the outer barrel body and the inner barrel body cannot hide, and is completely cleared, so that the washing machine is kept clean and sanitary; and in a washing process of the washing machine, three-dimensional packaged type ultrasonic cavitation effect is formed on clothes when the ultrasonic transducermodule works, so that cleaning degree of the clothes is better.

Owner:彭志军

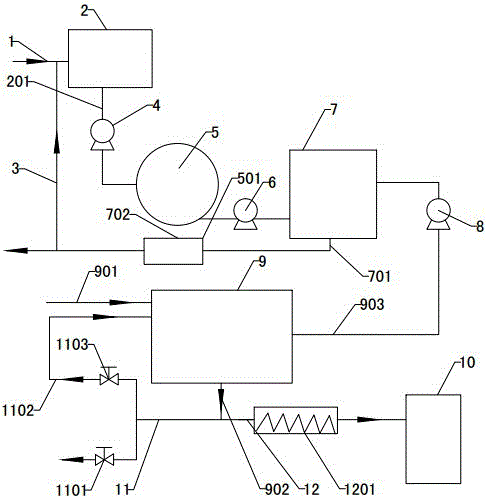

Fiber refining process

ActiveCN106381743AIncrease profitMeet the needs of environmental protectionWashing/displacing pulp-treating liquorsDigestersHigh concentrationFiber

The invention relates to a fiber refining process, which belongs to the technical field of fiber product processing, and is characterized by comprising the following steps of (1) burdening, and conveying an alkaline liquor into a spherical boiler (5); (2) cooking, high-temperature and high-pressure cooling fiber soaked in the alkaline liquor through the spherical boiler (5), and then discharging into a breaker beater (7); (3) stirring through the breaker beater (7) for re-cooling, and preliminarily separating the fiber from the alkaline liquor; (4) removing liquid from the fiber through rotation in the breaker beater (7); (5) separating the removed liquid to obtain an alkaline liquor and impurities; (6) feeding the fiber without the alkaline liquor into a liquid removal machine, and repetitively rinsing and spin-drying for multiple times through the liquid removal machine; (7) after completing rinsing, drying. According to the fiber refining process provided by the invention, the alkaline liquor contained in the fiber is separated, and the useful separated high-concentration alkaline liquor is recycled, so that the requirement on environment protection is met; alkaline containing wastewater has no need to be treated independently, so that the utilization rate of alkaline in a system is improved, and the production cost is further reduced.

