Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

115results about How to "Guaranteed screening efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

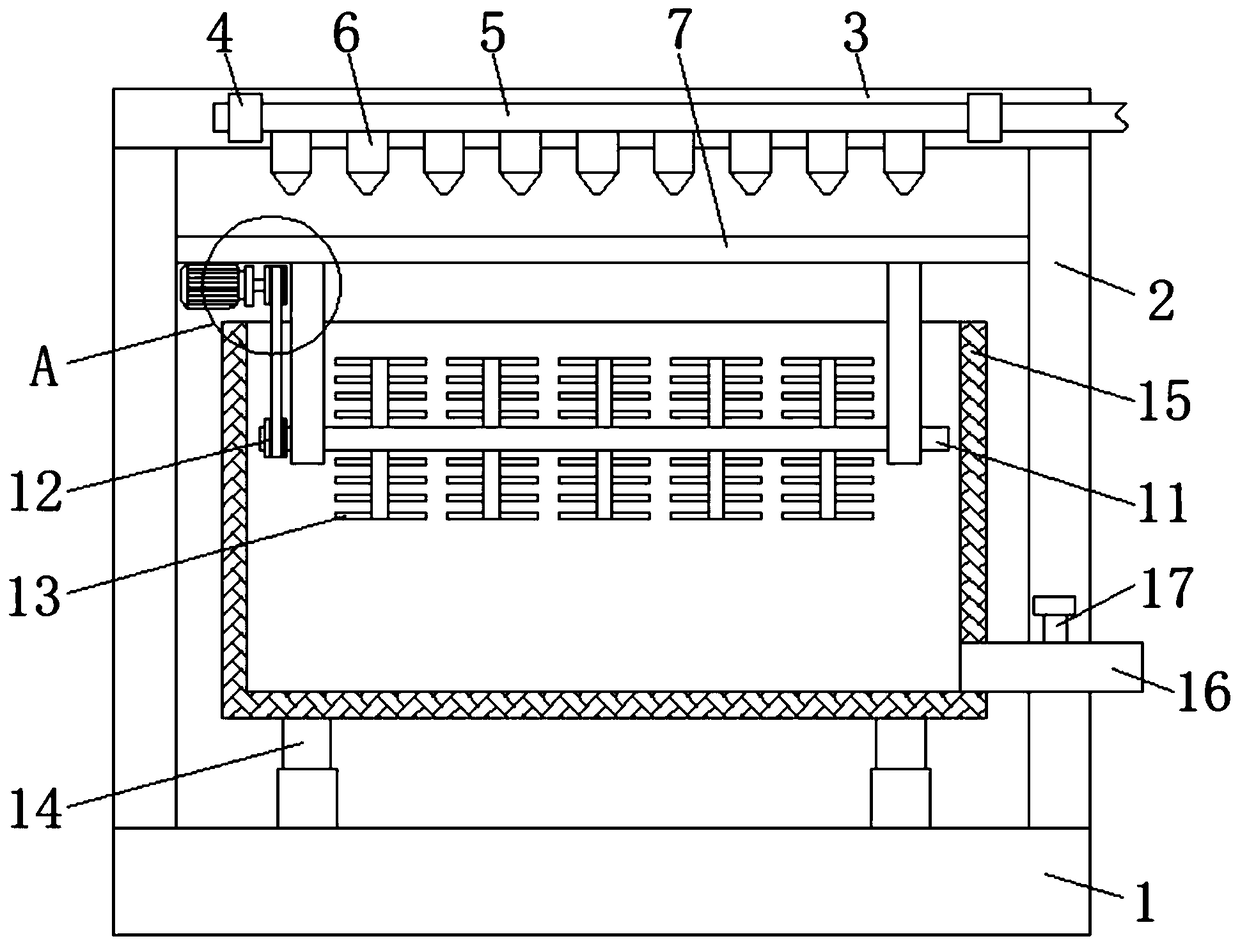

Extrusion-type straw smashing device

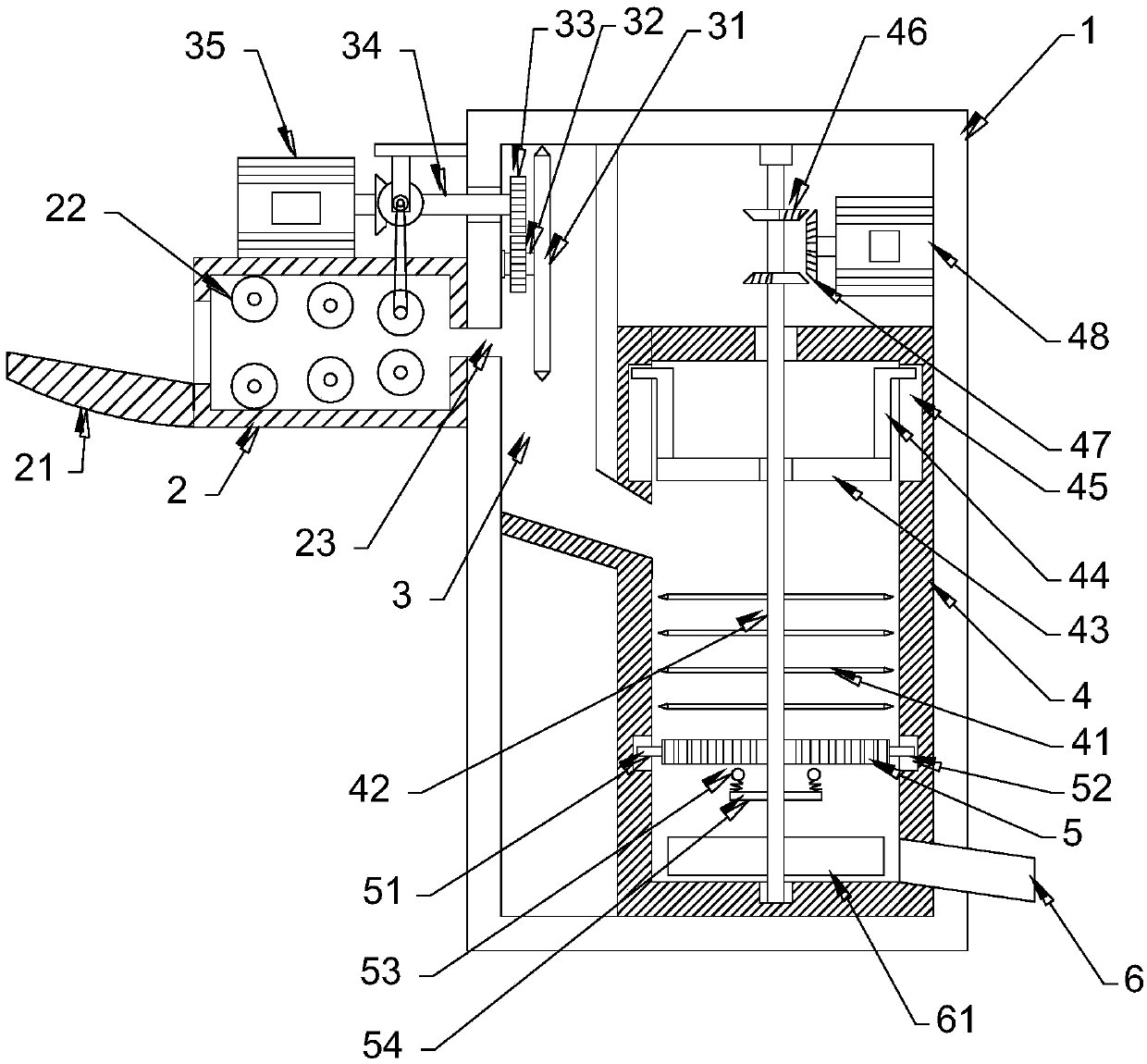

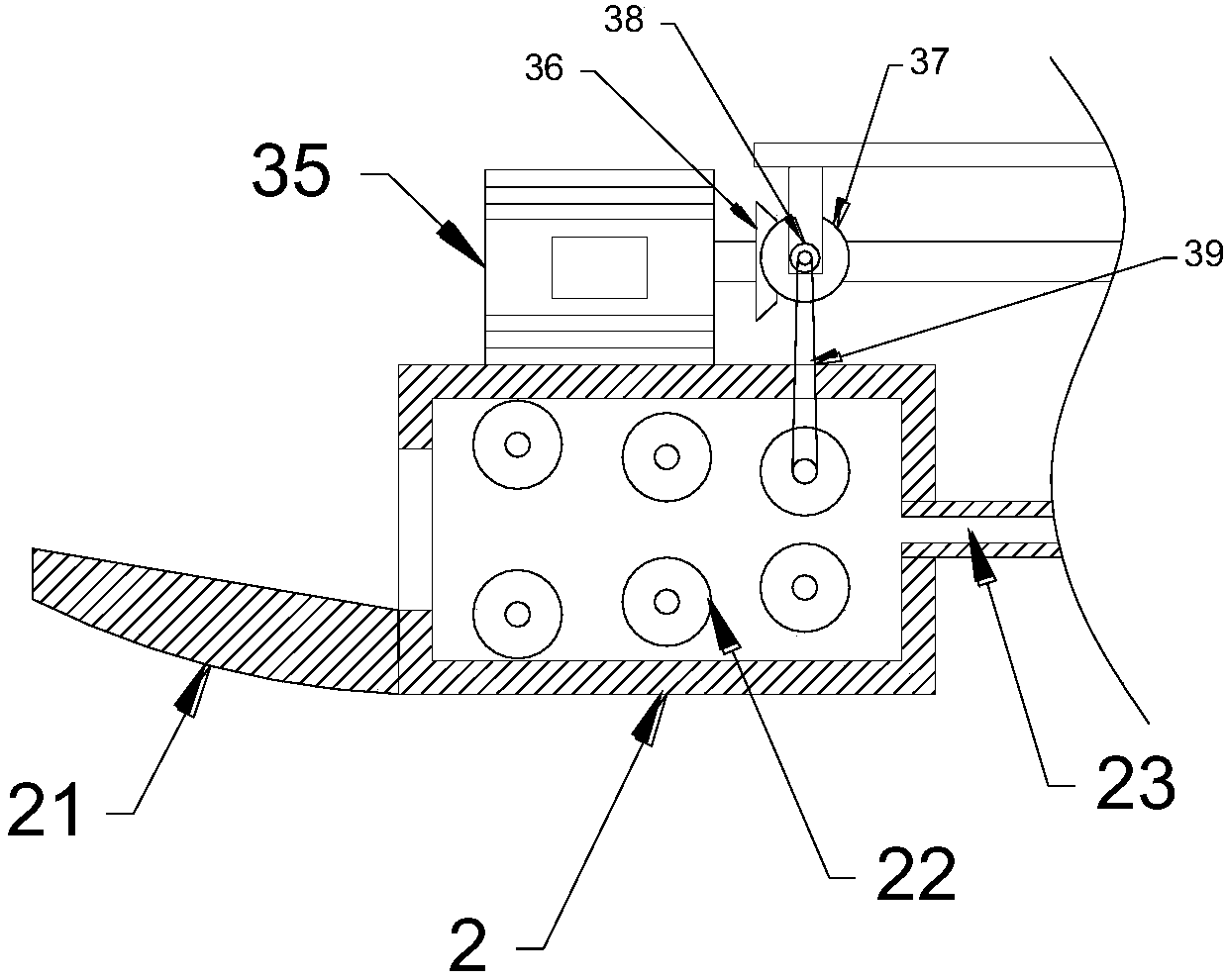

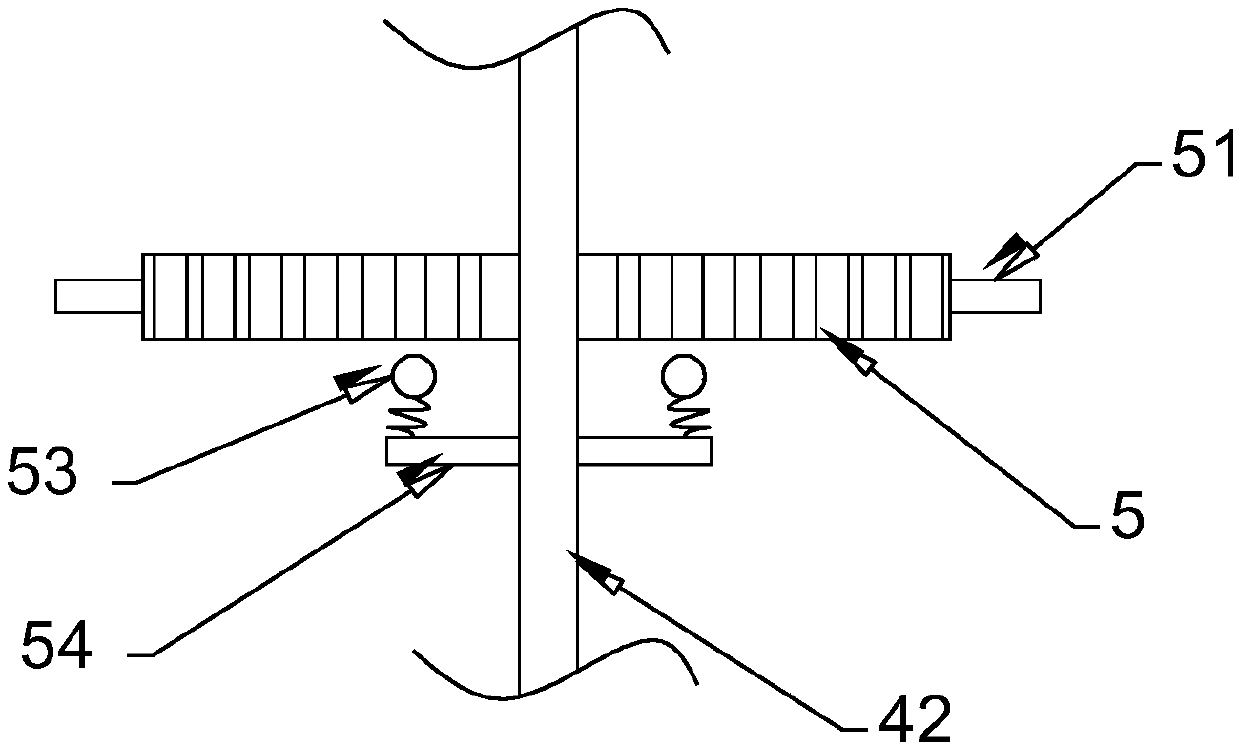

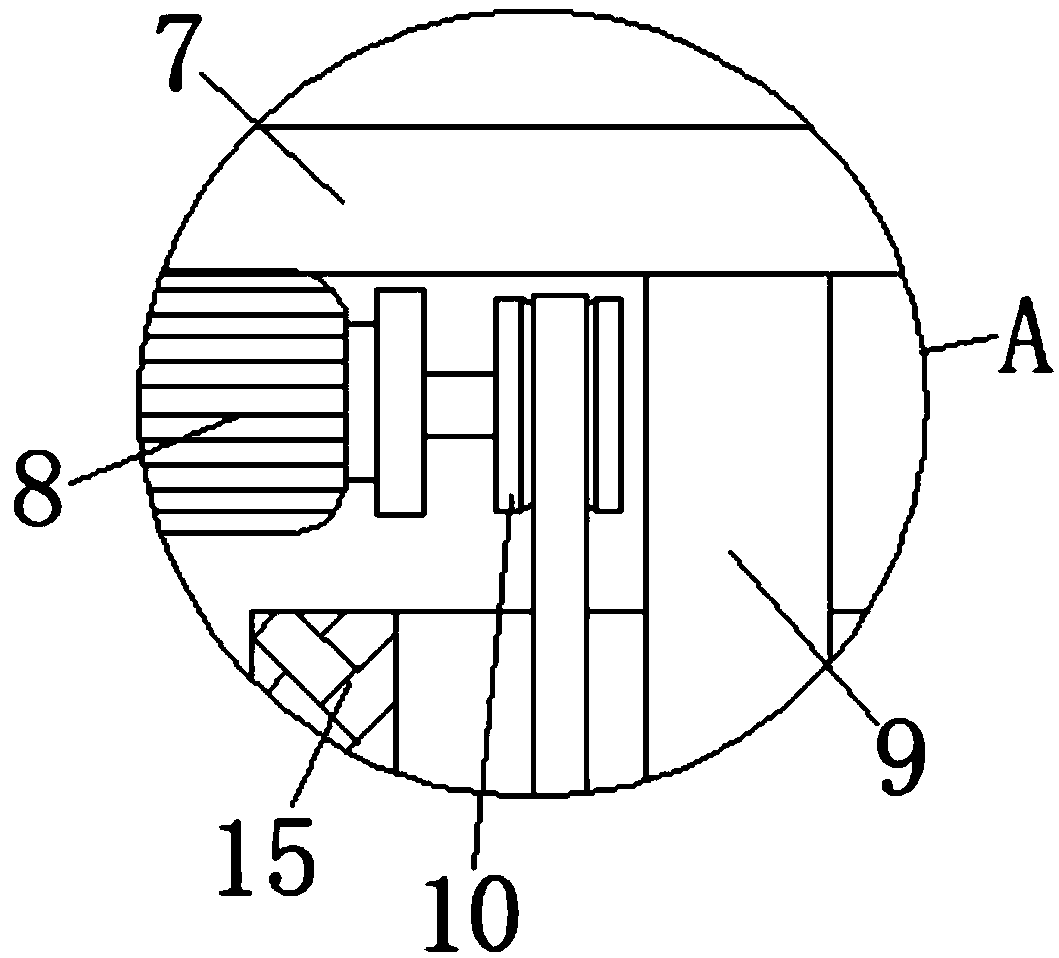

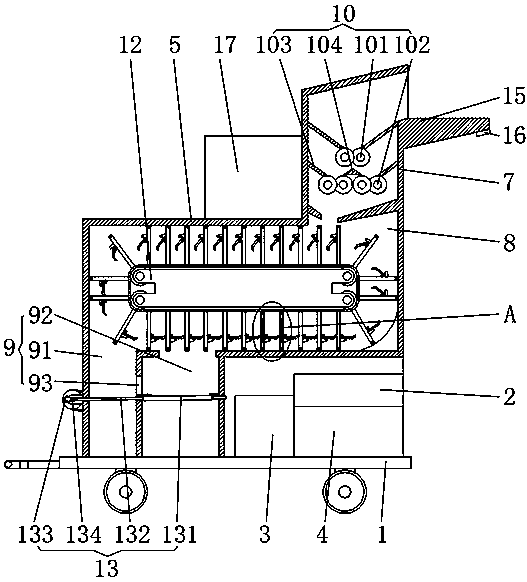

The invention discloses an extrusion-type straw smashing device. The device includes a shell, the left side of the shell is communicated with a feeding pipe, the communicated portion between the feeding pipe and the shell is provided with a communicating port, and the portion, at the right side of the communicating port, of the interior of the shell is provided with a cutting box; the right side of the cutting box is communicated with a smashing box. Through multiple groups of extrusion rollers which are arranged gradually close to one another, straw is extruded and conveyed by the extrusion rollers to provide convenience for follow-up cutting and smashing; by arranging cutting wheels and smashing cutters, straw strips are cut in a block shape by the cutting wheels to provide convenience for follow-up smashing, and the smashing efficiency is improved; by arranging an extruding plate to extrude the straw during smashing, the straw can be fully in contact with the smashing cutters, smashing can be achieved more thoroughly, and the smashing effect is improved; by arranging impact beads for beating a screening plate, the screening efficiency is ensured.

