A screening and drying device for metal powder

A drying device and metal powder technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of reduced screening efficiency, enlarged aperture, and failure to consider the influence of powder on the screen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

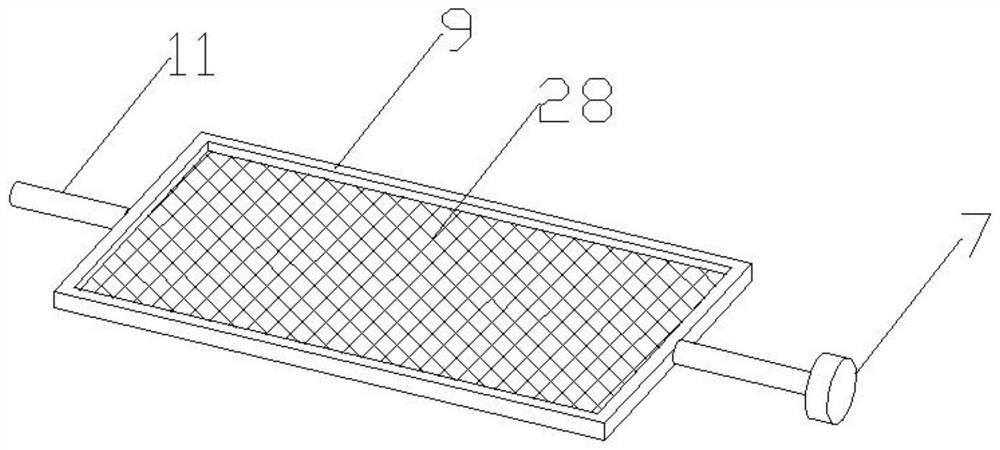

[0017] Such as Figure 1-4 As shown, the present invention is a screening and drying device for metal powder, comprising a hot air blower 1, a powder screening box 14, a material distribution box 15 and a dispersion box 21, and the upper end of the dispersion box 21 is provided with a motor two 25 and a feeding port 27, the dispersion box 21 is provided with a conical mixing drum 32, the main shaft of the motor 25 is provided with a stirring shaft 26, and the stirring shaft 26 is provided with a plurality of stirring frames 24 and is located in the conical mixing drum 32 , the wall of the conical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com