Owner:王芹

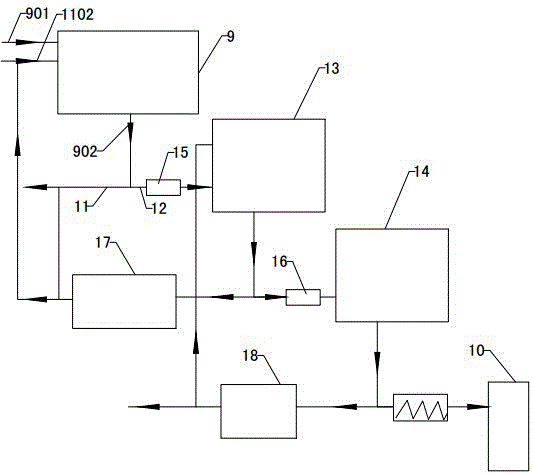

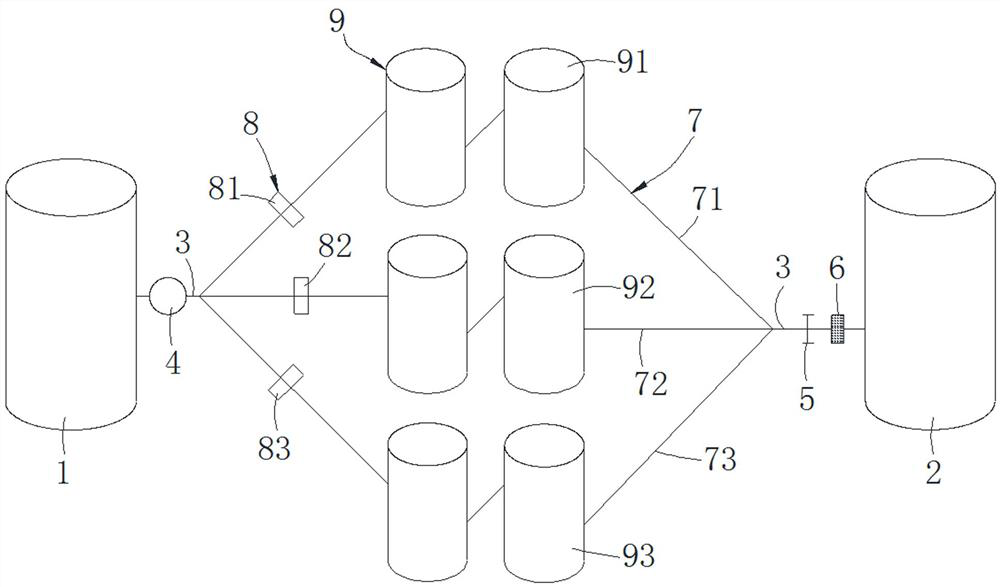

Ion exchange system and method for improving xylitol ion exchange efficiency

PendingCN112191281AImprove separation efficiencyIncrease profitIon exchange regulation/controlIon-exchange column/bed processesIon exchangeEngineering

The invention relates to an ion exchange system for improving xylitol ion exchange efficiency, wherein the system comprises a decolorizing liquid tank, an ion exchange liquid tank and a connecting pipeline, xylitol decolorizing liquid is temporarily stored in the decolorizing liquid tank, xylitol ion exchange liquid is temporarily stored in the ion exchange liquid tank, and a centrifugal pump andan online pH instrument are respectively connected in series on the connecting pipeline. at least three ion exchange pipelines are arranged on the connecting pipeline between the centrifugal pump andthe online pH instrument in parallel, and a pneumatic butterfly valve and an ion exchange column for combination are respectively arranged on each ion exchange pipeline in series. The invention also discloses a method for improving xylitol ion exchange efficiency by using the ion exchange system. The utilization rate of the ion exchange columns is improved, and the replacement frequency of the ionexchange columns is reduced.

Owner:ZHEJIANG HUAKANG PHARMA

Drainage device of washing machine and washing machine provided with drainage device

InactiveCN102888740ALess quantityReduce the number of rinsesOther washing machinesTextiles and paperWash waterEngineering

The invention relates to a drainage device of a washing machine. The drainage device of the washing machine comprises a water exhaust device connected with the water bucket of the washing machine, a water outlet pipeline extending out of the box body of the washing machine, and a dewatering pump connected between the water exhaust device and the water outlet pipeline, wherein the water exhaust device comprises at least two water outlets connected with the water bucket, wherein the first water outlet and the water bucket are connected opposite to the lowest point in the direction of gravity, and the second water outlet is higher than the first water outlet. The washing machine comprises the drainage device. Because the washing machine is additionally provided with the second water outlet, foams, cloth fragments, sebum and the like on water surface can flow out of the second water outlet when the water surface of wash water drops to, or is adjacent to the second water outlet, and the quantity of the foams, the cloth fragments, sebum and the like attached to clothes or the water bucket is reduced, thus, the rinsing time can be reduced, the rinsing efficiency is improved, and meanwhile water consumption is lowered.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

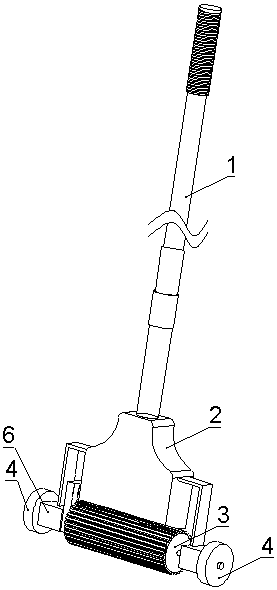

Wheel type mop

InactiveCN108742383AReduce the number of rinsesExtended service lifeCarpet cleanersFloor cleanersDrive wheelFixed frame