Owner:储君

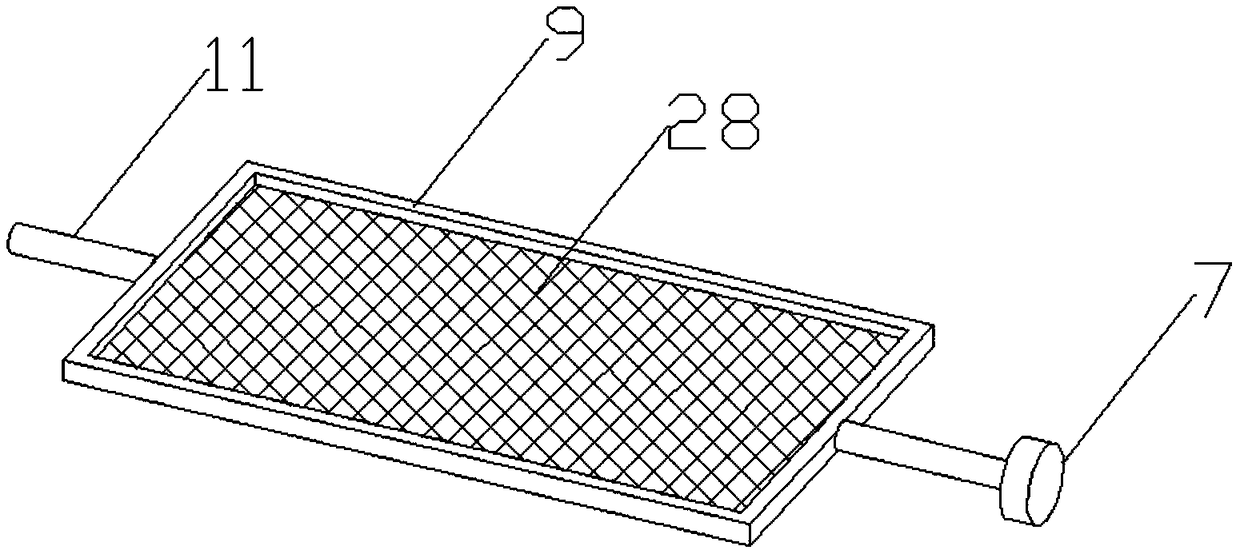

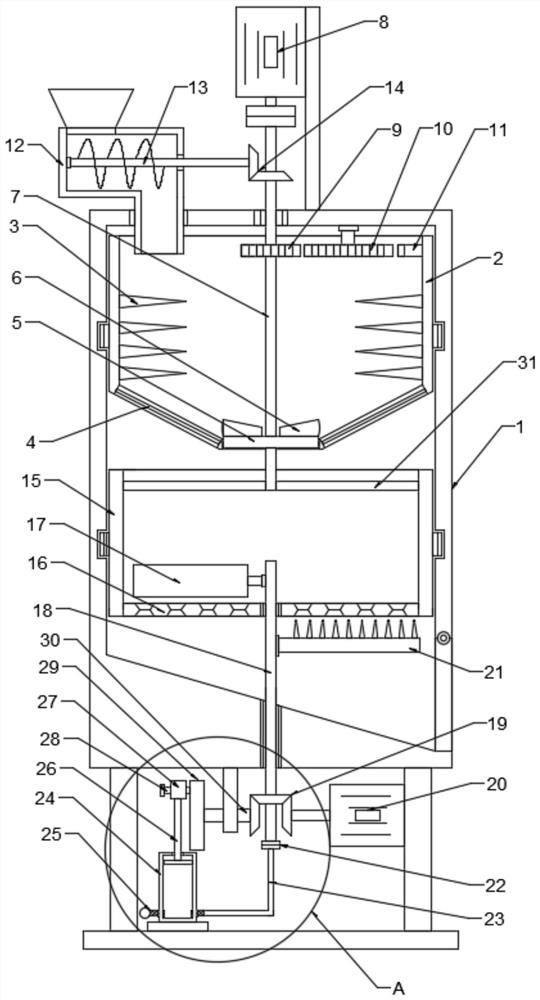

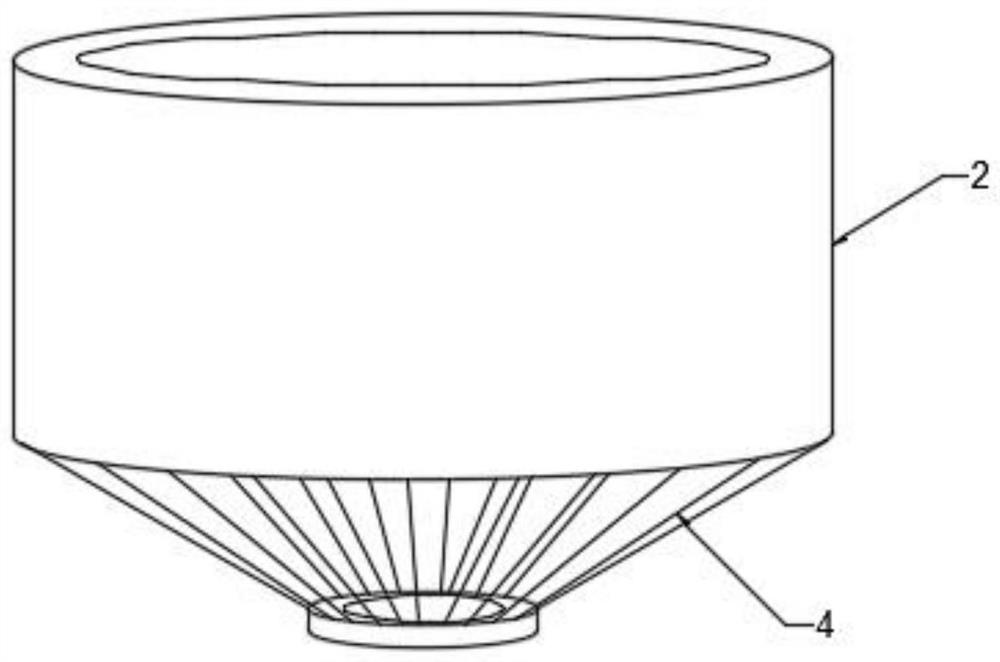

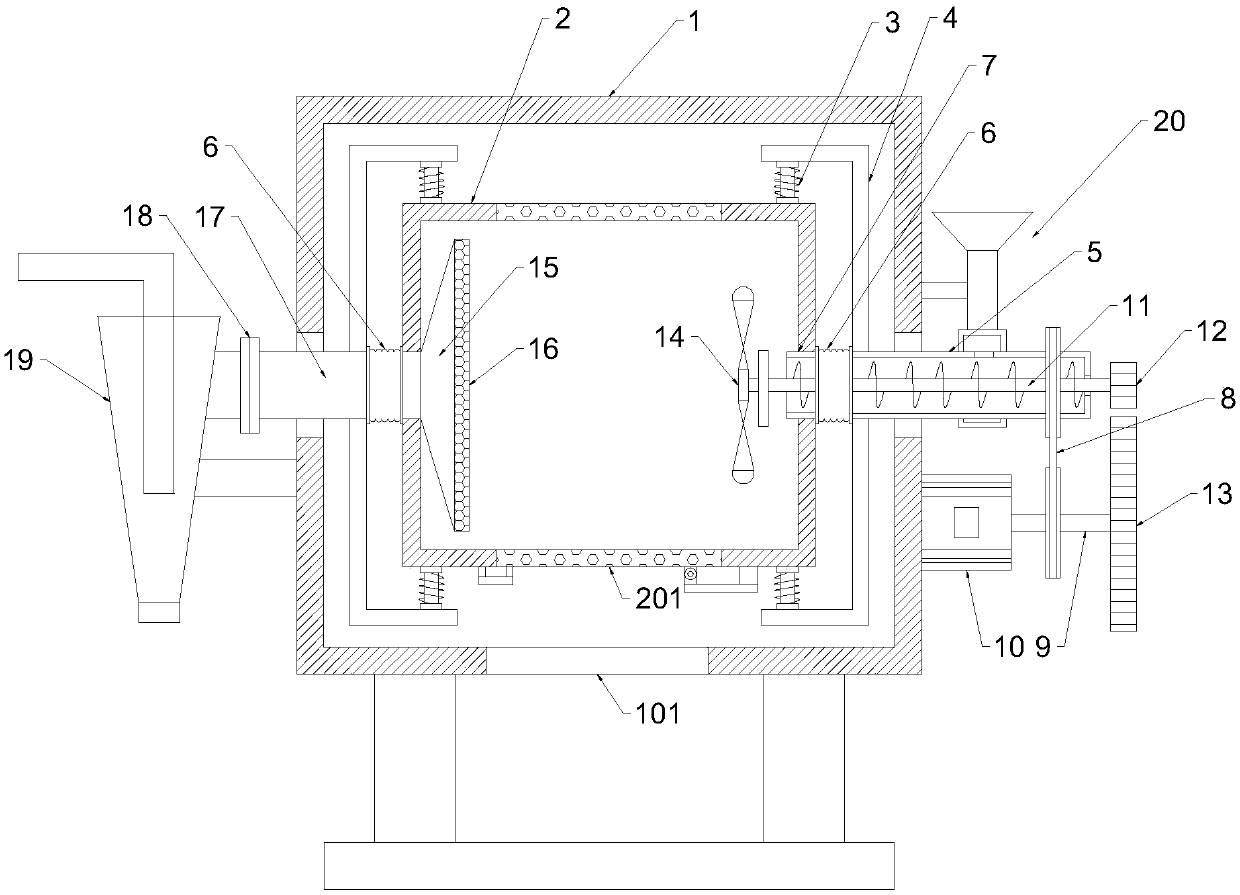

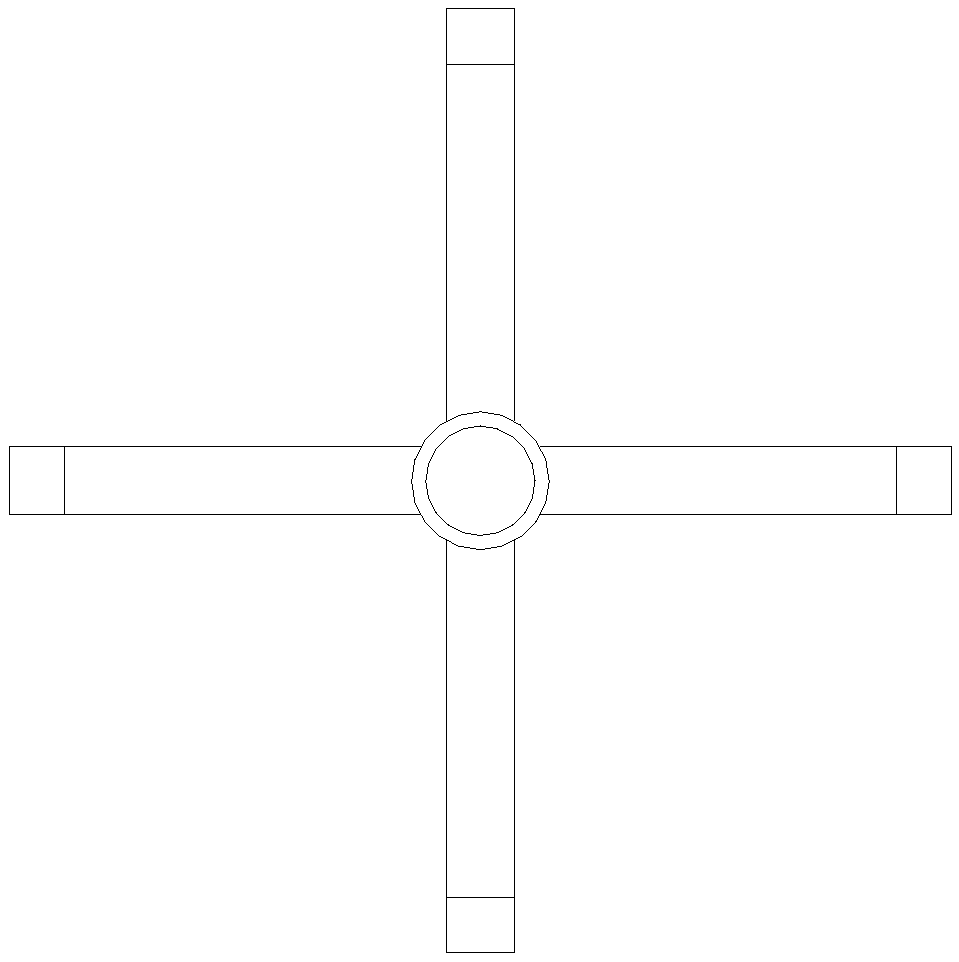

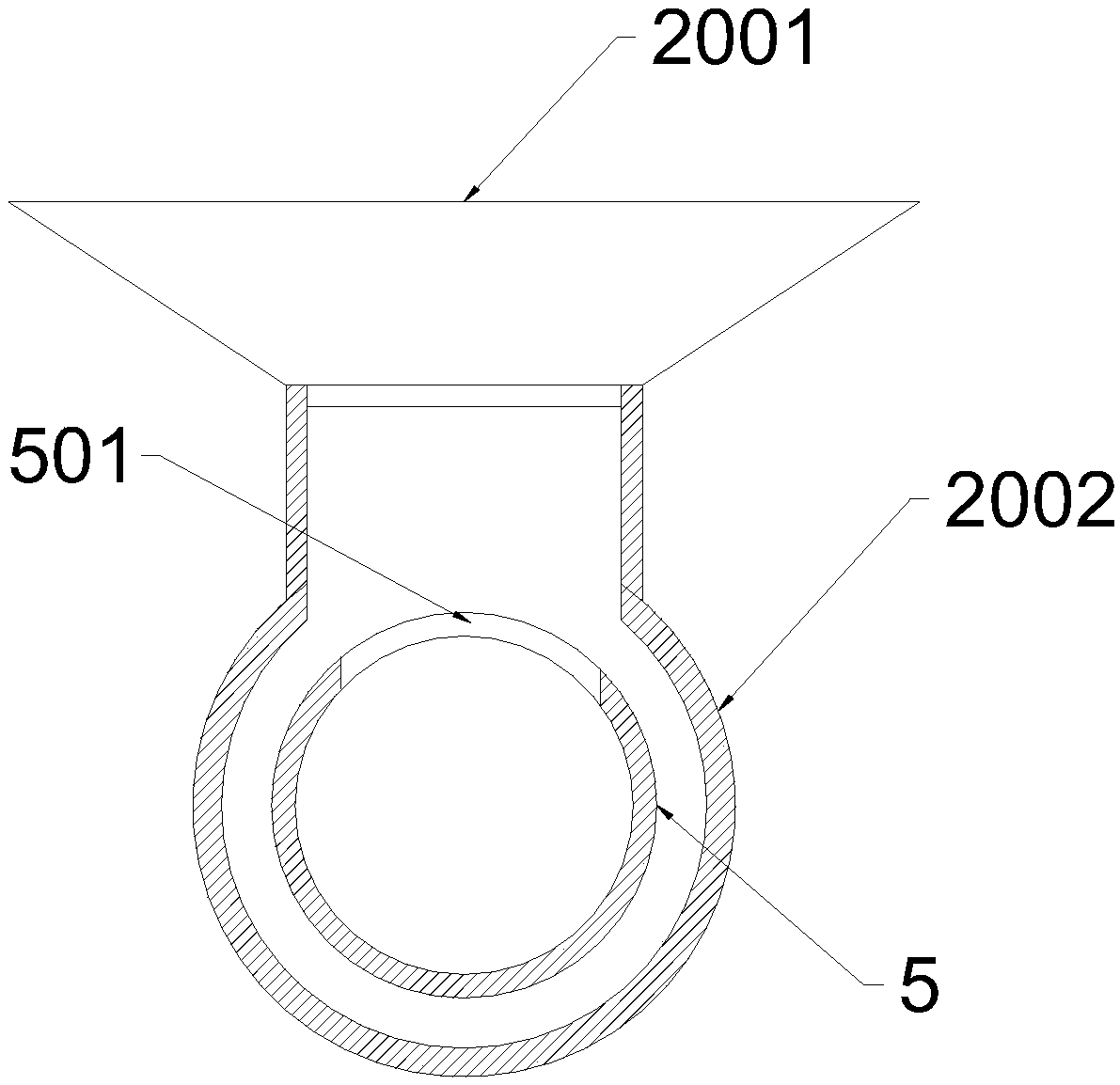

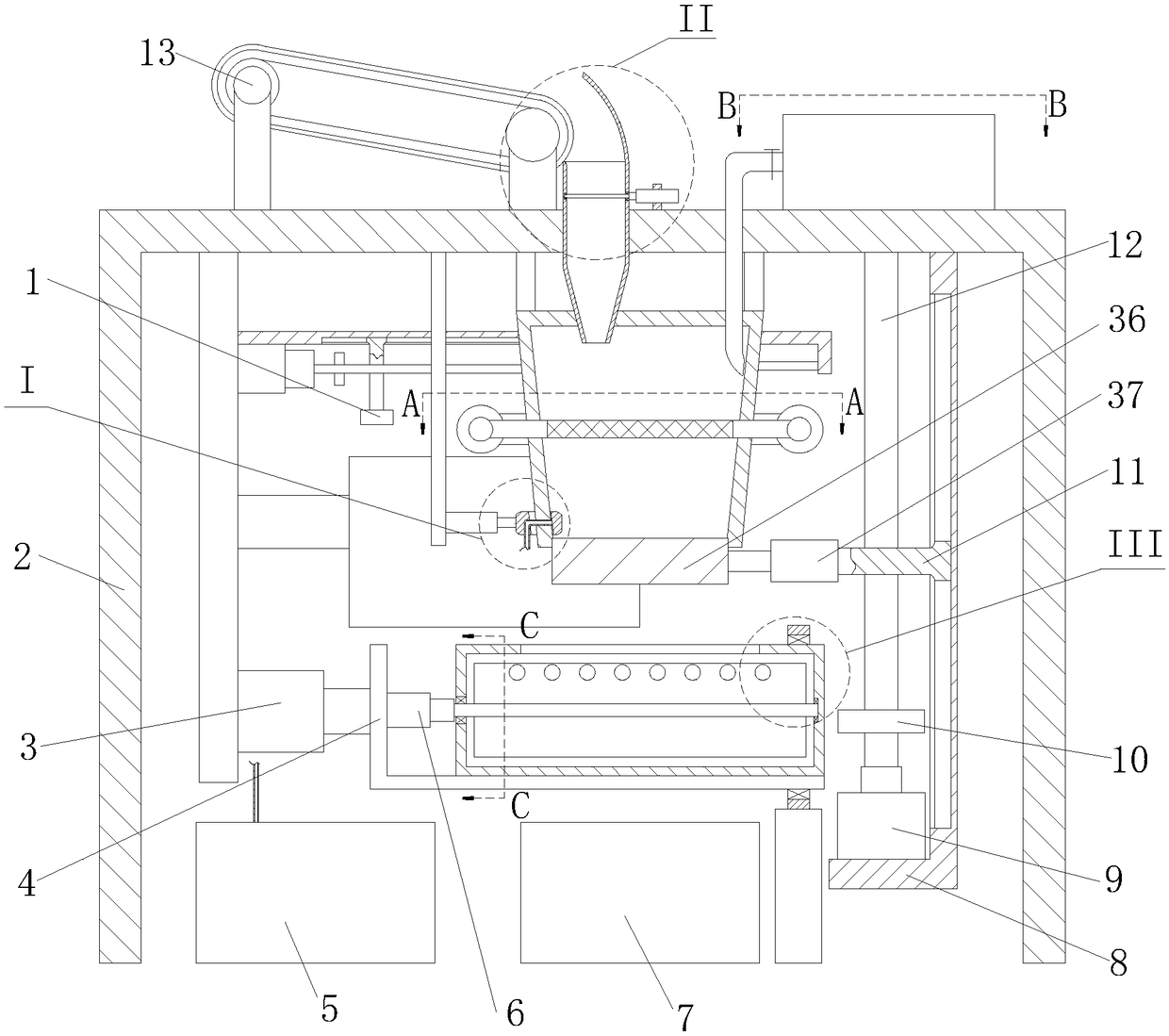

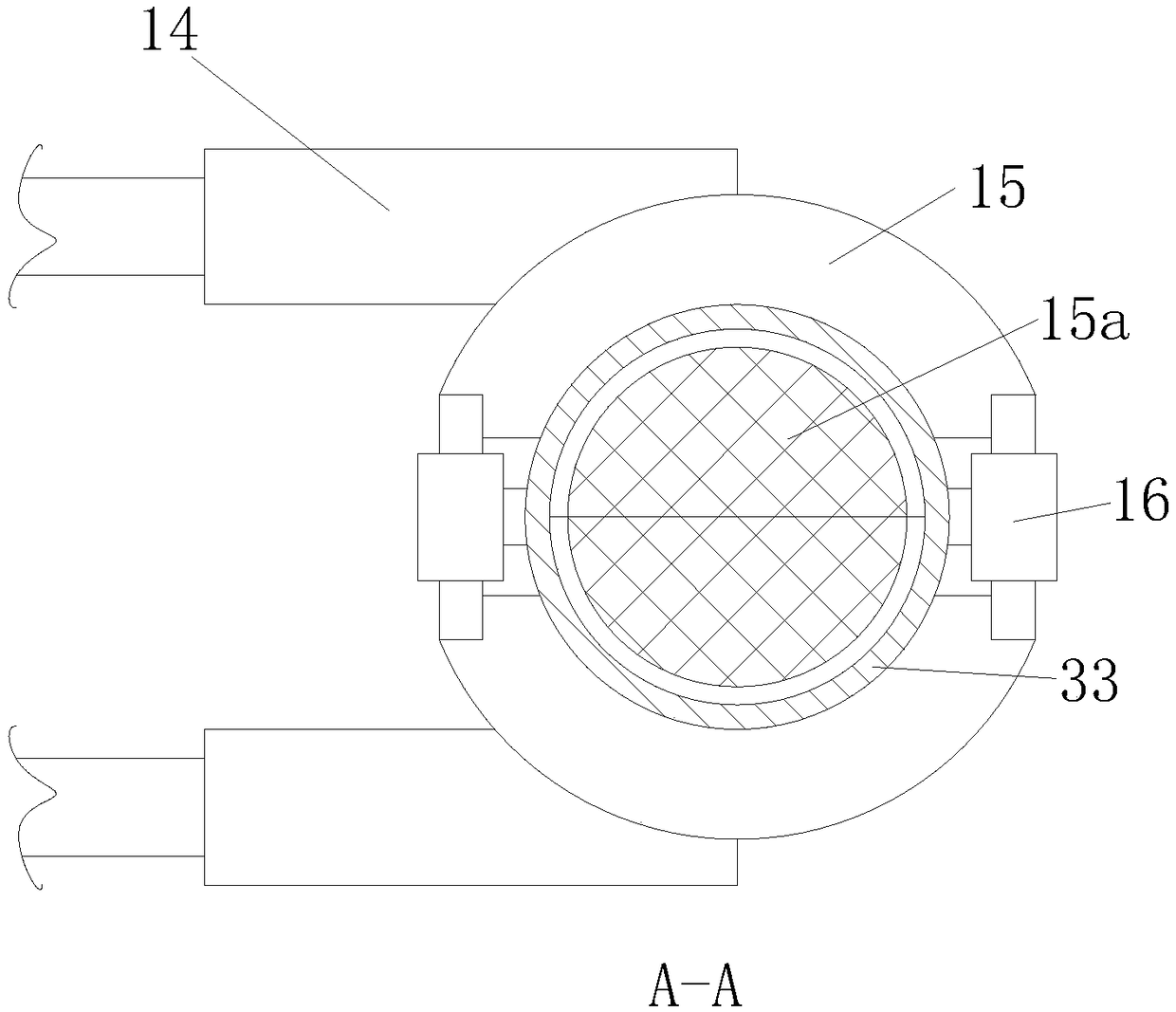

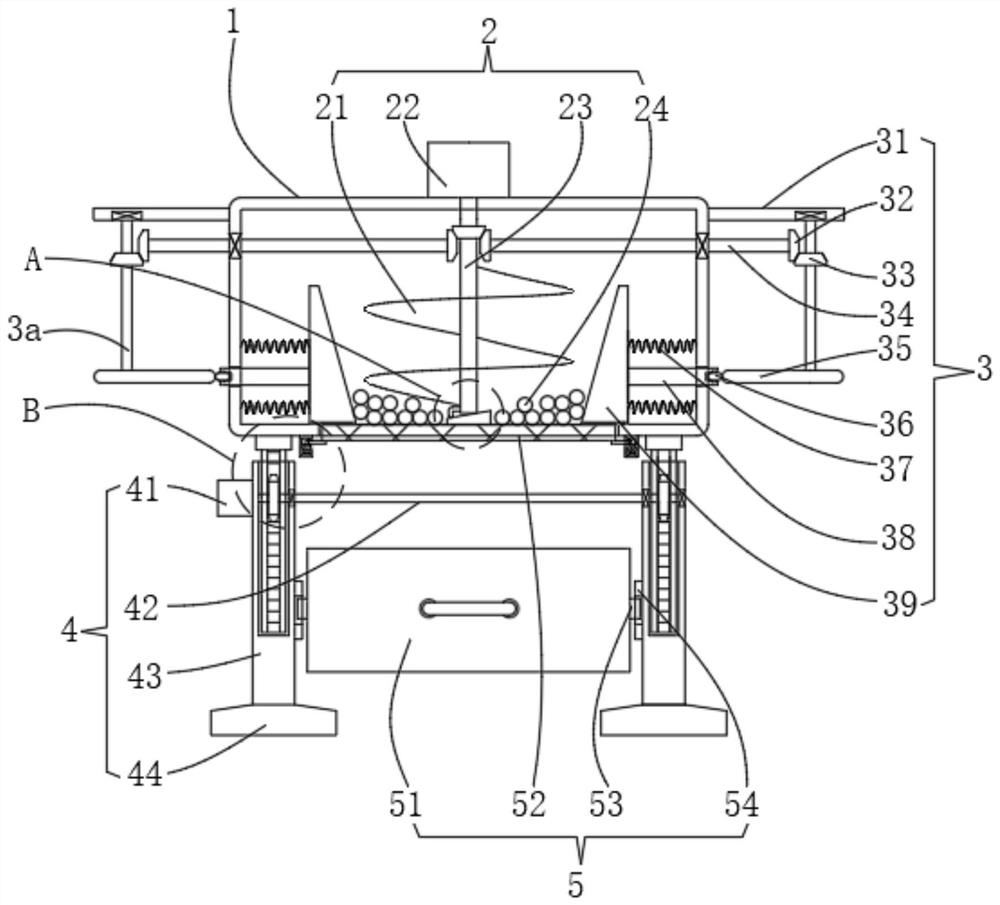

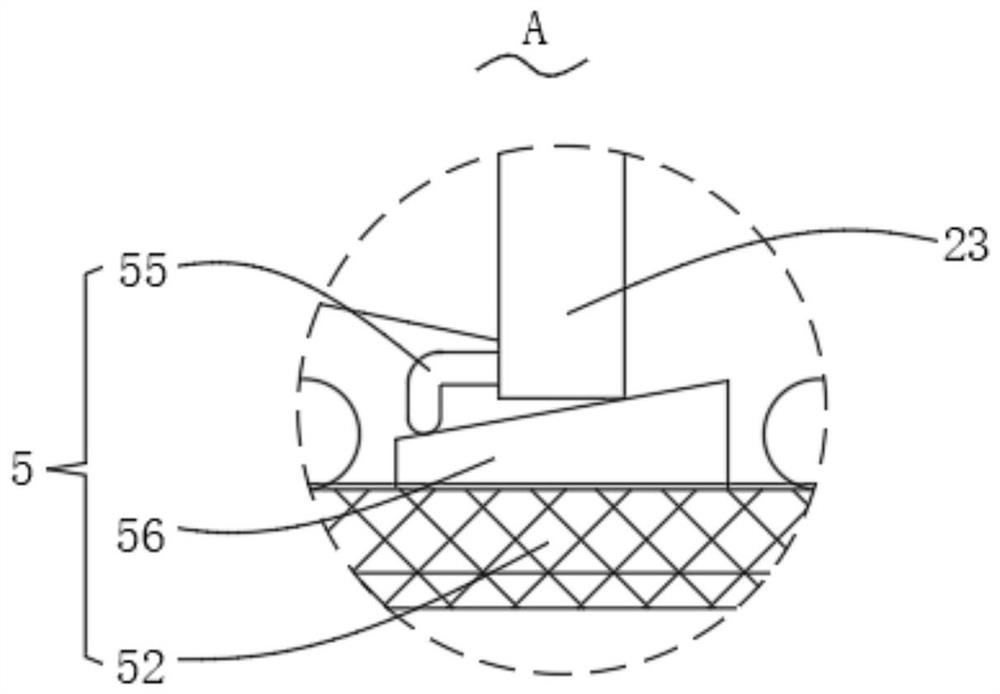

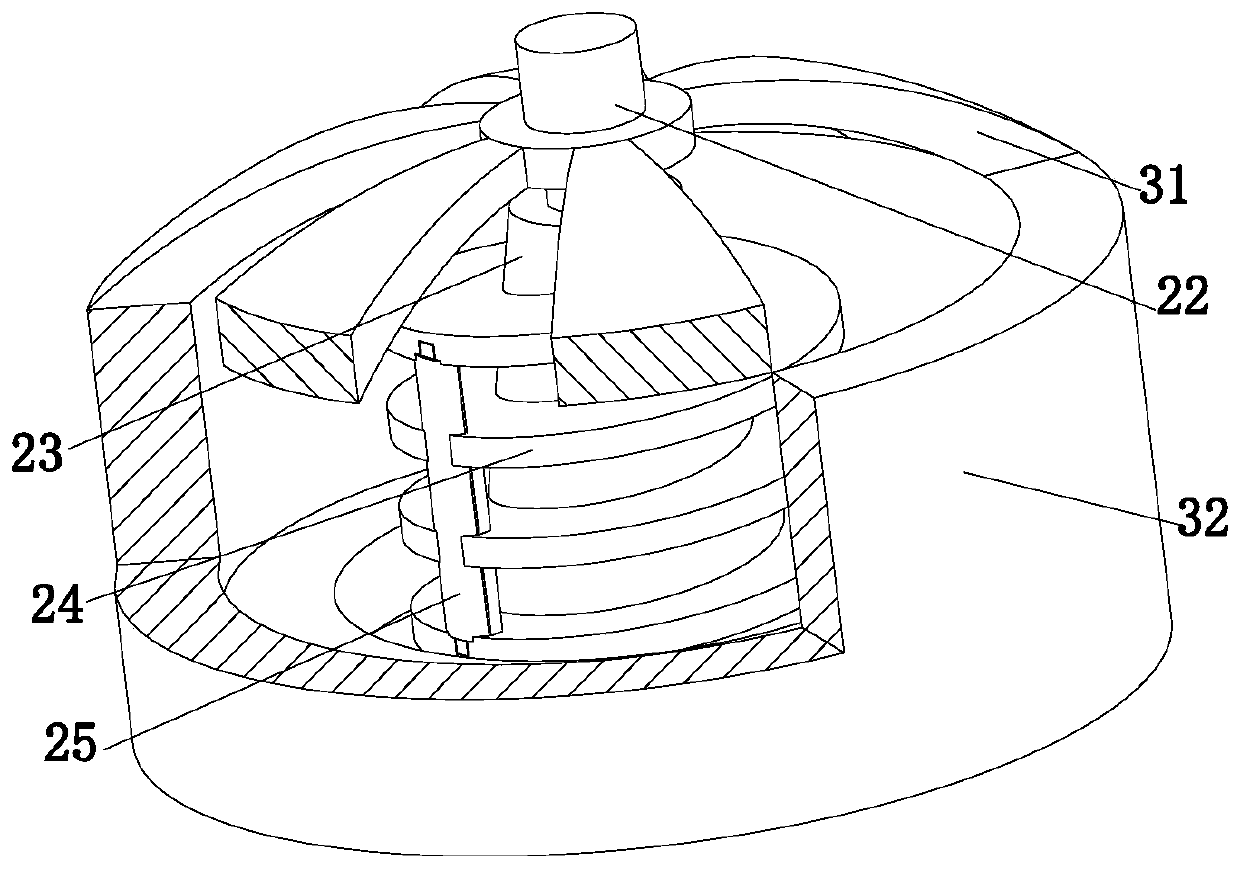

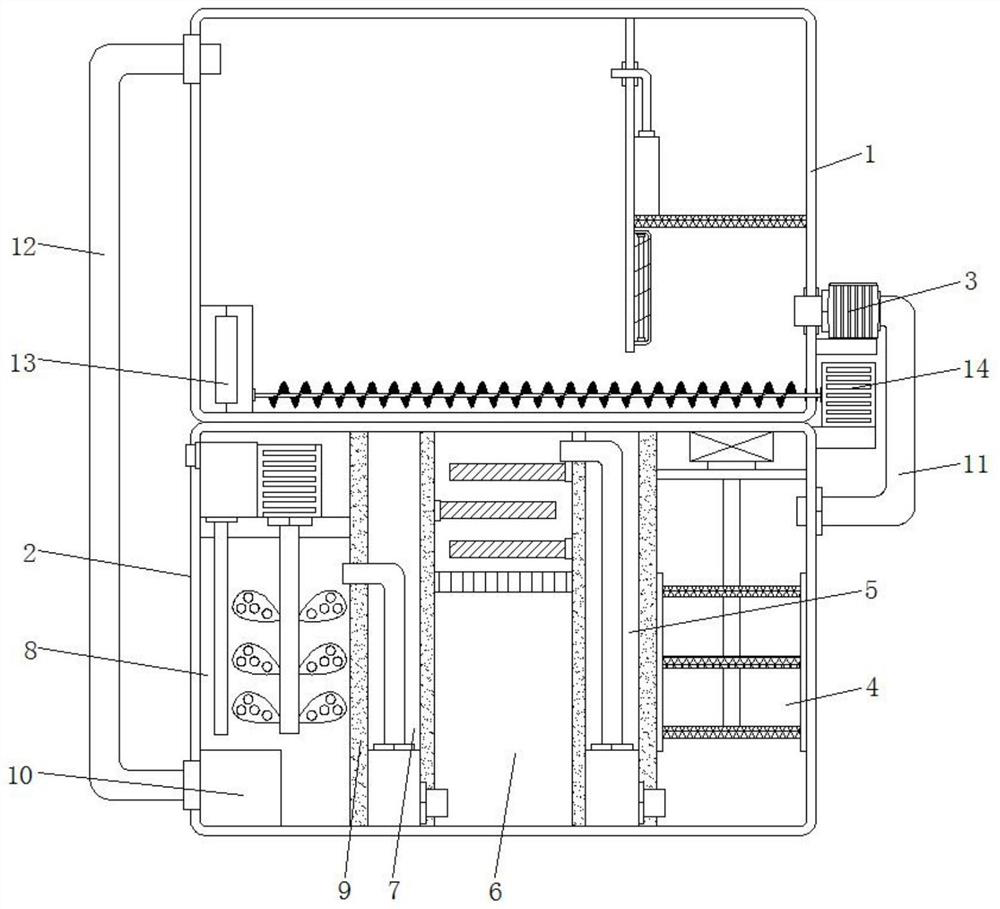

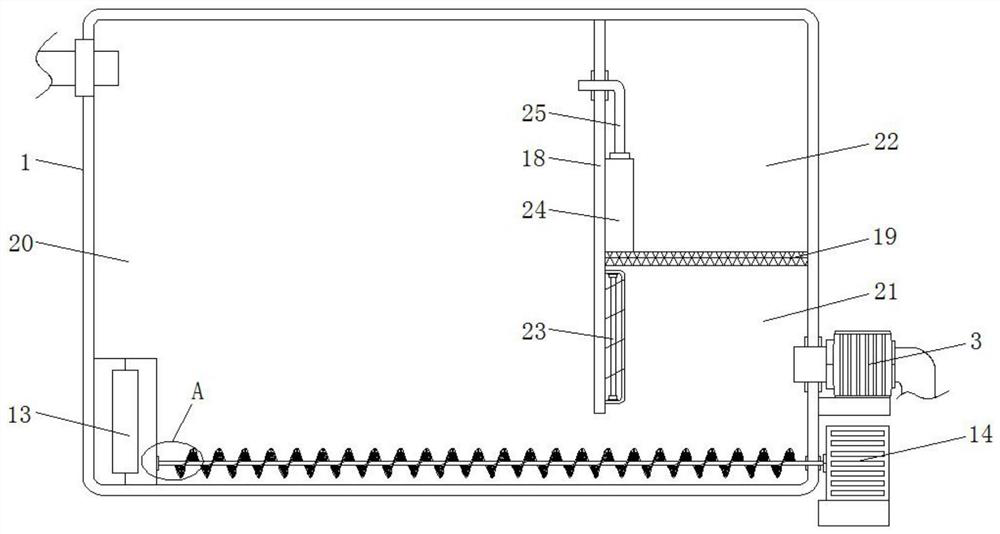

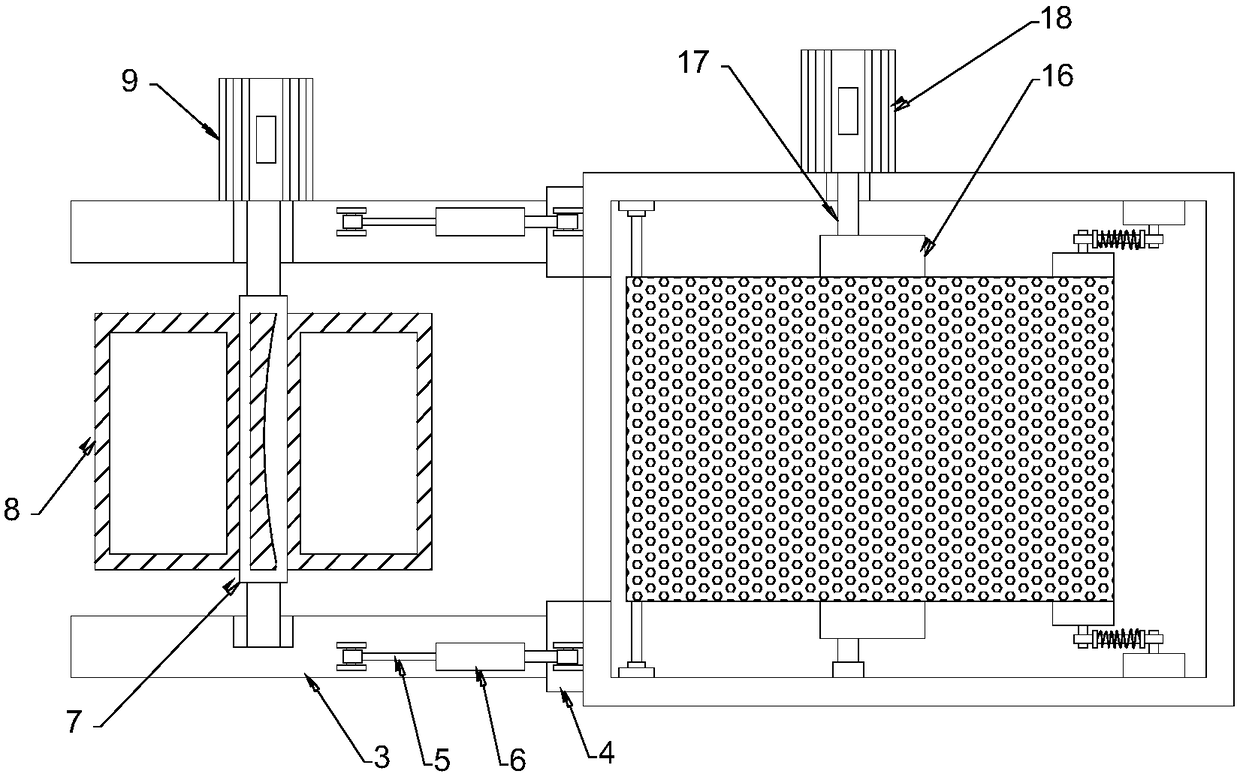

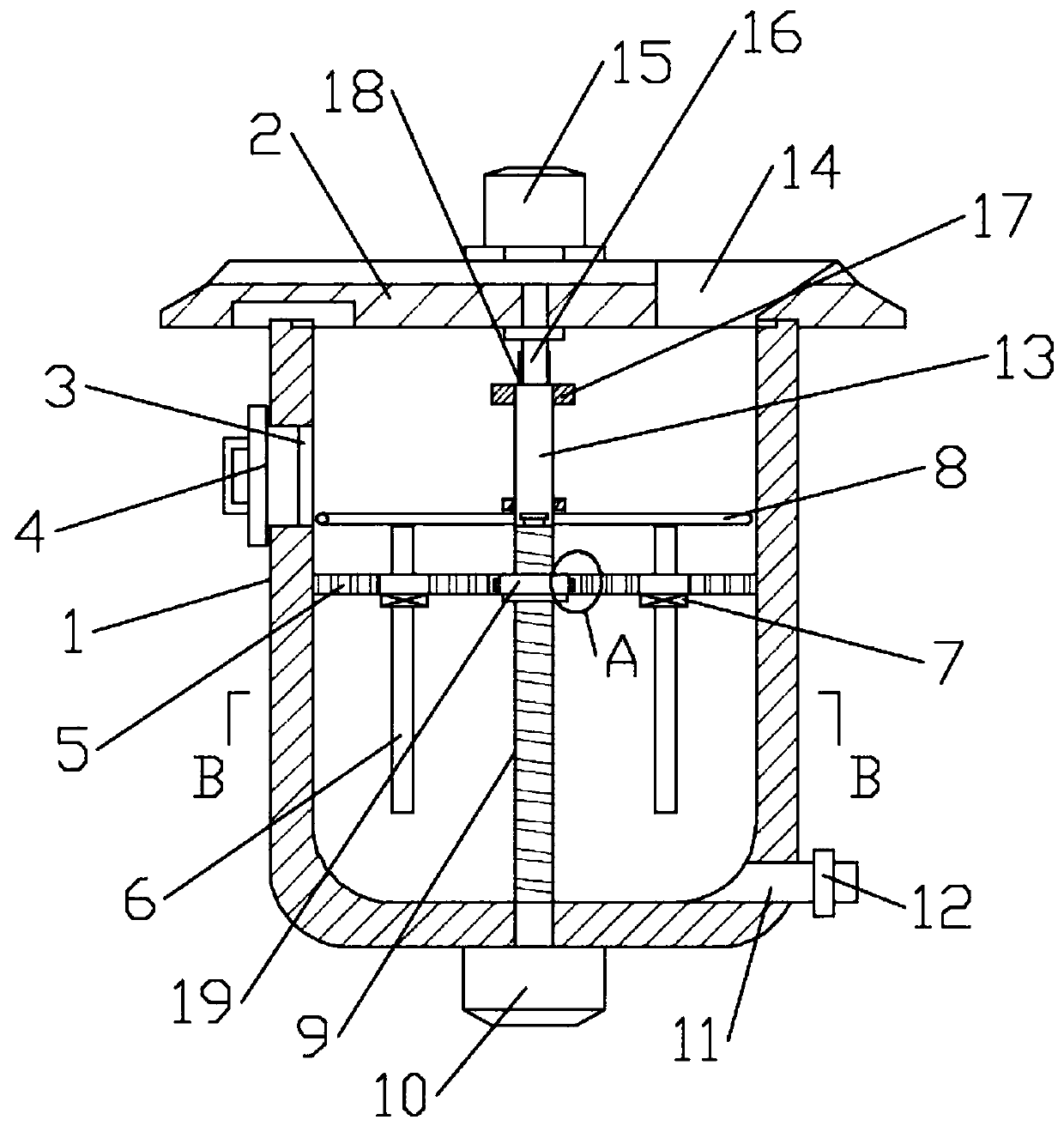

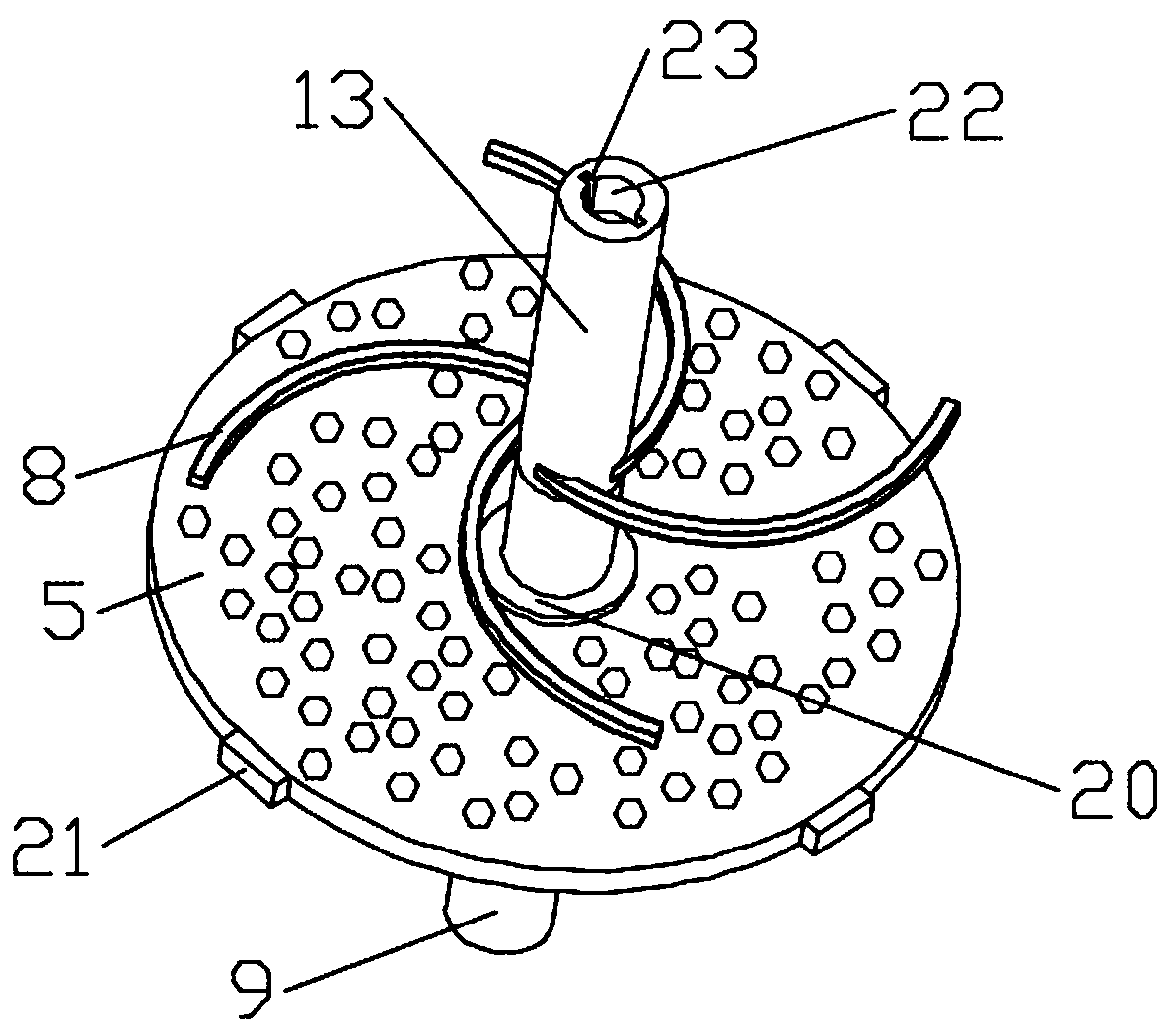

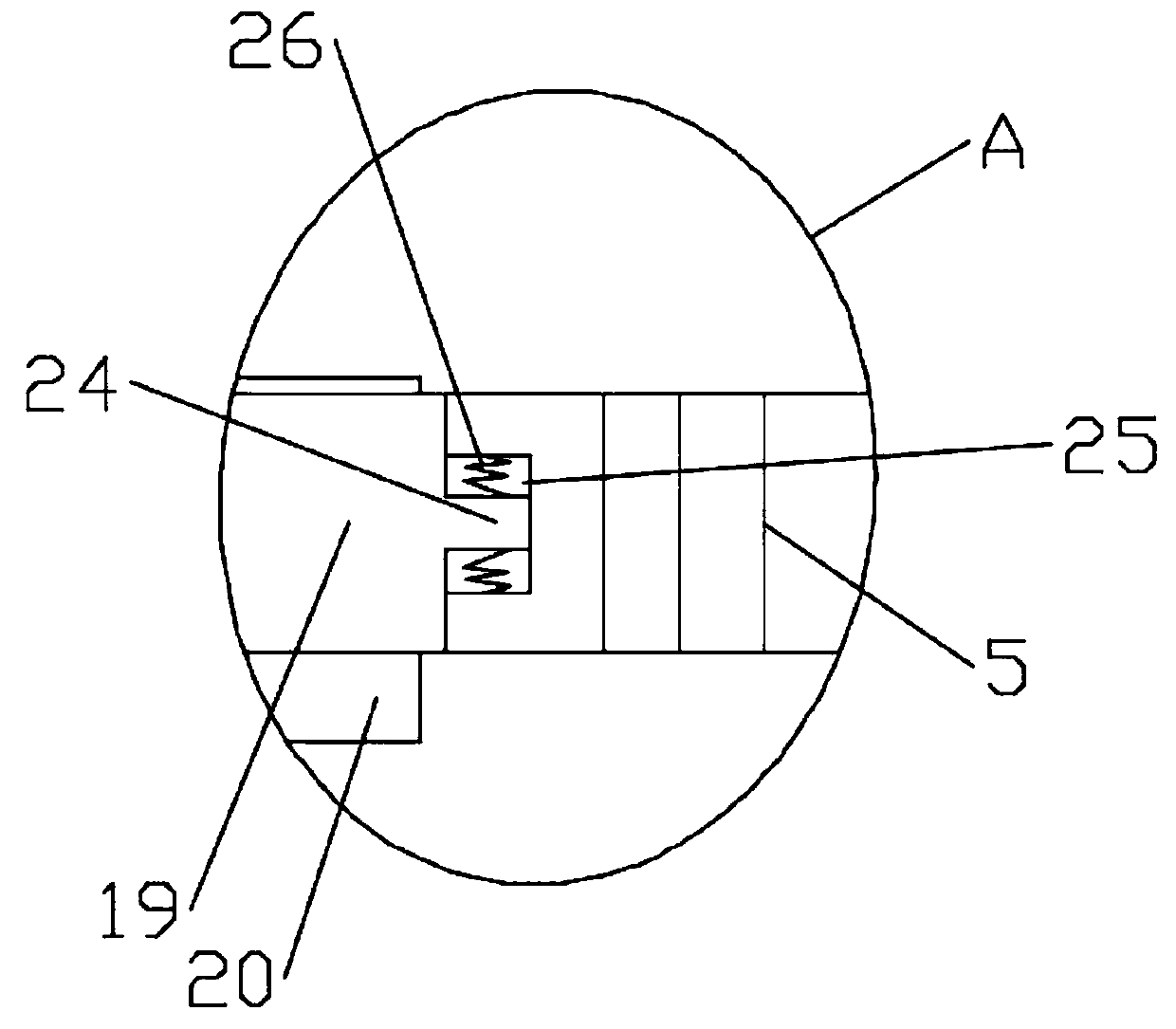

Sieving and drying device for metal powder

ActiveCN108889608ATo achieve the screening effectRealize quantitative screeningSievingTransportation and packagingScreening effectEngineering

The invention discloses a sieving and drying device for metal powder, include a hot air fan, sieve powder box, distribution box and dispersing box, An upper end of that dispersion box is provide witha motor 2 and a feeding port, A taper stirring drum is arrange in that dispersion box, the main shaft of the motor 2 is provided with a stirring shaft, the lower end of the conical stirring drum is provided with a blanking pipe, A low end of that blanking pipe is communicate with the distribution box, A control valve is arranged on the feeding pipe, A run wheel is arranged in the material distribution box, two grooves are symmetrically arranged on the runner, the upper end side of the sieve powder box is provided with a mounting seat, A motor 1 is arranged on the mounting seat, the main shaftof the motor is provided with an eccentric wheel, A screen net frame is arranged in the screen powder box, a screen net is arranged on the inner side of the screen net frame, a bracket is arranged onthe bottom of the screen powder box, and a recovery box is arranged on the upper end of the bracket. The device realizes the quantitative screening of the powder, ensures the screening effect and efficiency of the screen net, and the treated powder contains less impurities and the water content of the powder is low.

