Anti-blocking food raw material refining equipment

An anti-clogging, food technology, used in chemical instruments and methods, solid separation, sieves, etc., can solve problems such as sieve blockage, reduced production efficiency, processing interruption, etc., to ensure the effect of screening efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

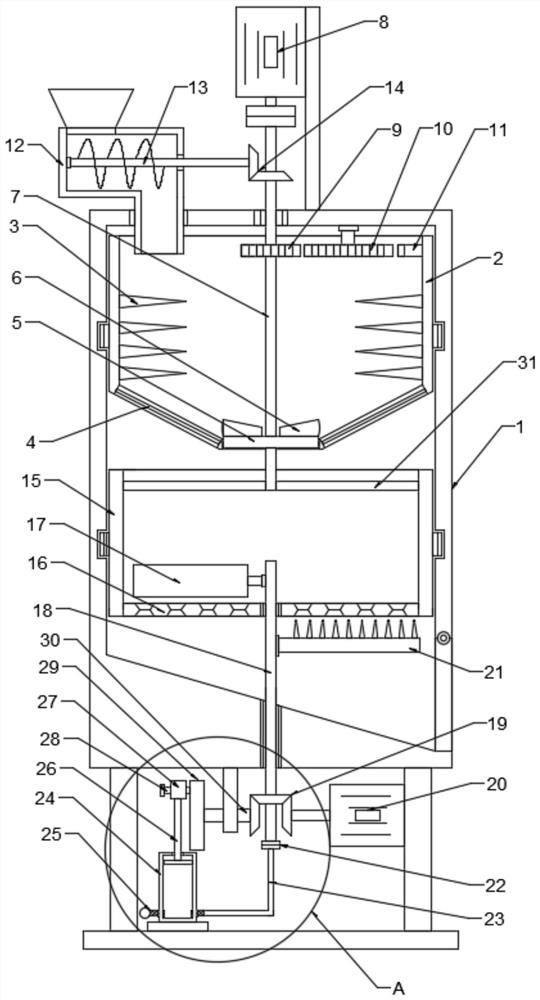

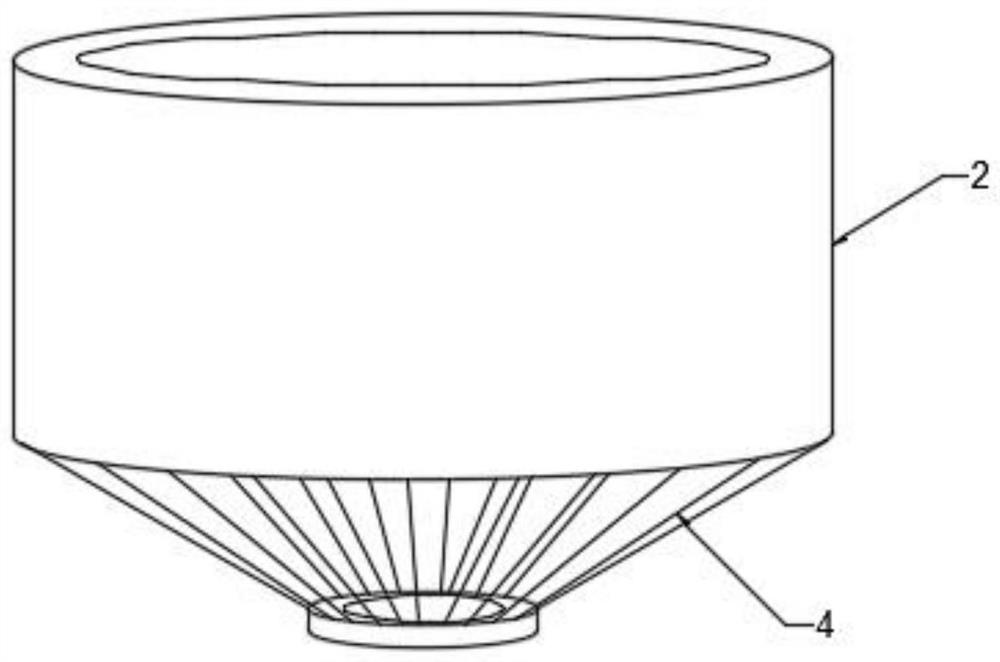

[0021] see Figure 1-5 , in the embodiment of the present invention, an anti-clogging food raw material refinement equipment includes a processing box 1; a crushing cylinder 2 is nested in the processing box 1, and the crushing cylinder 2 is rotationally connected with the inner wall of the processing box 1 through a bearing; The lower part of the crushing cylinder 2 is nested with a rotating disk 5, and the rotating disk 5 is fixedly connected with centrifugal throwing plates 6 distributed in a circle. The rotating disk 5 is fixedly connected with a first rotating shaft 7, and the first rotating shaft 7 extends to the top of the processing box 1. The output shaft of the first motor 8 is connected through a coupling, and the first motor 8 drives the rotating disk 5 to rotate; the inner wall of the crushing cylinder 2 is fixedly connected with pulverizing knives 3 distributed in a circle, and the lower part of the crushing cylinder 2 is in the shape of a circular table , the lo...

Embodiment 2

[0025] The difference between this embodiment and Embodiment 1 is that: in order to make the degree of refinement higher; a grinding cylinder 15 is provided below the crushing cylinder 2, and the grinding cylinder 15 is fixedly connected with the first rotating shaft 7 through a fixed rod 31, and the first rotating shaft 7 Drive the grinding cylinder 15 to rotate; the bottom of the grinding cylinder 15 is fixedly connected with a sieve plate 16, the upper end surface of the sieve plate 16 is abutted with a grinding roller 17, and the grinding roller 17 is rotatably connected with a second rotating shaft 18, which extends to the processing box 1 below and connected to the output shaft of the second motor 20 through the second transmission bevel gear set 19; the second motor 20 drives the grinding roller 17 to make a circular motion through the second rotating shaft 18, and the direction of the grinding roller 17's circular rotation is the same as that of the grinding cylinder 15....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com