Split type rotary drum pulping device

A split-drum technology, applied in the separation of raw materials, textile and papermaking, fiber raw material processing, etc., can solve the problems of low pulp quality and screening efficiency, difficult equipment processing and manufacturing, hoisting, transportation, installation and debugging, and the inability to meet the requirements of crushing at the same time. The requirements of pulp process and screening process, etc., can enhance the strength of impact resistance, solve processing and manufacturing, and achieve the effect of smooth flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

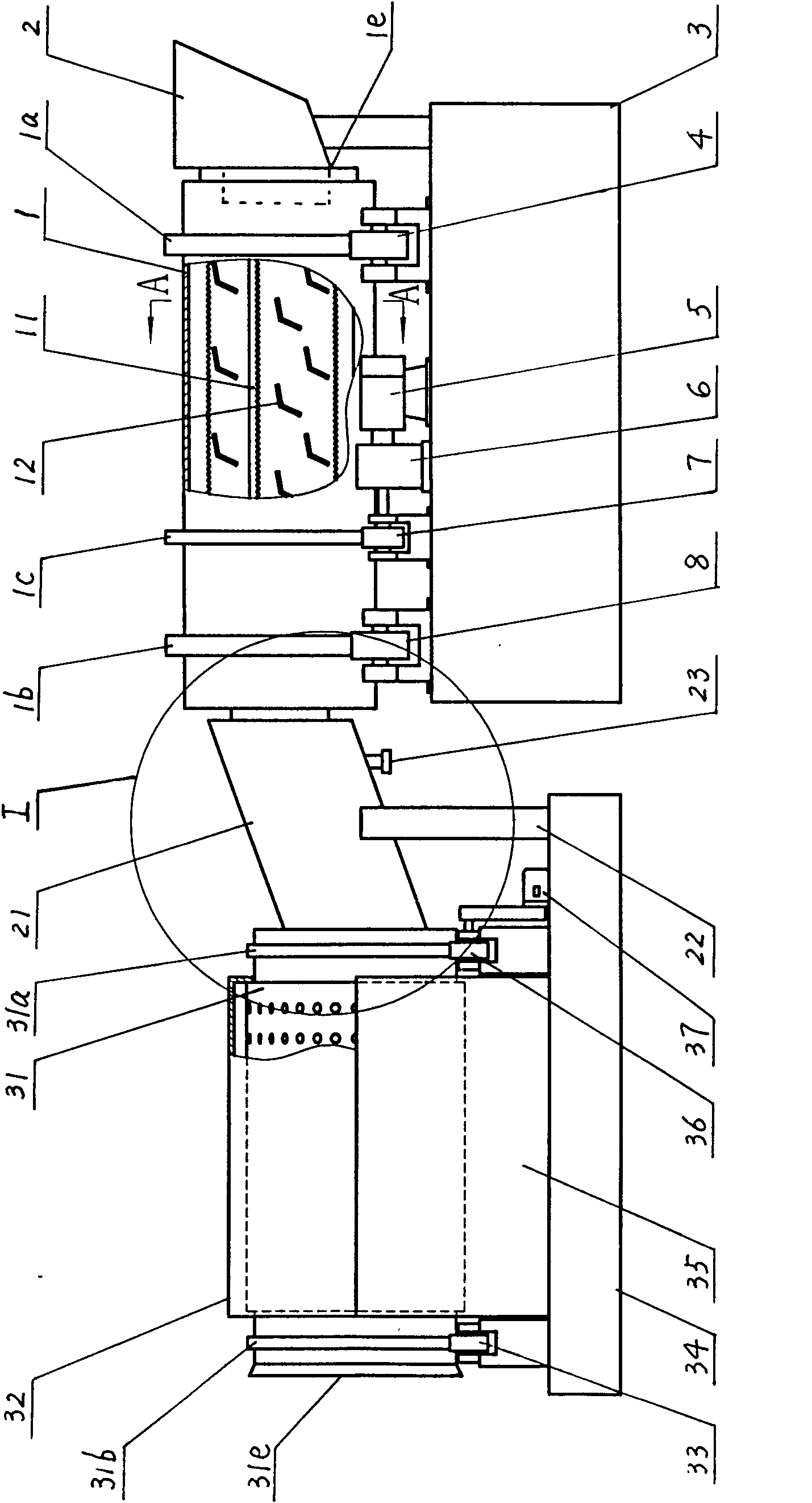

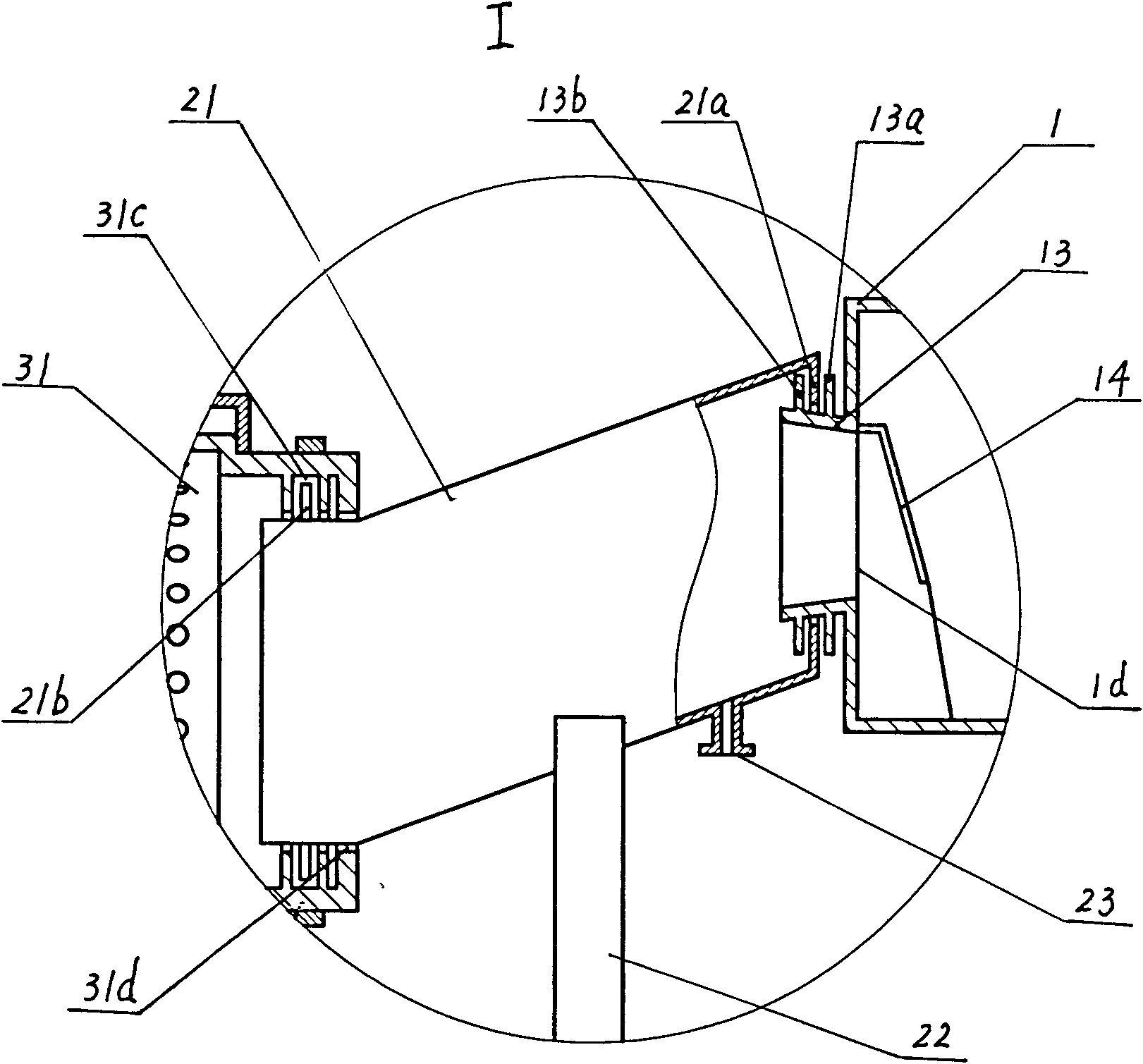

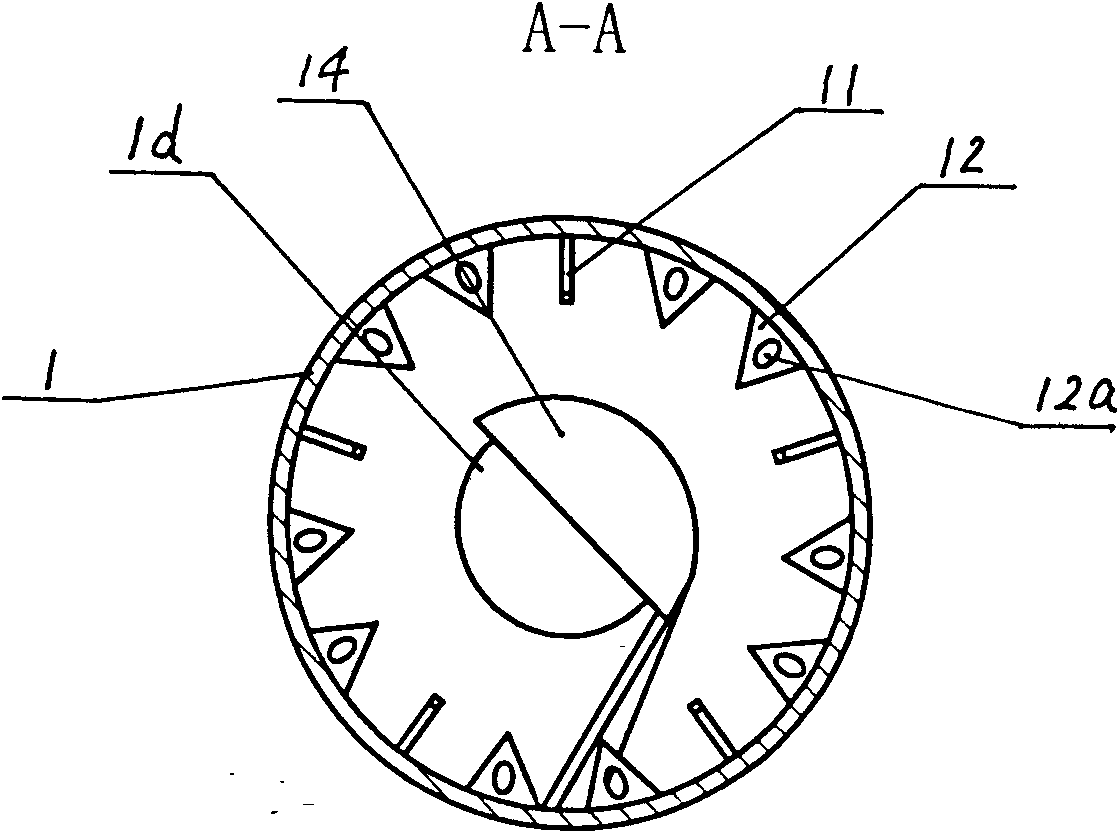

[0019] The split drum pulping device of the present invention comprises a pulper and a screening machine, a drum 1 is arranged in the pulper, several scrapers 11 are connected on the inner wall of the drum 1, and a screen cylinder 31 is arranged in the screening machine, There are several sieve holes on the wall of the screen drum 31, the bottom plane of the pulper is higher than the bottom plane of the screener, the pulper 21 is installed between the pulper and the screener in an inclined form, and the pulper 21 is fixedly installed on the base Above, the left port of the pulp passing cylinder 21 is installed on the pulp outlet 1d of the drum 1 and connected correspondingly, and the right port of the pulp passing cylinder 21 is installed in the pulp inlet 31d of the screen drum 31 and communicated correspondingly, the drum 1 is connected with a spoon-shaped pulp feeding hopper 14, which corresponds to the pulp outlet 1d. In the intervals between several scrapers 11 , several ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com