Owner:芜湖市晨睿建材有限公司

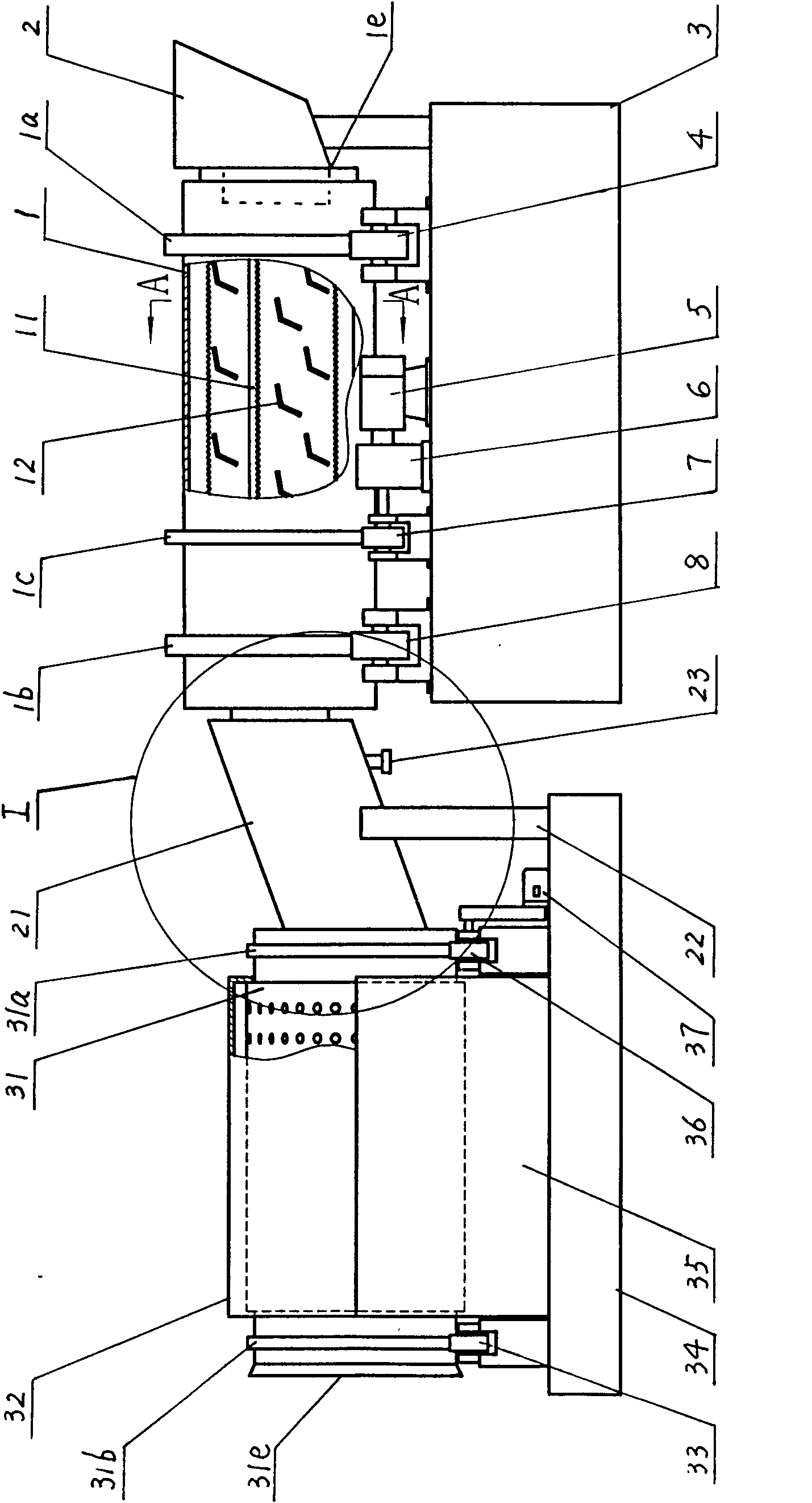

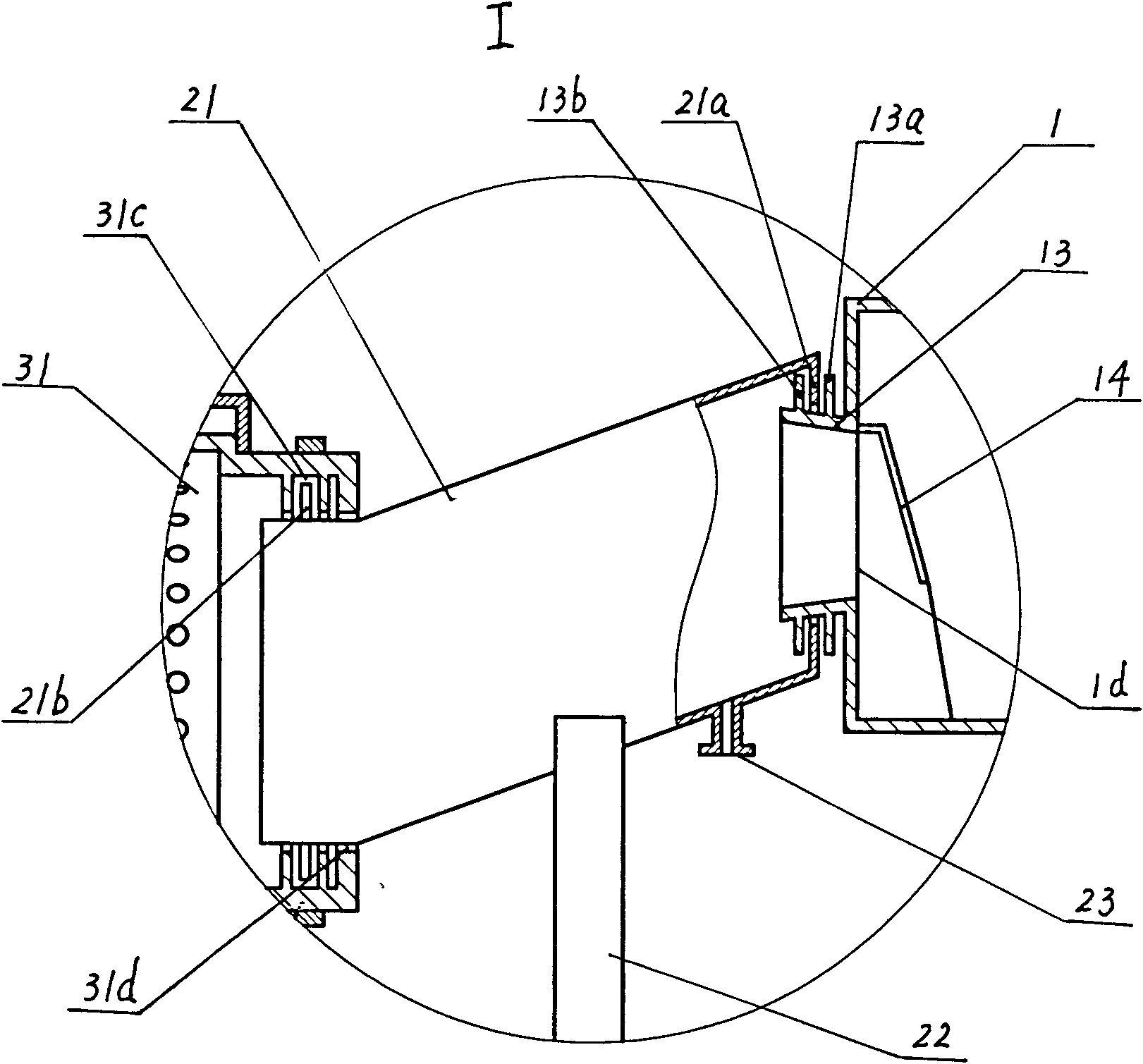

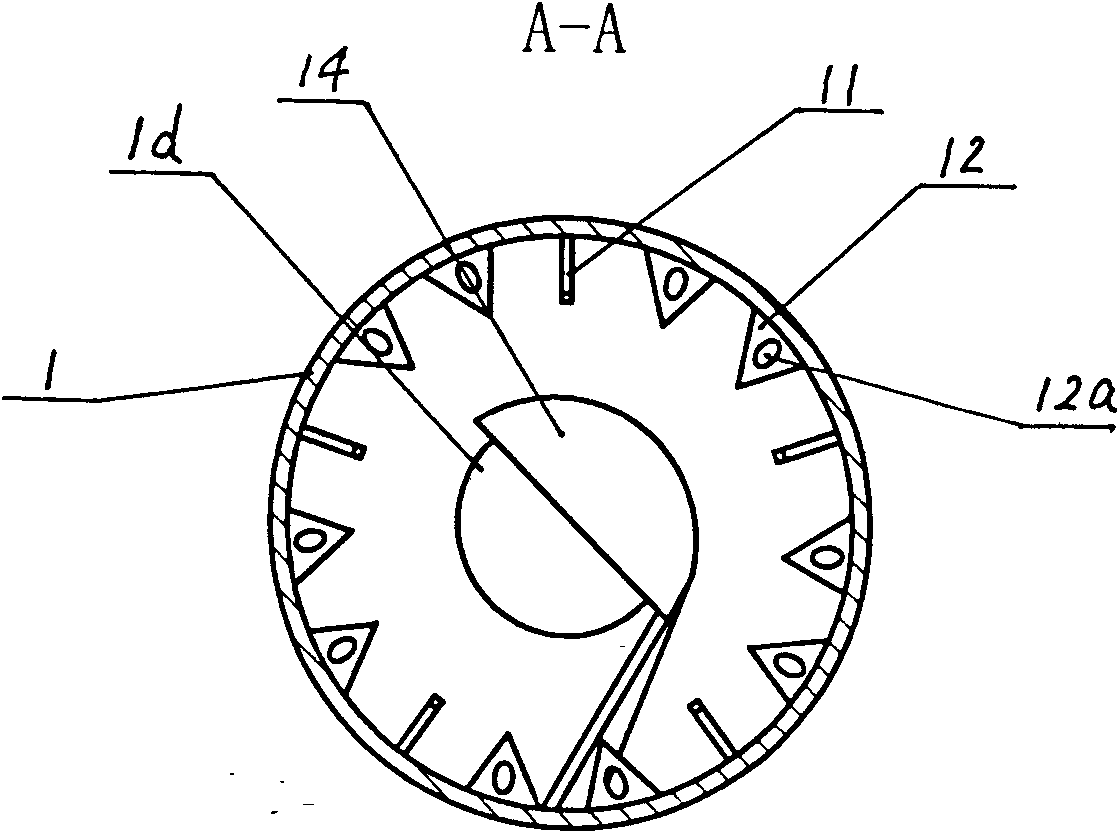

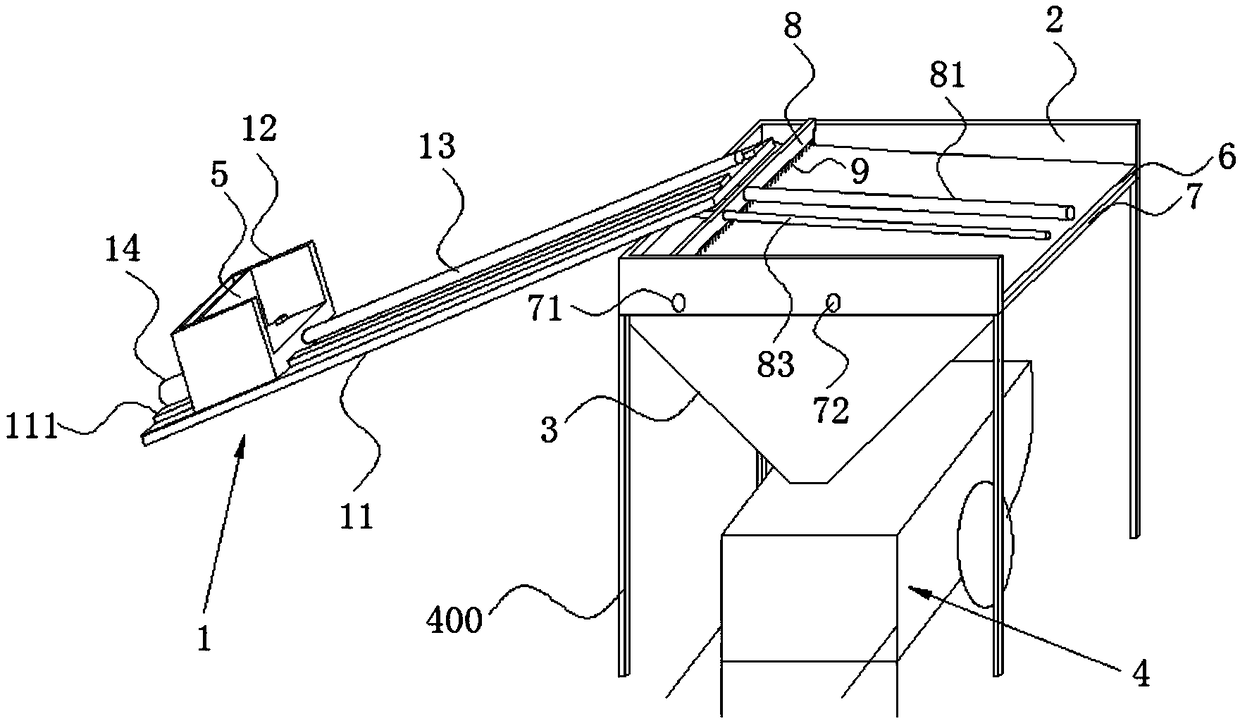

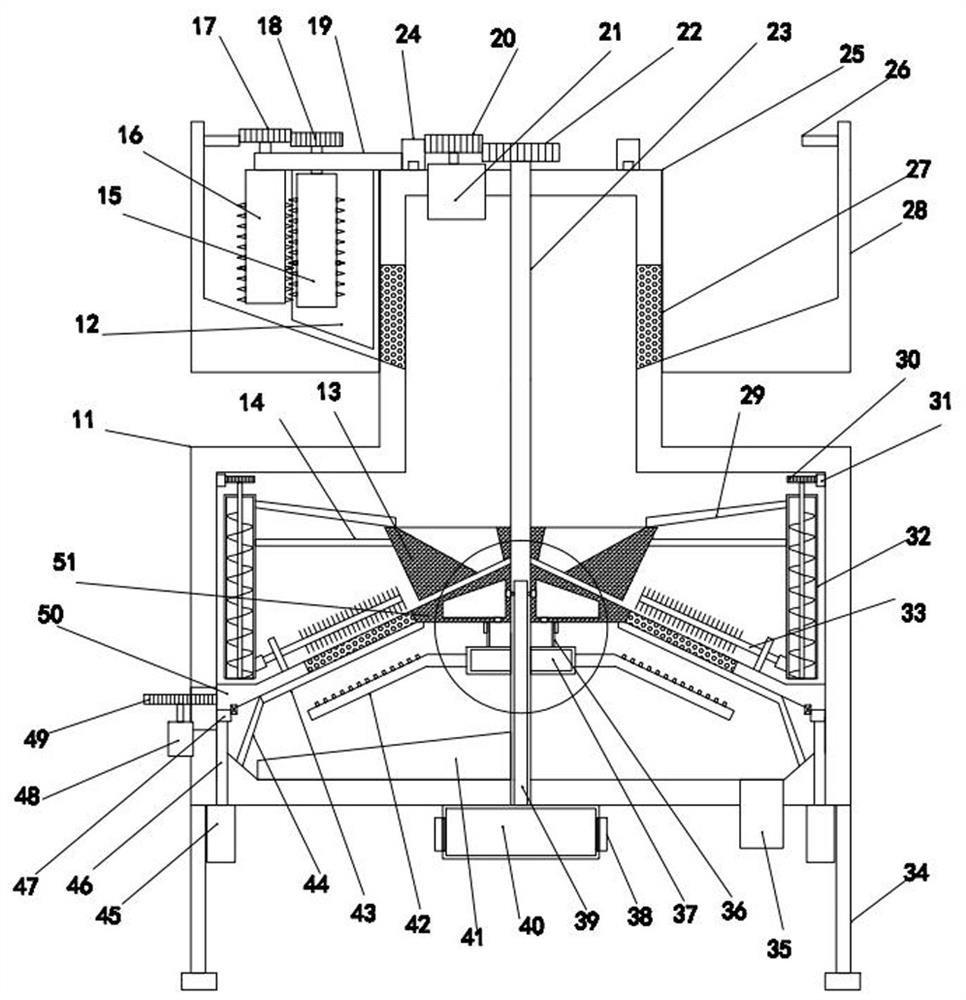

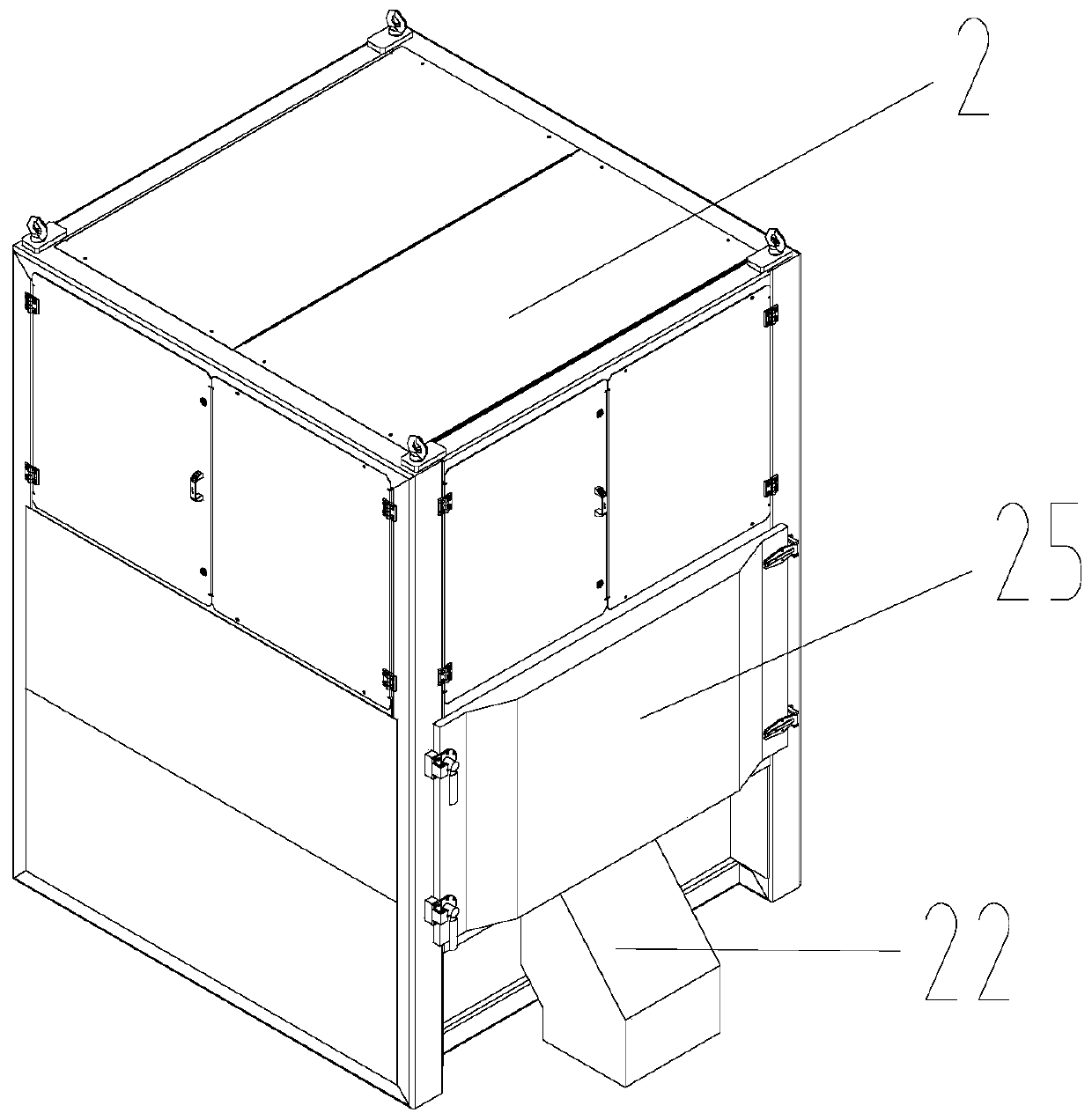

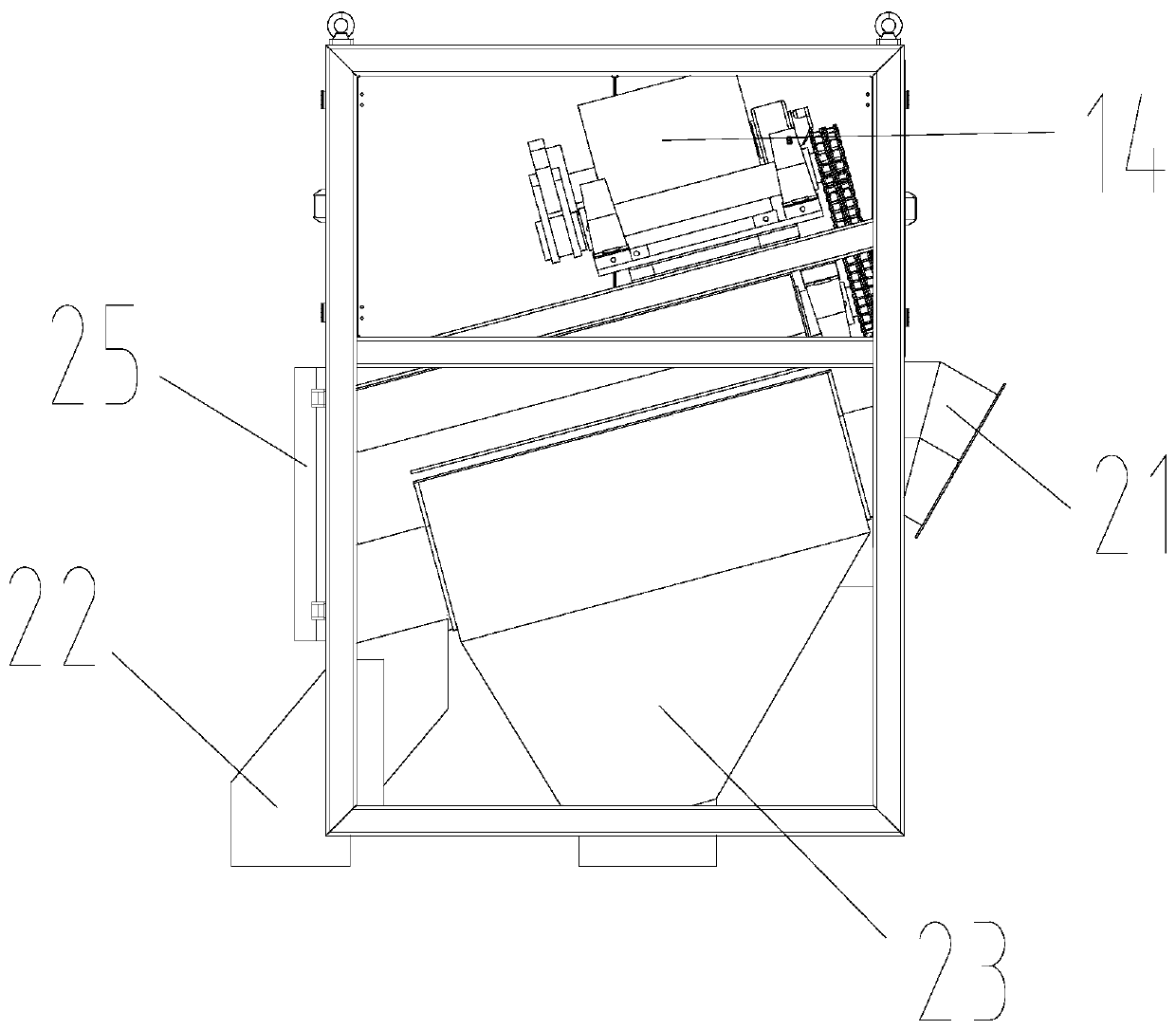

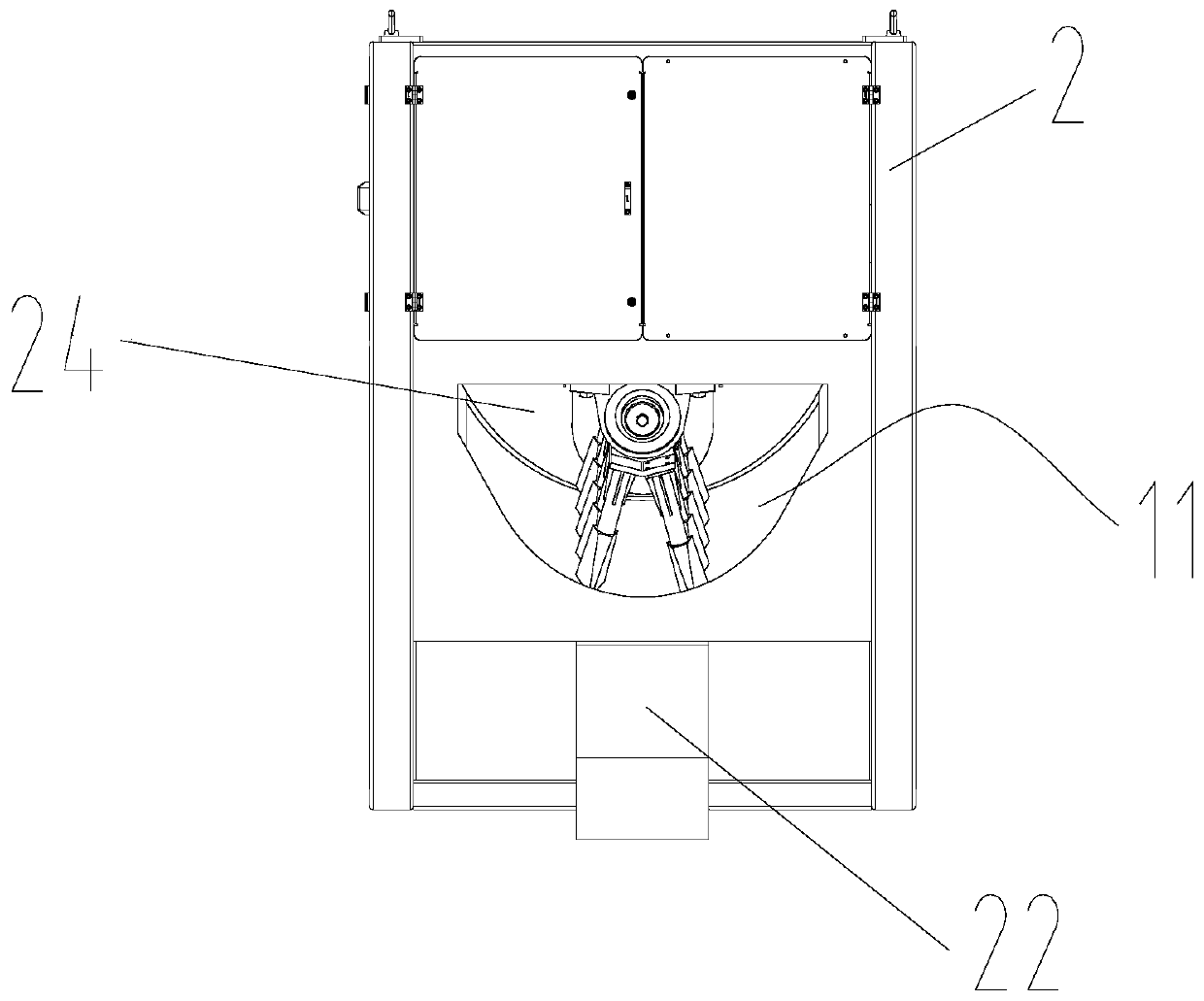

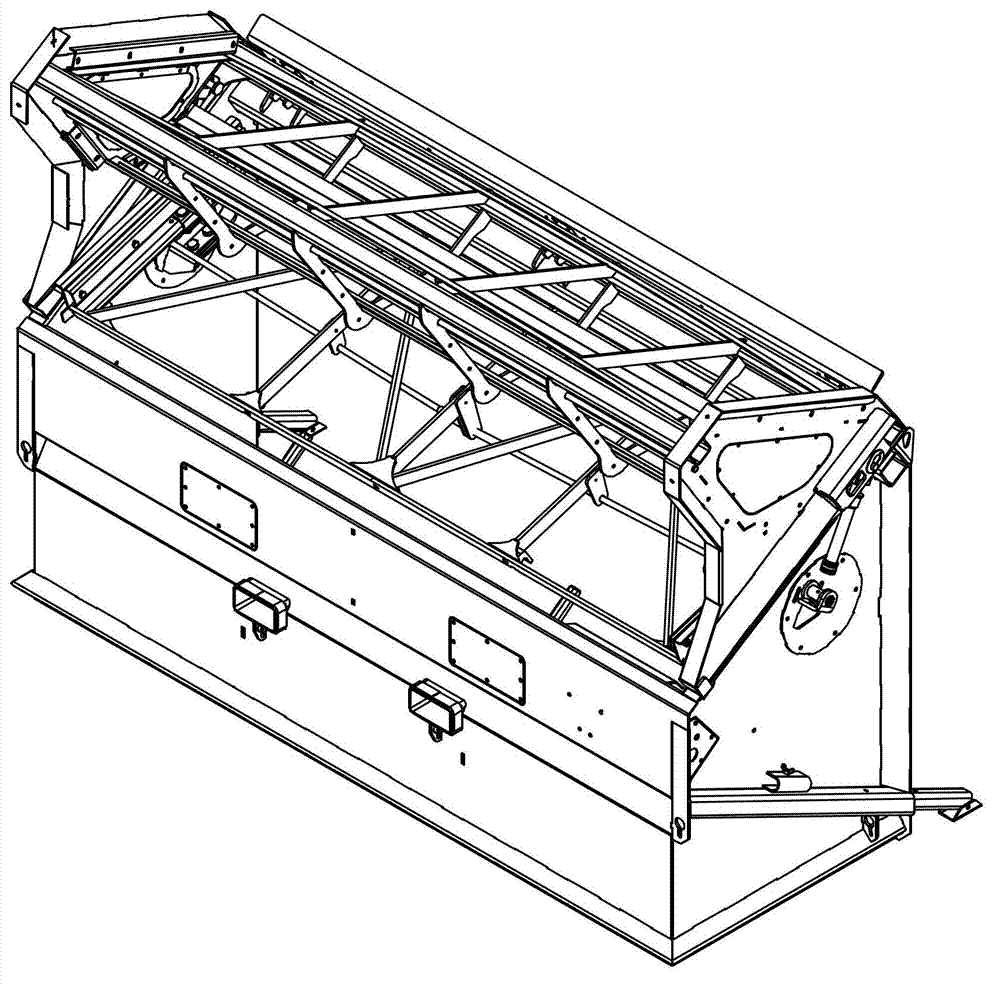

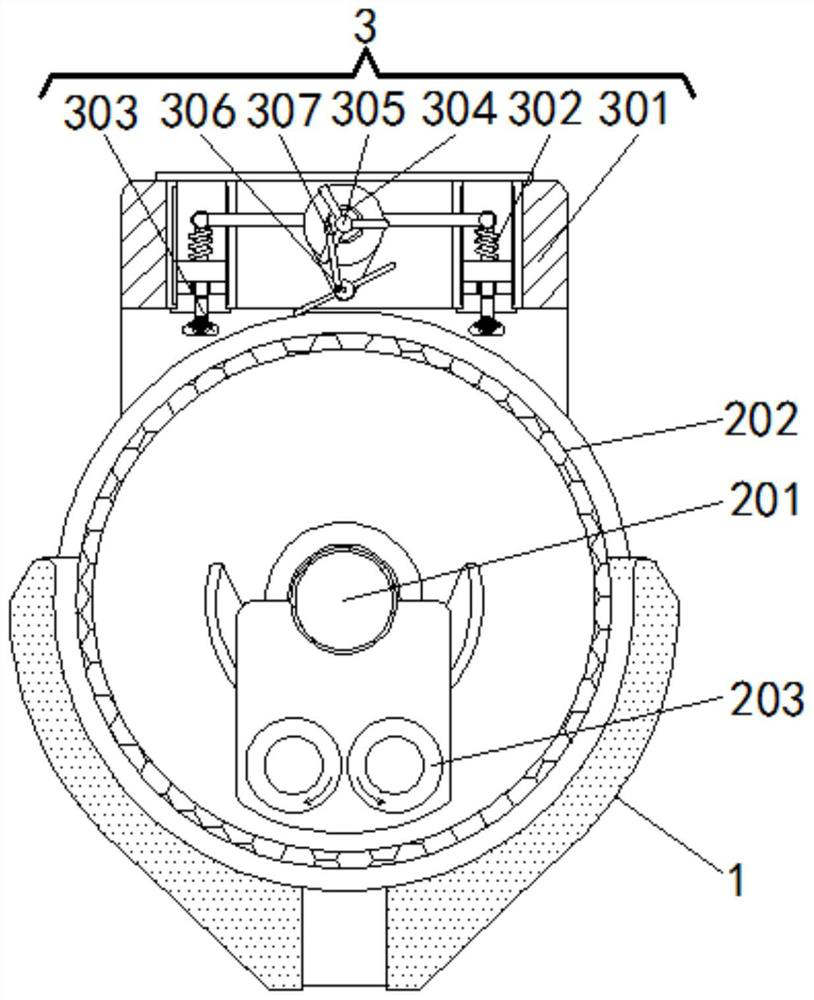

Split type rotary drum pulping device

InactiveCN101671970AGuarantee quality and efficiencyGuaranteed screening efficiencyRaw material divisionPulp and paper industry

The invention discloses a split type rotary drum pulping device comprising a pulping machine and a screening machine. The pulping machine is internally provided with a rotary drum; the inner wall of the rotary drum is connected with a plurality of scratch plates; the screening machine is internally provided with a screen drum; the wall of the screening drum is provided with a plurality of screen holes; a bottom plane of the pulping machine is higher than a bottom plane of the screening machine; a pulp passing drum is arranged between the pulping machine and the screening machine in an inclineway and is fixedly arranged on a base; a left port of the pulp passing drum is arranged on a pulp outlet of the rotary drum and communicated corresponding to the pulp outlet port; a right port of thepulp passing drum is arranged in a pulp inlet of the screen drum and communicated corresponding to the pulp inlet; and the rotary drum is internally connected with a pulp feeding hopper in a shape ofa spoon and the pulp feeding hopper corresponds to the pulp outlet port. The invention can solve the problems that the prior art cannot simultaneously meet the requirements of a pulping process and ascreening process, is easy to cause low pulping quality and screening efficiency and brings great difficulty to processing and manufacturing, hoisting transportation, installation and debugging of theequipment.