The invention discloses a wheel type mop. The wheel type mop comprises a handle, a fixing frame at one end of the handle, a cleaning drum and walking wheels, wherein the cleaning drum and the walkingwheels are rotationally connected to the fixing frame respectively. A water tank is arranged in an inner cavity of the fixing frame, a water inlet is formed in the top of the water tank, a water outlet is formed in the bottom, water absorption cotton is arranged between the bottom face of the water tank and the cleaning drum, and the water absorption cotton is attached to the cleaning drum. The cleaning drum is connected with the two walking wheels through differential drive mechanisms, each differential drive mechanism is provided with belt wheels including the driving belt wheel, the drivenbelt wheel, the driving transmission belt wheel and the driven transmission belt wheel, wherein the driving belt wheel is connected with the driving transmission belt wheel through a conveying belt, the driven belt wheel is connected with the driven transmission belt wheel, and the transmission ratio between the driving belt wheel and the driven belt wheel is larger than 1 or smaller than 1. By means of the mop, the utilization rate of the cylindrical cleaning drum can be improved, and the mop has the advantage of being good in cleaning effect.

Owner:田艺儿

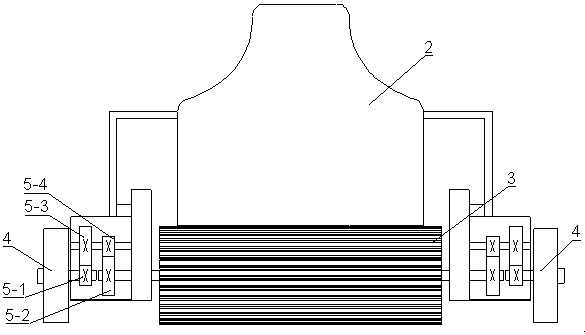

Down feather washing machine

InactiveCN107385520AEasy dischargeReduce the number of rinsesWool fibre washing/scouringPulp and paper industrySewage discharge

The invention discloses a wool scouring machine, which comprises a wool scouring machine body, a stirring device placed in the wool scouring machine body, a water outlet arranged at the bottom of the wool scouring machine and a water inlet at the top of the wool scouring machine, and the wool scouring machine body A mobile filter plate is provided, and slide rails are provided on both sides of the interior, the mobile filter plate can move up and down on the slide rails, and the stirring device is fixed on the mobile filter plate through a bracket. In the present invention, the stirring device is placed on the filter plate. After cleaning, the filter plate drives the stirring device and the down to move up, and the down is separated from the water surface for draining, which can increase sewage discharge and reduce the number of rinsing times.

Owner:JIANGYIN BAISHUN TECH

Method for preparing biomass polyoxyethylene ether carboxyl asymmetric gemini surfactant

ActiveCN103304800AIncrease profitReduce stimulationOrganic compound preparationTransportation and packagingSodium chloroacetateCarboxylic salt

The invention discloses a method for preparing a biomass polyoxyethylene ether carboxyl asymmetric gemini surfactant. The method comprises the steps of: firstly, putting cocinic acid into a stainless steel reaction kettle, dropwise adding diethanol amine to carry out amidation, so as to prepare cocinic acid diethanloamides; putting the cocinic acid diethanloamides into an ethoxylation reaction kettle to react with ethylene oxide, so as to generate coconut oil amide polyoxyethylene ether; putting the coconut oil amide polyoxyethylene ether into a carboxy methylation reaction kettle, so that hydroxyl at one end and sodium chloroacetate are subjected to carboxyl methylation, so as to generate the coconut oil amide polyoxyethylene ether single sodium carboxylate; finally putting the coconut oil amide polyoxyethylene ether single sodium carboxylate into an esterification reaction kettle, so that the residual hydroxyl and the oleic acid are subjected to esterification reaction, so as to generate the novel biomass polyoxyethylene ether carboxyl asymmetric gemini surfactant SX. The emulsifier is small in thrill on eyes and skin of a human body, has excellent emulsibility and cleaning force, and good biodegradability, and is a biomass surfactant with good cost performance.

