Ultrasonic washing drum device of washing machine

An ultrasonic and washing tub technology, applied in the field of washing machines, can solve the problems of poor laundry cleaning effect and dirt removal effect, weak ultrasonic cavitation, and unscientific design, so as to protect the natural ecological environment, achieve better cleaning, and reduce The effect of the number of rinses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

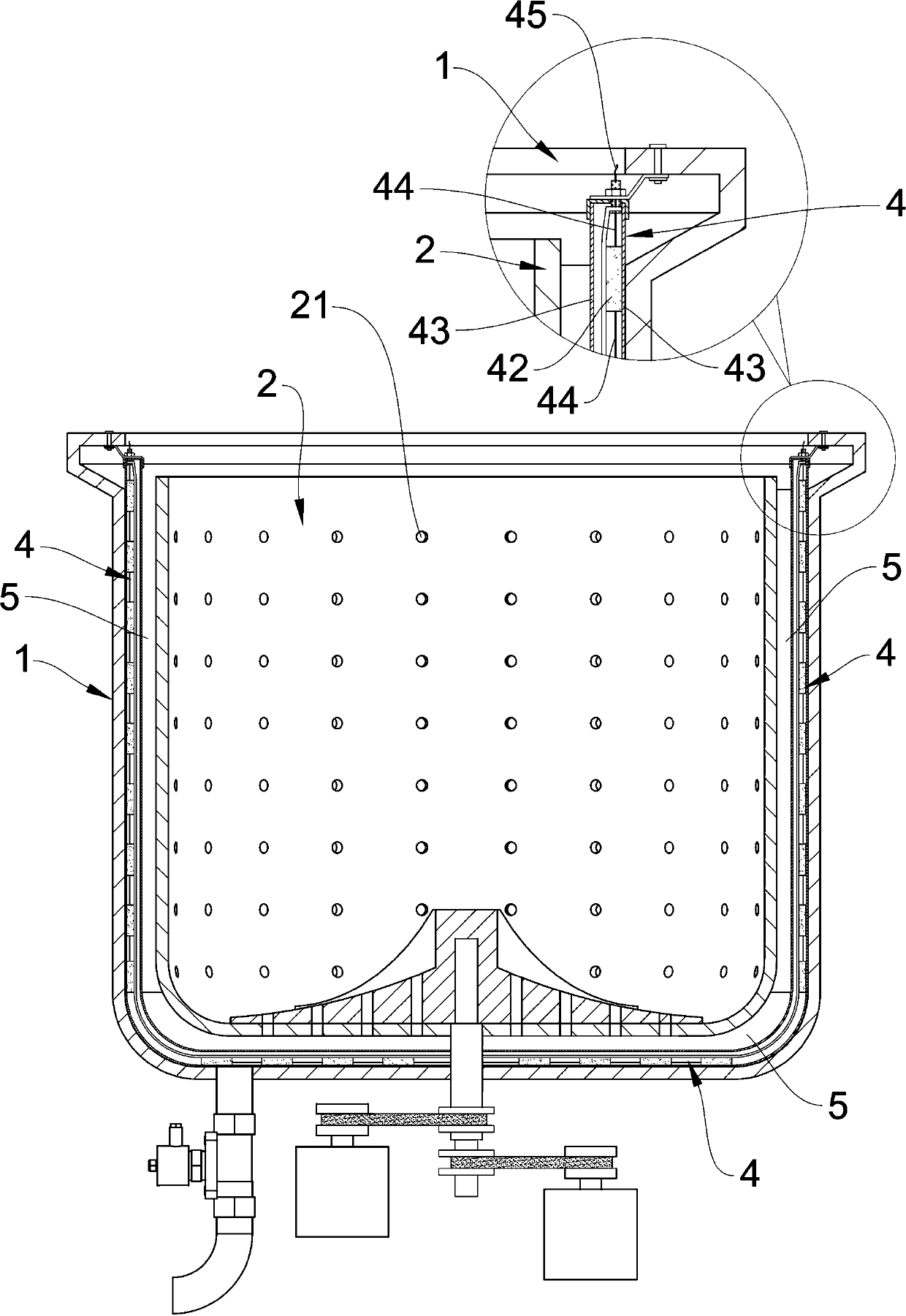

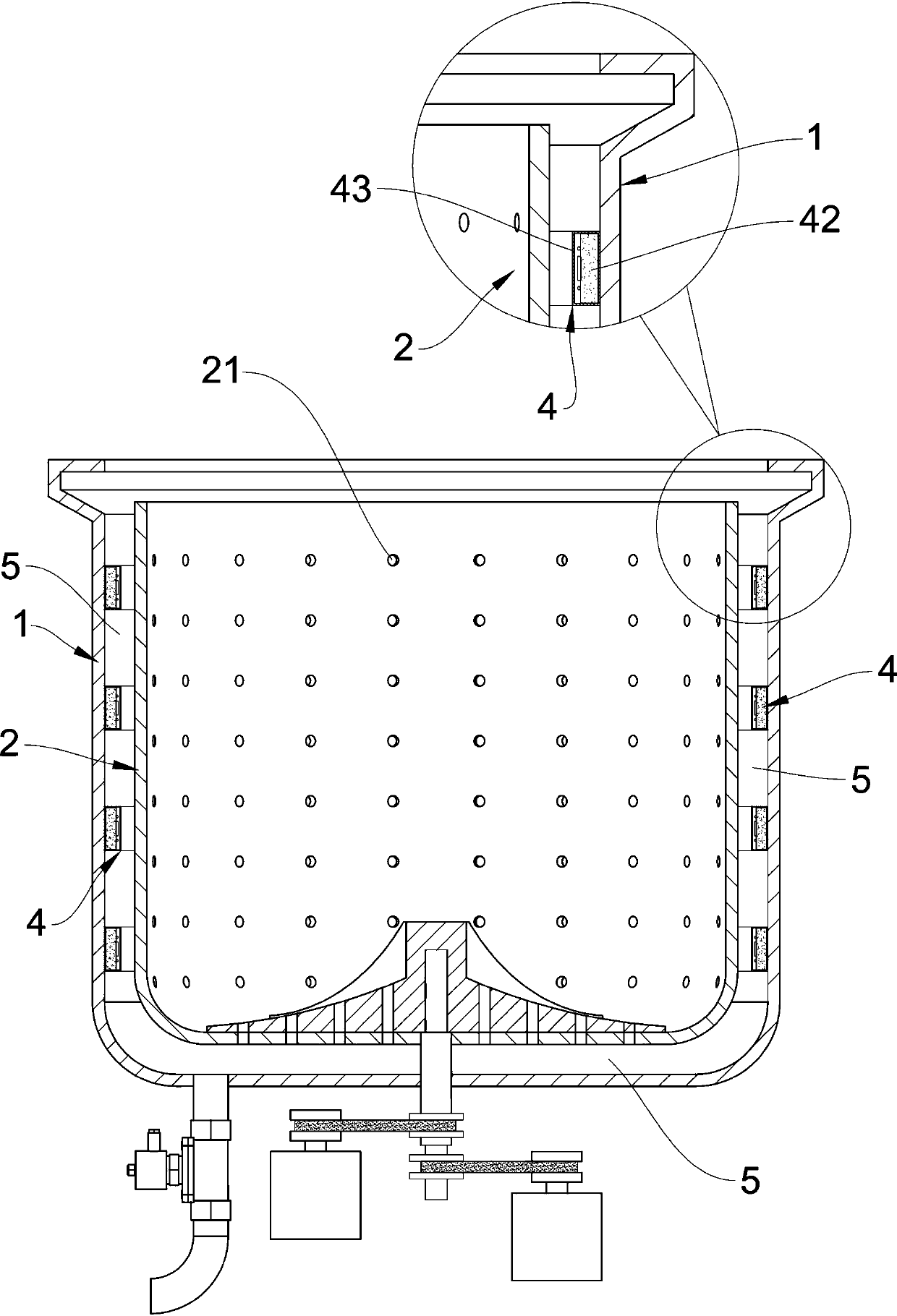