Owner:王秉华

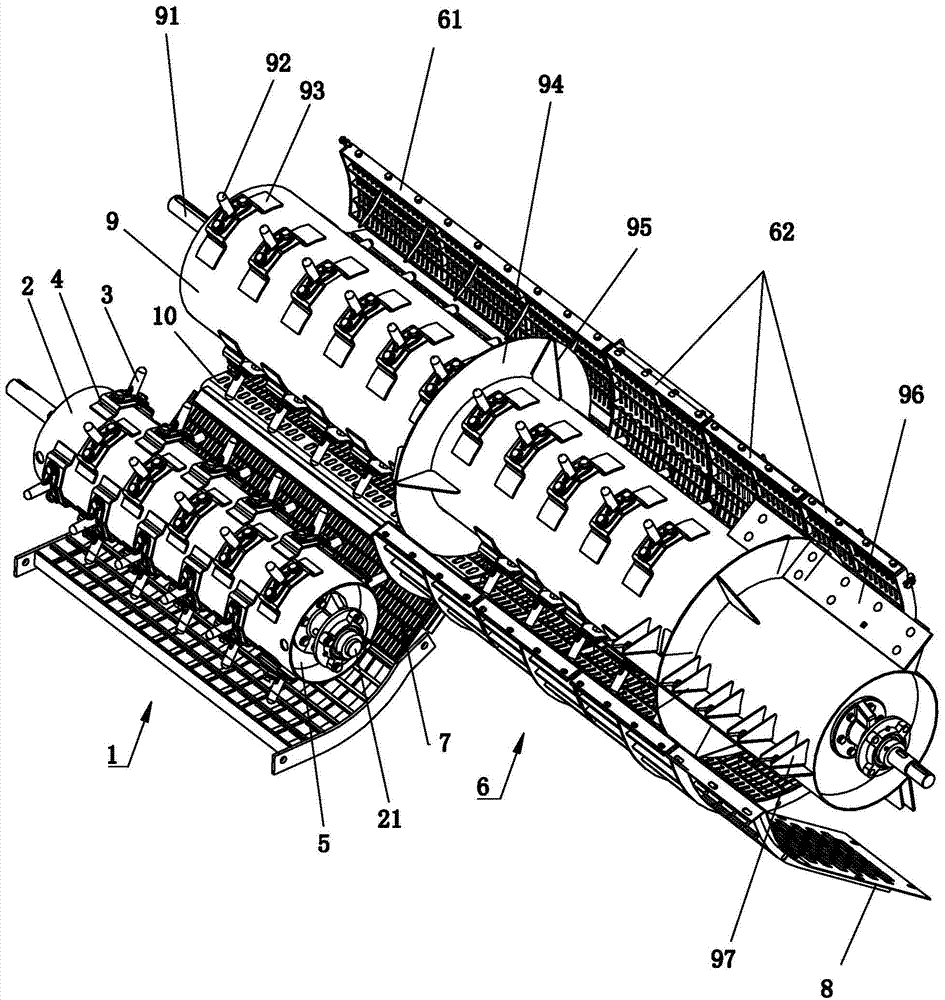

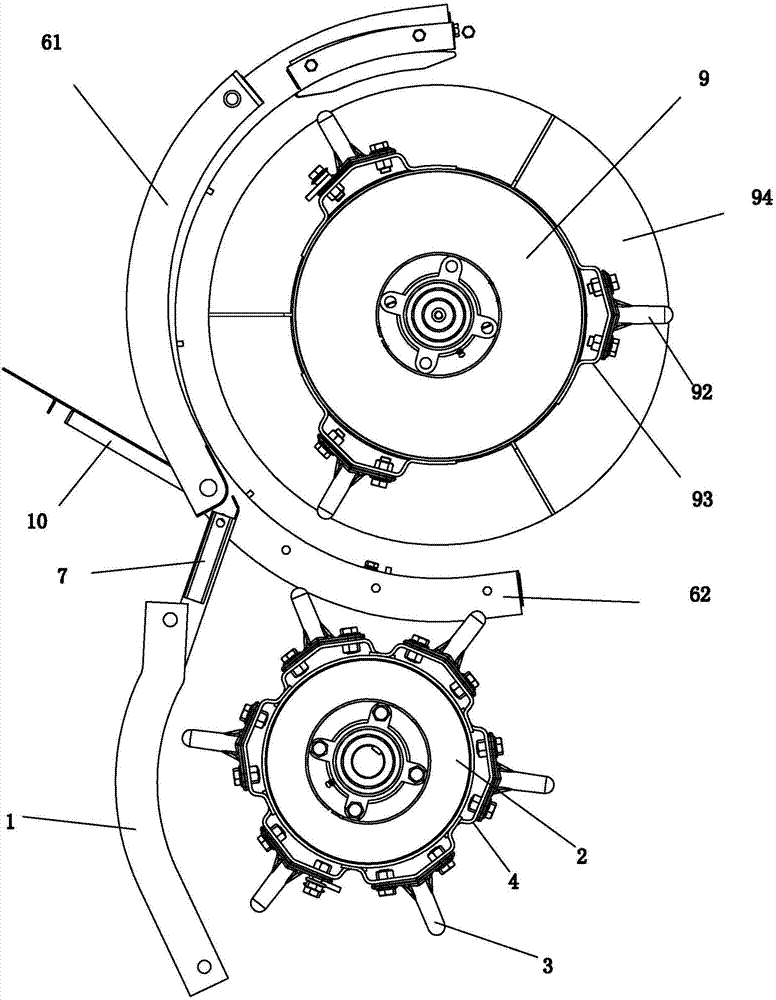

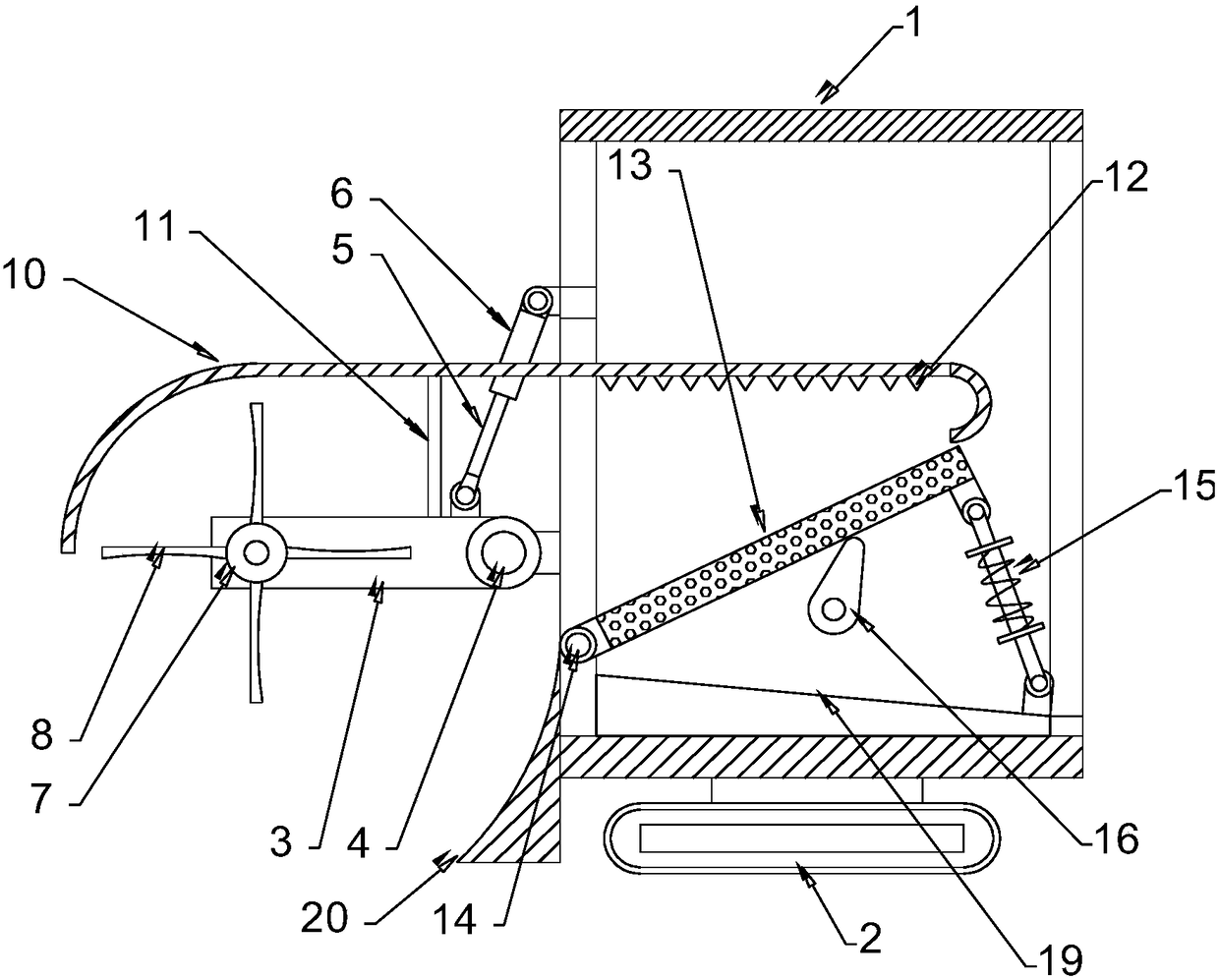

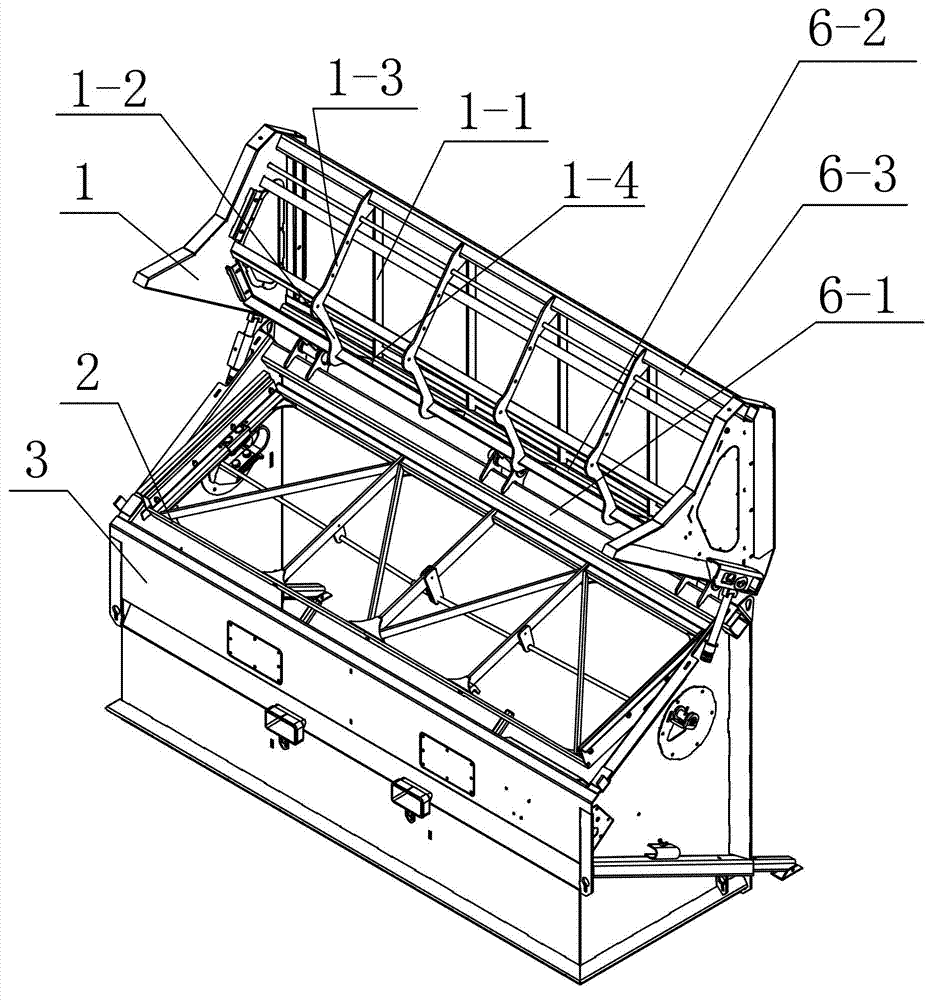

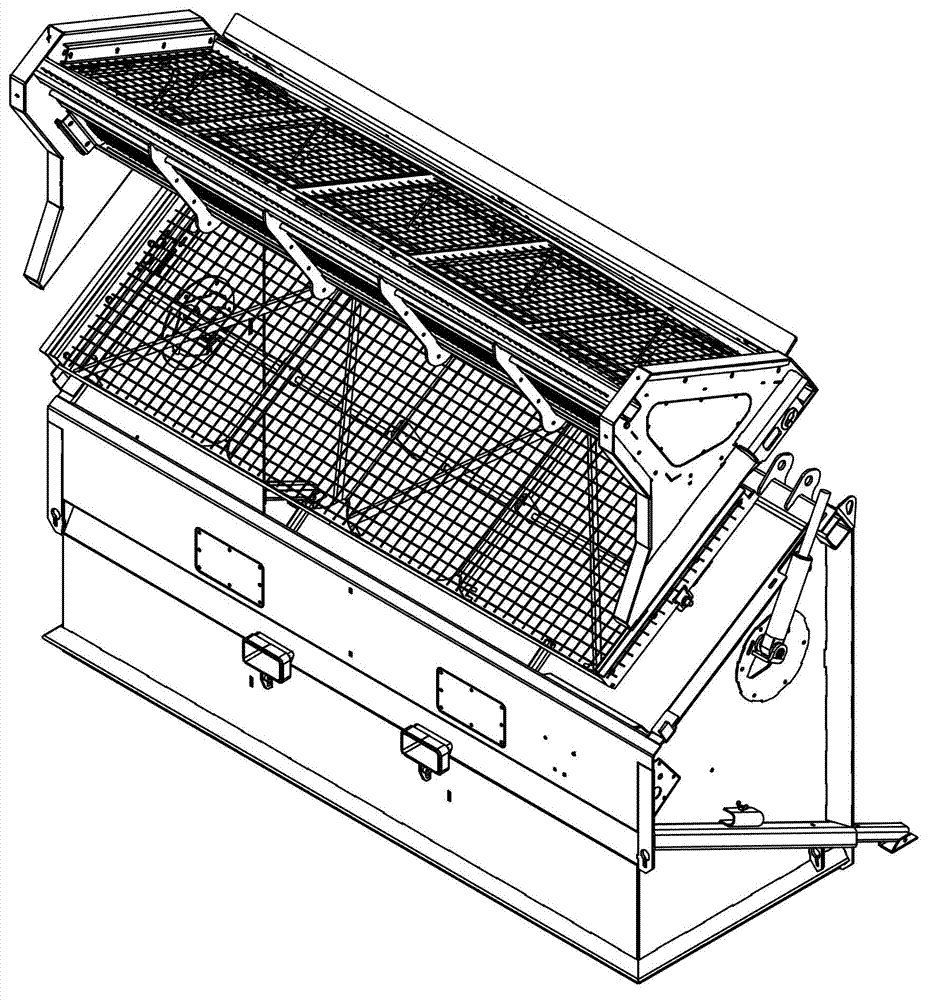

Corn kernel threshing and separating device

The invention discloses a corn kernel threshing and separating device which comprises a threshing roller with threshing teeth. Each threshing tooth comprises a tooth rod with a spherical top end, a threshing concave plate is arranged below the threshing roller and comprises a concave plate body, the concave plate body comprises two side plates, supporting plates are arranged between the two side plates, a longitudinal separation plate is arranged between the two supporting plates, separation bars are arranged on the longitudinal separation plate, and the separation bars and the longitudinal separation plate are flush with the side plates. A separation roller is arranged on one side of the flowing direction of crops, and separation teeth and separation plates are arranged on the separation roller in a staggered mode. A separation concave plate communicated with the threshing concave plate is arranged below the separation plate. Through rubbing between the threshing teeth and the threshing concave plate, threshing is achieved, power consumption is little, and cost is low. Through the threshing concave plate, while passing ability and screening efficiency are guaranteed, strength and use reliability are improved, and the crushing rate is lowered; meanwhile, through replacement of the corn kernel threshing and separating device, the effect of harvesting corn crops at the same time is achieved, and the use rate of a rice and wheat harvester is improved.

Owner:LOVOL HEAVY IND CO LTD

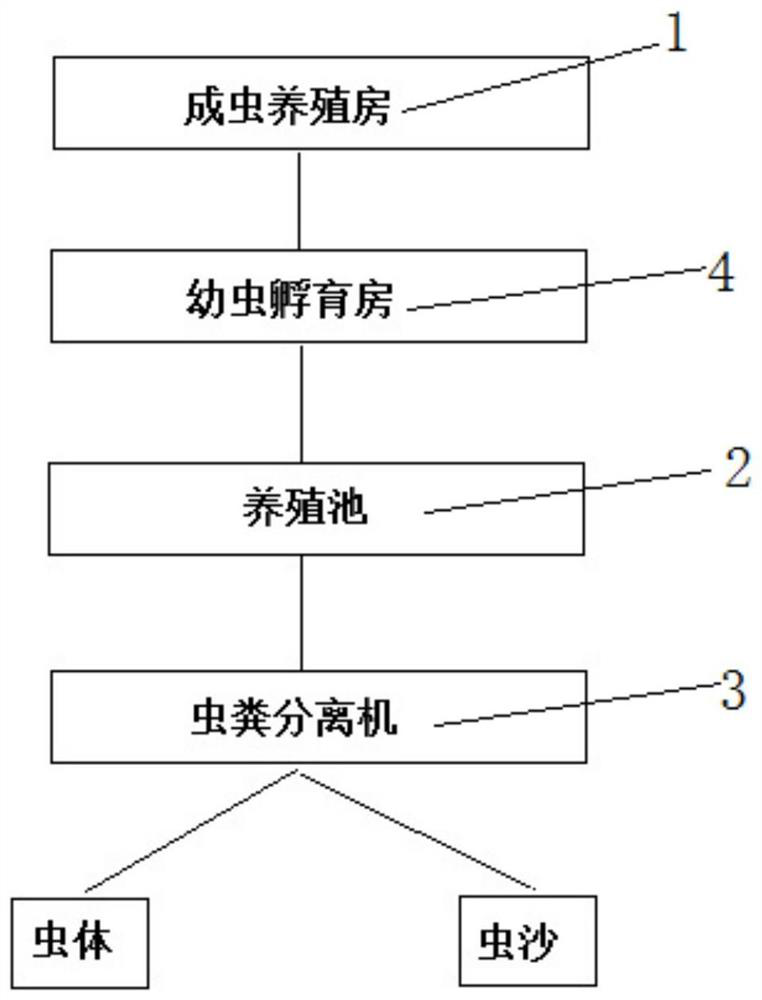

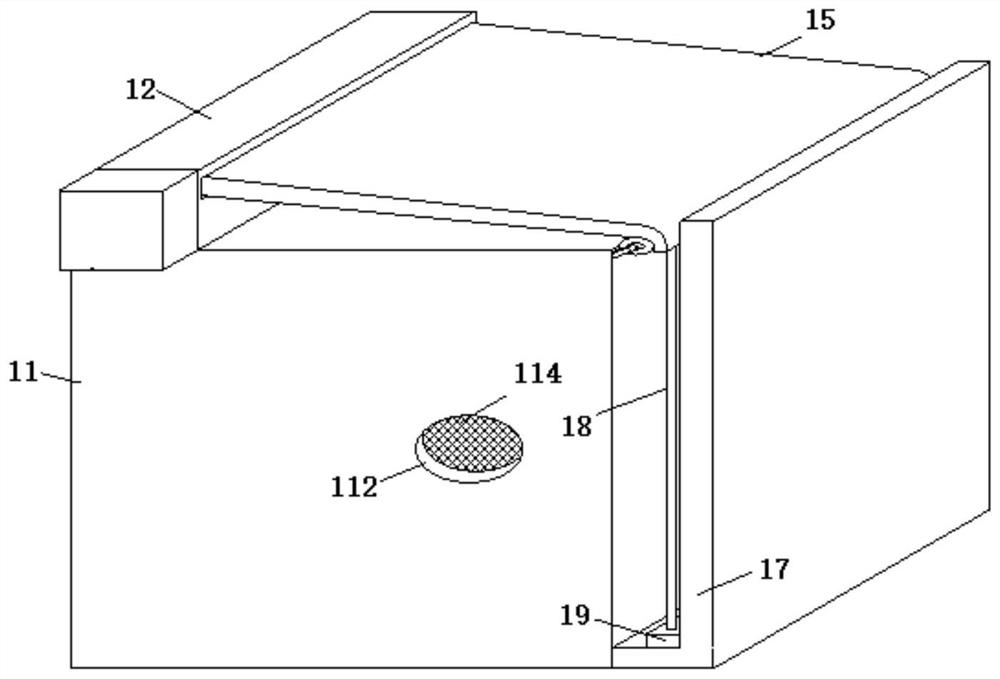

System for breeding hermetia illucens for treating livestock and poultry manure and application thereof

ActiveCN112753657AImprove eco-efficiencyEasy to operateSievingGas current separationBiotechnologyAnimal science

Owner:YUNNAN ANIMAL SCI & VETERINARY INST

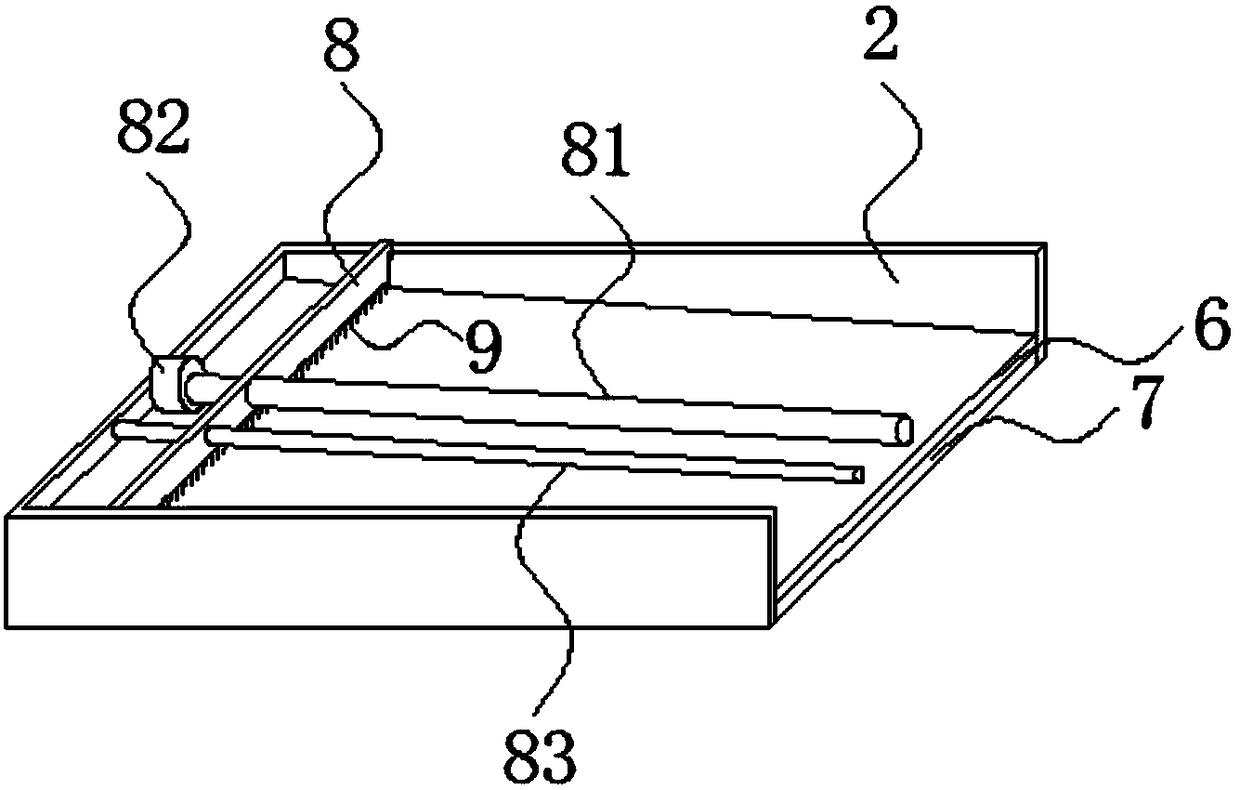

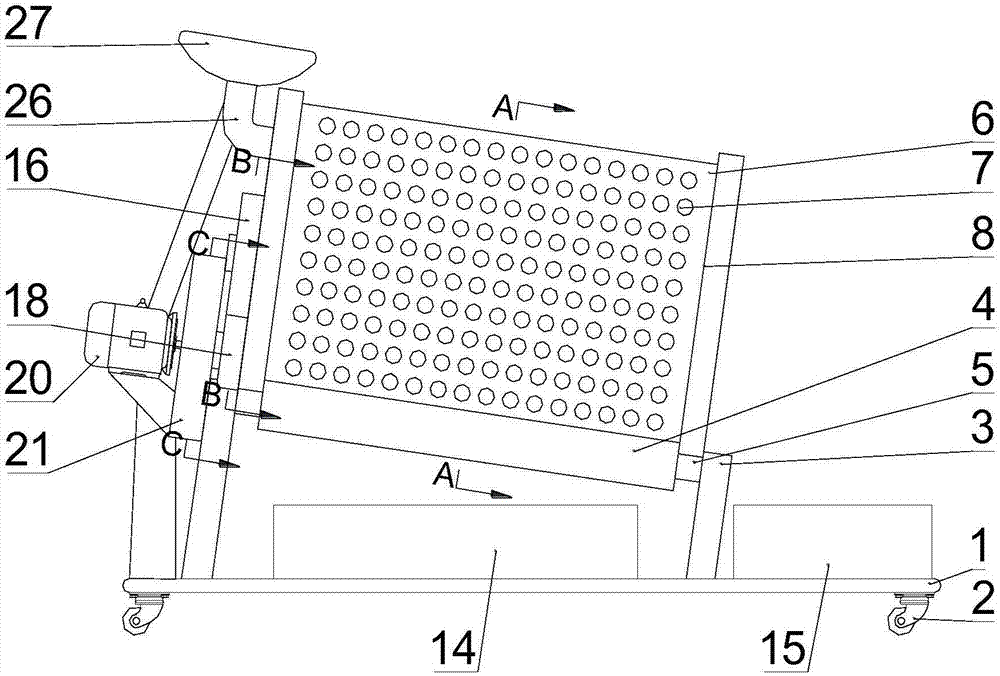

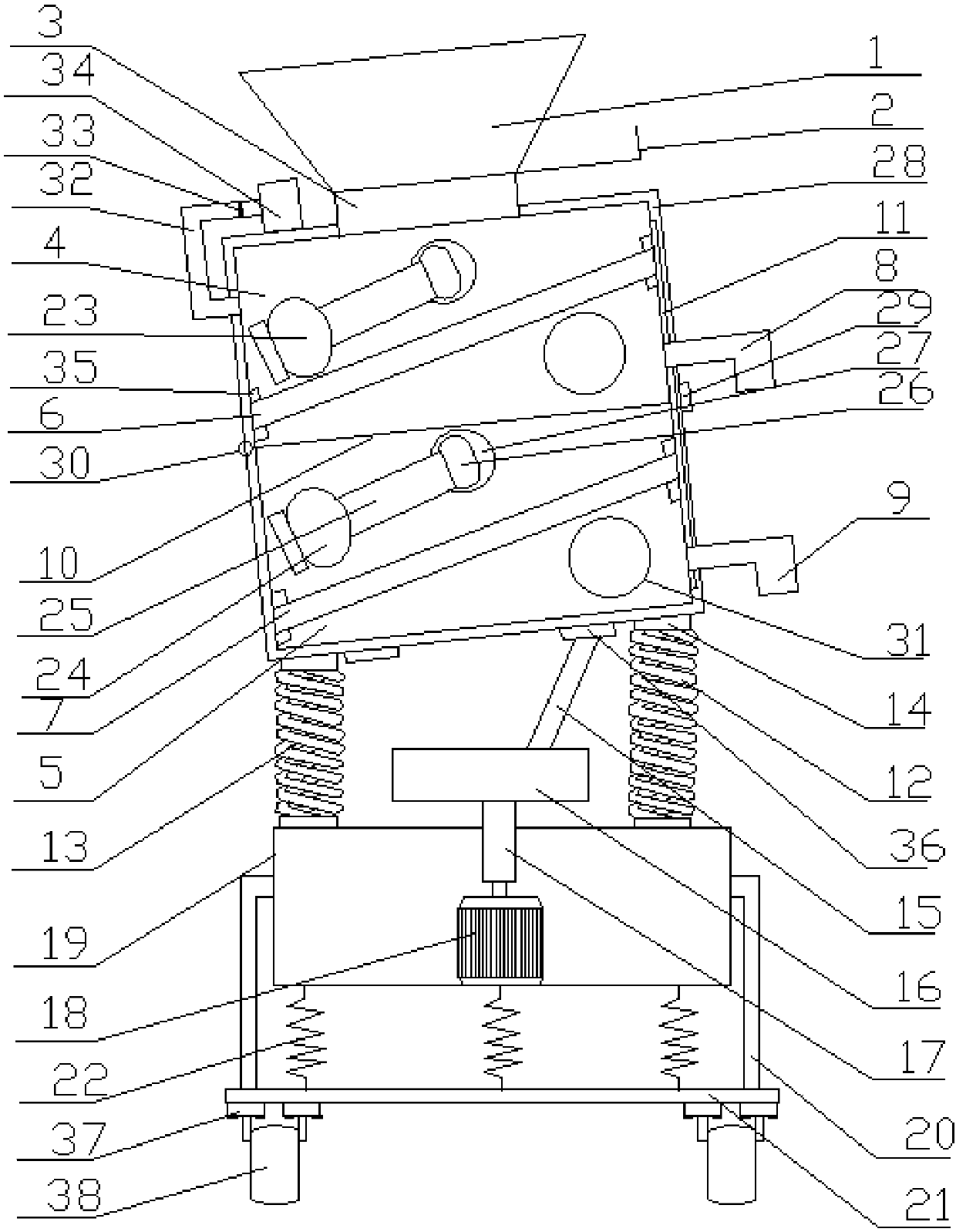

Efficient sand screening machine used for buildings

InactiveCN108144837AImprove sorting effectAvoid cloggingSievingScreeningEngineeringUltimate tensile strength

The invention discloses an efficient sand screening machine used for buildings. The efficient sand screening machine sequentially comprises a feeding mechanism, a sand screening groove, a sand hopperand a tilting cart according to the screening process of sand. The feeding mechanism is located on the upstream portion of the sand screening groove. The sand hopper is located below the sand screening groove and further communicates with the sand screening groove. The tilting cart is located below the sand hopper. The feeding mechanism comprises a supporting plate, a sand conveying groove, a first screw rod and a feeding drive motor used for driving the sand conveying groove to move in the length direction of the supporting plate. The sand conveying groove is located in the upper side of thesupporting plate. The side wall, close to the sand screening groove, of the side walls of the sand conveying groove is opened. The supporting plate is obliquely arranged. The lower end of the supporting plate is fixed to the ground, and the upper end of the supporting plate is located above the sand screening groove. According to the efficient sand screening machine used for the buildings, the labor intensity is low, the screening efficiency of the sand is high, the sand can be prevented from blocking screen holes, impurities like stone blocked into the screen holes can be removed, the particle size of the screened sand can be adjusted at any time, and the screening efficiency and screening quality are guaranteed.

