Ion exchange system and method for improving xylitol ion exchange efficiency

A xylitol and dissociation technology, applied in the direction of ion exchange column/bed method, ion exchange adjustment/control, separation/purification of hydroxyl compounds, etc., can solve unfavorable production, high cost, low utilization rate of ion exchange column, etc. To solve the problem, to achieve the effect of full utilization of resin, improved utilization rate, and reduction of the number of regeneration and rinsing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

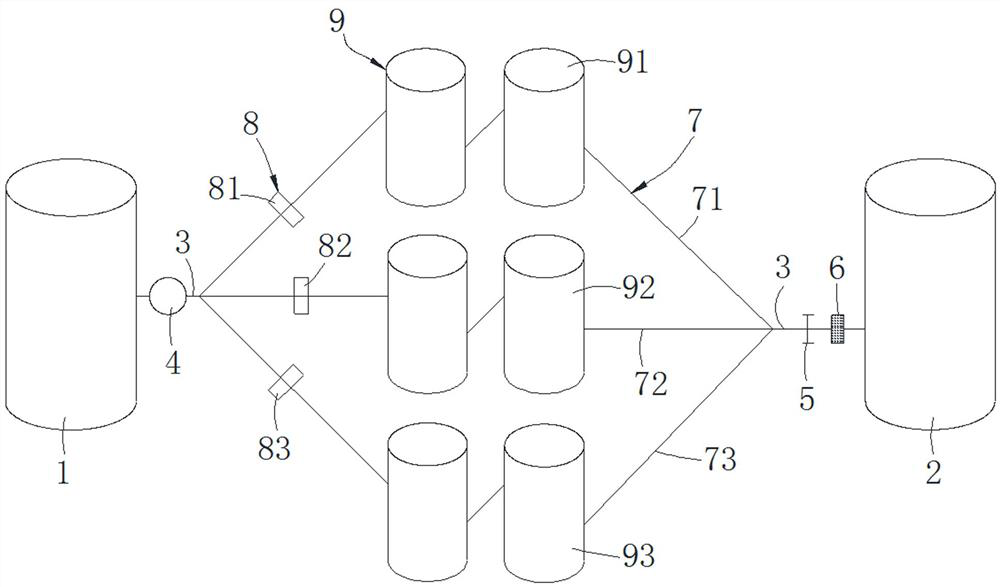

[0024] The first method embodiment of improving xylitol detachment efficiency of the present invention uses the detachment system for improving xylitol detachment efficiency as described above, comprising the following steps:

[0025] Step 1, open the centrifugal pump 4 and the first pneumatic butterfly valve 81 in the first ion exchange pipeline 71, close the pneumatic butterfly valve 8 in the other ion exchange pipeline 7, and temporarily store the xylose in the decolorization tank 1 The alcohol decolorizing liquid enters the ion exchange liquid tank 2 for temporary storage after passing through the first ion exchange column assembly 91 to complete the separation process. An on-line pH meter 5 and an on-line conductivity meter 6 arranged on the connecting pipeline 3 monitor the pH value and conductivity of the ion-exchange liquid flowing through.

[0026] Step 2. When it is detected that the pH value of the ion-exchange liquid passing through the first ion-exchange column co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com