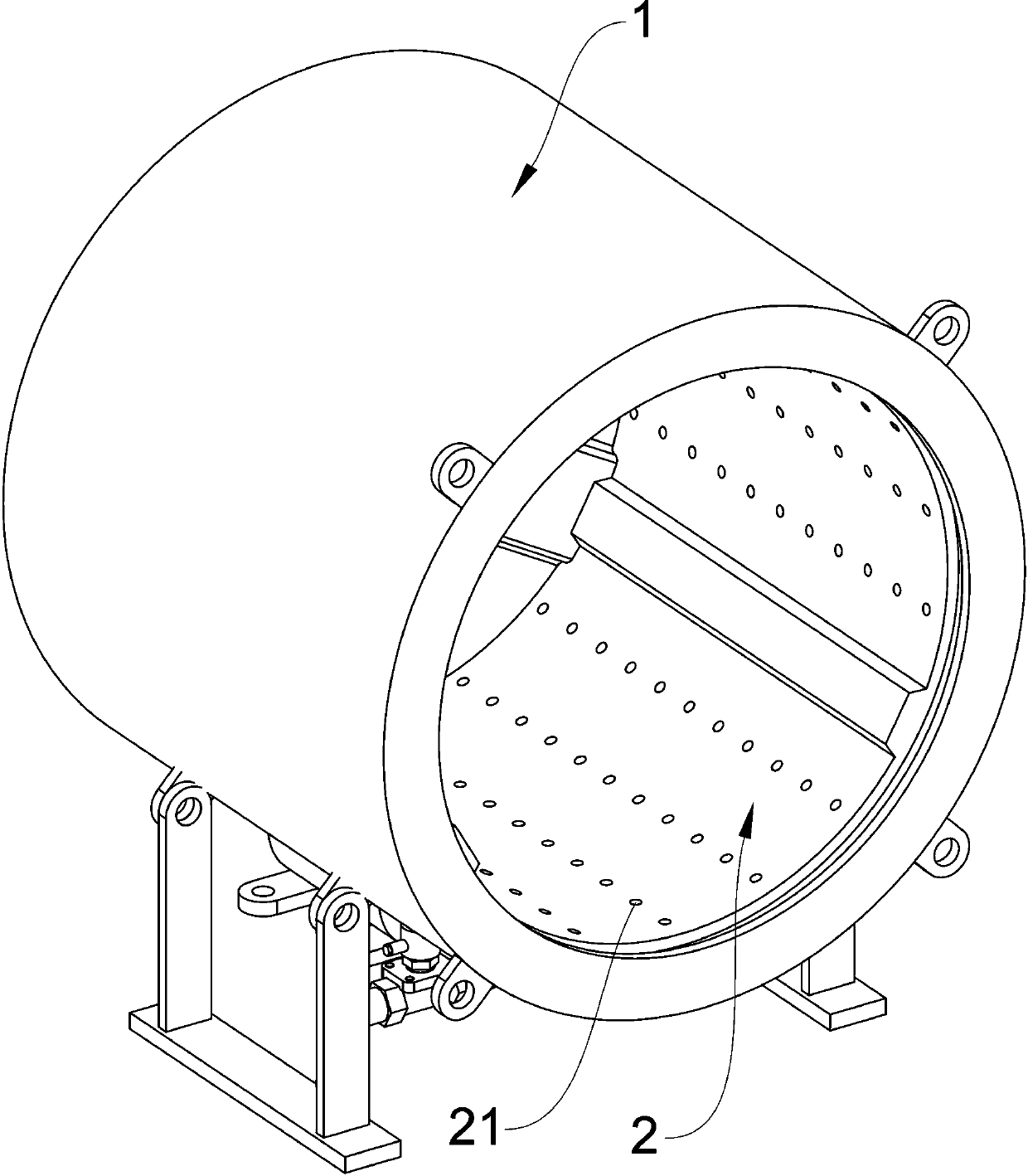

[0018] Such as Figure 1 to Figure 5 As shown, the ultrasonic washing drum device of a washing machine according to the present invention includes an outer cylinder 1, an inner cylinder 2, an ultrasonic transducer module 4, an ultrasonic generator or an ultrasonic generating drive circuit board, etc., when forming a complete For washing machine products, it also includes an outer casing, a control circuit board, a driving motor, an electric heating wire, a water inlet mechanism, a drainage mechanism, etc. These are all necessary components of a general washing machine product, and will not be described in detail here.

[0019] Such as figure 1 or figure 2 ,or Figure 4 and Figure 5 As shown, the inner cylinder 2 is installed in the outer cylinder 1, and there is also a gap between the outer wall of the inner cylinder 2 and the inner cavity wall of the outer cylinder 1 for the inner cylinder 2 to work and rotate. Slot 5. A number of mesh holes 21 are evenly arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com