Owner:KUNSHAN DINGNIU SHIZHENG CONSTR CO LTD

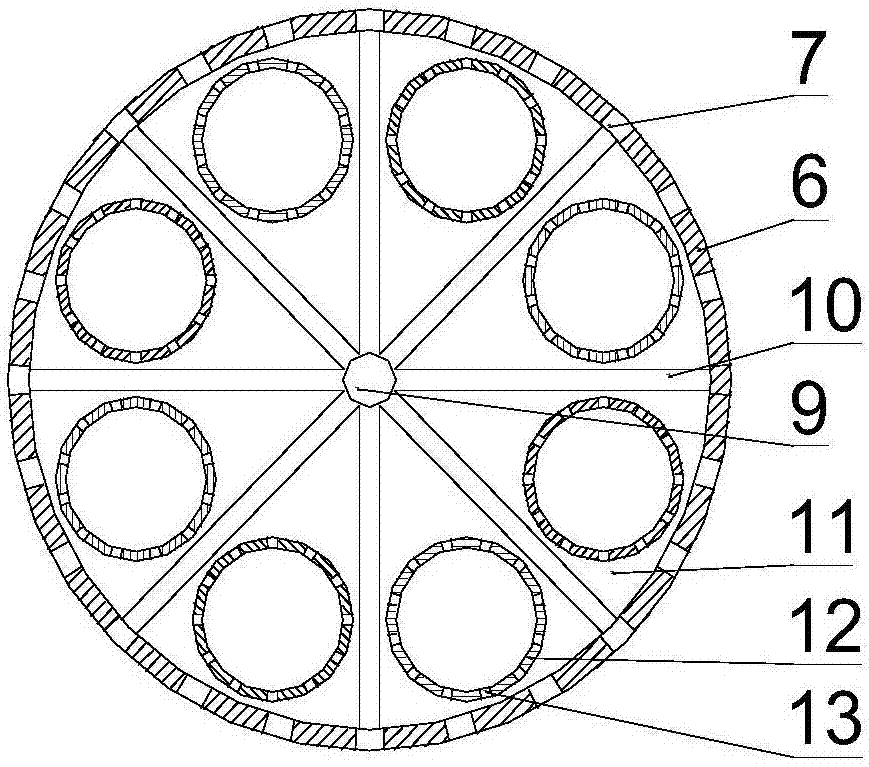

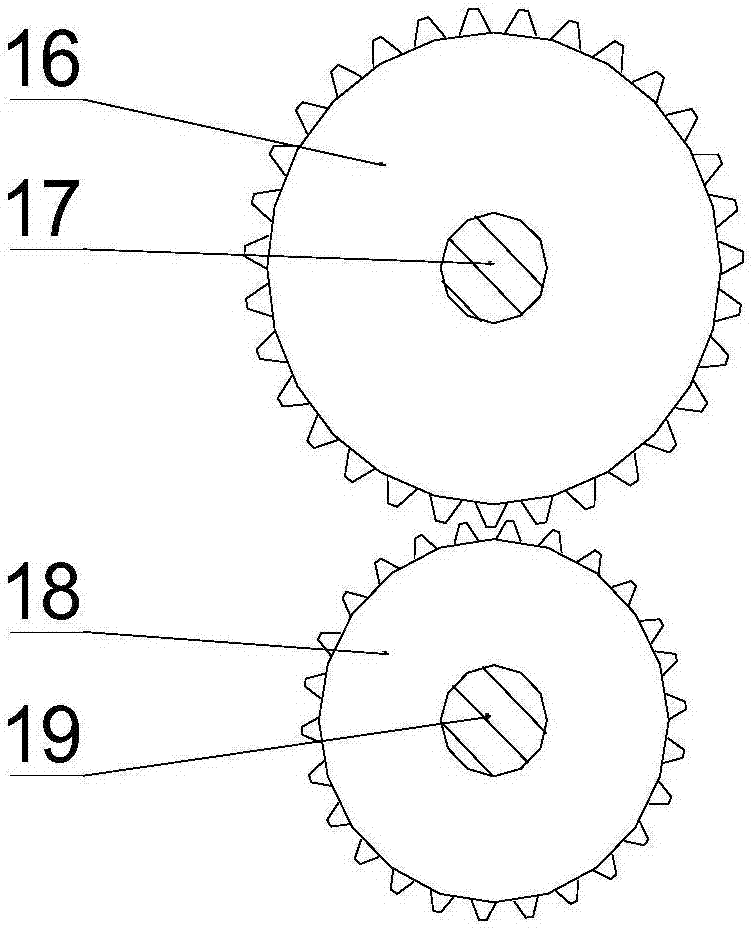

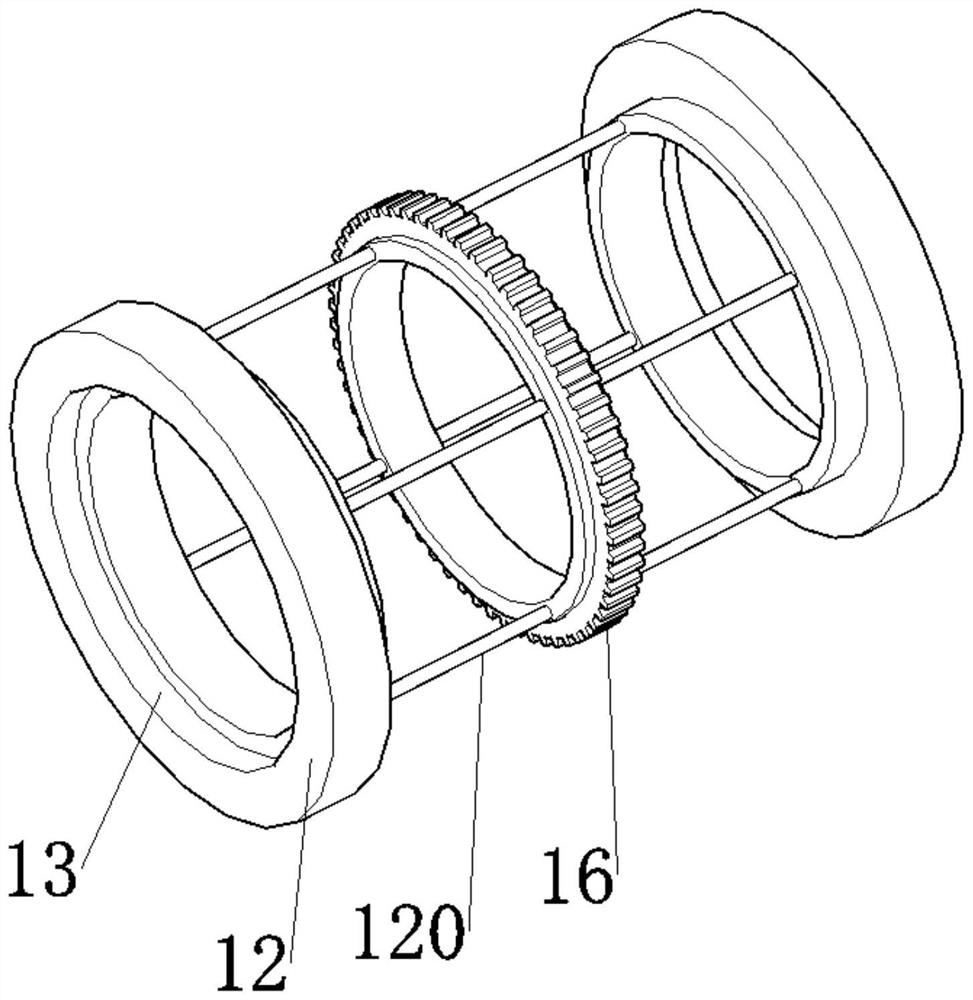

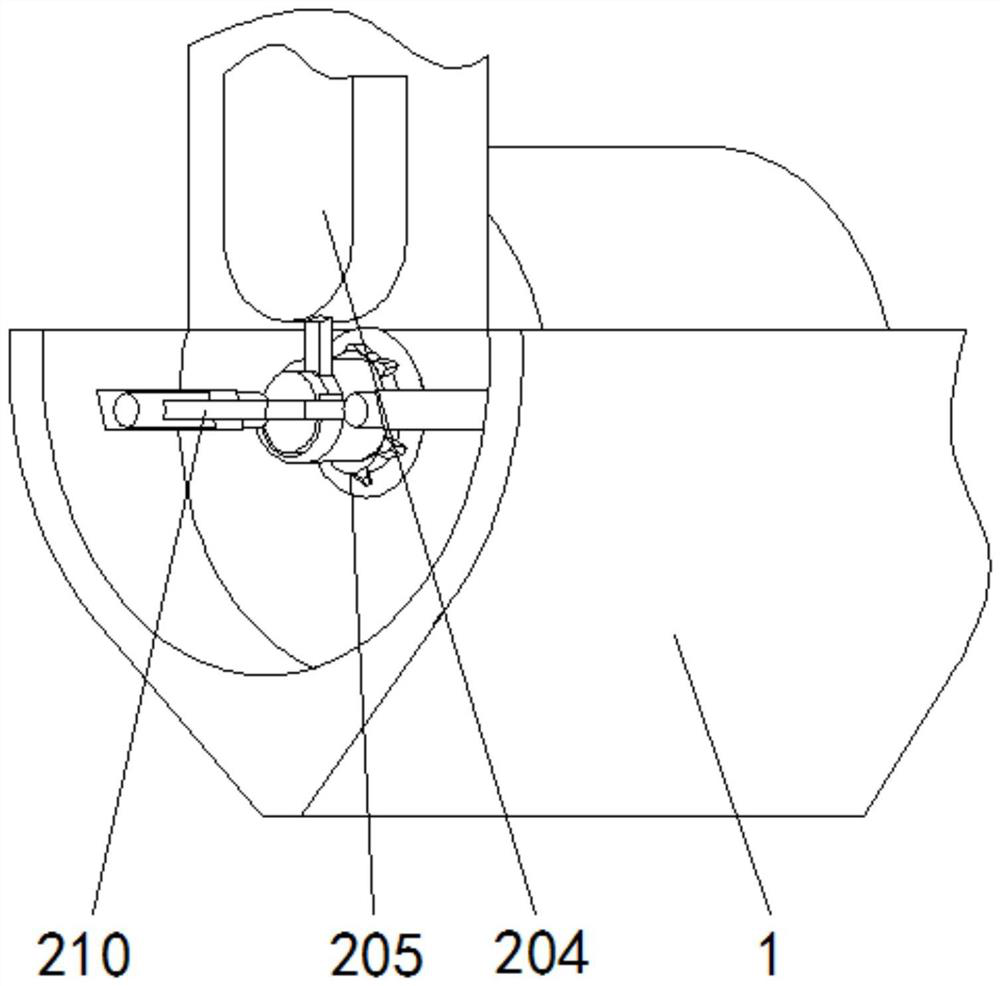

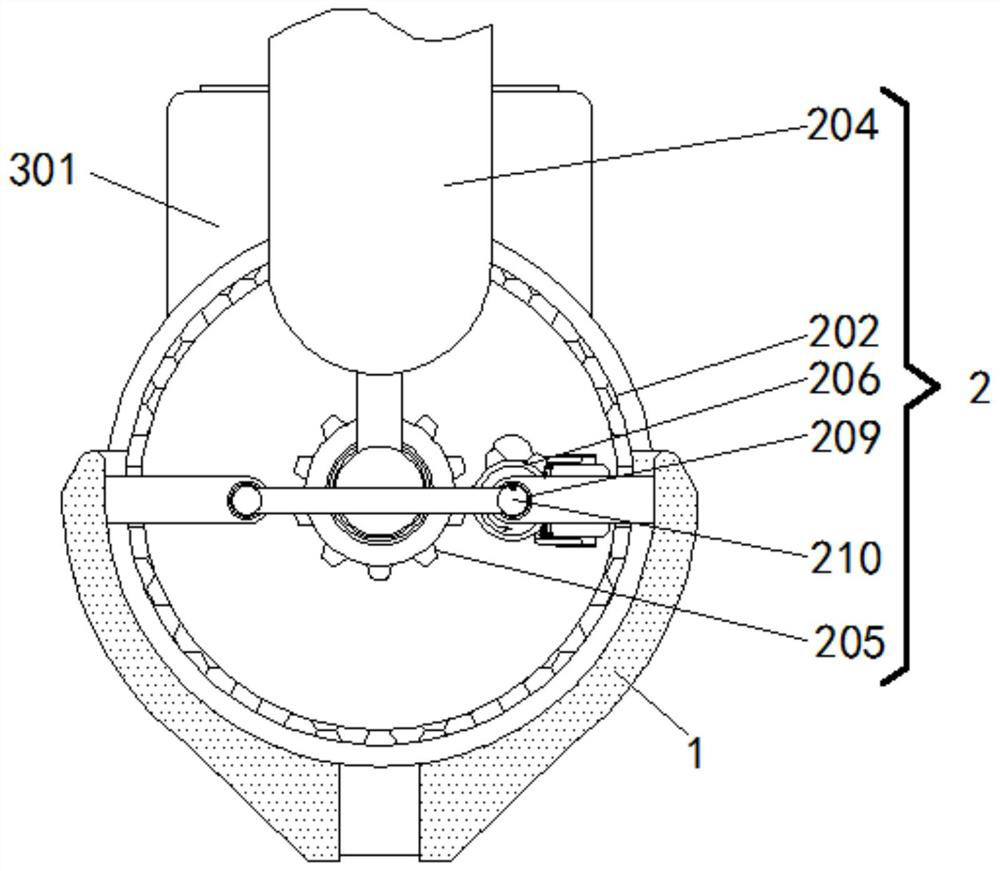

Intermittent rotating separation type drum screen for mining area of coal mine

InactiveCN107377356AImprove practicalityReduce hard-to-improvement situationsSievingScreeningGear wheelEngineering

The invention discloses an intermittent rotating separation type drum screen for a mining area of a coal mine. The intermittent rotating separation type drum screen comprises a bottom plate, mounting plates, a supporting column, a roller, inner cylinders, separation plates, a driving gear, a driven gear and an intermittent driving device. The upper portion of the bottom plate is fixedly connected with a pair of the mounting plates which are arranged in a manner of being parallel to each other. After the roller rotates intermittently every time, a discharge outlet of a feed pipe exactly corresponds to the left ends of the inner cylinders, and raw materials are uniformly scattered in the different inner cylinders. For a traditional overall large drum screen, there still exist the problems that the screening efficiency is affected by too little raw materials and the screening quality is affected by too many raw materials. According to the intermittent rotating separation type drum screen, the raw materials are located in the different inner cylinders, so that the probability of the situation that due to too many raw materials, the raw materials are mutually buried and consequently the screening quality is difficult to improve is reduced. Therefore, the intermittent rotating separation type drum screen improves the screening quality and has good practical effects as well as guaranteeing the screening efficiency.

Owner:陈旭东

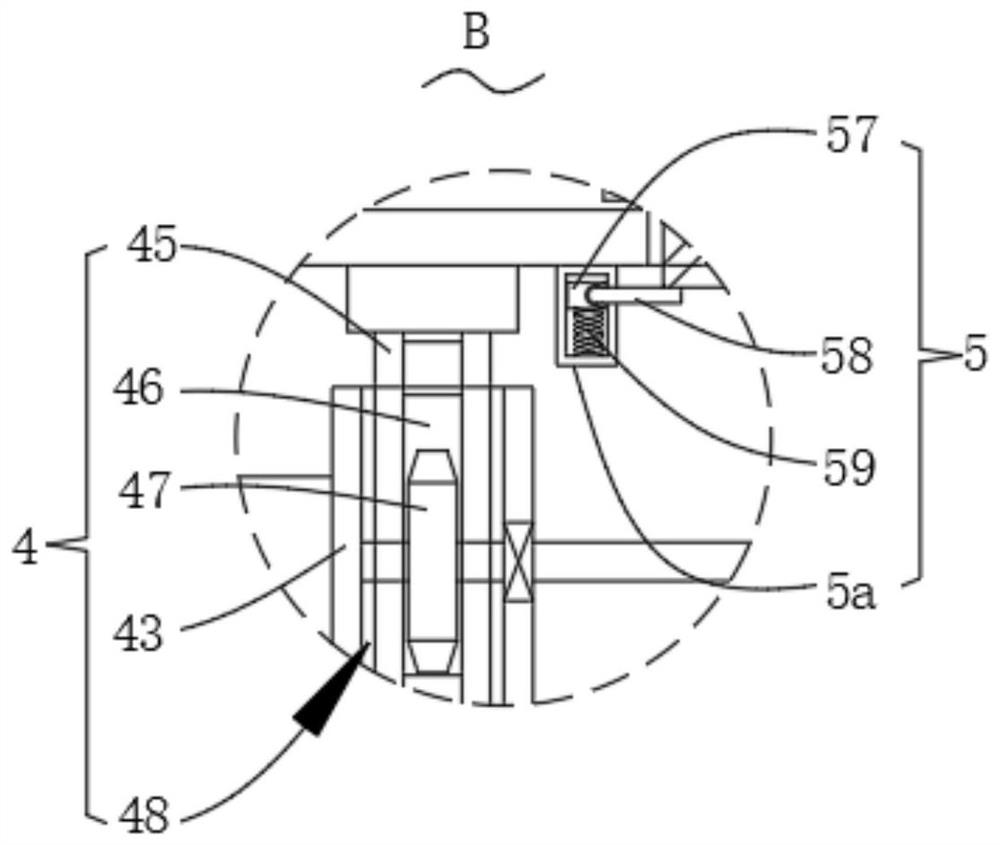

Anti-blocking food raw material refining equipment

The invention discloses anti-blocking food raw material refining equipment. The anti-blocking food raw material refining equipment comprises a processing box, a crushing cylinder is nested in the processing box, a rotating disc is nested in the lower part of the crushing cylinder, and centrifugal material throwing plates which are distributed circumferentially are fixedly connected to the rotatingdisc; the inner wall of the crushing cylinder is fixedly connected with crushing cutters distributed circumferentially, and the lower portion of the crushing cylinder is provided with a grating net in a nested mode. By arranging the crushing cylinder and the rotating disc which rotate reversely, the crushing cutters, the grating net and the centrifugal material throwing plates, food raw materialsare fully crushed and primarily screened; and through the arrangement of a grinding roller, a sieve plate, a blowing pipe staggered with the grinding roller and an air blowing cylinder, continuous blowing cleaning of sieve holes is achieved, and the sieving efficiency of the sieve plate is guaranteed.

Owner:王刚

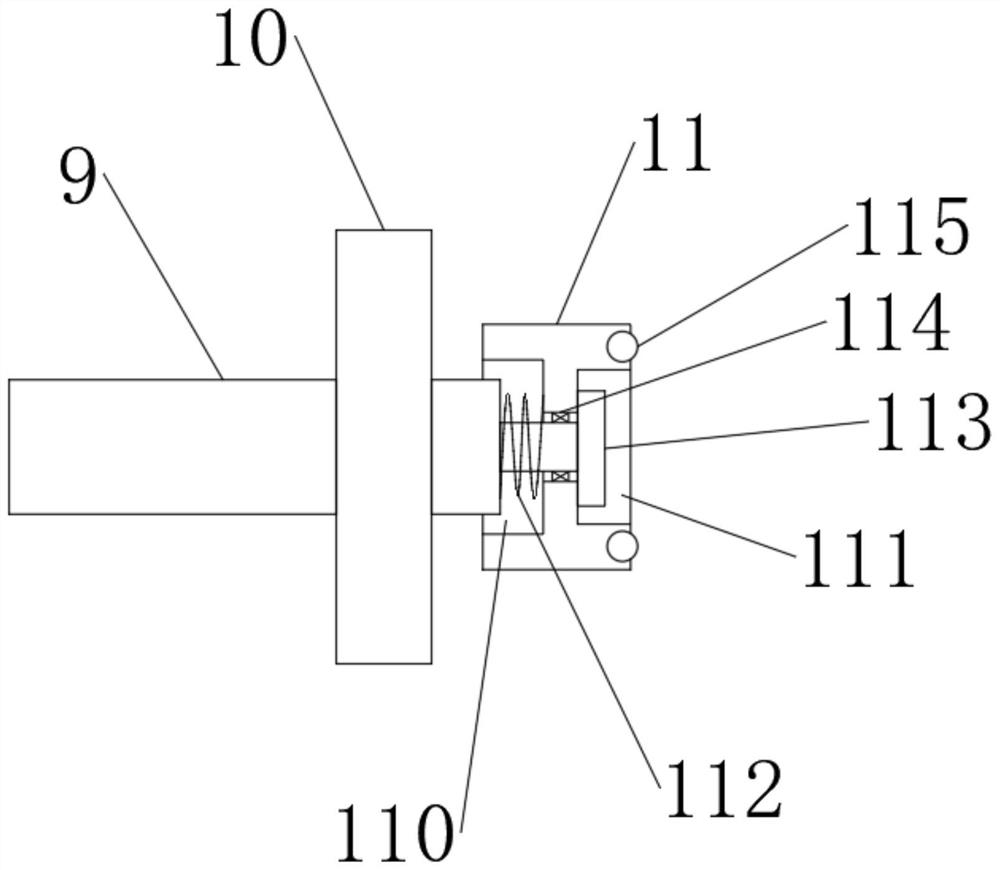

Rotary drum type grain impurity remover

InactiveCN108672295AAvoid cloggingEfficient removalSievingGas current separationAgricultural engineeringFeeding tube

The invention discloses a rotary drum type grain impurity remover. The rotary drum type grain impurity remover comprises a barrel body, a screening barrel and a cyclone dust-collecting barrel, whereinthe screening barrel is arranged in the barrel body; the two ends of the screening barrel are connected with rotary frames through spring sleeves; the center position of the right side of a rotary barrel frame is fixedly connected with a right sleeve; the left side of the right sleeve communicates with a feeding tube through a telescopic tube; and the right sleeve is sleeved with a feeding device. According to the rotary drum type grain impurity remover disclosed by the invention, the screening barrel, the spring sleeves and the rotary frames are arranged, and the screening barrel is used forcentrifugally screening grains to screen out large-particle solid impurities such as stones; and meanwhile, the spring sleeves enable the screening barrel to vibrate within a certain range, so that plug hole blockage is avoided, and screening efficiency is guaranteed. A hollow right rotary drum, a hollow left rotary drum, a spiral inlet roller, blades, a dust collecting cover and a cyclone sedimentation cylinder are arranged, so that feeding is convenient, dust in the grains is efficiently cleared, and screening and impurity-removal effect is good.

Owner:苏锦忠

Screening and drying apparatus for rice seeds

InactiveCN109013041ALarge screening baseImprove cleaning efficiencySeed and root treatmentDrying gas arrangementsWater pipeEngineering

The invention relates to the field of seed drying, in particular to screening and drying apparatus for rice seeds. The screening and drying apparatus for the rice seeds comprises a support and a screening box arranged on the support. A conveying device is arranged on the support. A water conveying device for screening and washing the seeds is also arranged on the support. A screening device is arranged on the screening box. An opening-and-closing device is arranged at the bottom of the screening box, wherein the opening-and-closing device is used for allowing the seeds screened to fall. A drying device is arranged at a lower end of the screening box, wherein the drying device is used for drying the seeds washed. A draining device for draining water is arranged inside the screening box. According to the screening and drying apparatus for the rice seeds, the rice seeds are screened and washed in a large scale; compared with traditional manual screening and washing, the screening cardinalnumber is large; washing efficiency is high; production efficiency is improved; the cost is lowered; and one end of a water conveying pipe is arranged to be a shape with certain radian, influence anddamage caused to the rice seeds due to drainage can be reduced, and screening efficiency and washing efficiency are guaranteed.