Owner:JIANGSU SIXIN SURFACTANT TECH

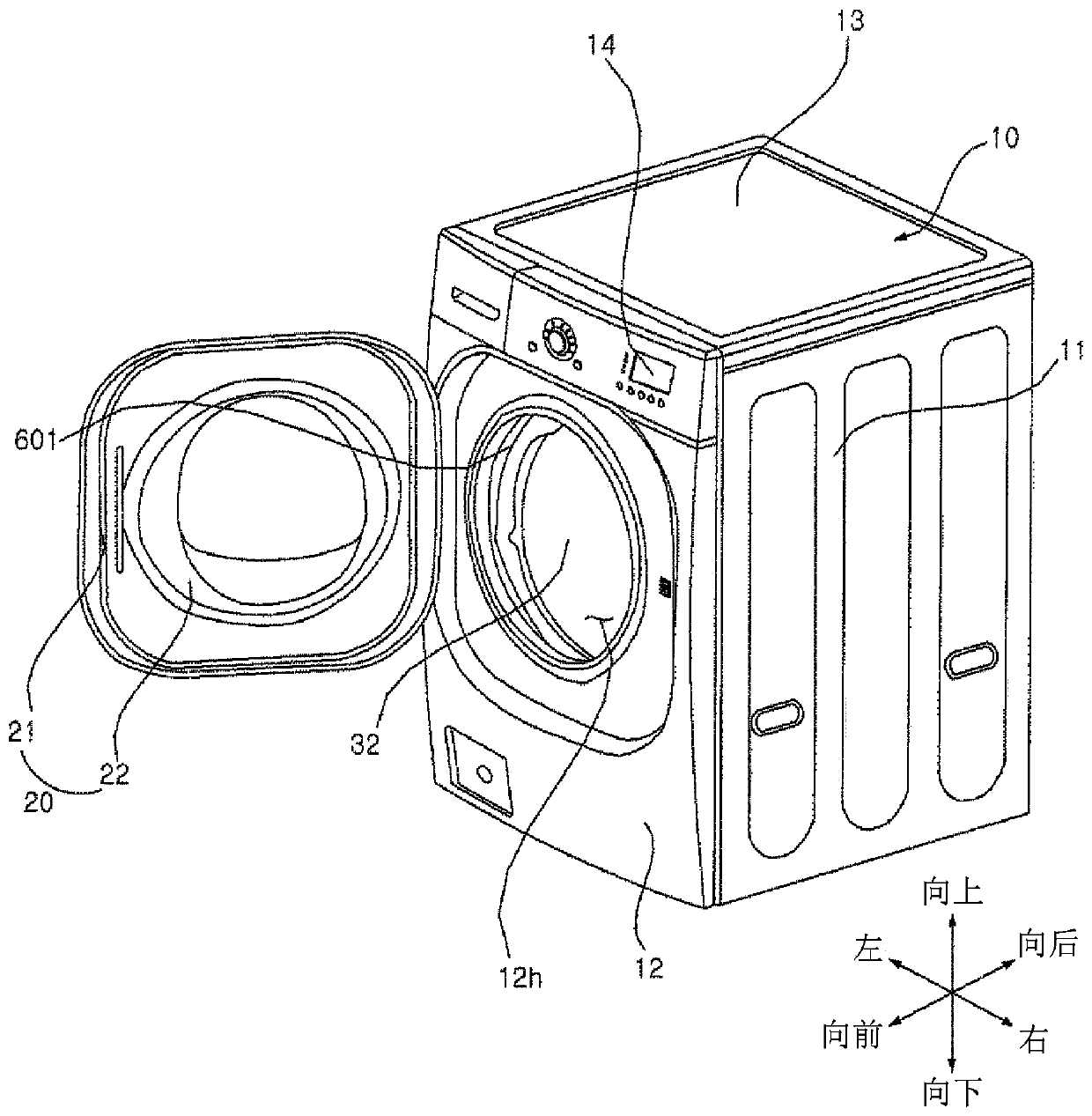

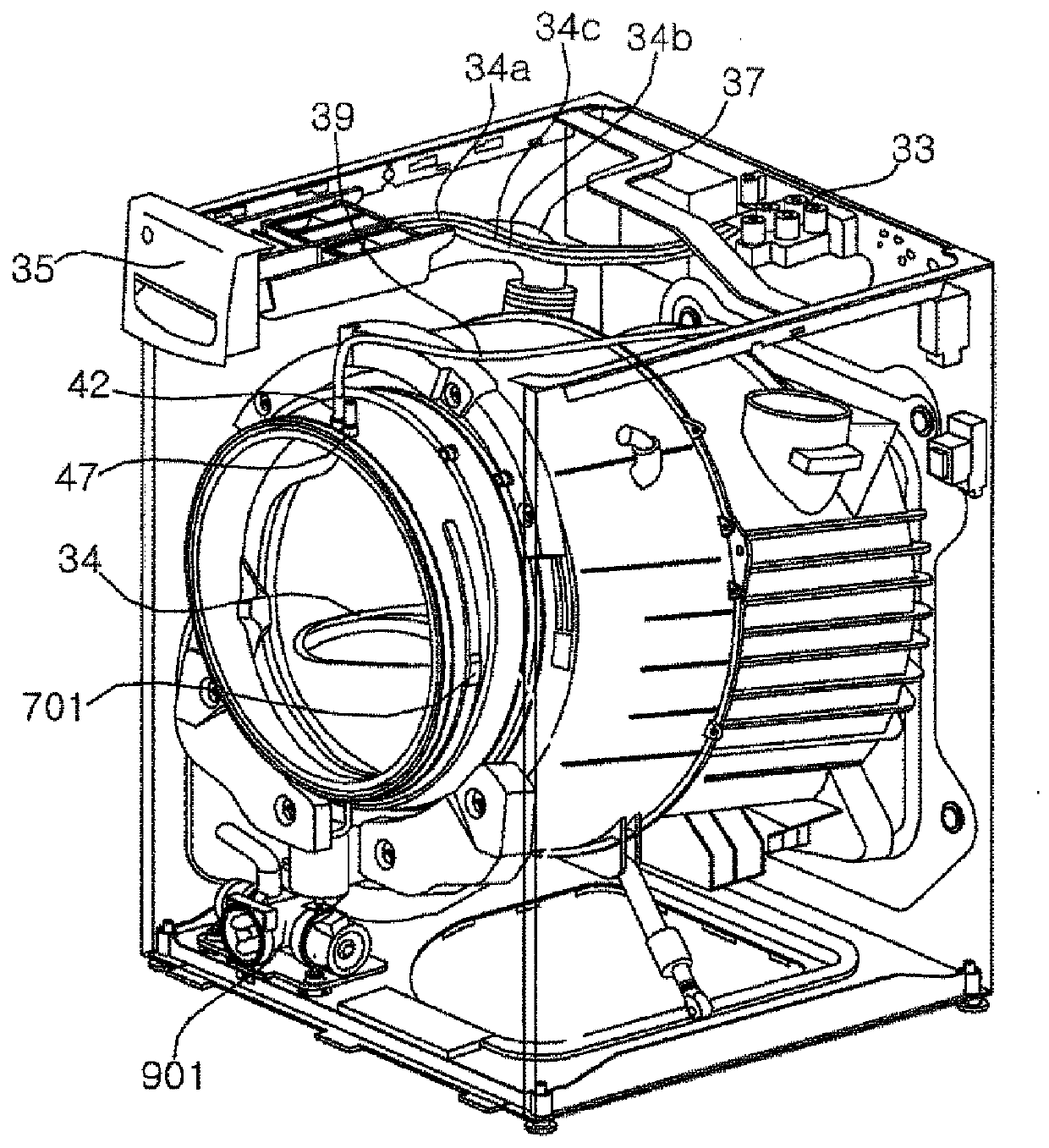

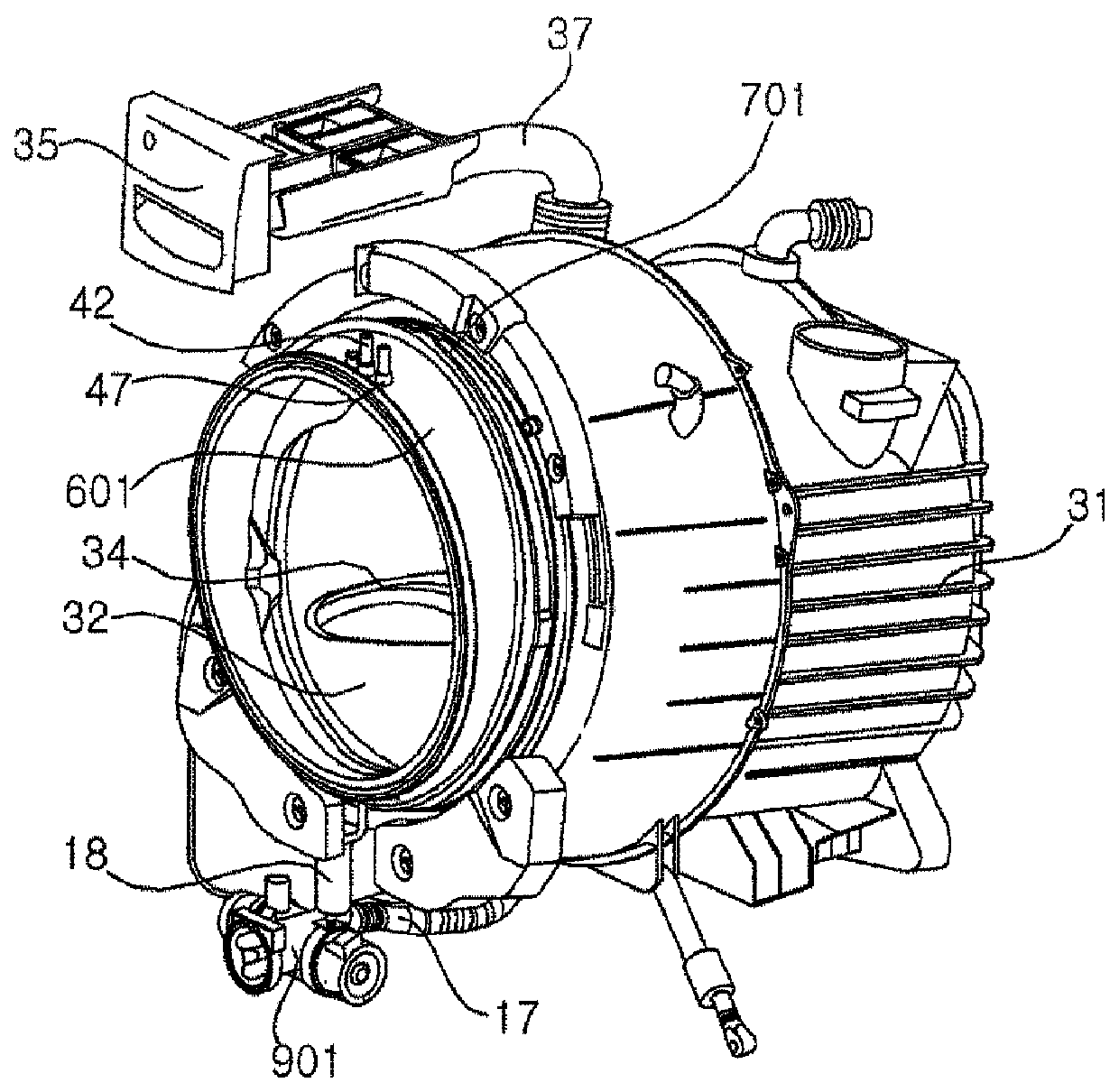

Washing machine

PendingCN110352274ASmooth releaseEasy to dryOther washing machinesControl devices for washing apparatusLaundry washing machineWasher

The present invention relates to a washing machine comprising: a casing having a insertion hole for inserting laundry thereinto on the front surface thereof; a tub disposed in the casing and containing laundry water and having an inlet communicating with the insertion hole; a drum, rotatably disposed within the tub, for accommodating laundry; a pump for pumping water discharged from the tub; a gasket for making the insertion hole communicate with the inlet of the tub and having a plurality of nozzles for spraying water into the drum; and a nozzle water supply pipe, fixed to the gasket and having an inlet through which water pumped by the pump flows, for dividing and guiding water that has flowed through the inlet into a first sub flow and a second sub flow, the nozzle water supply pipe including a plurality of first nozzle water supply ports, formed on a first flow passage to which the first sub flow is guided, for supplying the first sub flow individually to any two or more nozzles among the plurality of nozzles, and a plurality of second nozzle water supply ports, formed on a second flow passage to which the second sub flow is guided, for supplying the second sub flow individually to other two or more nozzles among the plurality of nozzles.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com