Owner:无为县嘉禾稻麦种植专业合作社联合社

Traditional Chinese medicine nursing smashing device and method for hypertension treatment

ActiveCN114733601AAvoid cloggingImprove grinding efficiencySievingScreeningMedicinal herbsNursing care

The traditional Chinese medicine nursing smashing device comprises a first box body and a plurality of supporting legs arranged at the lower end of the first box body, a second box body communicating with an inner cavity of the first box body is arranged in the middle of the upper end of the first box body, and a feeding groove used for feeding is formed in the outer side of the second box body; a feeding groove is formed in the outer side of the first box body, the feeding groove is annularly formed, a filtering ring net used for conducting preliminary screening on medicine is distributed on the outer side of the second box body, a smashing shaft is arranged between the first box body and the second box body, a fourth gear is arranged at the upper end of the smashing shaft, and a steering ring plate is rotationally arranged on the outer side of the upper end of the second box body; the screening device is designed according to existing requirements, medicinal materials can be pre-crushed so that the medicinal materials can be in a state suitable for grinding, the grinding efficiency can be improved, the surface of a screening face can be disturbed while grinding is conducted, reverse blowing operation can be conducted on the lower portion of the screening face, screening blockage is effectively avoided, and the screening efficiency is guaranteed.

Owner:THE CHINESE TRADITIONAL HERB MEDICINE RES INST HENAN PROV

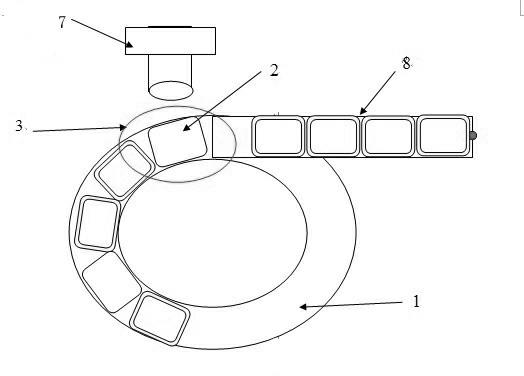

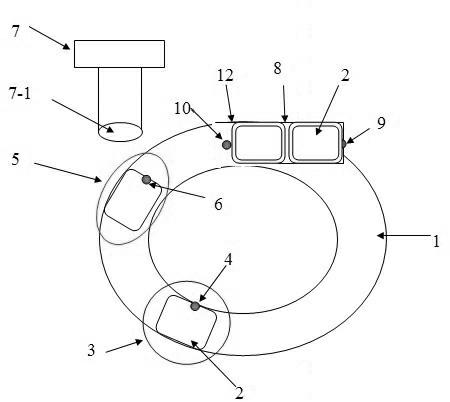

Reverse cover screening system

ActiveCN102435614AExpand the scope of recognitionEasy to identifyOptically investigating flaws/contaminationInductorMechanical engineering

The invention provides a reverse cover screening system which can improve the efficiency of automatically screening reverse covers and well avoids product appearance and performance defects. The reverse cover screening system comprises a vibration plate, wherein the vibration plate is provided with a circular orbit, the tail end of the circular orbit is provided with a pickup orbit, the pickup orbit is a section of straight vibration orbit, and an optical recognition system is positioned in front of the pickup orbit and above the circular orbit. The reverse cover screening system provided by the invention is characterized in that the initial position of the circular orbit is provided with a pre-screening area, a first inductor is arranged in the pre-screening area, the first inductor is positioned at the edge of a cover close to the inner side of the circular orbit, the middle section of the circular orbit is provided with a second inductor, the second inductor is positioned at the frontmost edge of the cover along the advancing direction of the orbit, and an optical lens of the optical recognition system faces the frontmost edge of the cover on the circular orbit along the advancing direction of the orbit.

Owner:RF360 TECH (WUXI) CO LTD

Raw material block grinding and derusting device for mechanical part machining

ActiveCN111805388AAutomatic separationPossibility to stay in touchEdge grinding machinesSievingMechanical componentsEngineering

The invention provides a raw material block grinding and derusting device for mechanical part machining. The raw material block grinding and derusting device for mechanical part machining comprises arectangular box body, a grinding and derusting structure, a material pushing structure, a lifting structure and a waste scrap screening structure. The waste scrap screening structure used for filtering and screening waste scraps generated in the grinding process is connected to the inner bottom of the rectangular box body. The waste scrap screening structure comprises a filter screen, a flat block, a sliding convex block, an L-shaped connecting rod, a vibration spring and a rectangular frame. A rectangular empty groove is formed in the center position of the bottom of the rectangular box body.A filter screen is arranged in a rectangular cavity. The raw material block grinding and derusting device for mechanical part machining has the advantages that screening for leakage can be conductedthrough the aperture of the filter screen, the content of contained rusted waste scrap materials is reduced, the possibility that a grinding ball is always in contact with a mechanical part is increased, the derusting efficiency is improved, waste scraps and grinding mechanical part mixtures can be automatically separated, and convenience is provided for picking ground mechanical parts.

Owner:湖北灿业科技有限公司

High-frequency screening method for vibrating screen

InactiveCN104043588AGuaranteed high screening efficiencyGuaranteed screening efficiencySievingScreeningVibration amplitudeScreening method

The invention discloses a high-frequency screening method for a vibrating screen. A vibration exciter and a vibration system are adopted, the vibration exciter drives a screen surface to make high-frequency vibration through a transmission mechanism, and a screen box is static at the moment; the vibration system works in a near-resonance state, the whole machine is supported through vibration attenuation, so that the ground does not bear dynamic loads basically, the bottom of a screen machine needs a foundation made of high-strength springs, and the foundation is directly installed on the solid and smooth ground or a common steel structure platform; the vibration frequency of the screen surface of the screen machine ranges from 50 Hz to 100 Hz, the vibration amplitude ranges from 0 mm to 2 mm, and the mechanical strength is 8 times to 10 times of the gravitational acceleration. According to the high-frequency screening method for the vibrating screen, holes of the screen surface are not prone to being blocked, the screening efficiency is high, and the handling capacity is high.

Owner:WUXI WEIHAIDA MACHINERY MFG

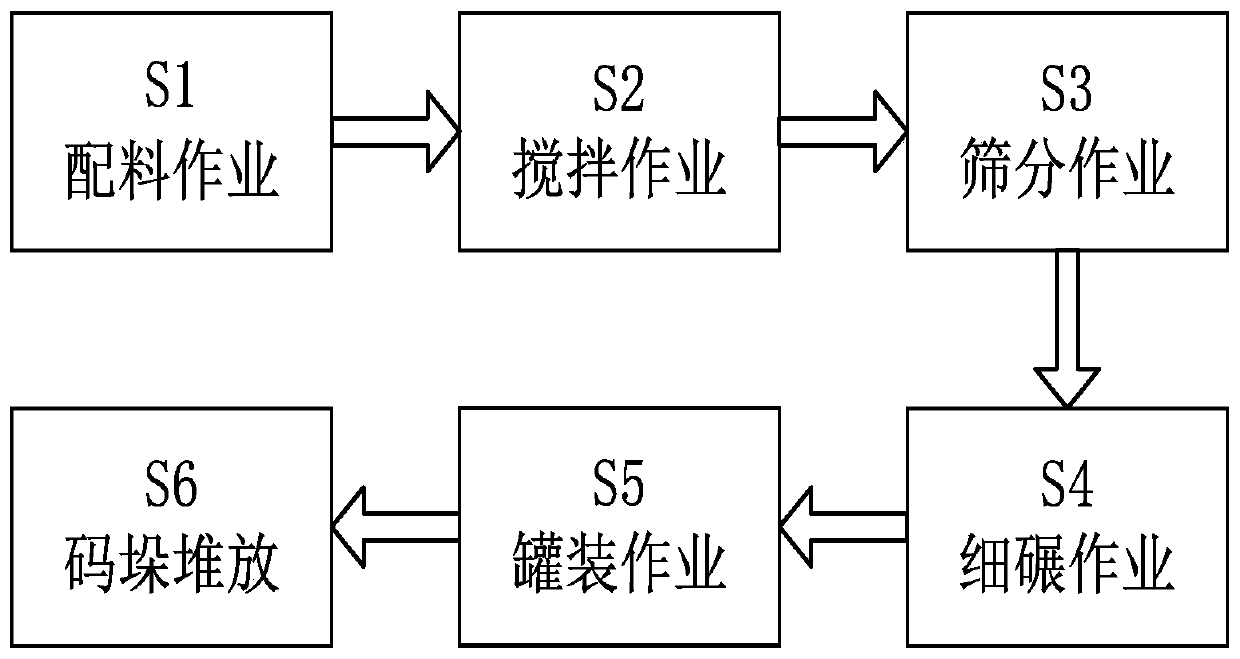

Production and preparation method of anticorrosive coating

ActiveCN110918458AImprove finenessShorten grinding timeSievingScreeningBatch operationCoarse particle

The invention provides a production and preparation method of an anticorrosive coating. According to the production and preparation method of the anticorrosive coating, an anticorrosive coating production device is used. The anticorrosive coating production device comprises a receiving barrel, a screening unit and a grinding unit. A specific method for producing the anticorrosive coating by usingthe anticorrosive coating production device comprises the following steps: S1, carrying out a material batching operation; S2, carrying out a stirring operation; S3, carrying out a screening operation; S4, carrying out a grinding operation; and S5, carrying out a filling operation. The screening unit is mounted on the inner wall of the lower end of the material receiving barrel; the grinding unitis mounted on the outer wall of the screening unit; the screening unit is used for screening an anticorrosive coating which meets a fineness standard; the grinding unit is used for grinding coarse particles failed in passing of screening; the anticorrosive coating is firstly screened; meanwhile, the coarse particles which cannot pass through meshes are ground, so that the anticorrosive coating isaccurately ground; the fineness of the anticorrosive coating is improved; and the grinding time of the anticorrosive coating is reduced.

Owner:东营海瑞宝新材料有限公司

Seed screening and water separating device

InactiveCN109013042AAgitation worksEffective settlementSeed and root treatmentCleaning using liquidsScreening effectSurface mounting

The invention relates to the technical field of seed water separation and screening and discloses a seed screening and water separating device. The device comprises a base, and top of the base is fixedly connected with two symmetric supporting frames. A supporting plate is fixedly connected between the top ends of the two supporting frames, and the front face of the supporting plate is fixedly connected with two symmetric fixed sleeves. A water inlet pipe is sleeved between the inner rings of the two fixed sleeves, and spray heads are mounted on the outer surface of the water inlet pipe at equal intervals. A fixed plate is fixedly connected between the opposite side faces of the two supporting frames. The bottom of the fixed plate is fixedly connected with a motor and two supports. An output shaft of the motor is fixedly connected with a first belt wheel through a rotary shaft, and a rotary rod is movably connected between the side faces of the two supports. The seed screening and water separating device solves the problems that an existing seed water separation device is not high in work efficiency, seed separation is not thorough, trouble is caused, and labor is wasted, and has the beneficial effects of being high in work efficiency and good in screening effect and saving trouble and labor.

Owner:合肥安农源生物工程技术有限公司

Coal screening system device based on big data and screening method thereof

PendingCN113385256AGuaranteed uniformityGuaranteed screening efficiencyGrain treatmentsControl signalProcess engineering

The invention provides a coal screening system device based on big data and a screening method thereof. In the coal processing direction, the system device comprises a pre-screening device, a crushing device and a screening device which are sequentially connected through a conveying belt; the system device further comprises a detection device, a control device and a data processing device, the detection device comprises a particle size analyzer, and the control device receives a detection signal sent by the particle size analyzer and feeds back and controls the screening speed of the pre-screening device, the crushing particle size of the crushing device and the screening speed of the screening device; and the data processing device records the detection signal received by the control device and a control signal sent by the control device, and feeds back and adjusts control parameters of the control device. The particle size distribution of coal at each stage is detected, and the data processing device is combined with the control device to adjust the parameters of the pre-screening device, the crushing device and the screening device, so that the screening particle size and the screening efficiency are ensured, and the coal screening system device has the characteristics of high stability, high efficiency, high reliability and the like.

Owner:中滦科技股份有限公司 +1

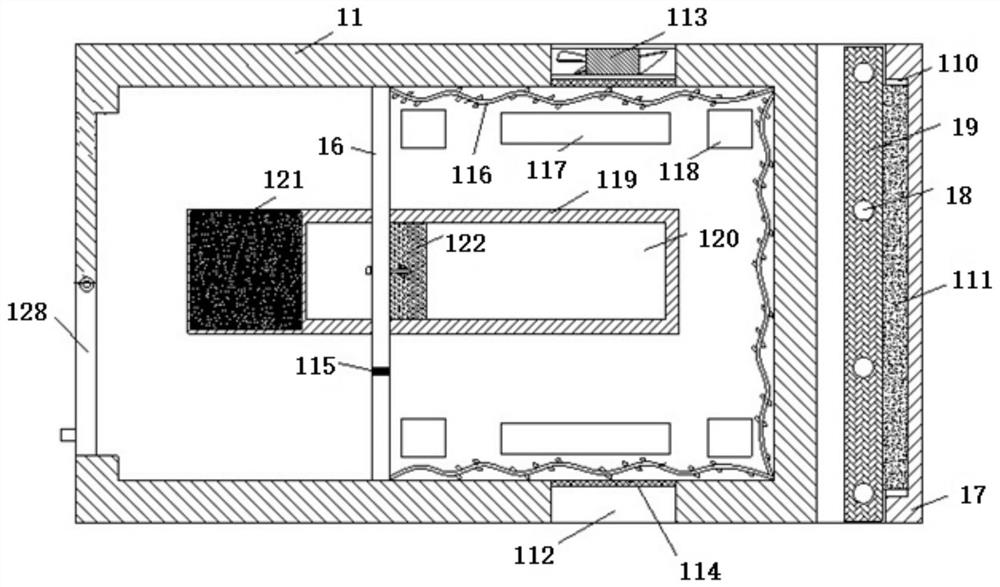

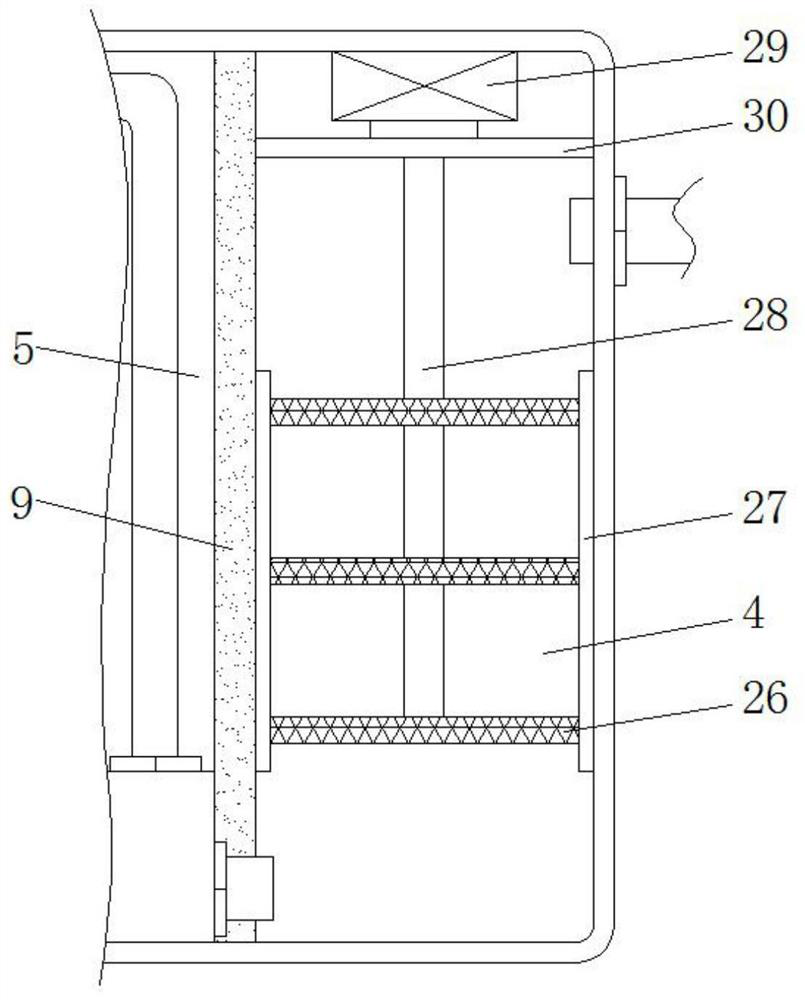

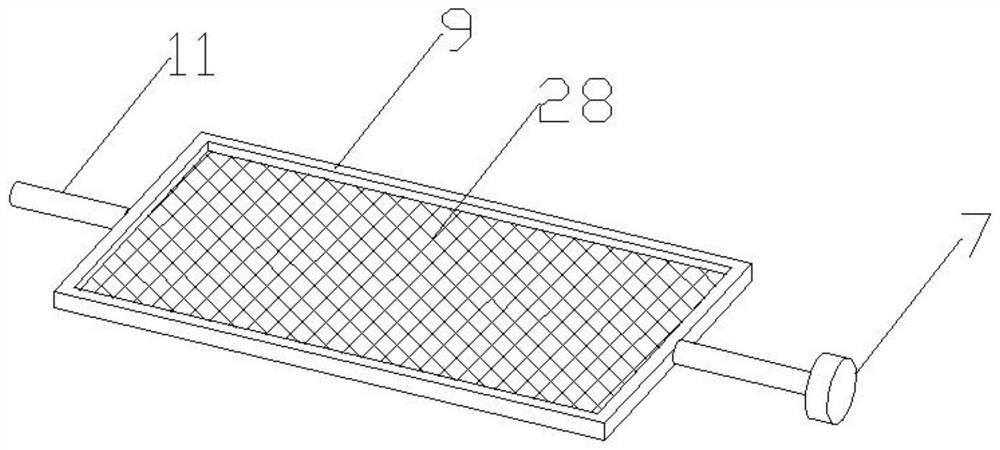

Internet of Things aquarium circulating water purifying device and purifying method thereof

InactiveCN112167144AGuaranteed screening efficiencyAvoid cloggingPisciculture and aquariaSewageOxygen enhanced

The invention discloses an Internet of Things aquarium circulating water purifying device and a purifying method thereof, and relates to the technical field of aquarium purifying devices. The Internetof Things aquarium circulating water purifying device comprises an aquarium and a purifying box, wherein a physical purifying cavity, a biological purifying cavity and an oxygen conveying cavity areformed in the purifying box, a booster water pump is fixedly installed at the bottom of the oxygen conveying cavity, the oxygen conveying cavity communicates with the aquarium, meanwhile, an extraction pump is arranged on the outer wall of the aquarium, the extraction pump communicates with the physical purifying cavity, sewage in the aquarium is guided into the physical purifying cavity in the purifying box through the extraction pump, the physical purifying cavity physically purifies the sewage, the physically purified water is guided into the biological purifying cavity through a first conveying cavity, the biological purifying cavity biologically purifies the sewage, toxic and harmful substances such as ammonia and hydrogen chloride in the sewage are filtered out, purified water is guided into the oxygen conveying cavity through a second conveying cavity, oxygen is guided into the water through the oxygen conveying cavity, oxygenated clear water is guided into the aquarium throughthe booster water pump, and purifying of aquaculture water is achieved.

Owner:NANJING NIEBO INTERNET OF THINGS TECH CO LTD

Screening device for snake gourd seed processing

ActiveCN113245182AGuaranteed screening efficiencyGuaranteed screening effectSievingScreeningAgricultural engineeringStructural engineering

The invention discloses a screening device for snake gourd seed processing. The screening device comprises a bottom plate, a feeding hopper is arranged on the vertical upper portion of the bottom plate, a first supporting column is arranged between the feeding hopper and the bottom plate, the outer edge of the bottom end of the feeding hopper is fixedly connected with an inclined rail surrounding ring, and the outer side of the inclined rail surrounding ring is sleeved with a material blocking inclined sleeve. A through hole is formed in the bottom of one end of the material blocking inclined sleeve and fixedly communicates with a discharging pipe, a first rotating seat and a second rotating seat are arranged between the bottom plate and the feeding hopper, a first rotating part and a second rotating part are rotationally installed in the first rotating seat and the second rotating seat correspondingly, and a top sieve plate is arranged between the first rotating part and the second rotating part. A material guide bottom plate is mounted at the bottom of the top sieve plate. According to the screening device, the screening efficiency and the screening effect of snake gourd seeds are guaranteed, the production efficiency is improved, manpower is saved, the structure is simple, the design is reasonable, the mechanism is ingenious, the linkage performance is high, and the use requirements of people in production and life are met.

Owner:安徽趣健乐食品科技有限公司

A screening and drying device for metal powder

ActiveCN108889608BTo achieve the screening effectRealize quantitative screeningSievingRotary stirring mixersElectric machineStructural engineering

The invention discloses a sieving and drying device for metal powder, which comprises a hot air blower, a powder sieving box, a material distribution box and a dispersion box. Conical mixing drum, the main shaft of the second motor is provided with a stirring shaft, the lower end of the conical mixing drum is provided with a feeding pipe, the lower end of the feeding pipe is connected with the distribution box, and the feeding pipe is provided with Control valve, a runner is provided in the distribution box, two grooves are symmetrically arranged on the runner, a mounting seat is provided on the side of the upper end of the powder sifting box, and a motor 1 is provided on the mounting seat. The main shaft of the motor is provided with an eccentric wheel, the powder sieving box is provided with a screen frame, the inside of the screen frame is provided with a screen, the bottom of the powder screening box is provided with a bracket, and the upper end of the bracket is provided with a Recycling box, this device realizes the quantitative screening of powder, ensures the screening effect and efficiency of the screen, the powder after processing by this device contains less impurities, and the powder has low water content.

Owner:芜湖市晨睿建材有限公司

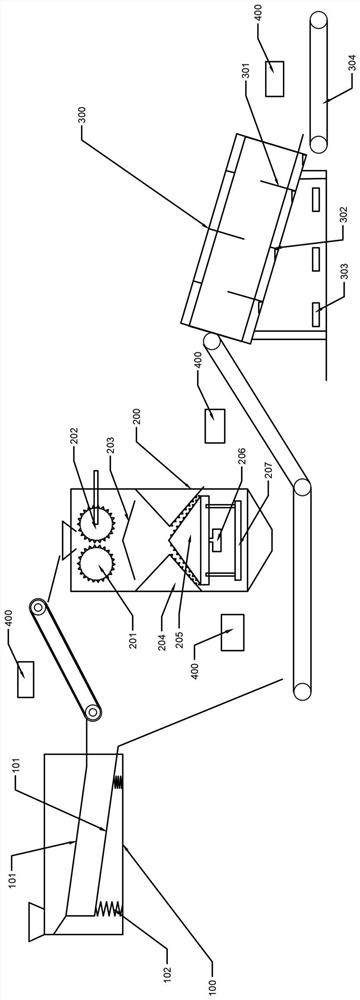

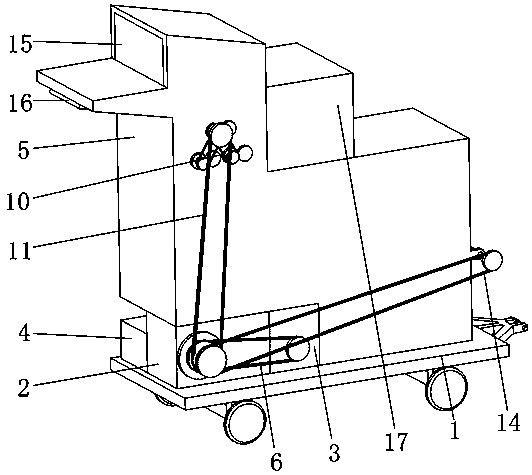

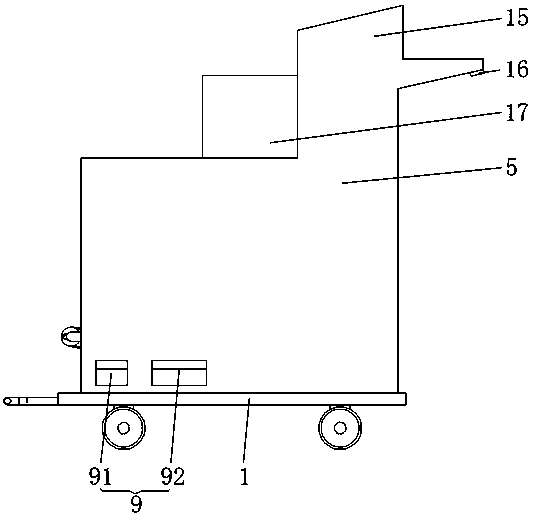

Biomass fuel preparation pretreatment device

ActiveCN111437916AImprove qualityGuaranteed fuel efficiencyDrying gas arrangementsGrain treatmentsDieselingEnvironmental engineering

The invention discloses a biomass fuel preparation pretreatment device. The biomass fuel preparation pretreatment device comprises a towing bracket. A micro diesel engine, a generator, a storage battery and a pretreatment box are arranged on the top of the towing bracket. A flywheel belt disc of the micro diesel engine is connected with a connecting belt pulley of the generator in a transmission mode through a first belt. A smashing chamber, a drying channel and a discharging chamber are formed inside the pretreatment box. A smashing device is arranged between the two opposite sides of the inner wall of the smashing chamber. Electric heating blocks are arranged on the front side and the rear side of the drying channel, and a material conveying device is arranged inside the drying channel.The invention relates to the technical field of biomass fuel. The biomass fuel preparation pretreatment device solves the problems that an existing raw material pretreatment device which adopts a smashing machine to smash and process raw materials only has a smashing effect and cannot remove soil or gravel and water in raw materials, specifically, the soil or the gravel and the water do not generate the heat, stacking storage is not facilitated, and the combustion efficiency of the biomass fuel is reduced.

Owner:东台市程骏能源环境科技有限公司

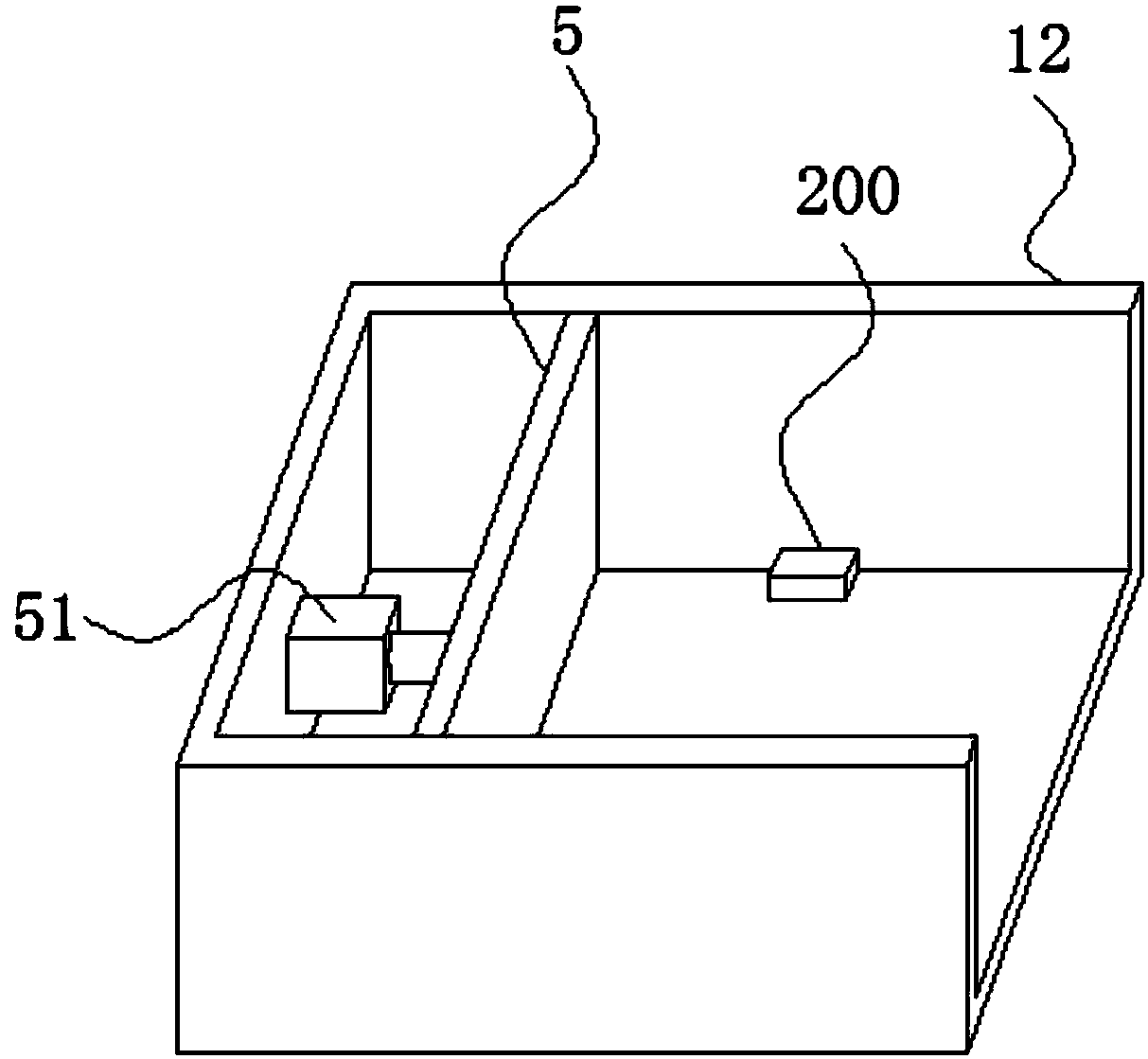

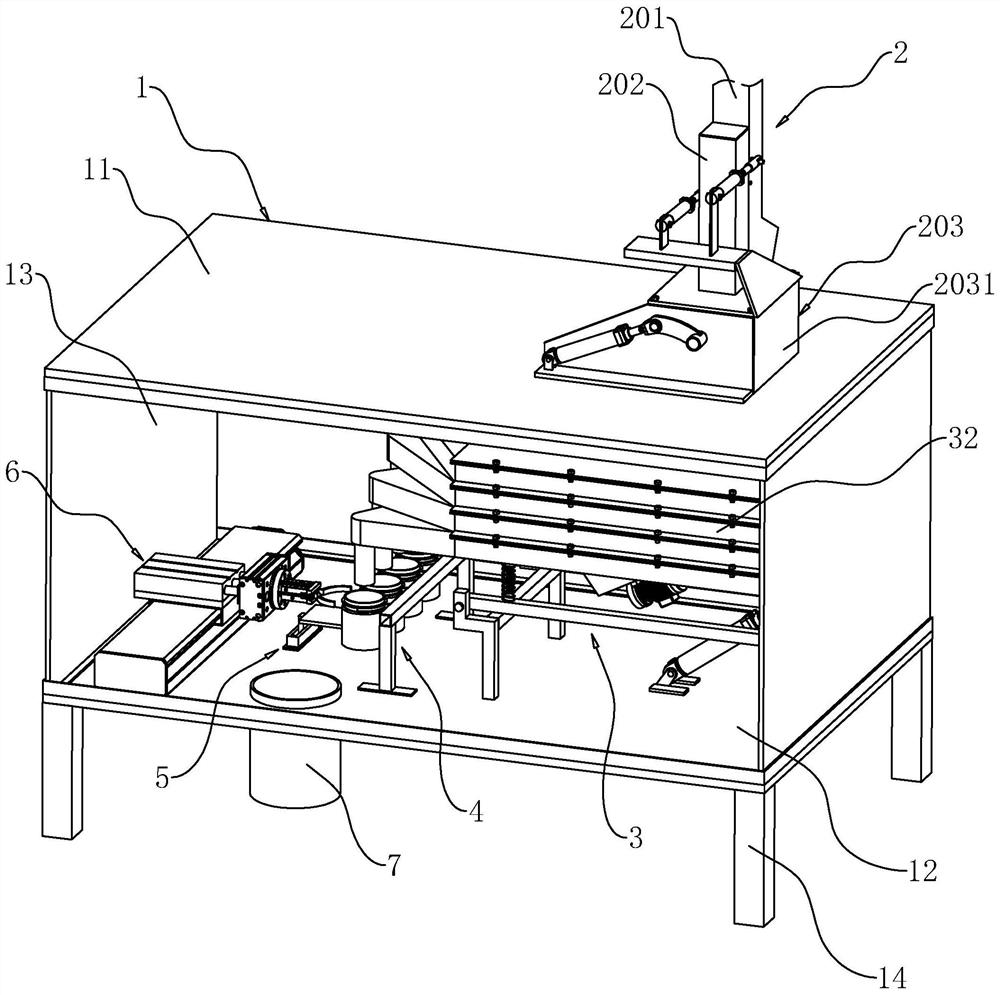

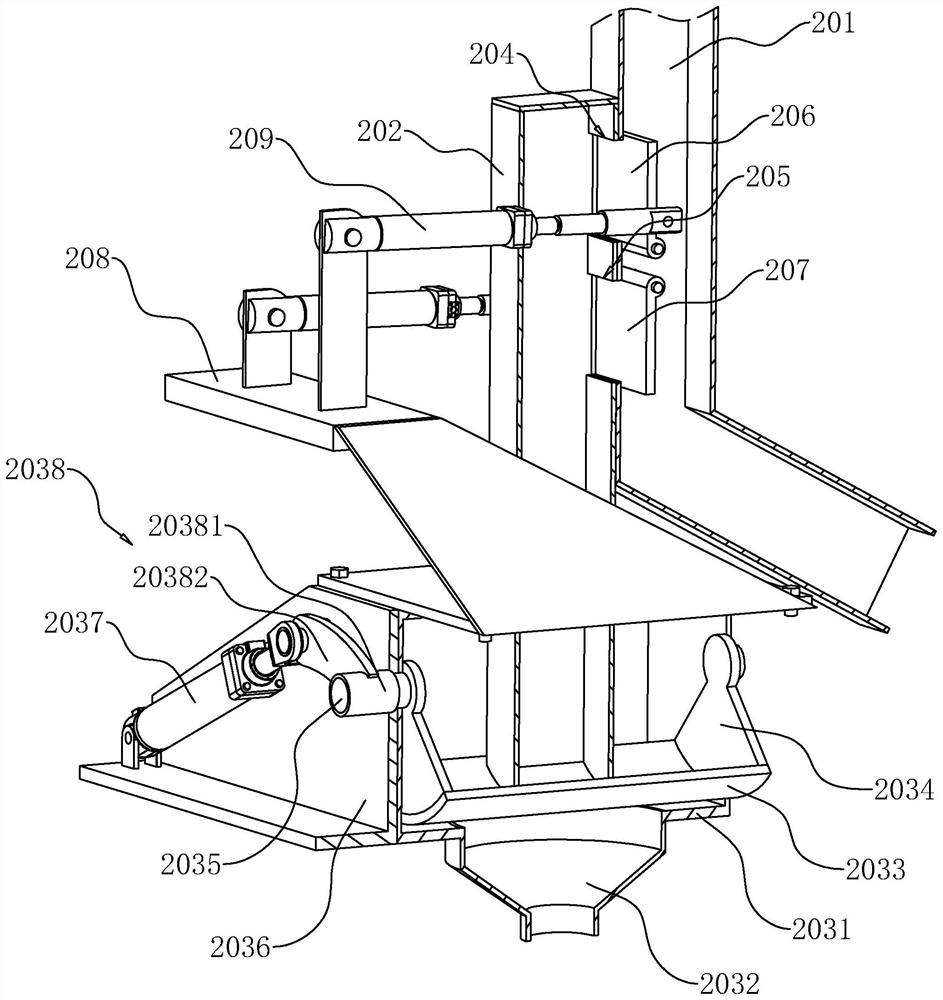

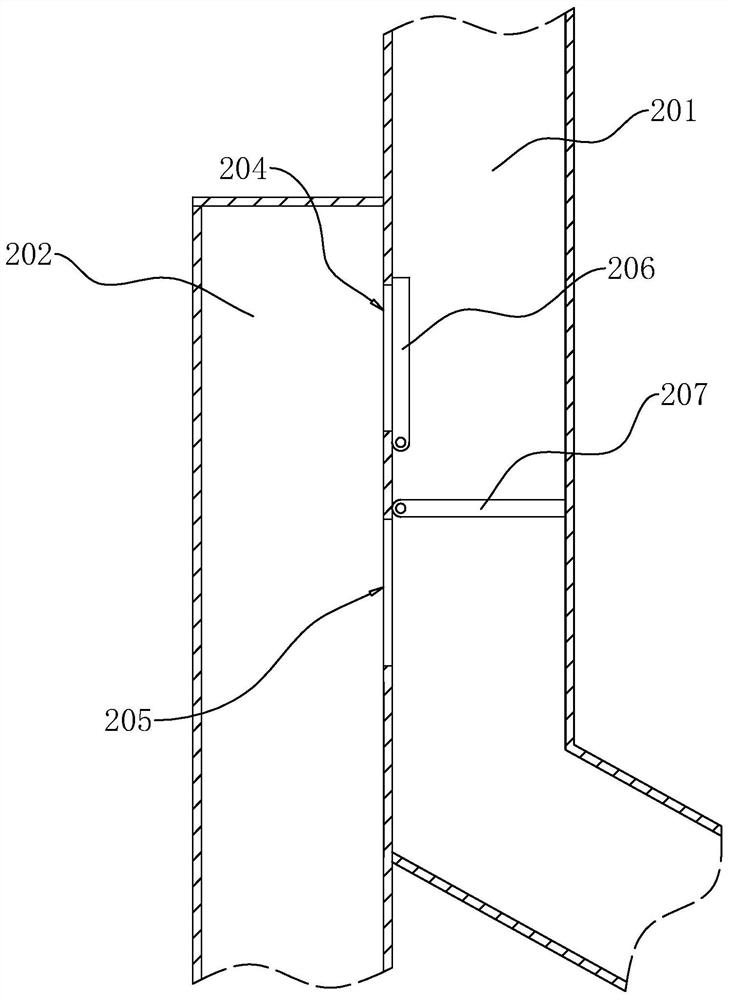

Scattering type high efficiency sand screening device

The invention discloses a scattering type high efficiency sand screening device. The scattering type high efficiency sand screening device comprises a car body; a crawler is arranged under the car body; the left side of the car body is hinged to rotating shafts through a first hinge shaft, a first driving shaft is rotatably connected between the rotating rods, the first driving shaft is fixedly connected with a circumferentially distributed throwing plate, and a guiding cover is arranged above the throwing plate. The guiding cover extends into the car body, and the inner wall of the guiding cover is evenly distributed with conical teeth; the car body is provided with a screen plate. Coarse sand is scattered by means of a throwing plate and a guiding cover, and sand blocks are initially broken by the conical teeth, later screening is convenoent and the screening efficiency is improved; an eccentric roller and a screen plate are arranged so as to vibrate the screen plate up and down, ensure the screening efficiency and avoide the blockage of a screen hole.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

Asphalt concrete quality monitoring method and equipment thereof

ActiveCN113740193AReduce transportationGuaranteed screening efficiencySolid waste managementMaterial testing goodsQuality monitoringGeotechnical engineering

The invention relates to an asphalt concrete quality monitoring method and equipment. The method comprises the following steps: acquiring a sample, and collecting sand grains screened out in an asphalt concrete production process; screening sand grains, and screening the sand grains into materials with different particle size ranges; weighing the materials, and obtaining the weights of the materials in different particle size ranges through weighing; calculating the numerical value to obtain the proportion of the materials in different particle size ranges in the total sample amount; comparing the numerical values, comparing the proportions of the materials in different particle size ranges in the total amount of the sample with a qualified range, and when the proportion of the material in at least one particle size range in the total amount of the sample exceeds the qualified range or is lower than the qualified range, remaining the produced asphalt concrete in an asphalt concrete plant to wait for reprocessing; and when the proportions of the materials in different particle size ranges in the total amount of the obtained sand grains are all within the qualified range, allowing the asphalt concrete to be transported out of a factory. The method has the effect that the situation that unqualified asphalt concrete is transported out of a factory after being produced is reduced.

Owner:北京路新沥青混凝土有限公司

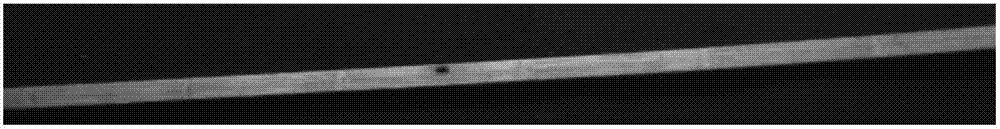

A method for detecting surface defects of bamboo strips based on computer vision

ActiveCN105158258BGuaranteed screening efficiencyGuaranteed screening qualityImage enhancementGeometric image transformationMethod of imagesMildew

The invention is a method for detecting defects on the surface of bamboo strips based on computer vision. The bamboo strip image is normalized, filtered and wavelet transformed; the maximum inter-class variance method is used to segment the image threshold, and the closed operation is used to fill the holes in the bamboo strip image, and then The negative effect of the closing operation is removed by the corrosion operation, and the wormhole and / or mildew defect in the bamboo strip image is segmented by the difference shadow method. If the area of the connected domain of the defect is smaller than the threshold A of the defect domain area, it is considered that there is no mold or wormhole defect. , enter the crack detection; otherwise, calculate the average gray value Gm of the defective connected domain image, if the difference between Gm and the average gray value G0 of the bamboo strip image is greater than the threshold G, there will be mold spots or wormholes, and it will be judged as a defective bamboo strip; otherwise, detect edges and cracks, Remove the bamboo edge of the image, if the total number of non-zero pixels or the length of the maximum connected domain is greater than the corresponding threshold, and the average gray value of the crack is greater than G0, it is determined that there is a crack defect, otherwise it is qualified. The method has high detection efficiency, strong noise resistance and high stability, and the correct recognition rate reaches over 95%.

Owner:GUANGXI NORMAL UNIV

An agricultural planting seed screening device capable of conveniently and quickly discharging residues

ActiveCN110899090AGuaranteed screening effectGuaranteed screening efficiencySievingSeed and root treatmentAgricultural engineeringPlanting seed

The invention particularly discloses an agricultural planting seed screening device capable of conveniently and quickly discharging residues. The device comprises a screening barrel. A supporting screw rod is rotationally arranged in the screening barrel along the central axis of the screening barrel; a filter screen arranged in the screening barrel in an up-and-down sliding manner is in threadedconnection with and sleeves the supporting screw rod through a supporting threaded sleeve located in the middle of the filter screen; a supporting block fixedly sleeves the supporting threaded sleeve;the supporting block is connected with the middle of the filter screen through an elastic supporting piece; the bottom end of a rotating column is rotatably connected with the top end of the supporting screw rod; at least one arc-shaped material stirring rod is fixedly mounted on the outer ring of the bottom of the rotating column; and the concave surface of the arc-shaped material stirring rod faces the direction opposite to the rotating direction of the rotating column. According to the embodiment of the invention, the screening effect of the filter screen can be ensured by virtue of the liftable filter screen and the started vibration motor, and the waste residues on the upper surface of the filter screen can be continuously pushed to move towards the outer ring by virtue of the rotating arc-shaped material stirring rod, so that the filtered residues can be conveniently discharged out of the screening barrel.

Owner:株洲香之优农业科技发展有限责任公司

Powder vibrating screen

ActiveCN108043712APrevent splashShort contact distanceSievingScreeningScreening proceduresElectric machinery

The invention discloses a powder vibrating screen. The powder vibrating screen comprises a feeding device, a screening device, a driving device and a cushioning device. The area of a top opening of abuffer hopper is larger than that of a bottom opening of the buffer hopper. The buffer hopper is arranged above a feeding inlet. The axis of the buffer hopper coincides with that of the feeding inlet.A feeding slide door penetrates through the feeding inlet in the horizontal direction and further extends out of the feeding inlet. The buffer hopper is in an inverted pyramid shape. Materials can slide into the feeding inlet along the oblique plane of the buffer hopper, and the phenomenon of material splashing caused when the materials are directly poured into the feeding inlet in the vertical direction of the bottom of the feeding inlet is avoided. The feeding slide door plays the effects of opening the feeding inlet and adding the materials, and meanwhile the effects of closing the feedinginlet and preventing the materials from splashing in the screening operation process can be achieved. The screening process of the coarse powder material and the screening process of the fine powdermaterial are both driven by a driving motor, so that screening efficiency is guaranteed, the screening procedure is omitted and the applied range is made wider.

Owner:湖南太子新材料科技有限公司

Sand screening device for constructional engineering

ActiveCN112387576APrevent leakageAvoid stickingSievingScreeningClassical mechanicsStructural engineering

The invention discloses a sand screening device for constructional engineering, relates to the technical field of constructional engineering, and mainly solves the problems that a sand screening device used in existing constructional engineering is not thorough in screening in the using process, and residual impurities are inconvenient to clean. The device comprises a base, wherein supporting columns are arranged on the base and are connected with a mounting base; a conveying belt is arranged on the mounting base; a top plate is arranged above the base; screen drums are arranged on the lower side of the top plate and are installed in a rolling mode through rolling wheels; screens are arranged on the side walls of the screen drums; connecting rods are arranged between the screen drums; thescreens are arranged between the connecting rods and the screen drums; outer gear rings are arranged in the middles of the screen drums; a power device is arranged in the middle of the top plate; theouter gear rings are connected with the power device; a first conveying belt is installed in the screen drums in a suspended mode; and a second conveying belt is arranged at the bottoms of the left sides of the screen drums.

Owner:喀什市新隆建设(集团)有限责任公司

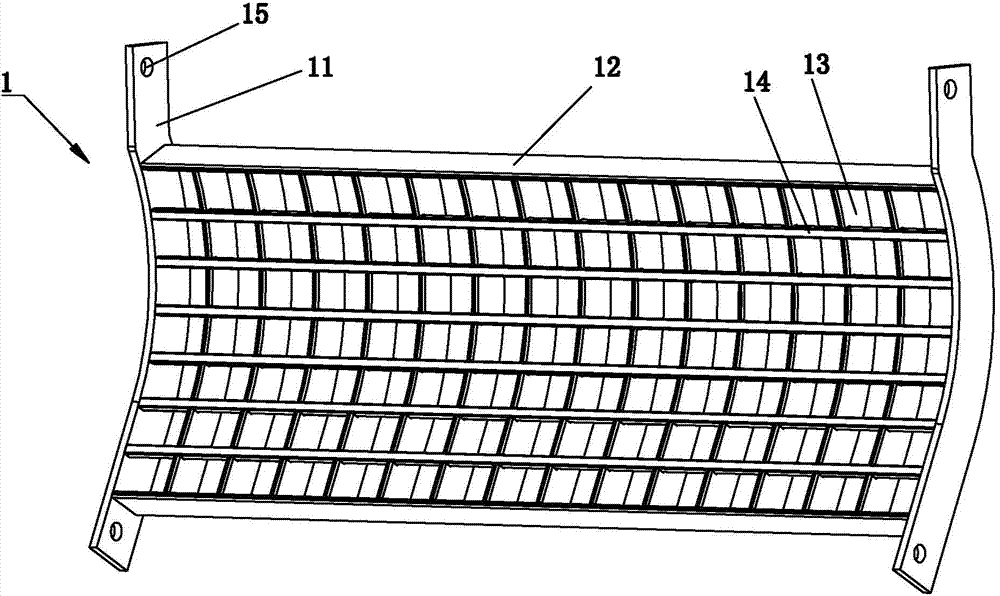

Large-substance sorting system for food waste

ActiveCN110152838AGuaranteed screening efficiencyReduce cloggingGrain treatmentsGratingMechanical engineering

The invention discloses a large-substance sorting system for food waste. The large-substance sorting system comprises a sorting mechanism, wherein the sorting mechanism comprises a screen, a sorting assembly, a rotary transmission assembly which is in transmission connection with the sorting assembly, and a driving assembly which is in transmission connection with the rotary transmission assembly;the sorting assembly comprises a swing shaft which is in transmission connection with the rotary transmission assembly, and stirring paddles which are arranged on the swing shaft; the screen is an arc-shaped grating plate, is obliquely arranged, and comprises a first supporting piece, a second supporting piece, a plurality of grating holes, a plurality of arc-shaped spacing plates and a pluralityof straight rods, the two ends of the arc-shaped spacing plates are connected with the first supporting piece and the second supporting piece, each straight rod penetrates through the plurality of arc-shaped spacing plates, and the grating holes are composed of the arc-shaped spacing plates and the straight rods; and swinging arcs of the stirring paddles are parallel to extension lines of the arc-shaped spacing plates, and round tubes are rotationally arranged on the parts, forming the grating holes, of the straight rods in a sleeve mode. The large-substance sorting system has the advantagesthat the high screening purity of large substances is achieved, the screening efficiency is high, and the screen is not easy to block.

Owner:SUZHOU JONO RECYCLING RESOURCES EQUIP

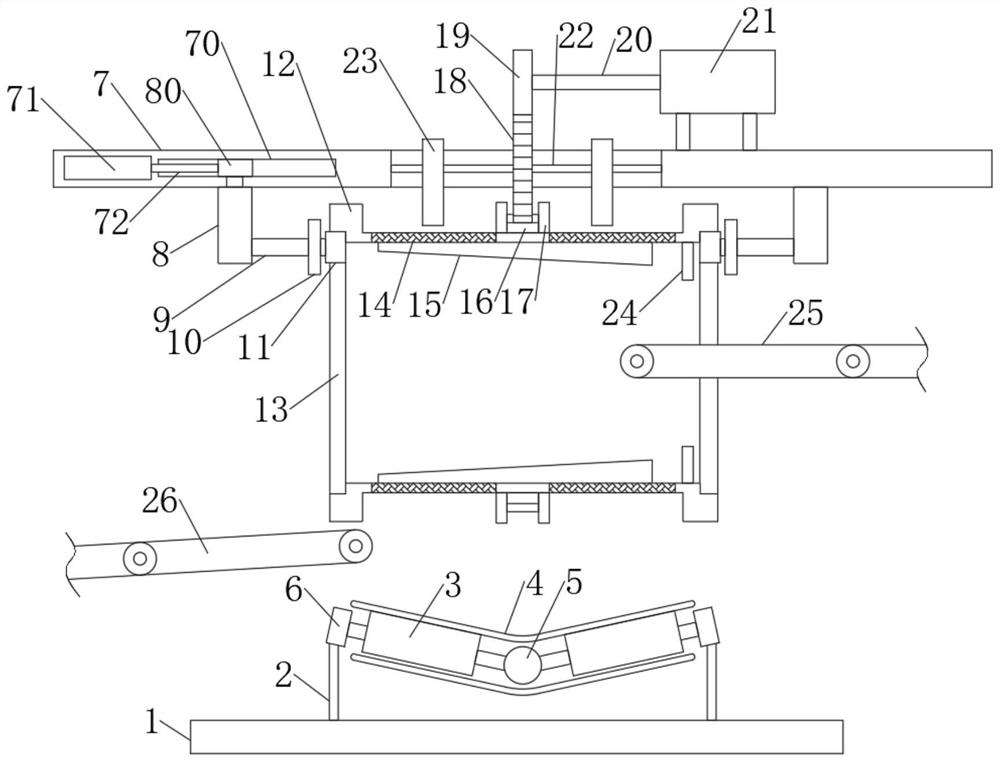

Portable screening machine

ActiveCN102896088AGuaranteed screening efficiencyNot easy to damageSievingScreeningEngineeringPerpendicular direction

The invention relates to a portable screening machine. The portable screening machine is provided with a supplied material screening device, wherein the supplied material screening device is provided with a left mounting guide plate and a right mounting guide plate; a first screen bracket is obliquely mounted at the tops of the left mounting guide plate and the right mounting guide plate; a second screen bracket and a screening table form a certain angle relative to a horizontal direction or in the horizontal direction; a third screen bracket and the screening table form a certain angle relative to a perpendicular direction or in the perpendicular direction; a fourth bracket is positioned between opposite connecting ends of the first screen bracket and the second screen bracket; a first screen can be mounted on the first screen bracket; a second screen can be mounted on the second screen bracket; a third screen can be mounted on the third screen bracket; screen holes of the first screen are larger than those of the second screen; and screen holes of the second screen are larger than those of the third screen. The portable screening machine can be used for mounting screens with different sizes to prevent ultra-large materials from entering the screening table, so that the damage of the screening machine can be alleviated.

Owner:KANGFEI AUTOMATION TECH CO LTD

Modified limestone powder dry grinding and screening equipment

InactiveCN113731560AImprove the overall processing effectAvoid severe blockageSievingScreeningManufacturing engineeringSieve

The invention relates to the technical field of limestone, and discloses modified limestone powder dry grinding and screening equipment. The equipment comprises a base, wherein the upper end of the base is movably connected with a dry grinding mechanism; the dry grinding mechanism comprises a shaft pipe; the shaft pipe is rotationally sleeved with an iron screen drum; the lower end of the shaft pipe is rotationally connected with a grinding roller extending to the inner wall of the iron screen drum; the position, at the upper end of the shaft pipe, of the front side of the iron screen drum is fixedly connected with a material box; and the front end of the iron screen drum is fixedly connected with a gear ring. According to the modified limestone powder dry grinding and screening equipment, the grinding roller is designed at the bottom of an inner cavity of the iron screen drum, an E-shaped rod is matched, the shaft pipe located at the upper side of the grinding roller is used for intermittent feeding, a convex half gear is used for driving the gear ring to rotate intermittently, an intermittent compression mechanism of a compression joint bag is matched, and then a knocking rod can knock the top of the iron screen drum intermittently, so that materials blocking sieve holes are vibrated off in time, the overall processing effect of the equipment is effectively improved, and the screening efficiency of the materials is guaranteed.

Owner:怀化明达建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com